Why is the XJR intercooler coolant circuit integrated into the engine coolant?

#1

So does anyone know (e.g. XJREngineer) why Jaguar designed the X300 XJR intercooler coolant circuit such that it is interconnected to the entire engine coolant circuit?

Does the X308 XJR have a similar design, or is its intercooler coolant circuit and reservoir separate from engine cooling?

Was the X300 XJR design decision based on a balance between function and simplicity, or is there a performance benefit in combining the circuits?

I would assume, perhaps incorrectly, that this arrangement was made to simplify the need for another coolant reservoir, hoses, etc exclusive to the intercooler and as such would be a compromise in intercooler performance by heating the intercooler coolant some (a lot?) since normal operating temps for the engine coolant are 180F.

Or maybe I'm not understanding the engineering....

But if I'm correct in the assumption that we are losing some intercooling efficiency by mixing the circuits and transferring some engine heat to the intercooler coolant, it would seem to make sense that 'divorcing' and isolating the intercooler circuit from the engine coolant circuit would improve intercooling efficacy.

I know that Doug did this with his former XJR, but he has said he never got a chance to verify if intercooling efficacy improved by doing so.

I would also be curious if there were any design intents that had the intercooler circuit help with overall engine cooling. In other words, would there be any negative impact to engine cooling if the intercooler and engine coolant circuits were separated? In this case I'd also have to assume that there wouldn't be any impact as the normally aspirated XJ6 does just fine keeping the engine cool without leveraging an intercooler.

Thoughts?

.

Does the X308 XJR have a similar design, or is its intercooler coolant circuit and reservoir separate from engine cooling?

Was the X300 XJR design decision based on a balance between function and simplicity, or is there a performance benefit in combining the circuits?

I would assume, perhaps incorrectly, that this arrangement was made to simplify the need for another coolant reservoir, hoses, etc exclusive to the intercooler and as such would be a compromise in intercooler performance by heating the intercooler coolant some (a lot?) since normal operating temps for the engine coolant are 180F.

Or maybe I'm not understanding the engineering....

But if I'm correct in the assumption that we are losing some intercooling efficiency by mixing the circuits and transferring some engine heat to the intercooler coolant, it would seem to make sense that 'divorcing' and isolating the intercooler circuit from the engine coolant circuit would improve intercooling efficacy.

I know that Doug did this with his former XJR, but he has said he never got a chance to verify if intercooling efficacy improved by doing so.

I would also be curious if there were any design intents that had the intercooler circuit help with overall engine cooling. In other words, would there be any negative impact to engine cooling if the intercooler and engine coolant circuits were separated? In this case I'd also have to assume that there wouldn't be any impact as the normally aspirated XJ6 does just fine keeping the engine cool without leveraging an intercooler.

Thoughts?

.

#2

It is basically a vent line between the two systems. There is little or no flow.

I monitor both IC coolant temperature and radiator coolant temperature on my XKR (similar design) and they vary independently, and IC temperature is just a few degrees above ambient until you push the supercharger hard.

Jaguar has been designing the R's like this for years...they are not ignorant of the benefit of cool charge air.

I monitor both IC coolant temperature and radiator coolant temperature on my XKR (similar design) and they vary independently, and IC temperature is just a few degrees above ambient until you push the supercharger hard.

Jaguar has been designing the R's like this for years...they are not ignorant of the benefit of cool charge air.

Last edited by WhiteXKR; 07-06-2015 at 02:51 PM.

The following 2 users liked this post by WhiteXKR:

al_roethlisberger (07-06-2015),

Don B (07-06-2015)

#3

Thanks for the feedback! I've read several of your posts in the other forum sections related to intercooling performance options, and noted in a thread a while back that you were opting for simply increasing air flow via a thermostatically controlled fan and maybe intercooler capacity, versus more complex solutions like a "Killer Chiller" or water/methanol injection.

Did you in the end find that the KISS (Keep It Simple S* ) method indeed was a better approach?

) method indeed was a better approach?

Please see the discussion (specifically post 33) at the end of the following thread where I was asking about the benefit of a larger lower SC pulley if one could increase intercooler capacity.

https://www.jaguarforums.com/forum/x...pulley-105701/

We've apparently had pretty reliable feedback from X300 XJR owners that have fitted the larger lower SC pulley that performance suffers after an initial increase as the air charge gets too hot. But that initial performance increase before 'overheating' does suggest that the larger pulley does allow the M90 SC to deliver a higher output versus the M90 being at max compression output with the OEM pulley ratio. But the high heat produced kills the performance gain once the intercooler system is overwhelmed. At least this is the anecdotal evidence others have gleaned from those that have tried the larger pulley.

So I wondered if we could increase the intercooling capacity by say adding a secondary intercooler such as:

https://www.jaguarforums.com/forum/x...er-why-141163/

Succinctly: I wonder if one would achieve sustainable improved boost with an upgraded lower XJR6 SC pulley if something like an auxiliary intercooler, upgraded Bosch pump, and perhaps a fan would keep the air charge cool enough.

I like KISS too, so it would be great if those simple upgrades could manage the heat well enough versus water/meth injection or an expensive "Killer Chiller".

