Dead boot lid button

#1

After stripping off the plinth and getting access to the button I discovered that it was actually working, so I set about the wiring harness that links the boot lid to the car. After a bit more testing with the multimeter I was able to isolate the broken wire in the harness.

The boot lid harness has a connector at the bottom right of the lid as you look at it from behind the car with the boot open. You need to strip back the lining to get access, the connector is actually tucked into the hole that the cable goes into but it can easily be pulled out and disconnected.

To get to the other end I pulled the boot liner on the back surface forwards and the side surface downwards, you then need to disconnect this connector, the part of the connector attached to the wiring that needs to come out needed to be pulled out with pliers as it has a slide on attachment to the car.

The grommets can then be pulled out and the harness extracted, the holes are bug enough for the connectors to go through.

I had planned to use the old wire to pull through the new one but it had completely snapped. I stripped back the insulating tape from either end of the flexible conduit and was able to push a new cable all the way through with out any real problem.

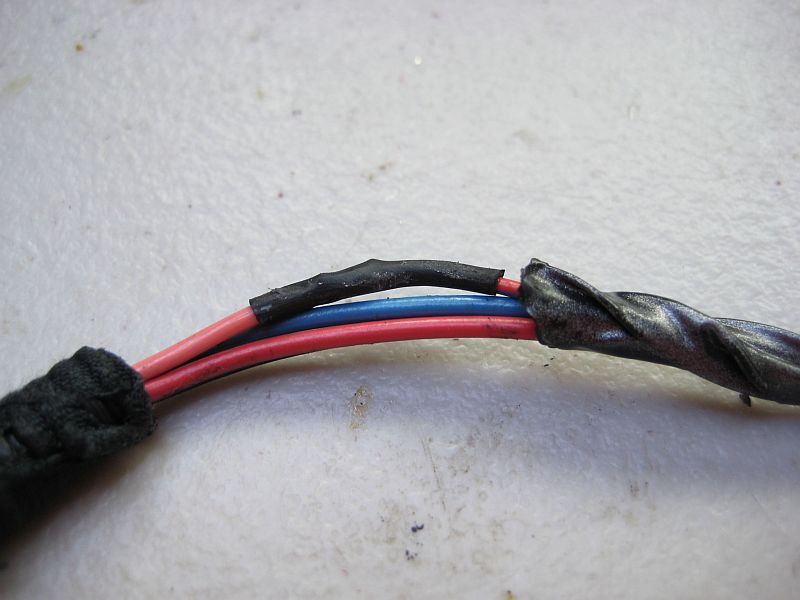

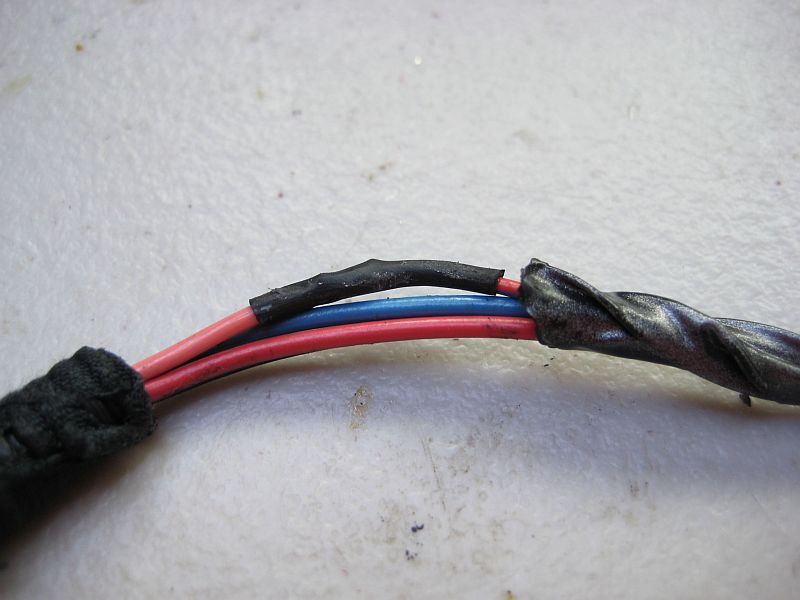

Both ends were them soldered together and covered in heat shrink and then taped back up with insulating tape.

The cable was then put back in the car, I used a bit of 3in1 oil on the grommets to get them back in place and the boot/lid lining replaced, job done!

The boot lid harness has a connector at the bottom right of the lid as you look at it from behind the car with the boot open. You need to strip back the lining to get access, the connector is actually tucked into the hole that the cable goes into but it can easily be pulled out and disconnected.

