Failing Head Gasket ?

#41

#42

Clarke,

Just looked at the Monotorque specs for that head gasket whilst at work.

1st round = 40NM

2nd round = 65NM

3rd round = 75NM

No mention of redoing the final after a 1 hour run up.

I always do that the next morning, and do 1 nut at a time, back if off and repull to 75NM.

Also checked the Permaseal, and Payen specs, exactly the same.

Hope that clears it up

Just looked at the Monotorque specs for that head gasket whilst at work.

1st round = 40NM

2nd round = 65NM

3rd round = 75NM

No mention of redoing the final after a 1 hour run up.

I always do that the next morning, and do 1 nut at a time, back if off and repull to 75NM.

Also checked the Permaseal, and Payen specs, exactly the same.

Hope that clears it up

The following users liked this post:

o1xjr (02-19-2016)

#43

Join Date: Jan 2014

Location: Delaneys Creek,Qld. Australia

Posts: 28,379

Received 6,317 Likes

on

4,367 Posts

Thanks for the torque settings Grant.

Got her safely up on stands tonight so I can dive under after work tomorrow to drain the coolant and get at the lower nuts on the manifolds from underneath before dropping back down and rolling forward under the lights.

Oh well, it's only 10 pm. May as well drain the radiator before bed. Damn, the rad holds a lot of coolant.

Got her safely up on stands tonight so I can dive under after work tomorrow to drain the coolant and get at the lower nuts on the manifolds from underneath before dropping back down and rolling forward under the lights.

Oh well, it's only 10 pm. May as well drain the radiator before bed. Damn, the rad holds a lot of coolant.

Last edited by o1xjr; 02-19-2016 at 06:40 AM.

The following users liked this post:

Daf11e (02-19-2016)

#46

Join Date: Jan 2014

Location: Delaneys Creek,Qld. Australia

Posts: 28,379

Received 6,317 Likes

on

4,367 Posts

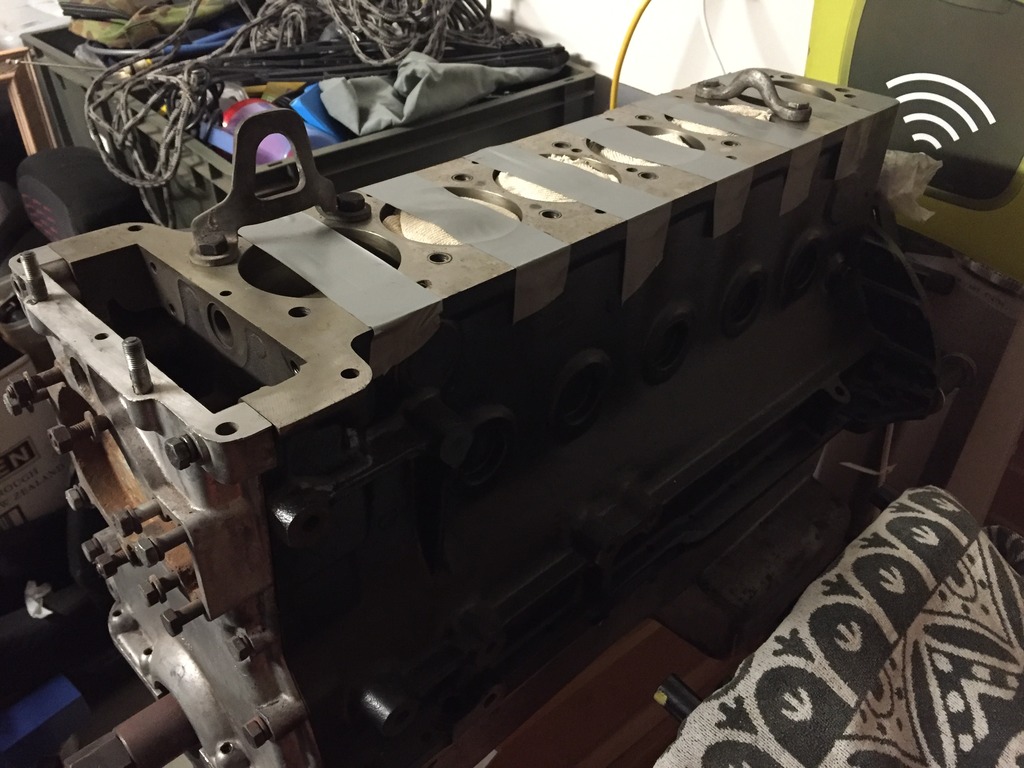

All went well removing the head, found no nasty surprises down below. So no need to dig deeper.

