I just changed my own timing chain tensioners........HOW TO

#341

The timing chain tutorial basically says to insure no slack on the drive side of the chains. With regard to the primary chains the drive side is referred to as "outermost". Well, the layout is the same on both sides, meaning the tensioner side of the primary chains is on the left (from front of engine). So, my thinking is that the "drive" side of the chain is the side WITHOUT the tensioner.

I am thinking likewise for the secondary chains as well. The right side tensioner moves in and out on the bottom foot, while the left side secondary tensioner has the upper foot that moves to create tension. So, is the drive side of the right upper chain on the top while the drive side of the left upper chain on the bottom?

I guess that's a clumsy way to ask a simple question. What is the "drive side" of each of the four chains.

Thanks,

By the way. That curved guide pivot bolt that broke was defective from the manufacturer. It was molded/cast (whatever) with an air pocked inside the threaded portion of the bolt. That air pocket is where the bolt snapped when trying to remove it. I asked the guy at the local Jaguar dealer parts counter if I could get a warranty replacement bolt since the original was defective, even though the car is 14 years old. He laughed a little. I did at least get a 10% pity discount.

I am thinking likewise for the secondary chains as well. The right side tensioner moves in and out on the bottom foot, while the left side secondary tensioner has the upper foot that moves to create tension. So, is the drive side of the right upper chain on the top while the drive side of the left upper chain on the bottom?

I guess that's a clumsy way to ask a simple question. What is the "drive side" of each of the four chains.

Thanks,

By the way. That curved guide pivot bolt that broke was defective from the manufacturer. It was molded/cast (whatever) with an air pocked inside the threaded portion of the bolt. That air pocket is where the bolt snapped when trying to remove it. I asked the guy at the local Jaguar dealer parts counter if I could get a warranty replacement bolt since the original was defective, even though the car is 14 years old. He laughed a little. I did at least get a 10% pity discount.

Last edited by harvest14; 09-18-2015 at 10:07 PM.

#343

The chains, guides and tensioners are installed and everything is tightened. The VVT adjusting tool that came in my kit will NOT engage the holes in the VVT pulley. I tried at every stage and the little pegs would not go into the adjustment holes inside the pulley.

Is the tool defective or am I doing something wrong? If I can get it to work, can the adjustment still be made even though everything is tensioned? The locking tools are still in place...

edit... Ok, so I filed down the tips and it now the tool engages the VVT adjustment holes. Nothing will turn though so I'm guessing I have to loosen the VVT bolt?

Second edit, I loosened each VVT pulley and it turns out they were already all the way counter-clockwise. I turned them clockwise and back counter-clockwise just to understand how it adjusts, and then held tension on the chain and tightened the VVT pulley bolt again(with the VVT adjusting tool in place watching that it didn't move).

Is the tool defective or am I doing something wrong? If I can get it to work, can the adjustment still be made even though everything is tensioned? The locking tools are still in place...

edit... Ok, so I filed down the tips and it now the tool engages the VVT adjustment holes. Nothing will turn though so I'm guessing I have to loosen the VVT bolt?

Second edit, I loosened each VVT pulley and it turns out they were already all the way counter-clockwise. I turned them clockwise and back counter-clockwise just to understand how it adjusts, and then held tension on the chain and tightened the VVT pulley bolt again(with the VVT adjusting tool in place watching that it didn't move).

Last edited by harvest14; 09-19-2015 at 08:39 PM.

