electric water pump?

#41

Join Date: Oct 2009

Location: Perth Ontario Canada

Posts: 11,058

Received 2,255 Likes

on

1,840 Posts

How about this as a theory- during an engine overheat event the seats do indeed lose their tight fit but due to the short time the valves are actually open while the engine is at high revs, the seats never have the opportunity to fall out completely and jamb up the works. The closing valve pushes them back into place and the owner is none the wiser.

However, after shutdown, the heat soak again provide the opportunity for a loose fit on the seat and any valve that happens to be open presents the possibility of one falling out?

#42

They also conduct differently. So on one hand the expansion rate of aluminum is twice that of steel (this doesn't mean it expands twice the size) but the thermal conductivity of aluminum is 13x that of steel.

So while you can argue that one will expand more, it also sheds that heat much much more quickly. Post shutdown I would speculate that the seats are much hotter than the surrounding area, making issues with interference nonexistent.

The issue would then come with actually overheating the engine while driving, where the parts are continuously fed heat without being able to shed it to operate in the correct temperature. At some point the temperature would finally be reached where the aluminum has expanded enough to drop the seat.

For some more numbers, if you have a piece of steel inside a piece of aluminum with the same interference fit as a typical seat in an aluminum head, they two only need to increase their temperature by 250 degree Fahrenheit to have a large enough clearance to separate from one enough.

Obviously the engine is operating at higher temperatures than this, which tells you just how much the thermal conductivity has an effect on this situation.

After shutdown the last bit of heat released is exactly the same everytime, it is the same explosion. The only difference I can see allowing a seat to drop at this point would be due to an increase in temperature as a result of the rest of the engine already being so hot. The heat wouldn't transfer away as quickly, and so the liner, valves, seats, etc would absorb much more of the heat than normal.

there are probably other factors I am not considering, I just don't see how the engine, operating in a normal range, could randomly drop a seat after shutdown. I am not saying it didn't happen to safari, but I do think something else was involved, whether the engine was actually overheating or some other defect caused it. If they dropped in that range, anyone who has ever even slightly overheated this engine would probably drop a seat while driving and would 100% drop a seat after shutdown of an overheated engine

So while you can argue that one will expand more, it also sheds that heat much much more quickly. Post shutdown I would speculate that the seats are much hotter than the surrounding area, making issues with interference nonexistent.

The issue would then come with actually overheating the engine while driving, where the parts are continuously fed heat without being able to shed it to operate in the correct temperature. At some point the temperature would finally be reached where the aluminum has expanded enough to drop the seat.

For some more numbers, if you have a piece of steel inside a piece of aluminum with the same interference fit as a typical seat in an aluminum head, they two only need to increase their temperature by 250 degree Fahrenheit to have a large enough clearance to separate from one enough.

Obviously the engine is operating at higher temperatures than this, which tells you just how much the thermal conductivity has an effect on this situation.

After shutdown the last bit of heat released is exactly the same everytime, it is the same explosion. The only difference I can see allowing a seat to drop at this point would be due to an increase in temperature as a result of the rest of the engine already being so hot. The heat wouldn't transfer away as quickly, and so the liner, valves, seats, etc would absorb much more of the heat than normal.

there are probably other factors I am not considering, I just don't see how the engine, operating in a normal range, could randomly drop a seat after shutdown. I am not saying it didn't happen to safari, but I do think something else was involved, whether the engine was actually overheating or some other defect caused it. If they dropped in that range, anyone who has ever even slightly overheated this engine would probably drop a seat while driving and would 100% drop a seat after shutdown of an overheated engine

#43

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

Tisn't only jaguars that have this issue. Way back when, I had a 63 Corvair camperized van. Nice truck, four on the floor ad rudimentary camp gear ala VW's camper of the era.

Then, it developed a miss and at times would run only on 5. As it had hydraulic lifters, the thing made no racket. But, at times missed and at times all 6 were on line. messed and messed trying to fond that miss and which cylinder was taking plays off!!!

At last, I drove into the rear drive, miss in progress. did another compression test. ) in one hole!!!

Note, a simple engine air cooled. No after run features what so ever.

I pulled the offending head. Not a big deal, except that it was done on the ground!!