To get to the other end I pulled the boot liner on the back surface forwards and the side surface downwards, you then need to disconnect this connector, the part of the connector attached to the wiring that needs to come out needed to be pulled out with pliers as it has a slide on attachment to the car.

The grommets can then be pulled out and the harness extracted, the holes are bug enough for the connectors to go through.

I had planned to use the old wire to pull through the new one but it had completely snapped. I stripped back the insulating tape from either end of the flexible conduit and was able to push a new cable all the way through with out any real problem.

Both ends were them soldered together and covered in heat shrink and then taped back up with insulating tape.

The cable was then put back in the car, I used a bit of 3in1 oil on the grommets to get them back in place and the boot/lid lining replaced, job done!

Last edited by GGG; 03-25-2019 at 02:54 PM.

The following users liked this post:

Orthodixie (09-30-2017)

#4

Thanks to Race Diagnostics for the repair tip for my inop trunk lid button. The trunk lead link wire harness that was mentioned had two broken wires in it. Not only was the lid button inop but the license plate lights were inop as well. Before I spent $180.00 for a new trunk lead link harness I followed the instructions for removal, soldered the two wires together, reinstalled and everything worked great. Thanks for the help!

#7

Great job RaceDiagnostics.

I have the same issue and was starting through the investigation when it occurred to me that that I might not be alone. With all the Machiavellian explanations that were floating through my mind I'm almost glad it it only a broken wire.

It reminds me of the old expression "electrics by Lucas the prince of darkness" - oh how little the world has changed.

I have the same issue and was starting through the investigation when it occurred to me that that I might not be alone. With all the Machiavellian explanations that were floating through my mind I'm almost glad it it only a broken wire.

It reminds me of the old expression "electrics by Lucas the prince of darkness" - oh how little the world has changed.

Trending Topics

#8

Great job RaceDiagnostics.

I have the same issue and was starting through the investigation when it occurred to me that that I might not be alone. With all the Machiavellian explanations that were floating through my mind I'm almost glad it it only a broken wire.

It reminds me of the old expression "electrics by Lucas the prince of darkness" - oh how little the world has changed.

I have the same issue and was starting through the investigation when it occurred to me that that I might not be alone. With all the Machiavellian explanations that were floating through my mind I'm almost glad it it only a broken wire.

It reminds me of the old expression "electrics by Lucas the prince of darkness" - oh how little the world has changed.

I believe the cause, for me at least, was shoddy workmanship rather than a sharp edge. The wire that was broken had clearly been put into the loom with a kink in it. Over time this seems to have been pulled tight and eventually caused the break. The other 3 wires were straight as a die but the broken one had a very tight bend at the break.

I hope that bodes well for others in suggesting that the systemic issue (unprotected sharp edges) has been resolved even if the quality control is still a little below par.

$0.02

#12

Experience with old outboard motor wiring helps me to find bad wires inside unbroken wire insulation inside wiring looms. Working on a friends Black Max with intermittent engine miss-firing, I began pulling on the individual wires going to the ignition coils looking for any that would stretch or snap easily. Have any of you ever tried to pull a wire in 2 before? It's not that easy if you can do it. He almost lost his mind when he saw that. This is one difference between a parts changer and a mechanic. I had to tell him that if they stretched at all, the wire was broken inside the insulation and needed replacing. Ocean air permeates the insulation and corrodes the copper. You sometimes see the wire where it was arcing inside and burns thru. A liberal dose of "liquid electric tape" helps seal out this moisture as a preventative measure. The breaks occur where you would expect them too. Usually not far from a terminal connector.

On our Jags, there is just no excuse for all these boot wires to part in 2 in the middle of a harness on so many different cars. If this is a wire handling problem from the factory, why don't we see this happening all thru out the rest of the cars electrical systems and not on different models and not on any doors where there are many bending moments?

My first thought was the break was going to be at the hinge since this is where the bending moment is and not up a long ways from this hinge. My theory is that slamming the boot causes the wire to contact a hidden sharp edge and over time it parts sharply and cleanly.

I know on the XK's the trunk doesn't lift all the way automatically when released as it does on most other cars. When you close it, it doesn't have the spring counterbalance as a resistance. When some not initiated close it, they usually slam it pretty hard, because it doesn't take the same effort that say our S Type takes. I have scolded my wife on more than one occasion for this. Her excuse is always the same, "Well, I have to close mine like that". My usual procedure is the same as the bonnet on the X. Bring it to the half way position and let it fall closed in a consistent satisfying manner. No need to hammer it shut at 32 feet per second.