#344

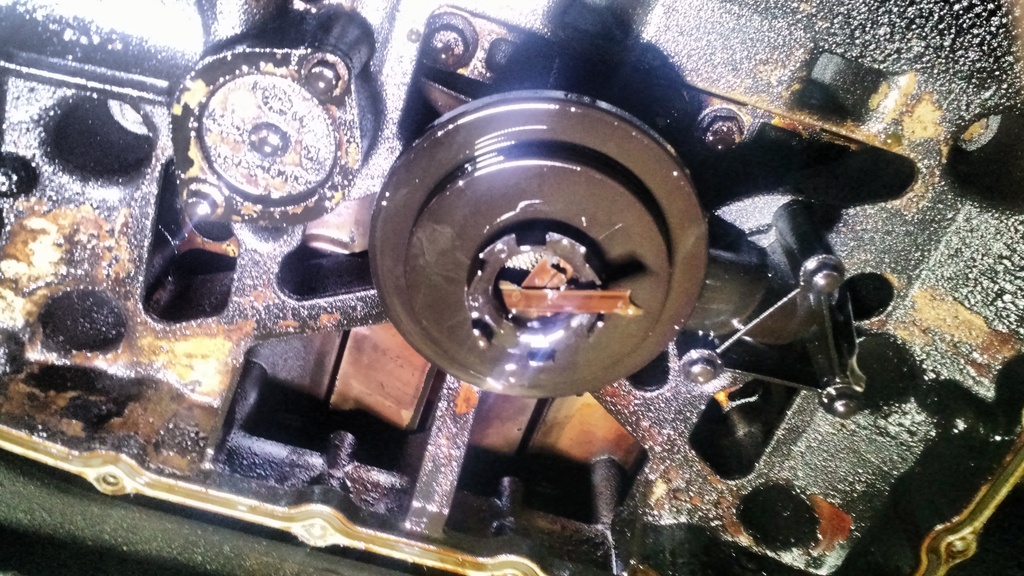

I got the bolt hole cleared out for the right side pivot bolt and threaded in a new bolt. The threads were a little damaged from the drilling out, but the bolt got a good bite and tightened down very snug. I added a little lock tight to what came on the bolt as well.

The curved guide however is not perfectly straight. It pivots freely and fully supports the chain but going from the top to the bottom the chain is a fraction of an inch closer to the outer edge of the guide as it goes down.

I have included a picture. When i turned the engine to check timing all was smooth.

I know i will get mixed opinions on this. My inclination is that it is such a small variation that it will not impede the guides intended function.

The curved guide however is not perfectly straight. It pivots freely and fully supports the chain but going from the top to the bottom the chain is a fraction of an inch closer to the outer edge of the guide as it goes down.

I have included a picture. When i turned the engine to check timing all was smooth.

I know i will get mixed opinions on this. My inclination is that it is such a small variation that it will not impede the guides intended function.

The following users liked this post:

cjd777 (09-21-2015)

#345

#346

I think it's appropriate that the one weak point in the X308 that probably contributed the most to it's heavy depreciation, the tensioner issue, has the longest and most enduring thread on the Jaguar forum. I guess we should all be thankful since it's a fixable problem and it allowed us to buy these beautiful machines at a fraction of their original cost.

But I digress,

My primary and secondary tensioner job is done! Not that anyone was on the edge of their chair waiting for an update, haha. I started it up last night after a very sincere prayer and was greeted with a wonderful purr and no engine lights. This job was bigger than I expected. I have done many timing belts but this was definitely a more complicated endeavor for a shade tree mechanic like myself. I learned a lot and the process brought me closer to God because I appealed to Him a LOT for comfort and guidance along the way.

So, in brief summary; I bought my first Jaguar on April 1st 2015, a 2001 XJ8 (94,000 miles) with a 1999 engine (41,000 miles claimed). Since that time I have:

1) Replaced the water pump (to one with metal impeller)

2) Replaced thermostat housing with aluminum one, plus new coolant temperature sensor and thermostat.

3) Changed differential fluid and cleaned out breather valve

4) Drained transmission and installed new filter, upgraded pressure valve, new gasket and 6.5 liters of ZF fluid to top it off.

5) New fuel and air filters.

6) New headliner

7) New (used-ebay) wood panels in the front, plus a wood shift knob.

8) New paint for poorly matched fender; matches rest of car perfect now.

9) New spark plugs and, out of necessity, one new coil (keep a spare in the trunk now).

10) New part load breather hose.

11) Removed throttle body for thorough cleaning and new gasket.

12) New idler and tensioner pulley/bearings.

13) New serpentine belt.

14) Complete timing system upgrade including all four tensioners, guides and chains with kit from Christopher's Foreign Car Parts. This of course included all associated gaskets, o rings, seals and in some cases new bolts.