Yup. One loose seat. So, the closing valve would seat the seat at times. No miss. but, on this occasion, it the seat was cocked. No seal at all, no compression.

A visit to the local machinist. Friendly folks. told me they had fixed several over the years. I was shown one pair with the seats affixed with pins! Sorta like later Jag engine lifters were staked in place!!!

We looked through their collection and decided to have min TIG's to fix the material and then machine and set new seats. They claimed to be able to seat the seats much

tighter and lessen the chance of a reoccurrence. It seemed to work as rthe engine ran great when sold.

I think my malady started when it threw a cooling fan belt and ran a tad hot til I got off the Golden State Freeway in Socal's San Fernando Valley.

So, is it the relation of the metals, the machining, the head design, I don't know.

Or a 90 HP engine vs a 300 HP engine???? Combustion temperatures???

My 36 and 40 hp VW's never had that issue.

Yet, when the DOHC in my 83 XJ bit the dust and I went engine shopping, I passed up on an alloy headed Corvette engine for a similar, but all iron engine.

Carl

Then, it developed a miss and at times would run only on 5. As it had hydraulic lifters, the thing made no racket. But, at times missed and at times all 6 were on line. messed and messed trying to fond that miss and which cylinder was taking plays off!!!

At last, I drove into the rear drive, miss in progress. did another compression test. ) in one hole!!!

Note, a simple engine air cooled. No after run features what so ever.

I pulled the offending head. Not a big deal, except that it was done on the ground!!

Yup. One loose seat. So, the closing valve would seat the seat at times. No miss. but, on this occasion, it the seat was cocked. No seal at all, no compression.

A visit to the local machinist. Friendly folks. told me they had fixed several over the years. I was shown one pair with the seats affixed with pins! Sorta like later Jag engine lifters were staked in place!!!

We looked through their collection and decided to have min TIG's to fix the material and then machine and set new seats. They claimed to be able to seat the seats much

tighter and lessen the chance of a reoccurrence. It seemed to work as rthe engine ran great when sold.

I think my malady started when it threw a cooling fan belt and ran a tad hot til I got off the Golden State Freeway in Socal's San Fernando Valley.

So, is it the relation of the metals, the machining, the head design, I don't know.

Or a 90 HP engine vs a 300 HP engine???? Combustion temperatures???

My 36 and 40 hp VW's never had that issue.

Yet, when the DOHC in my 83 XJ bit the dust and I went engine shopping, I passed up on an alloy headed Corvette engine for a similar, but all iron engine.

Carl

The following users liked this post:

ronbros (11-20-2014)

#44

My money is on varying tolerances inevitable in the manufacturing methods of the era being the reason why some drop and others do not, allied to the expansion/contraction rate differences so clearly explained in this thread. I have a photo of a guy banging in the seats with a hammer and a drift as part of the engine line manufacturing process!

I have a feeling, and I do not know why, that dropped seats are more of a problem in the USA lower compression engines than in the UK higher ones.

Greg

I have a feeling, and I do not know why, that dropped seats are more of a problem in the USA lower compression engines than in the UK higher ones.

Greg

#45

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,231 Likes

on

939 Posts

Tisn't only jaguars that have this issue. Way back when, I had a 63 Corvair camperized van. Nice truck, four on the floor ad rudimentary camp gear ala VW's camper of the era.

Then, it developed a miss and at times would run only on 5. As it had hydraulic lifters, the thing made no racket. But, at times missed and at times all 6 were on line. messed and messed trying to fond that miss and which cylinder was taking plays off!!!

At last, I drove into the rear drive, miss in progress. did another compression test. ) in one hole!!!

Note, a simple engine air cooled. No after run features what so ever.

I pulled the offending head. Not a big deal, except that it was done on the ground!!

Yup. One loose seat. So, the closing valve would seat the seat at times. No miss. but, on this occasion, it the seat was cocked. No seal at all, no compression.

A visit to the local machinist. Friendly folks. told me they had fixed several over the years. I was shown one pair with the seats affixed with pins! Sorta like later Jag engine lifters were staked in place!!!

