Making a new Injector Harness for the H.E

The following 2 users liked this post by JigJag:

orangeblossom (11-03-2016),

paulyling (11-03-2016)

#22

The following users liked this post:

orangeblossom (11-03-2016)

#23

The following 3 users liked this post by warrjon:

#24

I = V/R

13 Volts / 2.5 Ohms = 5.2 Amps

14 Gauge is 1.6mm. May be snug but you can always open the clip up a bit before crimping. Originals are probably closer to 16Ga. 1.2mm.

The following 2 users liked this post by JigJag:

orangeblossom (11-03-2016),

paulyling (11-03-2016)

#25

Use GXL wire, this is what all the car makers use these days for engine bay wiring as the insulation is higher temperature rated.

Wire size, in this case bigger is better. I'd use 3mm which is rated at 15amps. US AWG 16, 26 x 0.3.

.

Wire size, in this case bigger is better. I'd use 3mm which is rated at 15amps. US AWG 16, 26 x 0.3.

.

Jaguar EFI Injector Harness Rebuilding

I am just concerned 16 AWG might be a bit too chunky to fit in the connector.

The following users liked this post:

orangeblossom (11-03-2016)

#26

That's because 16awg is too big. For such a short run of cable I would use 18awg which is 3mm˛ or just over 1mm in diameter. GXL wire has thinner insulation than PVC used by Jaguar so the wire will look smaller.

The following 3 users liked this post by warrjon:

#27

I am an electrician by trade but in Oz we usually talk in metric sizes (eg 1.5mm, 2.5mm, 4mm cable etc). The AWG is throwing me a bit as we don't get a direct conversion.

As far as I can see 16AWG is just shy of our 1.5mm cable we use for 10Amp lighting circuits with a voltage here in Oz of 240V.

The diameter for 16AWG is supposed to be 1.29mm. So if we want to find the cross sectional area (to get mm2) we'd have to go half that for the radius so 0.645mm. Plug er in and you get:

A=πr2=π·0.652≈1.30698 so that would make it just shy of 1.5mm cable yes?

If we did the same for 18AWG she'd be just be just bigger than our oz 0.75mm cable @ 0.81mm. That should be good for 5.6Amps or more so would also be adequate if those injectors are only drawing just below 5Amps however if we were using standard cable and placing it back in the "Vee" we would have to consider what effect heat would have on the current rating.

Using GXL wire and taking it up out of the V and I think 18 AWG would be fine.

Still I might err on the side of caution and go the 16AWG as I only want to do this once!

The chart I used is here:

Wire Gauges - Current Ratings

Last edited by paulyling; 11-04-2016 at 12:40 PM.

The following users liked this post:

orangeblossom (11-04-2016)

#28

As you know with power cable bigger is better. I would use the largest cable that fits in the connector and is able to be crimped. If you go too big then you run the risk of not crimping the conductor properly. It might not fit in the connector housing or some strands might not get crimped.

The following 2 users liked this post by warrjon:

orangeblossom (11-04-2016),

paulyling (11-04-2016)

#29

The following 4 users liked this post by warrjon:

Greg in France (11-06-2016),

orangeblossom (11-04-2016),

PaulRoper (11-05-2016),

paulyling (11-05-2016)

#30

The following 2 users liked this post by PaulRoper:

orangeblossom (11-22-2016),

paulyling (11-06-2016)

#31

Ok back from sea  and time to hit the ground running before I have to go back again!

and time to hit the ground running before I have to go back again!

So first things first, I was happy to say all my parts arrived whilst I was away for the injector harness. Still waiting for my 16CU due soon but that is in another thread.

So my first question is, these little white plastic beads came with the Bosch Injector plugs. I had a few ideas what they might before but does anybody know for sure? There seems to be enough for each wire so I am assuming they go around each conductor maybe as like a strain relief to stop it pulling out? Any clues?

The whole kit, enough for 15 injectors (I bought spares)

The little white beads:

So first things first, I was happy to say all my parts arrived whilst I was away for the injector harness. Still waiting for my 16CU due soon but that is in another thread.