15) New (gently used) crank pulley/balancer with new cone washer, o ring and crank bolt.

Obviously there is probably a lot more but that's the stuff that comes to mind. This does not include a similar list that applies to my wife's 2004 XJ8 (X350), but that's for a different section.

So, is it official? Am I in the Jaguar forum club now? The only two things on the above list I did not do myself were the headliner and the fender paint.

Have a blessed day!!

But I digress,

My primary and secondary tensioner job is done! Not that anyone was on the edge of their chair waiting for an update, haha. I started it up last night after a very sincere prayer and was greeted with a wonderful purr and no engine lights. This job was bigger than I expected. I have done many timing belts but this was definitely a more complicated endeavor for a shade tree mechanic like myself. I learned a lot and the process brought me closer to God because I appealed to Him a LOT for comfort and guidance along the way.

So, in brief summary; I bought my first Jaguar on April 1st 2015, a 2001 XJ8 (94,000 miles) with a 1999 engine (41,000 miles claimed). Since that time I have:

1) Replaced the water pump (to one with metal impeller)

2) Replaced thermostat housing with aluminum one, plus new coolant temperature sensor and thermostat.

3) Changed differential fluid and cleaned out breather valve

4) Drained transmission and installed new filter, upgraded pressure valve, new gasket and 6.5 liters of ZF fluid to top it off.

5) New fuel and air filters.

6) New headliner

7) New (used-ebay) wood panels in the front, plus a wood shift knob.

8) New paint for poorly matched fender; matches rest of car perfect now.

9) New spark plugs and, out of necessity, one new coil (keep a spare in the trunk now).

10) New part load breather hose.

11) Removed throttle body for thorough cleaning and new gasket.

12) New idler and tensioner pulley/bearings.

13) New serpentine belt.

14) Complete timing system upgrade including all four tensioners, guides and chains with kit from Christopher's Foreign Car Parts. This of course included all associated gaskets, o rings, seals and in some cases new bolts.

15) New (gently used) crank pulley/balancer with new cone washer, o ring and crank bolt.

Obviously there is probably a lot more but that's the stuff that comes to mind. This does not include a similar list that applies to my wife's 2004 XJ8 (X350), but that's for a different section.

So, is it official? Am I in the Jaguar forum club now? The only two things on the above list I did not do myself were the headliner and the fender paint.

Have a blessed day!!

#347

#348

Jeff, My only regret is I could not be there to assist or cheer you on. What a great feeling it must be to have done this job with all the little problems that came up. You are my hero and glad that you are close enough to get some face to face advise.

Job well done.

I did see a few XK8's at the beach and one off our group drove his down. It showed a low coolant light one time, but was fine and I could not see any leak, I will check it out in a couple of days, he is only a couple of blocks away and made it home with no incident.

Again, nice job and thanks for all the direction, Wayne.

Job well done.

I did see a few XK8's at the beach and one off our group drove his down. It showed a low coolant light one time, but was fine and I could not see any leak, I will check it out in a couple of days, he is only a couple of blocks away and made it home with no incident.

Again, nice job and thanks for all the direction, Wayne.

#349

Thanks for the encouragement guys. I am happy to have that to-do list behind me!

I have one lingering question though if anyone would care to provide some insight. When tightening the crank pulley bolt I was using a homemade pulley holder fashioned from a BMW pulley holder tool. It is made of impressive steel and seemed more than up to the task, however...

I got a few turns on the bolt with my $60 Craftsman torque wrench and the holder tool bent! I had the wrench set at it's maximum which is 250 ft lbs. but it had not yet clicked when the holder tool failed. The resistance was pretty great, definitely more than twice the effort it takes to torque a lug nut, but I can't be sure what torque I finally achieved.

I re- fashioned the tool to try again but by that time the lock tight had set up and the tool would just bend immediately. I have driven about 100 miles since the project with no problems. Should i be trying to get it torqued more or should i leave well enough alone?

I would really like some opinions regarding this.

Thanks.

P.S. - Spark, the XJ convertible option is not off the table. However I think I have gotten the novelty out of a drop top and may prefer a coupe next time.