We looked through their collection and decided to have min TIG's to fix the material and then machine and set new seats. They claimed to be able to seat the seats much

tighter and lessen the chance of a reoccurrence. It seemed to work as rthe engine ran great when sold.

I think my malady started when it threw a cooling fan belt and ran a tad hot til I got off the Golden State Freeway in Socal's San Fernando Valley.

So, is it the relation of the metals, the machining, the head design, I don't know.

Or a 90 HP engine vs a 300 HP engine???? Combustion temperatures???

My 36 and 40 hp VW's never had that issue.

Yet, when the DOHC in my 83 XJ bit the dust and I went engine shopping, I passed up on an alloy headed Corvette engine for a similar, but all iron engine.

Carl

Then, it developed a miss and at times would run only on 5. As it had hydraulic lifters, the thing made no racket. But, at times missed and at times all 6 were on line. messed and messed trying to fond that miss and which cylinder was taking plays off!!!

At last, I drove into the rear drive, miss in progress. did another compression test. ) in one hole!!!

Note, a simple engine air cooled. No after run features what so ever.

I pulled the offending head. Not a big deal, except that it was done on the ground!!

Yup. One loose seat. So, the closing valve would seat the seat at times. No miss. but, on this occasion, it the seat was cocked. No seal at all, no compression.

A visit to the local machinist. Friendly folks. told me they had fixed several over the years. I was shown one pair with the seats affixed with pins! Sorta like later Jag engine lifters were staked in place!!!

We looked through their collection and decided to have min TIG's to fix the material and then machine and set new seats. They claimed to be able to seat the seats much

tighter and lessen the chance of a reoccurrence. It seemed to work as rthe engine ran great when sold.

I think my malady started when it threw a cooling fan belt and ran a tad hot til I got off the Golden State Freeway in Socal's San Fernando Valley.

So, is it the relation of the metals, the machining, the head design, I don't know.

Or a 90 HP engine vs a 300 HP engine???? Combustion temperatures???

My 36 and 40 hp VW's never had that issue.

Yet, when the DOHC in my 83 XJ bit the dust and I went engine shopping, I passed up on an alloy headed Corvette engine for a similar, but all iron engine.

Carl

i been doing engine rebuilds since 1949, i would thinkl i learned something in that time, i'm kinda retired, but cant keep my hands off cars! gotta love em!

#46

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,231 Likes

on

939 Posts

They also conduct differently. So on one hand the expansion rate of aluminum is twice that of steel (this doesn't mean it expands twice the size) but the thermal conductivity of aluminum is 13x that of steel.

So while you can argue that one will expand more, it also sheds that heat much much more quickly. Post shutdown I would speculate that the seats are much hotter than the surrounding area, making issues with interference nonexistent.

The issue would then come with actually overheating the engine while driving, where the parts are continuously fed heat without being able to shed it to operate in the correct temperature. At some point the temperature would finally be reached where the aluminum has expanded enough to drop the seat.

For some more numbers, if you have a piece of steel inside a piece of aluminum with the same interference fit as a typical seat in an aluminum head, they two only need to increase their temperature by 250 degree Fahrenheit to have a large enough clearance to separate from one enough.

Obviously the engine is operating at higher temperatures than this, which tells you just how much the thermal conductivity has an effect on this situation.

After shutdown the last bit of heat released is exactly the same everytime, it is the same explosion. The only difference I can see allowing a seat to drop at this point would be due to an increase in temperature as a result of the rest of the engine already being so hot. The heat wouldn't transfer away as quickly, and so the liner, valves, seats, etc would absorb much more of the heat than normal.

there are probably other factors I am not considering, I just don't see how the engine, operating in a normal range, could randomly drop a seat after shutdown. I am not saying it didn't happen to safari, but I do think something else was involved, whether the engine was actually overheating or some other defect caused it. If they dropped in that range, anyone who has ever even slightly overheated this engine would probably drop a seat while driving and would 100% drop a seat after shutdown of an overheated engine

So while you can argue that one will expand more, it also sheds that heat much much more quickly. Post shutdown I would speculate that the seats are much hotter than the surrounding area, making issues with interference nonexistent.