So my first question is, these little white plastic beads came with the Bosch Injector plugs. I had a few ideas what they might before but does anybody know for sure? There seems to be enough for each wire so I am assuming they go around each conductor maybe as like a strain relief to stop it pulling out? Any clues?

The whole kit, enough for 15 injectors (I bought spares)

The little white beads:

The following users liked this post:

orangeblossom (11-22-2016)

#32

The following users liked this post:

paulyling (11-22-2016)

The following users liked this post:

paulyling (11-22-2016)

#34

Hi Bro

Welcome home but check this out, now that's what I would call a Wiring Harness!

https://www.jaguarforums.com/forum/x...rl-out-172408/

Welcome home but check this out, now that's what I would call a Wiring Harness!

https://www.jaguarforums.com/forum/x...rl-out-172408/

The following users liked this post:

paulyling (11-22-2016)

#35

Cheers for the feedback guys.

Well...i made a start.

The first one was a bit scary as I didn't want to break the female end attached to the needle valve itself...I don't have spare ones of those!

First thing was trying to figure out how it comes off....it looks simple. Pull out the little retaining clip and pull...but why is it so bloody hard to come off still dammit ? Ok....will have to use a little force....pop! She came off no worries. The P.O has used RTV to keep it in place for extra support. Not a bad idea actually and will probably do the same on the new one if they feel loose when I put them back on

? Ok....will have to use a little force....pop! She came off no worries. The P.O has used RTV to keep it in place for extra support. Not a bad idea actually and will probably do the same on the new one if they feel loose when I put them back on

First one off hurray!

Most were easy to pop off however the last two for some reason were a P.I.A. I had to lever my screwdriver on the fuel rail a little bit to try and wedge them up....scared the crap out of me as a little bit of fuel dribbled out and I though I might of busted something . Obviously I still had a bit of fuel pressured up in the line from before I turned her off. I think I just opened the seal up a bit. I stopped immediately and checked and all looks good. Whew.....although I did notice on one of them that the rubber tubing doesn't cover very much of the top of the valve...should I be concerned?

. Obviously I still had a bit of fuel pressured up in the line from before I turned her off. I think I just opened the seal up a bit. I stopped immediately and checked and all looks good. Whew.....although I did notice on one of them that the rubber tubing doesn't cover very much of the top of the valve...should I be concerned?

I found it helpful to label them as I go, just to help things along when I put it up for my template:

Lasty, something strange I came across. The braces that hold the cable harness in place....two of those bolts, when you take them off seem to go straight down into the engine. I can smell oil when I open them and could see it on one of the bolts. What are these bolts for normally?

Well got them all off, pulled the plug on the other end and found I have another plug (those remaining wires that go to the ECU)

It felt good to get it finally out....but I felt like I have ripped out her spine and feeling a little brutal....I hope she'll forgive me!

Well...i made a start.

The first one was a bit scary as I didn't want to break the female end attached to the needle valve itself...I don't have spare ones of those!

First thing was trying to figure out how it comes off....it looks simple. Pull out the little retaining clip and pull...but why is it so bloody hard to come off still dammit

First one off hurray!

Most were easy to pop off however the last two for some reason were a P.I.A. I had to lever my screwdriver on the fuel rail a little bit to try and wedge them up....scared the crap out of me as a little bit of fuel dribbled out and I though I might of busted something

I found it helpful to label them as I go, just to help things along when I put it up for my template:

Lasty, something strange I came across. The braces that hold the cable harness in place....two of those bolts, when you take them off seem to go straight down into the engine. I can smell oil when I open them and could see it on one of the bolts. What are these bolts for normally?

Well got them all off, pulled the plug on the other end and found I have another plug (those remaining wires that go to the ECU)

It felt good to get it finally out....but I felt like I have ripped out her spine and feeling a little brutal....I hope she'll forgive me!

Last edited by paulyling; 11-23-2016 at 12:04 AM.

