Upper ball joint replacement

#1

Okay so I have had a bit of play up front for the past couple weeks on the XJR. Was hoping to wait til spring to see what was up but today it took a major turn for the worse. Wheel shaking, darting handling etc. Traced it back to a bum upper ball joint (had all 4 replaced along with new poly bushes back in 2013 (maybe 20k or so ago). This time I'm planning to replace it.

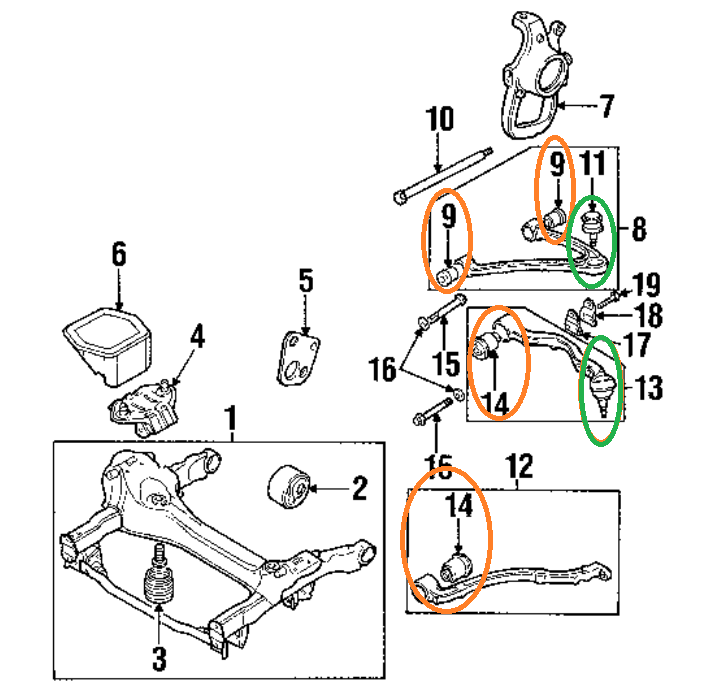

Okay here are my questions as I will be working outside since the snow we just got means the TVR stays in the garage another few weeks so I'm assuming the upper arm bolt will slide forward enough without removing anything right? As for pressing the bj out I am assuming I will need to grind off the lip like I had to do on my Xk8 when I did a front suspension rebuild on that or can I press it out from the "rubber side" I do have a 20 ton press so that shouldn't be an issue as at least the arm on the xjr is flat and should be easy compared to the XK. Anything else you can think I need to do aside from doing a warm weather dance?

Thanks!

Okay here are my questions as I will be working outside since the snow we just got means the TVR stays in the garage another few weeks so I'm assuming the upper arm bolt will slide forward enough without removing anything right? As for pressing the bj out I am assuming I will need to grind off the lip like I had to do on my Xk8 when I did a front suspension rebuild on that or can I press it out from the "rubber side" I do have a 20 ton press so that shouldn't be an issue as at least the arm on the xjr is flat and should be easy compared to the XK. Anything else you can think I need to do aside from doing a warm weather dance?

Thanks!

#2

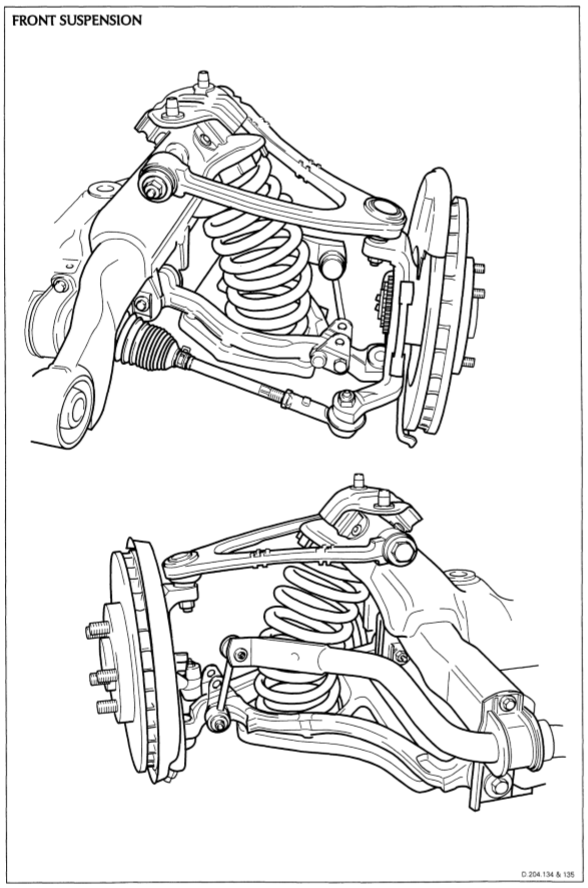

The suspension on the X308 is the same as the XK8's (97-on), so whatever you did on that should work fine on this.