The issue would then come with actually overheating the engine while driving, where the parts are continuously fed heat without being able to shed it to operate in the correct temperature. At some point the temperature would finally be reached where the aluminum has expanded enough to drop the seat.

For some more numbers, if you have a piece of steel inside a piece of aluminum with the same interference fit as a typical seat in an aluminum head, they two only need to increase their temperature by 250 degree Fahrenheit to have a large enough clearance to separate from one enough.

Obviously the engine is operating at higher temperatures than this, which tells you just how much the thermal conductivity has an effect on this situation.

After shutdown the last bit of heat released is exactly the same everytime, it is the same explosion. The only difference I can see allowing a seat to drop at this point would be due to an increase in temperature as a result of the rest of the engine already being so hot. The heat wouldn't transfer away as quickly, and so the liner, valves, seats, etc would absorb much more of the heat than normal.

there are probably other factors I am not considering, I just don't see how the engine, operating in a normal range, could randomly drop a seat after shutdown. I am not saying it didn't happen to safari, but I do think something else was involved, whether the engine was actually overheating or some other defect caused it. If they dropped in that range, anyone who has ever even slightly overheated this engine would probably drop a seat while driving and would 100% drop a seat after shutdown of an overheated engine

Last edited by ronbros; 11-20-2014 at 11:54 AM.

The following 2 users liked this post by ronbros:

Greg in France (11-20-2014),

xjsv12 (11-24-2014)

#47

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

Thanks.

Son did a pair of Corvair heads for my sorta turbo 63 Monza decades ago. he had a full service auto machine shop at the time. Now retired into manufacture and sales of performance products. A self taught master machinist and fabricator.

But, as to the public, no VW or Jaguar engines allowed!!!

Humour: some decades ago, I stopped by his shop to visit in my Jaguar. a pal of

his, a county building inspector there as well in his county truck. His quote, My reputation is ruined forever....

Carl

Son did a pair of Corvair heads for my sorta turbo 63 Monza decades ago. he had a full service auto machine shop at the time. Now retired into manufacture and sales of performance products. A self taught master machinist and fabricator.

But, as to the public, no VW or Jaguar engines allowed!!!

Humour: some decades ago, I stopped by his shop to visit in my Jaguar. a pal of

his, a county building inspector there as well in his county truck. His quote, My reputation is ruined forever....

Carl

The following users liked this post:

ronbros (11-20-2014)

#48

neat excerpt but don't see how it makes sense. Heat always transfers to areas of lower temperature, and the combustion going on in the cylinder is the main producer of all the heat inside an engine. The oil also absorbs heat and is partially cooled, so it acts as a coolant, but it is not the primary coolant, so keeping it cool is only necessary to maintain proper viscosity. The coolant is the primary source of cooling and so it is necessary to keep it cool, thus the difference noted in the excerpt of 90 degrees compared to 140 (about 80 degrees F).

It is simple to see that isn't the cause if you make a simple example like sticking hot rods in water to raise its temperature. If you had three rods in a pot and one of them was room temperature, another nearby that was 300 degrees, and the final rod further away at 100 degrees, it is easy to understand the closer rod that has the higher temperature would be the main reason the cold rod is increasing in temperature.

I am pretty sure Allan was an engineer that worked on the rx7 engines at TWR, so it is surprising he would make a statement like that and that he would simply state the engines would boil over. Regardless of the reasoning, if he helped build race cars and it is weird couldn't piece together an improvement in the cooling system.

It is simple to see that isn't the cause if you make a simple example like sticking hot rods in water to raise its temperature. If you had three rods in a pot and one of them was room temperature, another nearby that was 300 degrees, and the final rod further away at 100 degrees, it is easy to understand the closer rod that has the higher temperature would be the main reason the cold rod is increasing in temperature.

I am pretty sure Allan was an engineer that worked on the rx7 engines at TWR, so it is surprising he would make a statement like that and that he would simply state the engines would boil over. Regardless of the reasoning, if he helped build race cars and it is weird couldn't piece together an improvement in the cooling system.

#49

I am pretty sure Allan was an engineer that worked on the rx7 engines at TWR, so it is surprising he would make a statement like that and that he would simply state the engines would boil over. Regardless of the reasoning, if he helped build race cars and it is weird couldn't piece together an improvement in the cooling system.