The following users liked this post:

orangeblossom (11-23-2016)

#36

The following users liked this post:

paulyling (11-23-2016)

#37

The following users liked this post:

paulyling (11-23-2016)

#38

EDIT:On second look, those appear to be two-layered straps and the inner strap is likely smooth.

It may be a good time to pull the whole rail and update the hoses and replace the ferules.

Lasty, something strange I came across. The braces that hold the cable harness in place....two of those bolts, when you take them off seem to go straight down into the engine. I can smell oil when I open them and could see it on one of the bolts. What are these bolts for normally?

Last edited by JigJag; 11-23-2016 at 09:08 AM.

The following 2 users liked this post by JigJag:

orangeblossom (11-23-2016),

paulyling (11-23-2016)

#39

Thanks for the heads up Jig Jag.

Fortunately my hoses on my fuel rail should be ok as they were touched by the Great Wizard's magic

As quoted from Grant from my spark plug post:

Fortunately my hoses on my fuel rail should be ok as they were touched by the Great Wizard's magic

As quoted from Grant from my spark plug post:

So true.

However, when I did the hoses on the Goose, long before Paul got it, the PO had made a savage mess of the barbs removing what must have been bakelite hard hoses. The hoses he fitted were sad in the way you mentioned.

Soooo, the barbs on the injectors and the rail were "wet and dry papered" smooth (less sharp). Hence the clamps being required, and only gently firmed up, but they cannot cut the hose lining.

My HE was similar, and it has clamps also, although many years before the Goose appeared.

I would not fit clamps to the OE sharp barb arrangement, that would be an engine fire just waiting.

However, when I did the hoses on the Goose, long before Paul got it, the PO had made a savage mess of the barbs removing what must have been bakelite hard hoses. The hoses he fitted were sad in the way you mentioned.

Soooo, the barbs on the injectors and the rail were "wet and dry papered" smooth (less sharp). Hence the clamps being required, and only gently firmed up, but they cannot cut the hose lining.

My HE was similar, and it has clamps also, although many years before the Goose appeared.

I would not fit clamps to the OE sharp barb arrangement, that would be an engine fire just waiting.

Last edited by paulyling; 11-23-2016 at 01:35 PM.

The following users liked this post:

orangeblossom (11-23-2016)

#40

Day 2 on the harness:

Couldn't even move in my shed as it was full of kids bicycles, rubbish, Daddy Long Legs and who knows what else.....how does it get this messy after only a month offshore?

Once I could move in there I started by taking off all the old brittle tape bonding the wires together. Crikey it just all turned into crumble!

Next up I i had to untangle everything so I could make logical sense of what goes where:

Didn't have any hooks but I had a crap load of Koala nails sitting around so used them instead (Because I don't use them for much else...my wood skills suck!) One either side of the Bosch plug to keep it in place:

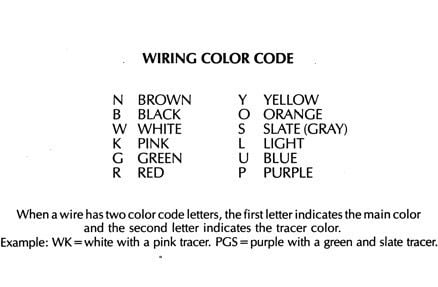

Finally I made some copies of the schematic for reference as well as the old colour code chart.

Next step. Start running in the new wire on top of the old.

To be continued....

Couldn't even move in my shed as it was full of kids bicycles, rubbish, Daddy Long Legs and who knows what else.....how does it get this messy after only a month offshore?

Once I could move in there I started by taking off all the old brittle tape bonding the wires together. Crikey it just all turned into crumble!

Next up I i had to untangle everything so I could make logical sense of what goes where:

Didn't have any hooks but I had a crap load of Koala nails sitting around so used them instead (Because I don't use them for much else...my wood skills suck!) One either side of the Bosch plug to keep it in place:

Finally I made some copies of the schematic for reference as well as the old colour code chart.

Next step. Start running in the new wire on top of the old.

To be continued....

Last edited by paulyling; 11-24-2016 at 01:58 AM.

The following users liked this post:

Greg in France (11-24-2016)