On our Jags, there is just no excuse for all these boot wires to part in 2 in the middle of a harness on so many different cars. If this is a wire handling problem from the factory, why don't we see this happening all thru out the rest of the cars electrical systems and not on different models and not on any doors where there are many bending moments?

My first thought was the break was going to be at the hinge since this is where the bending moment is and not up a long ways from this hinge. My theory is that slamming the boot causes the wire to contact a hidden sharp edge and over time it parts sharply and cleanly.

I know on the XK's the trunk doesn't lift all the way automatically when released as it does on most other cars. When you close it, it doesn't have the spring counterbalance as a resistance. When some not initiated close it, they usually slam it pretty hard, because it doesn't take the same effort that say our S Type takes. I have scolded my wife on more than one occasion for this. Her excuse is always the same, "Well, I have to close mine like that". My usual procedure is the same as the bonnet on the X. Bring it to the half way position and let it fall closed in a consistent satisfying manner. No need to hammer it shut at 32 feet per second.

#13

Where did you live ? does it get really cold during winter ? cause this is the main reason why the wires in my xf have part in two ! I leave in the north of quebec, close to the baie-james XD and it goes minus 50 during winter and +45 degrees during summer ! I guess jaguar haven't design the car for every kind of weather ! which is a major problem they will have to find a solution to that !

Anyway to make sure this kind of things wouldn't happen again, I took all wires I could possibly find and could cause the same problem and tape it all together and put some isolated rubber over it.

For those in the engine I replace all the plastic tube (like the vacuum line) and replace it with the tube they use for brake line on transport truck so I haven't experience no leak of air since then and my car work better XD

But the problem you mention here I never seen anythings like that till now ! your friends should really get to the dealers and demands some explanations or even change the car for another one ! or if he is ready to put the money in the car change all the bad wires, repairs those who can be, check to get some off ebay or from jaguar parts.com and gets some from his jaguar dealer, but it will be over priced as always.

If you find the solution get back to us !

Anyway to make sure this kind of things wouldn't happen again, I took all wires I could possibly find and could cause the same problem and tape it all together and put some isolated rubber over it.

For those in the engine I replace all the plastic tube (like the vacuum line) and replace it with the tube they use for brake line on transport truck so I haven't experience no leak of air since then and my car work better XD

But the problem you mention here I never seen anythings like that till now ! your friends should really get to the dealers and demands some explanations or even change the car for another one ! or if he is ready to put the money in the car change all the bad wires, repairs those who can be, check to get some off ebay or from jaguar parts.com and gets some from his jaguar dealer, but it will be over priced as always.

If you find the solution get back to us !

#14

Hi jaguarxfv8

I live in Southern California and my 2006 XKR has done so for its entire life. I, too, fixed this problem with the help of this forum. I don't believe it can be related to fold as it just doesn't get cold here. It does get a trifle warm but nowhere hot enough to make a difference. And anyway heat would help by annealing the metal. Also when I inspected the bundle under a magnifying glass there was no sign if abrasion on the insulation. I had to conclude that this was work hardening of the wires (ie due to constant flexing of the loom).

The only good news is that it's pretty easy to fix thanks to all here :-)

$0.02

Nick

I live in Southern California and my 2006 XKR has done so for its entire life. I, too, fixed this problem with the help of this forum. I don't believe it can be related to fold as it just doesn't get cold here. It does get a trifle warm but nowhere hot enough to make a difference. And anyway heat would help by annealing the metal. Also when I inspected the bundle under a magnifying glass there was no sign if abrasion on the insulation. I had to conclude that this was work hardening of the wires (ie due to constant flexing of the loom).

The only good news is that it's pretty easy to fix thanks to all here :-)

$0.02

Nick

Experience with old outboard motor wiring helps me to find bad wires inside unbroken wire insulation inside wiring looms. Working on a friends Black Max with intermittent engine miss-firing, I began pulling on the individual wires going to the ignition coils looking for any that would stretch or snap easily. Have any of you ever tried to pull a wire in 2 before? It's not that easy if you can do it. He almost lost his mind when he saw that. This is one difference between a parts changer and a mechanic. I had to tell him that if they stretched at all, the wire was broken inside the insulation and needed replacing. Ocean air permeates the insulation and corrodes the copper. You sometimes see the wire where it was arcing inside and burns thru. A liberal dose of "liquid electric tape" helps seal out this moisture as a preventative measure. The breaks occur where you would expect them too. Usually not far from a terminal connector.