Greg

The following users liked this post:

ronbros (11-21-2014)

#50

Yes, agreed.

How about this as a theory- during an engine overheat event the seats do indeed lose their tight fit but due to the short time the valves are actually open while the engine is at high revs, the seats never have the opportunity to fall out completely and jamb up the works. The closing valve pushes them back into place and the owner is none the wiser.

However, after shutdown, the heat soak again provide the opportunity for a loose fit on the seat and any valve that happens to be open presents the possibility of one falling out?

How about this as a theory- during an engine overheat event the seats do indeed lose their tight fit but due to the short time the valves are actually open while the engine is at high revs, the seats never have the opportunity to fall out completely and jamb up the works. The closing valve pushes them back into place and the owner is none the wiser.

However, after shutdown, the heat soak again provide the opportunity for a loose fit on the seat and any valve that happens to be open presents the possibility of one falling out?

In my case I think the engine was overheating as it was being driven (even though the gauge was not indicating a problem). The operation of the valves prevented any loose seats from slipping too far. Once the engine was shut down any valve that remained in the open position allowed the loose seats to drop out.

I will be tearing this motor apart soon to see how extensive the damage is and see if I can rebuild it. I will post pictures once I get the heads off.

Mark

Last edited by Safari; 11-21-2014 at 08:53 AM.

#51

Join Date: Oct 2009

Location: Perth Ontario Canada

Posts: 11,058

Received 2,255 Likes

on

1,840 Posts

The big lump of metal that comprises the combustion chamber does an excellent job of retaining heat. The oil does too, but is far far away in the engine sump where it has little effect.

#52

- possibly the world's foremost expert on the XJS engine in race trim says the oil can become so hot it can, when the engine is stopped, overheat the block and head's water jacket and cause heat related failures in the heads.

Greg

The following users liked this post:

ronbros (11-21-2014)

#53

All I am going to say is that I have met plenty of people that can rebuild an engine that couldn't pass a 8th grade physics class.

My argument is simply that the last heat created in the engine as it shuts down is dispersed when the engine is no longer operating such that it can utilize its cooling system as primary means to transfer heat away from the engine. This is the primary cause for "increased" post shut-down temperatures.

If the other theory is true, maybe the coolant should be surround the sump and carry heat away from it instead of the cylinder heads then?

My argument is simply that the last heat created in the engine as it shuts down is dispersed when the engine is no longer operating such that it can utilize its cooling system as primary means to transfer heat away from the engine. This is the primary cause for "increased" post shut-down temperatures.

If the other theory is true, maybe the coolant should be surround the sump and carry heat away from it instead of the cylinder heads then?

#54

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,231 Likes

on

939 Posts

if a car has been running for some time(at least an hour), the oil is splashing against the bottom of the piston crown, con rod& main bearing oil throw off, it is constantly absorbing heat from the piston(a very nessesary requirement,or the piston would melt). good modern engines now have oil squirters spraying COOL oil up into the piston.

MANY tests have been made and modern engines ALL run higher oil temps than coolant temps. some times as high as 300*F, where water temp could be 240-250*F.

as long as the water pump is moving coolant thru the engine&cooling system all is fine until you stop and shut down the engine, then the hi oil temps rise thru the sides of the aluminum blocks(plus all the internal components are very hot ,cranks,rods etc).

and coolant can/will gurgle or boil, sometimes spraying out of the coolant tank or pressure cap.

and my experience the HE head with chamber in the head, has more significant area to make more heat than the Jag V12 was ever designed for,lower part of the engine, none had adequate OIL cooling system. all are borderline for proper oil cooling.

i have made extensive tests and mods on my own V12, i use a digital readout temp gage(in car) and non-contact hand held just to be sure how close temps maybe around different places of the engine.

quick ques; what place on Jag V12 runs warmer than other places?

has anyone here ever measured there exhaust temps(dont forget its a V engine)?

on my car after a 1/2hr drive ,hot day 90+ ambient), my cylinder head temps run about 180-185*F digital taken hottest part(not exh.manis etc.). i run 180 thermostats.

now please explain why temp readings off the top of cam covers run 210-220*F?

all readings taken while idling after drive 1/2hr.

after shutdown 15 minutes, heads at 195-200F, cam covers at 225F?

there are all kinds of fixes for cooling,im not going into right now!

because some of you already know everything!