It would be great to hear your opinions based upon your experience testing the options on your car.

.

Did you in the end find that the KISS (Keep It Simple S*

) method indeed was a better approach?

) method indeed was a better approach?Please see the discussion (specifically post 33) at the end of the following thread where I was asking about the benefit of a larger lower SC pulley if one could increase intercooler capacity.

https://www.jaguarforums.com/forum/x...pulley-105701/

We've apparently had pretty reliable feedback from X300 XJR owners that have fitted the larger lower SC pulley that performance suffers after an initial increase as the air charge gets too hot. But that initial performance increase before 'overheating' does suggest that the larger pulley does allow the M90 SC to deliver a higher output versus the M90 being at max compression output with the OEM pulley ratio. But the high heat produced kills the performance gain once the intercooler system is overwhelmed. At least this is the anecdotal evidence others have gleaned from those that have tried the larger pulley.

So I wondered if we could increase the intercooling capacity by say adding a secondary intercooler such as:

https://www.jaguarforums.com/forum/x...er-why-141163/

Succinctly: I wonder if one would achieve sustainable improved boost with an upgraded lower XJR6 SC pulley if something like an auxiliary intercooler, upgraded Bosch pump, and perhaps a fan would keep the air charge cool enough.

I like KISS too, so it would be great if those simple upgrades could manage the heat well enough versus water/meth injection or an expensive "Killer Chiller".

It would be great to hear your opinions based upon your experience testing the options on your car.

.

Last edited by al_roethlisberger; 07-06-2015 at 05:01 PM.

#4

My thoughts so far with lower pulley, upgraded water pump, dual auxiliary intercooler fans...? Car definitely pulls a lot harder and I can break traction from a stand still for about 20feet even with 255 series tires.

As far as temperatures go with engine and intercooler coolant... they seem to be connected but also separate enough to where temps don't seem to be affected.

#5

I'm in the process of finding this out since I've already got the upgraded bosch pump and fans but still trying to figure out if I should mount a secondary SC intercooler underneath the existing or if it should be an oil or transmission cooler.

My thoughts so far with lower pulley, upgraded water pump, dual auxiliary intercooler fans...? Car definitely pulls a lot harder and I can break traction from a stand still for about 20feet even with 255 series tires.

As far as temperatures go with engine and intercooler coolant... they seem to be connected but also separate enough to where temps don't seem to be affected.

My thoughts so far with lower pulley, upgraded water pump, dual auxiliary intercooler fans...? Car definitely pulls a lot harder and I can break traction from a stand still for about 20feet even with 255 series tires.

As far as temperatures go with engine and intercooler coolant... they seem to be connected but also separate enough to where temps don't seem to be affected.

Thanks for the additional info. Definitely interested to hear how your incremental changes work out so we can understand the cost/benefit cutoff and minimum requirements to make the lower pulley worthwhile if at all.

Have you been able to monitor:

1) If boost continues to climb with RPM all the way to redline or if the M90 "runs out of steam" before redline with the increased lower pulley?

2) Intercooler coolant temps to see if your current setup will keep it near ambient under load, or if it gets heat-soaked faster (or at all) than OEM?

Also, what fans did you use, how did you choose to power them, and how are they triggered (e.g. on all the time or temperature controlled and how).

.

#6

1. I haven't been able to measure boost psi. Honestly because I'm not exactly sure how to hook up a boost gauge to the blower. Also I can't "feel" a difference yet if the lower pulley maxes out the supercharger before redline but then again I haven't really paid attention.

2. I had plans last Thursday to test the cooling system with the fans up in my local mountain road but they had it closed for the holiday weekend. So I'm not sure if heat soak sets in "still" but I only have my "non working IC pump" performance to compare it to since I think my pump went out way back in October or November. Hopefully I'll be able to test it's cooling performance within the next few weeks.

As for the fans I used, they're these: 2 x Universal Slim 7" Pull Push Radiator Engine Bay Cooling Fan Mounting Black | eBay

Two of them are a perfect fit for the front mount IC. They're wired up reverse polarity so they pull air into the IC and the radiator cooling fans help pull air towards the rear. I'm pulling power from the original radiator cooling fans to power them but have a thermostatic fan controller with a temperature sensor that sits right behind the front mounted intercooler. I can configure it to engage at 60 degrees all the way up to 160. The fans don't come on until around 150degrees according to my intake temp readings. My fan controller doesn't have an dial setting of when to engage the fans so I just have it set at about 6 if the dial went from 1-10

2. I had plans last Thursday to test the cooling system with the fans up in my local mountain road but they had it closed for the holiday weekend. So I'm not sure if heat soak sets in "still" but I only have my "non working IC pump" performance to compare it to since I think my pump went out way back in October or November. Hopefully I'll be able to test it's cooling performance within the next few weeks.