It looks like the bottom end has been rebuilt in the not too distant past, studs have been replaced at some stage.

Head is off to the shop tomorrow, hoping to have it back Thursday or Friday. So should be back on the road next weekend with a week to spare before our next JF run up into the mountains.

https://www.jaguarforums.com/forum/a...bruary-154508/

Dr Phill thinks the head probably won't need much work,just a skim and seals. But that is in the hands of the shop, they will do what they think best.

Not too much else found wrong, a couple of coolant hoses to replace and a bit of rewiring to fix dodgy connectors etc. Fuse connector for the fans was melted so going to investigate that during the week, it was ok last time I had the radiator out a few months ago. So the end result isn't bad at all.

Gasket was blown between 5 & 6, top of 5 piston a bit washed and plug as well. So just up for a thermostat,plugs,hoses. Should come in under $1000 for everything.

Had the job done by 9.30, had to wait for Supercheap Auto to open so I could buy a bottle jack to lift the head. So spent the rest of the day sitting back enjoying a few ales since we didn't have to pull the engine out.

It looks like the bottom end has been rebuilt in the not too distant past, studs have been replaced at some stage.

Head is off to the shop tomorrow, hoping to have it back Thursday or Friday. So should be back on the road next weekend with a week to spare before our next JF run up into the mountains.

https://www.jaguarforums.com/forum/a...bruary-154508/

Dr Phill thinks the head probably won't need much work,just a skim and seals. But that is in the hands of the shop, they will do what they think best.

Not too much else found wrong, a couple of coolant hoses to replace and a bit of rewiring to fix dodgy connectors etc. Fuse connector for the fans was melted so going to investigate that during the week, it was ok last time I had the radiator out a few months ago. So the end result isn't bad at all.

Gasket was blown between 5 & 6, top of 5 piston a bit washed and plug as well. So just up for a thermostat,plugs,hoses. Should come in under $1000 for everything.

Had the job done by 9.30, had to wait for Supercheap Auto to open so I could buy a bottle jack to lift the head. So spent the rest of the day sitting back enjoying a few ales since we didn't have to pull the engine out.

Last edited by o1xjr; 02-21-2016 at 06:04 AM.

The following 3 users liked this post by o1xjr:

#47

#48

Join Date: Jan 2014

Location: Delaneys Creek,Qld. Australia

Posts: 28,379

Received 6,317 Likes

on

4,367 Posts

Got to listen to Phill on this one, he's been spannering 33 years so his opinion works for me.

The following users liked this post:

Grant Francis (02-21-2016)

#49

Join Date: Mar 2014

Location: Tehama County, California, USA

Posts: 25,178

Received 8,946 Likes

on

5,293 Posts

The following users liked this post:

o1xjr (02-22-2016)

#51

The following users liked this post:

o1xjr (02-22-2016)

#52

Join Date: Jan 2014

Location: Delaneys Creek,Qld. Australia

Posts: 28,379

Received 6,317 Likes

on

4,367 Posts

A couple of questions.

