Exedy Stage 2 clutches installed in the ZF 6HP26!

#1

Hi,

I want to let you know that the Exedy Stage 2 friction & steel kit fits the 6HP26 gearbox in the X350. I took my gearbox to a shop where I had it rebuilt, I had new solenoids in the valve body, but also the Exedy frictions & plates kit for the 1000hp Mustangs. I was afraid it won't work for the 6HP26, because it was made for the 6R80 (basically the 6HP28), even though Exedy said it works for the 26 too.

I tried inserting pics along the way, but they are put into the beginning of the post with no option to move them, so I'll attach them.

I got the gearbox torn apart, and I found out the Exedy frictions & steels are a perfect fit! Only difference is that unlike the 6r80, the 6hp26 hasn't got the drum heights, so in some places there was a disk that wouldn't fit. Don't fret however, because there are more clutches than standard, and the material is heavy duty. So if there are twin screw 4.2 XKRs out there which are fine with the stock 6hp26, I suspect that in this configuration, the 6 speeder would accept upwards of 1000Nm, no problem.

The big unknown, in my opinion, is the torque converter. My torque converter clutch was dying, so I changed it with a band of more surface area, and made from a heavy duty composition. It takes roughly 30% torque more than stock, but is that all to it? Theoretically, above 2000rpm, the TCC is always locked, so the turbine, stator etc. doesn't matter.... right?

After all was done, everything was put back together, and the trans bolted up. I took only a short test drive, I want to let it break in before I go full throttle. The good news is, if anyone wants to go all-out with Avos' TS, and doesn't have the tough MB gearbox, we now know the clutch packs can stand whatever you throw at them. So that means that if you also upgrade the TCC, the input shaft is now the limit. From our Australian friends, I understand that's about 500rwkw (~600rwhp), so that's not too bad!

I want to let you know that the Exedy Stage 2 friction & steel kit fits the 6HP26 gearbox in the X350. I took my gearbox to a shop where I had it rebuilt, I had new solenoids in the valve body, but also the Exedy frictions & plates kit for the 1000hp Mustangs. I was afraid it won't work for the 6HP26, because it was made for the 6R80 (basically the 6HP28), even though Exedy said it works for the 26 too.

I tried inserting pics along the way, but they are put into the beginning of the post with no option to move them, so I'll attach them.

I got the gearbox torn apart, and I found out the Exedy frictions & steels are a perfect fit! Only difference is that unlike the 6r80, the 6hp26 hasn't got the drum heights, so in some places there was a disk that wouldn't fit. Don't fret however, because there are more clutches than standard, and the material is heavy duty. So if there are twin screw 4.2 XKRs out there which are fine with the stock 6hp26, I suspect that in this configuration, the 6 speeder would accept upwards of 1000Nm, no problem.

The big unknown, in my opinion, is the torque converter. My torque converter clutch was dying, so I changed it with a band of more surface area, and made from a heavy duty composition. It takes roughly 30% torque more than stock, but is that all to it? Theoretically, above 2000rpm, the TCC is always locked, so the turbine, stator etc. doesn't matter.... right?

After all was done, everything was put back together, and the trans bolted up. I took only a short test drive, I want to let it break in before I go full throttle. The good news is, if anyone wants to go all-out with Avos' TS, and doesn't have the tough MB gearbox, we now know the clutch packs can stand whatever you throw at them. So that means that if you also upgrade the TCC, the input shaft is now the limit. From our Australian friends, I understand that's about 500rwkw (~600rwhp), so that's not too bad!