As for the fans I used, they're these: 2 x Universal Slim 7" Pull Push Radiator Engine Bay Cooling Fan Mounting Black | eBay

Two of them are a perfect fit for the front mount IC. They're wired up reverse polarity so they pull air into the IC and the radiator cooling fans help pull air towards the rear. I'm pulling power from the original radiator cooling fans to power them but have a thermostatic fan controller with a temperature sensor that sits right behind the front mounted intercooler. I can configure it to engage at 60 degrees all the way up to 160. The fans don't come on until around 150degrees according to my intake temp readings. My fan controller doesn't have an dial setting of when to engage the fans so I just have it set at about 6 if the dial went from 1-10

The following users liked this post:

Don B (07-07-2015)

#7

The following users liked this post:

al_roethlisberger (07-08-2015)

Trending Topics

#9

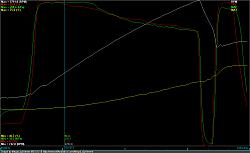

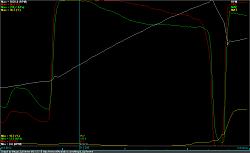

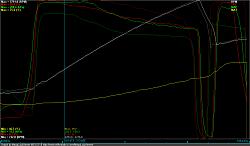

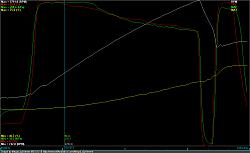

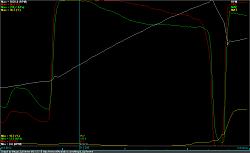

Have some graph pics that maybe could be of interest on this boost-temperature-power topic. Or eventually add some more confusing or contradictory aspects.

Should add that this XJR6 engine is not in an X300 but in an old series1 car using a standalone, speed density ECU. No spark retarding from knock or inlet temp is enabled.

The pictures is from logfiles taken after I had done some minor, not very professional home porting of the M90.

First pic, (red trace throttle, yellow inlet temp, green boost, white rpm) is from a log during a short WOT in third gear (5-sp), showed an impressive max reading of 208.6 kPa (15.7 psi). Seems to have been a very effective porting indeed, an increase with about 20kPa!

Until noticing that the max temp reading was 75.6 deg C (168 F). And no, not the engine coolant but the MAT, inlet manifold air temp.

Found out that I had messed up things when refilling and bleeding the IC, water had not circulated at all.

Added the required coolant and, next day, did a new quick test with log. Same road, same 5 deg C ambient winter temperature. Could of course have been some small differences in wind, humidity or baro.

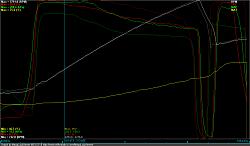

Pic 2, very different numbers. At the 3200rpm range temp is down from 54.4 deg C to 15.7 C, (130F to 60F) and boost has dropped off from 205.3 kPa to 189.6 kPa (15.3 psi to 13.0 psi). Very similar to what was seen before the sc porting.

Pic 3 is booth pics in one, no 2 overlaying no 1. Very interesting thing is that the white rpm traces are more or less paralell, no changes at all in rpm/time accelaration.

Should add that this XJR6 engine is not in an X300 but in an old series1 car using a standalone, speed density ECU. No spark retarding from knock or inlet temp is enabled.

The pictures is from logfiles taken after I had done some minor, not very professional home porting of the M90.

First pic, (red trace throttle, yellow inlet temp, green boost, white rpm) is from a log during a short WOT in third gear (5-sp), showed an impressive max reading of 208.6 kPa (15.7 psi). Seems to have been a very effective porting indeed, an increase with about 20kPa!

Until noticing that the max temp reading was 75.6 deg C (168 F). And no, not the engine coolant but the MAT, inlet manifold air temp.

Found out that I had messed up things when refilling and bleeding the IC, water had not circulated at all.

Added the required coolant and, next day, did a new quick test with log. Same road, same 5 deg C ambient winter temperature. Could of course have been some small differences in wind, humidity or baro.

Pic 2, very different numbers. At the 3200rpm range temp is down from 54.4 deg C to 15.7 C, (130F to 60F) and boost has dropped off from 205.3 kPa to 189.6 kPa (15.3 psi to 13.0 psi). Very similar to what was seen before the sc porting.

Pic 3 is booth pics in one, no 2 overlaying no 1. Very interesting thing is that the white rpm traces are more or less paralell, no changes at all in rpm/time accelaration.

#10

if it is available in obd-ii, absolute manifold pressure

and adjust to atmospheric.

At 14.7psi or 1bar, you have zero boost/vacuum.

Subtract that from absolute manifold pressure and you

have boost.

The following users liked this post:

AlbBolivar (07-08-2015)

#11

If one wanted to install a boost gauge, any idea which vacuum line I would need to patch into?

#12

You'll have to look in your obd-ii screens.

As for the vacuum port, if you add two more cylinders I could tell

you.

Maybe Doc knows.

XJREngineer would know for sure.

Last edited by plums; 07-08-2015 at 11:22 PM.

#13

I just didn't know it was available via obd-II at all. But unfortunately I looked through my ultraguage pages and couldn't find anything related to a absolute manifold pressure sensor.

So now hopefully someone that knows the vacuum lines of the XJR-6 will be able to know which one works for a boost gauge.

So now hopefully someone that knows the vacuum lines of the XJR-6 will be able to know which one works for a boost gauge.

Thread

Thread Starter

Forum

Replies

Last Post

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)