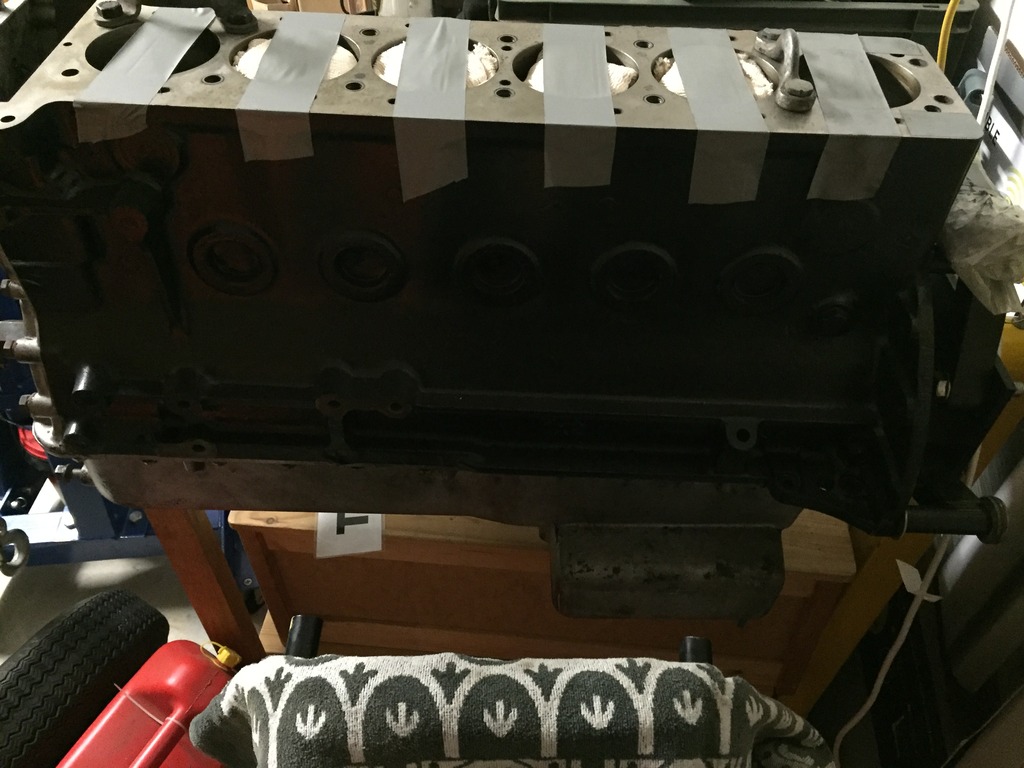

1. Is the upper timing chain tensioner supposed to be hard to move, we only managed to move it a couple of notches. Do we use more force, or are we missing something?

2. Is there two different head gaskets(different spacing between the bores). When the engineer doing the head saw the old gasket and head he said it was slightly offset to the bores. So has asked me to drop off the new gasket tomorrow so he can check it is the right one.

3. Has anyone heard of this before. Filling the expansion slots between the bores (about 5mm deep) with Plastibond to give a bigger surface area for the gasket to bond between the cylinders?

(recommended by the engineer)

1. Is the upper timing chain tensioner supposed to be hard to move, we only managed to move it a couple of notches. Do we use more force, or are we missing something?

2. Is there two different head gaskets(different spacing between the bores). When the engineer doing the head saw the old gasket and head he said it was slightly offset to the bores. So has asked me to drop off the new gasket tomorrow so he can check it is the right one.

3. Has anyone heard of this before. Filling the expansion slots between the bores (about 5mm deep) with Plastibond to give a bigger surface area for the gasket to bond between the cylinders?

(recommended by the engineer)

Last edited by o1xjr; 02-22-2016 at 03:48 AM.

#53

A couple of questions.

1. Is the upper timing chain tensioner supposed to be hard to move, we only managed to move it a couple of notches. Do we use more force, or are we missing something?

Attachment 125900

2. Is there two different head gaskets(different spacing between the bores). When the engineer doing the head saw the old gasket and head he said it was slightly offset to the bores. So has asked me to drop off the new gasket tomorrow so he can check it is the right one.

3. Has anyone heard of this before. Filling the expansion slots between the bores (about 5mm deep) with Plastibond to give a bigger surface area for the gasket to bond between the cylinders?

(recommended by the engineer)

Attachment 125901

1. Is the upper timing chain tensioner supposed to be hard to move, we only managed to move it a couple of notches. Do we use more force, or are we missing something?

Attachment 125900

2. Is there two different head gaskets(different spacing between the bores). When the engineer doing the head saw the old gasket and head he said it was slightly offset to the bores. So has asked me to drop off the new gasket tomorrow so he can check it is the right one.

3. Has anyone heard of this before. Filling the expansion slots between the bores (about 5mm deep) with Plastibond to give a bigger surface area for the gasket to bond between the cylinders?

(recommended by the engineer)

Attachment 125901

2) I have heard of that, but I think that was the short stud versus the long stud?????, but I really dont want to be quoted on it, as it was so long ago. The Permaseal book I have, as old as I am, lists one headgasket from E- Type to S2, when the book runs out by its age.

3) Never heard of that. Not something I would do.