MANY tests have been made and modern engines ALL run higher oil temps than coolant temps. some times as high as 300*F, where water temp could be 240-250*F.

as long as the water pump is moving coolant thru the engine&cooling system all is fine until you stop and shut down the engine, then the hi oil temps rise thru the sides of the aluminum blocks(plus all the internal components are very hot ,cranks,rods etc).

and coolant can/will gurgle or boil, sometimes spraying out of the coolant tank or pressure cap.

and my experience the HE head with chamber in the head, has more significant area to make more heat than the Jag V12 was ever designed for,lower part of the engine, none had adequate OIL cooling system. all are borderline for proper oil cooling.

i have made extensive tests and mods on my own V12, i use a digital readout temp gage(in car) and non-contact hand held just to be sure how close temps maybe around different places of the engine.

quick ques; what place on Jag V12 runs warmer than other places?

has anyone here ever measured there exhaust temps(dont forget its a V engine)?

on my car after a 1/2hr drive ,hot day 90+ ambient), my cylinder head temps run about 180-185*F digital taken hottest part(not exh.manis etc.). i run 180 thermostats.

now please explain why temp readings off the top of cam covers run 210-220*F?

all readings taken while idling after drive 1/2hr.

after shutdown 15 minutes, heads at 195-200F, cam covers at 225F?

there are all kinds of fixes for cooling,im not going into right now!

because some of you already know everything!

The following users liked this post:

Greg in France (11-22-2014)

#55

To answer your question, the head is being cooled and the valvetrain is not.

Heads are no longer being actively cooled, essentially only losing heat from radiation and some conduction and still a bit of convection. The little of the same the valvetrain was getting is also no longer happening either, so both increase. Based on your own claims the cam cover should be dramatically colder if the heat is mainly due to oil, because the oil is no longer running over the valvetrain.

180 degree thermostats don't do anything.

Even with bad overheating pegging the H multiple times, my car has not blown the caps after shutdown.

What do you mean that the area in the head of an HE is a more significant area to produce heat than the V12 was designed for?

Heads are no longer being actively cooled, essentially only losing heat from radiation and some conduction and still a bit of convection. The little of the same the valvetrain was getting is also no longer happening either, so both increase. Based on your own claims the cam cover should be dramatically colder if the heat is mainly due to oil, because the oil is no longer running over the valvetrain.

180 degree thermostats don't do anything.

Even with bad overheating pegging the H multiple times, my car has not blown the caps after shutdown.

What do you mean that the area in the head of an HE is a more significant area to produce heat than the V12 was designed for?

#56

In the end, there was a separate scavenge pump and special tubular pathways down the sandwich plate to the sump to ensure that oil got 100% circulated and cooled and did not lay about in the engine getting hot. Even so, and with gearbox and diff cooling to help, the XJSs regularly were absolutely on the margin from the engine oil temp point of view, right through their winning seasons.

In fact, as Scott says, the only really effective way to do it would have been dry sumping the system, but this was not allowed under he rules. Personally, I was surprised they got away with the scavenge pump.

In reply to your point to Ronbros about the heads, I think he was referring to the configuration of the exhaust valve/spark plug/squish tube arrangement, which concentrates heat into one very small part of the combustion chamber.

As to oil heating the valve covers, what else is going to heat it ? If the heads are are (say) 190°F what, apart from hot oil, raises the valvecovers to 225°F. The valvecover is not being cooled by the water cooling system, but that if that system is maintaining the heads at 190°F, how else apart from the oil is the valvecover getting heated above 190°F?

Greg

Last edited by Greg in France; 11-22-2014 at 02:40 AM.

The following users liked this post:

ronbros (11-22-2014)

#57

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,231 Likes

on

939 Posts

OK ,now for some trivia, the combustion chamber in the head HE,(not the piston),

Jag called it the HI-effeciency chamber or HE as we say,developed BY Michael May, a Swiss engineer.