The upper arm comes out quite easily, and yes there was nothing in the way of the bolt when I did the job. Given you'll be working in cold weather, definitely take the arm off the car, and work on it inside at your leisure.

You have to grind or cut two slices off the upper shoulder of the joint so that there's something to press against with the arbor plates. Then push it out from the taper side. Make sense? I cut the taper (moving) part off with an angle grinder, makes it easier to get in the press.

The upper arm comes out quite easily, and yes there was nothing in the way of the bolt when I did the job. Given you'll be working in cold weather, definitely take the arm off the car, and work on it inside at your leisure.

You have to grind or cut two slices off the upper shoulder of the joint so that there's something to press against with the arbor plates. Then push it out from the taper side. Make sense? I cut the taper (moving) part off with an angle grinder, makes it easier to get in the press.

The following users liked this post:

TreVoRTasmin (03-15-2017)

#3

Join Date: Feb 2013

Location: Trying to escape Central Florida

Posts: 4,636

Received 1,769 Likes

on

1,303 Posts

The following users liked this post:

TreVoRTasmin (03-15-2017)

#4

The suspension on the X308 is the same as the XK8's (97-on), so whatever you did on that should work fine on this.

The upper arm comes out quite easily, and yes there was nothing in the way of the bolt when I did the job. Given you'll be working in cold weather, definitely take the arm off the car, and work on it inside at your leisure.

You have to grind or cut two slices off the upper shoulder of the joint so that there's something to press against with the arbor plates. Then push it out from the taper side. Make sense? I cut the taper (moving) part off with an angle grinder, makes it easier to get in the press.

The upper arm comes out quite easily, and yes there was nothing in the way of the bolt when I did the job. Given you'll be working in cold weather, definitely take the arm off the car, and work on it inside at your leisure.

You have to grind or cut two slices off the upper shoulder of the joint so that there's something to press against with the arbor plates. Then push it out from the taper side. Make sense? I cut the taper (moving) part off with an angle grinder, makes it easier to get in the press.

#6

Thanks for the help, went great. From jack to drive less than an hour and a half! Popped out so much easier then the XK joints did. Didn't go with Jag ones as that is the one that failed so soon and it was toast. Normally the boots go or at least are dry rotted but not the case. Guess it helped make it easier to press in and out though. Now if I could only solve the vibration out of the XK that gets nasty around 80mph I would be a happy man. Everything seems tight so I will take it to get the tire balanced and see if the wheel might have had an issue with a pothole.

#7

Join Date: Feb 2013

Location: Trying to escape Central Florida

Posts: 4,636

Received 1,769 Likes

on

1,303 Posts

Good to hear, now its fun time....drive, drive, drive...

I have found, depending on the type of tire, alignment can cause the issue if the balance doesn't resolve it. Most balance machines don't go above 65 btw.

I am running, and really shouldn't, Goodyear Eagles with an aggressive tread pattern. If my alignment is out just a bit, they will vibrate (or should I say cavitate) at certain speeds (50ish and 75ish). Running an aggressive performance tire isn't really recommended because of this. Even Mercedes put out a bulletin regarding such on its performance saloons. I'm probably going to switch to the Michelin A/S +3 or the like.

Even the Michelin Pilot S/S I had on previously had less issues than these Goodyears.

I have found, depending on the type of tire, alignment can cause the issue if the balance doesn't resolve it. Most balance machines don't go above 65 btw.

I am running, and really shouldn't, Goodyear Eagles with an aggressive tread pattern. If my alignment is out just a bit, they will vibrate (or should I say cavitate) at certain speeds (50ish and 75ish). Running an aggressive performance tire isn't really recommended because of this. Even Mercedes put out a bulletin regarding such on its performance saloons. I'm probably going to switch to the Michelin A/S +3 or the like.

Even the Michelin Pilot S/S I had on previously had less issues than these Goodyears.