The following users liked this post:

o1xjr (02-22-2016)

#54

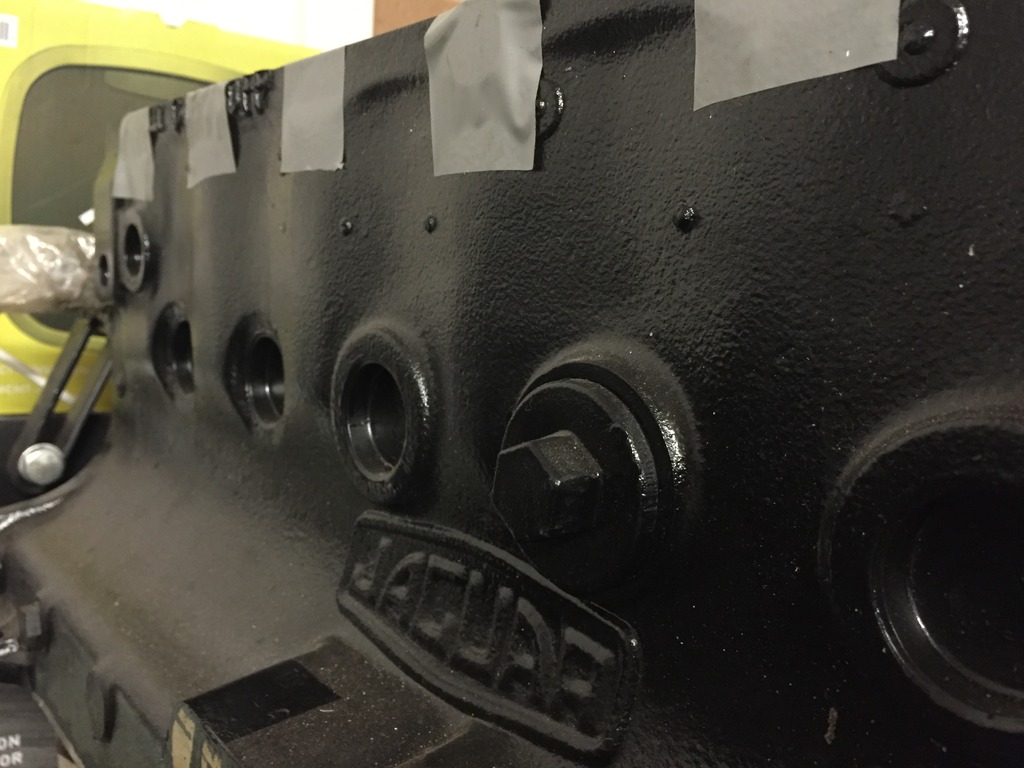

The slotted block replaced the previous block that tended to crack between the bores. This was because there were horizontal cross-block coolant passages machined via the bores, with a liner to cover them. The slotted block eliminated the cracking problem, but head gaskets still usually only manage about 80-90k miles before they go somewhere. Its just something the XJ owner has to get used to, (along with a lot of other things !!)

I've attached a photo of these passages in the old blocks

I've attached a photo of these passages in the old blocks

The following users liked this post:

Grant Francis (02-22-2016)

#55

3. Has anyone heard of this before. Filling the expansion slots between the bores (about 5mm deep) with Plastibond to give a bigger surface area for the gasket to bond between the cylinders?

(recommended by the engineer)

Attachment 125901

The following users liked this post:

o1xjr (02-23-2016)

#56

Join Date: Jan 2014

Location: Delaneys Creek,Qld. Australia

Posts: 28,379

Received 6,317 Likes

on

4,367 Posts

Apparently the slotted block like mine is a series 3 block.(sourced info from Doug at Jagdaim), and the head is a series 2.

The engine re-builder says it is a common thing to do, but we are looking further into it. The theory sounds good, as it does seem to be a weak point in the head gaskets. But I will give Peninsula jag a call to see what they say.

I am leaning towards giving it go, at worst it will be the cost of a VRS kit if there are issues. As the gasket does not have openings for the slots so they will be blanked off anyway, just 5 mm's lower and doubling the surface area for the gasket to seal.

Uncharted territory here, but one way to find out.

Nothing like being the pioneer, it beats cutting a track through the outback on foot 200 years ago. (I'm not that pioneering, but this I may have a go)

The engine re-builder says it is a common thing to do, but we are looking further into it. The theory sounds good, as it does seem to be a weak point in the head gaskets. But I will give Peninsula jag a call to see what they say.

I am leaning towards giving it go, at worst it will be the cost of a VRS kit if there are issues. As the gasket does not have openings for the slots so they will be blanked off anyway, just 5 mm's lower and doubling the surface area for the gasket to seal.

Uncharted territory here, but one way to find out.