May called it the Fireball chamber, in respect to the USA engineer David Buick,yup owner designer for early Buick cars(a division of GM).( he had a patent on the chamber, so much for patent infringement). or buick said go ahead an use it, i'm to old to care.

Buick invented the Buick engines and he called them Fireball engines(i owned two of them). they had a combustion chamber that had the very same design as the HE. just 30yrs earlier!

that my friends is why Jag dont refer to them as Fireball BUT do say HI-effciency engines,(i donno its some kind of English mentality).

OH yes, maybe that David Buick was Scotch not english?

Jag called it the HI-effeciency chamber or HE as we say,developed BY Michael May, a Swiss engineer.

May called it the Fireball chamber, in respect to the USA engineer David Buick,yup owner designer for early Buick cars(a division of GM).( he had a patent on the chamber, so much for patent infringement). or buick said go ahead an use it, i'm to old to care.

Buick invented the Buick engines and he called them Fireball engines(i owned two of them). they had a combustion chamber that had the very same design as the HE. just 30yrs earlier!

that my friends is why Jag dont refer to them as Fireball BUT do say HI-effciency engines,(i donno its some kind of English mentality).

OH yes, maybe that David Buick was Scotch not english?

#58

It don't think any sort of english mentality matters, marketing is what matters. Changing the heads and calling it the XJS FIREBALL isn't going to do diddly for sales. However, during a fuel crisis, changing the name to high efficiency will have an impact.

The straight 8 fireball was named because of its piston top, not its combustion chamber. The v12 and straight 8 couldn't be more different in chamber design. The may design and use of the name fireball is just him being uncreative. I mean "fireball," really? It is used because it is a type of stratified charged and the turbulence "makes a fireball" just like the pistons on the buick made a "fireball." The fireball name was something used by May, not jaguar, but Jaguar picked him up and applied it to the V12.

If may really did need to ask permission for the use of the name, its because buick snagged the patent/copyright for it when they changed the piston, so of course he had to ask. It wasn't because of similar design, just the name.

Also, you are correct, David Buick was scottish

The straight 8 fireball was named because of its piston top, not its combustion chamber. The v12 and straight 8 couldn't be more different in chamber design. The may design and use of the name fireball is just him being uncreative. I mean "fireball," really? It is used because it is a type of stratified charged and the turbulence "makes a fireball" just like the pistons on the buick made a "fireball." The fireball name was something used by May, not jaguar, but Jaguar picked him up and applied it to the V12.

If may really did need to ask permission for the use of the name, its because buick snagged the patent/copyright for it when they changed the piston, so of course he had to ask. It wasn't because of similar design, just the name.

Also, you are correct, David Buick was scottish

Last edited by sidescrollin; 11-22-2014 at 08:30 PM.