I have one lingering question though if anyone would care to provide some insight. When tightening the crank pulley bolt I was using a homemade pulley holder fashioned from a BMW pulley holder tool. It is made of impressive steel and seemed more than up to the task, however...

I got a few turns on the bolt with my $60 Craftsman torque wrench and the holder tool bent! I had the wrench set at it's maximum which is 250 ft lbs. but it had not yet clicked when the holder tool failed. The resistance was pretty great, definitely more than twice the effort it takes to torque a lug nut, but I can't be sure what torque I finally achieved.

I re- fashioned the tool to try again but by that time the lock tight had set up and the tool would just bend immediately. I have driven about 100 miles since the project with no problems. Should i be trying to get it torqued more or should i leave well enough alone?

I would really like some opinions regarding this.

Thanks.

P.S. - Spark, the XJ convertible option is not off the table. However I think I have gotten the novelty out of a drop top and may prefer a coupe next time.

Last edited by harvest14; 09-24-2015 at 08:31 AM.

#351

I am gathering the tools and parts to replace the upper and lower tensioners and chains on our 1999 XJ8L (80,000 miles). I ordered the basic tools through Amazon – they are by KTC and seem well made. However, I noted that the cam locking bars in the kit do not have a center bolt – only bolts at each end. Is it necessary to have a center bolt on the bars in order to perform the job properly?

Thanks.

Thanks.

#352

The following users liked this post:

jmbpharris (10-06-2015)

#353

#354

vdpnyc, that sounds similar to what I had with my jag with the tensioner issue. Noise worse at idle, worse when cold, etc. I'll upload a video in a bit which shows the noise quickly, I'm actually right in deep in the tensioner job right now. Got everything off, including primary chains.

Last thing i need to do is try and extract a bolt that broke off in the block then I can bang out the tensioner swap and start reassembling everything!

Last thing i need to do is try and extract a bolt that broke off in the block then I can bang out the tensioner swap and start reassembling everything!

#356

Here is the video of mine making the noise. Secondaries going bad may sound slightly different, on mine the passenger side primary tensioner was broken into pieces.

https://drive.google.com/open?id=0B5...2FjQkEyZnE2V0E

https://drive.google.com/open?id=0B5...2FjQkEyZnE2V0E

#357

After changing out secondary tensioners and 2 years of driving on old primary tensioners the start up ticking started again. I changed out the primarys, and I was still left with the ticking. I decided to buy the kit, and resnap the timing, to just find the startup tick. I found the ccw retard on the vvt confusing, and the vvt tool was useless. After driving with this start up tick, I found a thread on the AJ26, and I am sure the worn springs contribute to the tick on the AJ27 also. After replacing the VVT units on each intake cam, my 98 vdp no longer sounds like a junker. The skinny on the AJ26 VVT cam actuators is that they are in a fully retard position without oil pressure, and the tool is not needed. I found with flywheel pinned, and cam locks on and primary rail shimmed, let the spring pressure in the 2ndary tensioners take up the slack, and with the cam sprocket tool hold pressure and tighten to spec.

#358

Here is the video of mine making the noise. Secondaries going bad may sound slightly different, on mine the passenger side primary tensioner was broken into pieces.

https://drive.google.com/open?id=0B5...2FjQkEyZnE2V0E

https://drive.google.com/open?id=0B5...2FjQkEyZnE2V0E

#359

I think what Donzi may be alluding to is the zip-tie method that other folks have used, which avoids having to invest in the cam lock tools.

#360

Ok, maybe I'm being paranoid, but I just read in this article about the early 4.2 V8s requiring tensioner changes. I knew this was a problem with the 4.0 engines (been there, done that with my last car, an XK8), but is it necessary to do the tensioners on the newer engines too? Please say no....

Would have thought they fixed this problem with the introduction of the new engine.

Early 4.2 engines had plastic timing chain tensioners, which sounds like another instance when accountants won their argument with engineers. Jaguar eventually went to steel versions and there are steel replacement parts. Anyone buying an XK where this hasn't been replaced should get it done as soon as possible or risk turning the engine into so much scrap metal.