Nothing like being the pioneer, it beats cutting a track through the outback on foot 200 years ago. (I'm not that pioneering, but this I may have a go)

#57

Join Date: Nov 2013

Location: Inverell, NSW, Australia

Posts: 3,014

Received 1,410 Likes

on

876 Posts

Gosh Clarke,

I leave the room for a few days to rush down to the coast to hurry the sale of our former home . . . and return tonight to find that between you, Dr Phil, Grant (Aged Oracle; Great Friend) and all the crew, you have done a truly spiffy job of spannering, lateral thinking, brave re-engineering and wonderings!

Cannot offer owt but praise for the fine job of R&R Head. Totally agree with all Grant's advice . . . upper t/c tensioner can be stiff unless the locknut is well backed off (and even then . . . !!! - put it dowm to POs trying to turn without slacking off fully). Good to see tension specs clearly laid out by Grant also.

Which brings us to the Pliobond in throughways between adjacent cylinders - theory being to do so before truing the blockface, which I gather you are not planning to do. I have heard of this theory - and I have seen it in action - on race engines where they were filled not with Pliobond but welded, again using your observation that the head gasket would blank them anyway.

I don't like it!

I recall that, from the advent of the original 4.2L XK, they (and later) engines were considered less race-durable than the prior 3.8s. Even Jane, the Geoghans and others racing Mk2s, found the bore spacing less than ideal . . . BUT, the problem was NOT lack of adequate gasket between cylinders; it was less than adequate cylinder stiffness . . . causing the flexing and fracturing already referred to.

Answer? IMHO, you make good the faces on both block and head (nothing wrong with manual hand scraper if done carefully and properly); you fit a new gasket (preferably with the rolled lips encompassing cylinders) and you follow Grants previously advised regimen of head tensioning . . . see also my previous post on this. Then, with any of these later design "long stud" 6s, you resign yourself to the inherent need to periodically check and reset head stud tension, and R&R Head Gasket each 100,000 miles.

Like Grant, I can only justify bigger valves if you are forced to do a complete replacement. As I stated previously, these engines were fairly good "breathers" for their day . . . and improvements to both the induction and exhaust systems will gain far more for far less money.

Now a question from me. What condition are the upper t/c camshaft gear wheels in? How much "scalloping"? Only if unacceptable, should you consider replacement, and only then need you even bother inspecting the bottom chain (famous last words, but held to be true!). Even with the far more direct "slap and kick" that the top t/c undergoes under the duress of those cam lobes, most last effortlessly up into 250,000 mile territory . . . BUT, do check!

Cheers,

Ken

I leave the room for a few days to rush down to the coast to hurry the sale of our former home . . . and return tonight to find that between you, Dr Phil, Grant (Aged Oracle; Great Friend) and all the crew, you have done a truly spiffy job of spannering, lateral thinking, brave re-engineering and wonderings!

Cannot offer owt but praise for the fine job of R&R Head. Totally agree with all Grant's advice . . . upper t/c tensioner can be stiff unless the locknut is well backed off (and even then . . . !!! - put it dowm to POs trying to turn without slacking off fully). Good to see tension specs clearly laid out by Grant also.

Which brings us to the Pliobond in throughways between adjacent cylinders - theory being to do so before truing the blockface, which I gather you are not planning to do. I have heard of this theory - and I have seen it in action - on race engines where they were filled not with Pliobond but welded, again using your observation that the head gasket would blank them anyway.

I don't like it!

- these throughways were introduced, as others have commented, to overcome the propensity of these engines to develop stress fracturing between cylinders . . . sealing them would seem to defeat that purpose;

- it is difficult to be convinced that any filler (Pliobond, metal or whatever) will add to the sealing area in the clamp of head to block, because . . .

- in most head gasket designs I have seen and used on all these engines, the actual sealing pressure is carried only in the 2mm or so bead that encircles the cylinder bore.

I recall that, from the advent of the original 4.2L XK, they (and later) engines were considered less race-durable than the prior 3.8s. Even Jane, the Geoghans and others racing Mk2s, found the bore spacing less than ideal . . . BUT, the problem was NOT lack of adequate gasket between cylinders; it was less than adequate cylinder stiffness . . . causing the flexing and fracturing already referred to.

Answer? IMHO, you make good the faces on both block and head (nothing wrong with manual hand scraper if done carefully and properly); you fit a new gasket (preferably with the rolled lips encompassing cylinders) and you follow Grants previously advised regimen of head tensioning . . . see also my previous post on this. Then, with any of these later design "long stud" 6s, you resign yourself to the inherent need to periodically check and reset head stud tension, and R&R Head Gasket each 100,000 miles.