#3

all taken apart, in preparation for the upgrade

getting the frictions out

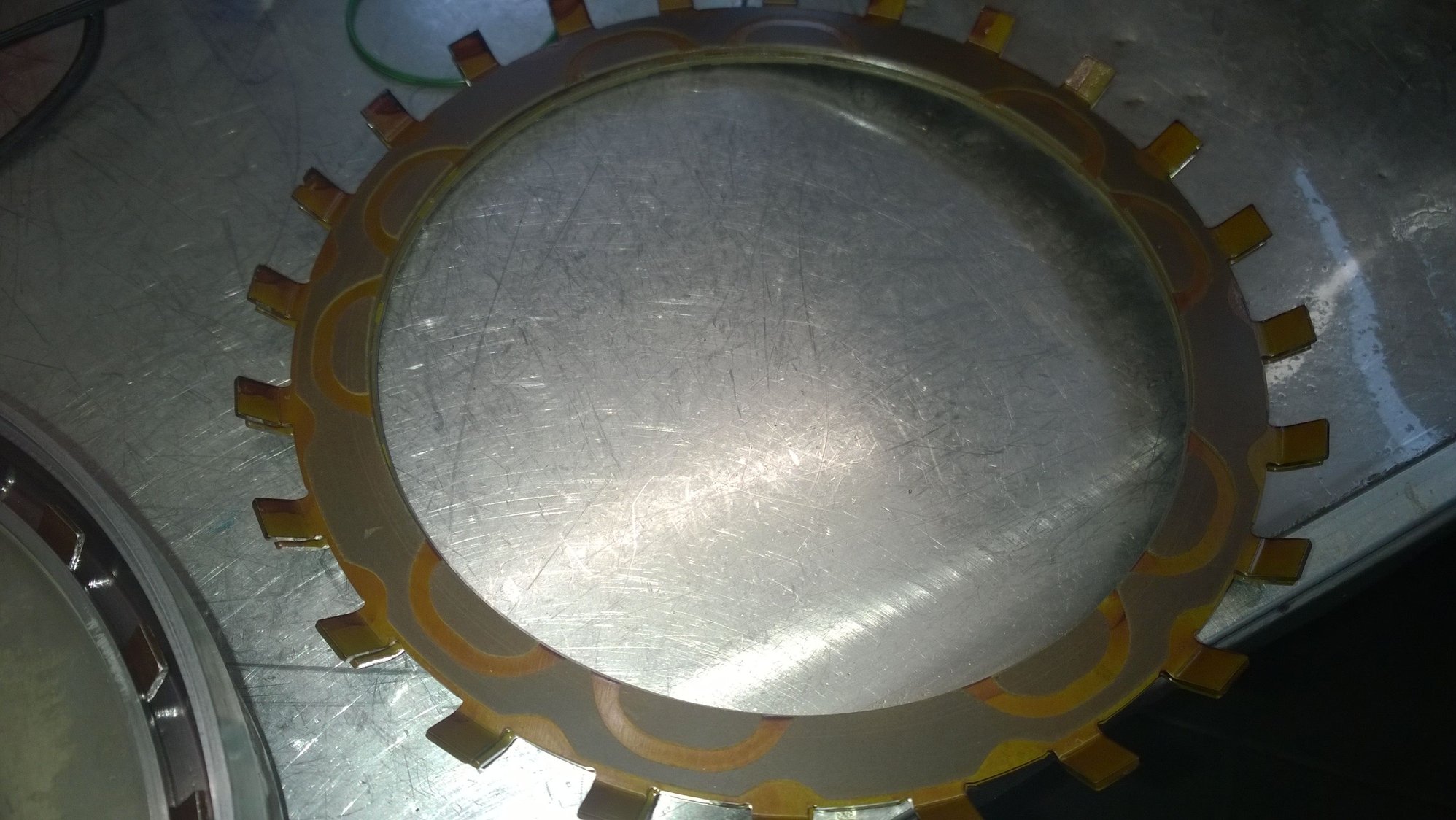

Notice the increase clutch count from OEM. But not all the new clutches fit, because drum height in the 6r80/6hp28 is greater. Also, because of this, when putting the stage 2 clutches, one has to reuse the stock snap-ring, the one supplied is too thin, and there's too much play in the discs

new solenoids put in, work almost done

the old torque converter clutch, it was worn out

upgraded, full-width clutch band tor the TCC. I forgot to take the photo before the new one was put in.

if there are torque converter experts out there, by the look of it, how much power can go through this unit before furnace brazing & the rest of the mods is needed?

wrapping everything up

#4

I want to apologize for the pics, I remember painstakingly uploading them one by one, but alas, to no avail, I see. I put a new post, which I see did the trick.

BlackKat, I don't know if costs are relevant to anyone in Western Europe, or the US, because labor is so much cheaper here. However, parts are almost twice as expensive as in the States, so perhaps it evens out. The Stage 2 clutches were around $500 (friend brought them, so no shipping + taxes), labor was 500 Euros. Solenoids + labor were 1000 Euros, and torque converter work + new clutch was 300 Euros.

BlackKat, I don't know if costs are relevant to anyone in Western Europe, or the US, because labor is so much cheaper here. However, parts are almost twice as expensive as in the States, so perhaps it evens out. The Stage 2 clutches were around $500 (friend brought them, so no shipping + taxes), labor was 500 Euros. Solenoids + labor were 1000 Euros, and torque converter work + new clutch was 300 Euros.

#5

#6

Than you! I dyno'd it before any mods, and I got 291rwhp, after it was heat soaked from consecutive calibration runs, in July, at around 30 degrees Celsius. The most reliable marker is my trap speed, originally it was 166 km/h. After ECU, smaller pulley, intake elbow & mina induction kit, best was 171 km/h. After the supercharger rebuild & port, coupled with an even smaller pulley, and ported intake along with 81mm TB, I suspect I am at around ~175-176 km/h. I understand there is a rule of thumb for power levels such as ours, that every mph in trap speed is about 10hp, so theoretically I am about 60hp more than at the beginning. Note that perhaps I didn't make the full 400hp then.