#59

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,231 Likes

on

939 Posts

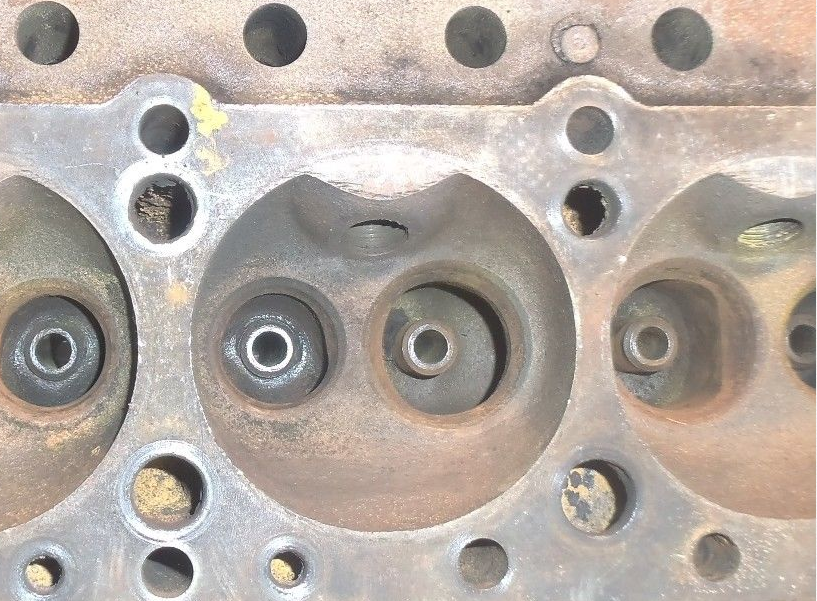

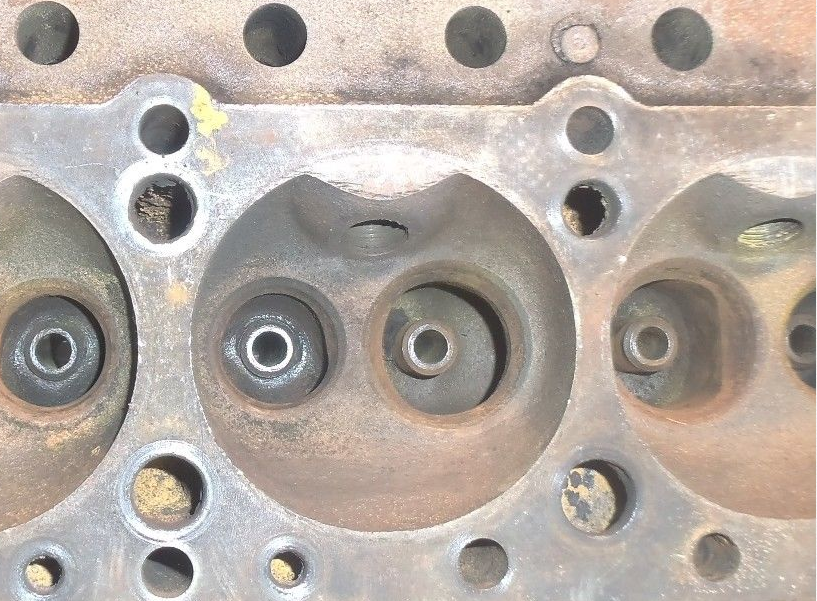

i have no idea where you got pic of that chamber, but this is the pic of chamber i have for the buick fireball engine!

notice the deep recess of exhaust valve(spark plug beside it), and the tight squish of piston to head at inlet valve,plus small channel to swirl air flow!

not an EXACT copy, but the same principals of combustion, done for the same reasons, it was patented.

mpg and detonation control, using low octane fuels!

and GM bought Buick for the rights to use his patent!

just like why FORD bought Jaguar, to use jag R&D plus patents for Ford future cars. then sold it off when they were done with jag. smart business move(its always about the money).

also i have owned and rebuilt many of those cylinder heads,

was an engine machinist for at least 50yrs!

notice the deep recess of exhaust valve(spark plug beside it), and the tight squish of piston to head at inlet valve,plus small channel to swirl air flow!

not an EXACT copy, but the same principals of combustion, done for the same reasons, it was patented.

mpg and detonation control, using low octane fuels!

and GM bought Buick for the rights to use his patent!

just like why FORD bought Jaguar, to use jag R&D plus patents for Ford future cars. then sold it off when they were done with jag. smart business move(its always about the money).

also i have owned and rebuilt many of those cylinder heads,

was an engine machinist for at least 50yrs!

The following users liked this post:

Greg in France (11-23-2014)

#60

Just for the record, Ford lost a FORTUNE on both buying Jaguar and on running it subsequently. Minimum 3 billion USD, from start to finish including all annual losses, write-downs, purchase costs and sale revenues. Ford bought Jaguar because it felt it needed upmarket brands to develop its penetration of European and other global non-USA upmarket car sales.

The R&D Jaguar had at the time of the Ford purchase was just about non-existent, the Browns Lane plant was considered by the Ford professionals to be so outdated as to be as bad or worse than anything they had seen including behind the iron curtain.

IMO the reason Jaguars are much more reliable and much better built now than before the Ford era is because of the disciplines, reliable in-car systems, production and development expertise, that Ford brought to the company's operations. It is, in my view, entirely possible that this effect may gradually wear off under the present ownership. We shall see, but right now, both Jaguar and Land Rover are benefitting hugely from the spadework that Ford did. Good old US knowhow, which I am sure you realise!

Greg