On our Jags, there is just no excuse for all these boot wires to part in 2 in the middle of a harness on so many different cars. If this is a wire handling problem from the factory, why don't we see this happening all thru out the rest of the cars electrical systems and not on different models and not on any doors where there are many bending moments?

My first thought was the break was going to be at the hinge since this is where the bending moment is and not up a long ways from this hinge. My theory is that slamming the boot causes the wire to contact a hidden sharp edge and over time it parts sharply and cleanly.

I know on the XK's the trunk doesn't lift all the way automatically when released as it does on most other cars. When you close it, it doesn't have the spring counterbalance as a resistance. When some not initiated close it, they usually slam it pretty hard, because it doesn't take the same effort that say our S Type takes. I have scolded my wife on more than one occasion for this. Her excuse is always the same, "Well, I have to close mine like that". My usual procedure is the same as the bonnet on the X. Bring it to the half way position and let it fall closed in a consistent satisfying manner. No need to hammer it shut at 32 feet per second.

On our Jags, there is just no excuse for all these boot wires to part in 2 in the middle of a harness on so many different cars. If this is a wire handling problem from the factory, why don't we see this happening all thru out the rest of the cars electrical systems and not on different models and not on any doors where there are many bending moments?

My first thought was the break was going to be at the hinge since this is where the bending moment is and not up a long ways from this hinge. My theory is that slamming the boot causes the wire to contact a hidden sharp edge and over time it parts sharply and cleanly.

I know on the XK's the trunk doesn't lift all the way automatically when released as it does on most other cars. When you close it, it doesn't have the spring counterbalance as a resistance. When some not initiated close it, they usually slam it pretty hard, because it doesn't take the same effort that say our S Type takes. I have scolded my wife on more than one occasion for this. Her excuse is always the same, "Well, I have to close mine like that". My usual procedure is the same as the bonnet on the X. Bring it to the half way position and let it fall closed in a consistent satisfying manner. No need to hammer it shut at 32 feet per second.

#15

Hi jaguarxfv8

I live in Southern California and my 2006 XKR has done so for its entire life. I, too, fixed this problem with the help of this forum. I don't believe it can be related to fold as it just doesn't get cold here. It does get a trifle warm but nowhere hot enough to make a difference. And anyway heat would help by annealing the metal. Also when I inspected the bundle under a magnifying glass there was no sign if abrasion on the insulation. I had to conclude that this was work hardening of the wires (ie due to constant flexing of the loom).

The only good news is that it's pretty easy to fix thanks to all here :-)

$0.02

Nick

I live in Southern California and my 2006 XKR has done so for its entire life. I, too, fixed this problem with the help of this forum. I don't believe it can be related to fold as it just doesn't get cold here. It does get a trifle warm but nowhere hot enough to make a difference. And anyway heat would help by annealing the metal. Also when I inspected the bundle under a magnifying glass there was no sign if abrasion on the insulation. I had to conclude that this was work hardening of the wires (ie due to constant flexing of the loom).

The only good news is that it's pretty easy to fix thanks to all here :-)

$0.02

Nick

#17

#18

#19

Last edited by WhiteXKR; 05-27-2015 at 07:27 PM.

#20

Trunk lid button stopped working so I bought a new switch and replaced it. No help. After reading this thread I was able to find and fix the broken wire. It broke just above the clip on the trunk hinge but I didn't know that until I had the harness on my kitchen table. I could have avoided some disassembly for access. Not too bad though.

I believe that the flexing of the harness each time the trunk is open is the culprit, not so much how hard I close the trunk. The harness has to bend pretty sharp just above the clip so it's probably just the design more than how hard you close the trunk, not that it really matters in the end. When the wire breaks it needs to be fixed. I'm just glad that I read this thread.

After years of chasing wiring problems on commercial aircraft, I always look for areas where something moves to break wires like the opening and closing of the trunk.

Now I have a spare trunk lid switch. Maybe I'll put it on ebay.

I believe that the flexing of the harness each time the trunk is open is the culprit, not so much how hard I close the trunk. The harness has to bend pretty sharp just above the clip so it's probably just the design more than how hard you close the trunk, not that it really matters in the end. When the wire breaks it needs to be fixed. I'm just glad that I read this thread.

After years of chasing wiring problems on commercial aircraft, I always look for areas where something moves to break wires like the opening and closing of the trunk.

Now I have a spare trunk lid switch. Maybe I'll put it on ebay.