Last edited by Matei Dima; 01-25-2015 at 04:17 PM.

#7

Trending Topics

#8

I haven't felt it, as I am not very far away from stock torque levels, but a funny thing that occurred was that in 4th, the car stopped accelerating at 5500rpm, like it had a speed limiter. I am investigating as for why this happened. Before the rebuild, the car refused to upshift from 3rd to 4th, and from 4th to 5th (only at WOT), it would just stay there at redline... if anybody has a clue as for why, please chime in

Last edited by Matei Dima; 01-26-2015 at 04:11 PM.

The following users liked this post:

XxSlowpokexX (01-06-2016)

#9

#10

I haven't felt it, as I am not very far away from stock torque levels, but a funny thing that occurred was that in 4th, the car stopped accelerating at 5500rpm, like it had a speed limiter. I am investigating as for why this happened. Before the rebuild, the car refused to upshift from 3rd to 4th, and from 4th to 5th (only at WOT), it would just stay there at redline... if anybody has a clue as for why, please chime in

#11

Hi,

I want to let you know that the Exedy Stage 2 friction & steel kit fits the 6HP26 gearbox in the X350. I took my gearbox to a shop where I had it rebuilt, I had new solenoids in the valve body, but also the Exedy frictions & plates kit for the 1000hp Mustangs. I was afraid it won't work for the 6HP26, because it was made for the 6R80 (basically the 6HP28), even though Exedy said it works for the 26 too.

I tried inserting pics along the way, but they are put into the beginning of the post with no option to move them, so I'll attach them.

I got the gearbox torn apart, and I found out the Exedy frictions & steels are a perfect fit! Only difference is that unlike the 6r80, the 6hp26 hasn't got the drum heights, so in some places there was a disk that wouldn't fit. Don't fret however, because there are more clutches than standard, and the material is heavy duty. So if there are twin screw 4.2 XKRs out there which are fine with the stock 6hp26, I suspect that in this configuration, the 6 speeder would accept upwards of 1000Nm, no problem.

The big unknown, in my opinion, is the torque converter. My torque converter clutch was dying, so I changed it with a band of more surface area, and made from a heavy duty composition. It takes roughly 30% torque more than stock, but is that all to it? Theoretically, above 2000rpm, the TCC is always locked, so the turbine, stator etc. doesn't matter.... right?

After all was done, everything was put back together, and the trans bolted up. I took only a short test drive, I want to let it break in before I go full throttle. The good news is, if anyone wants to go all-out with Avos' TS, and doesn't have the tough MB gearbox, we now know the clutch packs can stand whatever you throw at them. So that means that if you also upgrade the TCC, the input shaft is now the limit. From our Australian friends, I understand that's about 500rwkw (~600rwhp), so that's not too bad!

I want to let you know that the Exedy Stage 2 friction & steel kit fits the 6HP26 gearbox in the X350. I took my gearbox to a shop where I had it rebuilt, I had new solenoids in the valve body, but also the Exedy frictions & plates kit for the 1000hp Mustangs. I was afraid it won't work for the 6HP26, because it was made for the 6R80 (basically the 6HP28), even though Exedy said it works for the 26 too.

I tried inserting pics along the way, but they are put into the beginning of the post with no option to move them, so I'll attach them.

I got the gearbox torn apart, and I found out the Exedy frictions & steels are a perfect fit! Only difference is that unlike the 6r80, the 6hp26 hasn't got the drum heights, so in some places there was a disk that wouldn't fit. Don't fret however, because there are more clutches than standard, and the material is heavy duty. So if there are twin screw 4.2 XKRs out there which are fine with the stock 6hp26, I suspect that in this configuration, the 6 speeder would accept upwards of 1000Nm, no problem.

The big unknown, in my opinion, is the torque converter. My torque converter clutch was dying, so I changed it with a band of more surface area, and made from a heavy duty composition. It takes roughly 30% torque more than stock, but is that all to it? Theoretically, above 2000rpm, the TCC is always locked, so the turbine, stator etc. doesn't matter.... right?

After all was done, everything was put back together, and the trans bolted up. I took only a short test drive, I want to let it break in before I go full throttle. The good news is, if anyone wants to go all-out with Avos' TS, and doesn't have the tough MB gearbox, we now know the clutch packs can stand whatever you throw at them. So that means that if you also upgrade the TCC, the input shaft is now the limit. From our Australian friends, I understand that's about 500rwkw (~600rwhp), so that's not too bad!

I need to rebuild my HP28 and wanted to do this upgrade.

Also did you have the torque converter serviced or replaced? Transmission pump?

Thread

Thread Starter

Forum

Replies

Last Post

Dickie_L_J_O

XJ XJ8 / XJR ( X308 )

8

09-13-2015 07:44 AM

1964Daimler

MKI / MKII S type 240 340 & Daimler

0

09-09-2015 11:28 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)