Like Grant, I can only justify bigger valves if you are forced to do a complete replacement. As I stated previously, these engines were fairly good "breathers" for their day . . . and improvements to both the induction and exhaust systems will gain far more for far less money.

Now a question from me. What condition are the upper t/c camshaft gear wheels in? How much "scalloping"? Only if unacceptable, should you consider replacement, and only then need you even bother inspecting the bottom chain (famous last words, but held to be true!). Even with the far more direct "slap and kick" that the top t/c undergoes under the duress of those cam lobes, most last effortlessly up into 250,000 mile territory . . . BUT, do check!

Cheers,

Ken

The following 2 users liked this post by cat_as_trophy:

Grant Francis (02-23-2016),

o1xjr (02-23-2016)

#58

Join Date: Jan 2014

Location: Delaneys Creek,Qld. Australia

Posts: 28,379

Received 6,317 Likes

on

4,367 Posts

A question from Phill.

Timing gears ok,no nasty wear, I did look. Now I tend to agree with him on filling water jackets but don't understand why you wouldn't do something there to try to eliminate the 100k gasket change. With them staying as is it allows coolant to "attack" the gasket at a very vulnerable area and over time will create failure. See what the response is to that and say you are only going in 5mm to stop the coolant attack.

I'm open to reasoning, I'm new to these things

I'm open to reasoning, I'm new to these things

Last edited by o1xjr; 02-24-2016 at 02:59 AM.

#60

I am mixed, but if push came to shove I would leave it be.

Modern Coolants are not near as attacking as older spec stuff, or tap water that most have been on for how long???? before we rescued them.

The damage may hve been done a while back, and then the Red Herring, did the guy who did it then tension the head properly, and then redo it after a few hours workshop running prior to returning to the owner, no one knows. My bet is NO.

I have left the S2 and S3 engines I have done, "as is", and the Daimler has now topped 200k Kms since I did that engine, and is not having issues.

The V12 engine is an open deck engine, and the head gasket is in constant contact with coolant on the underside. Except where the "sandwich" between the block/liners/head is happening. Granted, they dissolve over years and form the "mud" in the block we V12 guys all know too well, but the "fire ring" and the outer circumference is always intact that I have found. Head corrosion is rampant where the gaskets dissolves away from, and is a PITA.

I agree with what has been said about "block movement", and that has been a 4.2 issue from the beginning. The 3.4 and 3.8 do not have that issue, only the 4.2.

I maintain that regular retensioning of the head, DO NOT overheat it, and the "****" maintenence that you are famous for, will see this last a long time.

Of course, the block face integrity is something that Ken touched on, and I also touch on. A LARGE lump of steel plate (3" X 1", about 12" long), some 240 Wet/dry wrapped around it, and work away for a few hours, just to be sure, is what I would 100% be doing. The head may be 100% spot on, but an imperfection in the mating face of the block will screw all that work in a heartbeat.

I need a drink after that marathon.

Modern Coolants are not near as attacking as older spec stuff, or tap water that most have been on for how long???? before we rescued them.

The damage may hve been done a while back, and then the Red Herring, did the guy who did it then tension the head properly, and then redo it after a few hours workshop running prior to returning to the owner, no one knows. My bet is NO.

I have left the S2 and S3 engines I have done, "as is", and the Daimler has now topped 200k Kms since I did that engine, and is not having issues.

The V12 engine is an open deck engine, and the head gasket is in constant contact with coolant on the underside. Except where the "sandwich" between the block/liners/head is happening. Granted, they dissolve over years and form the "mud" in the block we V12 guys all know too well, but the "fire ring" and the outer circumference is always intact that I have found. Head corrosion is rampant where the gaskets dissolves away from, and is a PITA.

I agree with what has been said about "block movement", and that has been a 4.2 issue from the beginning. The 3.4 and 3.8 do not have that issue, only the 4.2.

I maintain that regular retensioning of the head, DO NOT overheat it, and the "****" maintenence that you are famous for, will see this last a long time.

Of course, the block face integrity is something that Ken touched on, and I also touch on. A LARGE lump of steel plate (3" X 1", about 12" long), some 240 Wet/dry wrapped around it, and work away for a few hours, just to be sure, is what I would 100% be doing. The head may be 100% spot on, but an imperfection in the mating face of the block will screw all that work in a heartbeat.

I need a drink after that marathon.

Last edited by Grant Francis; 02-24-2016 at 05:33 AM.

The following 2 users liked this post by Grant Francis:

cat_as_trophy (02-25-2016),

o1xjr (02-24-2016)