Wheel nuts

#1

#2

Join Date: May 2008

Location: Great Mills, MD

Posts: 14,197

Likes: 0

Received 3,823 Likes

on

3,142 Posts

Jagisbest, I know of 3 options for you. The first one I would try is to get yourself an impact socket that fits tightly on the lugnut (19mm unless the cap has come off, then it is like a 3/4" as I recall). Slide it onto what is left and see if you can back the lugnut off from there. In some cases, you can use an impact socket that is just a bit too small and then beat it on to the lug nug to force the socket over the lugnut to get a good fit. People have had to do that when the tin caps on the lugnuts start slipping and the normal socket will not allow removal of the lugnut.

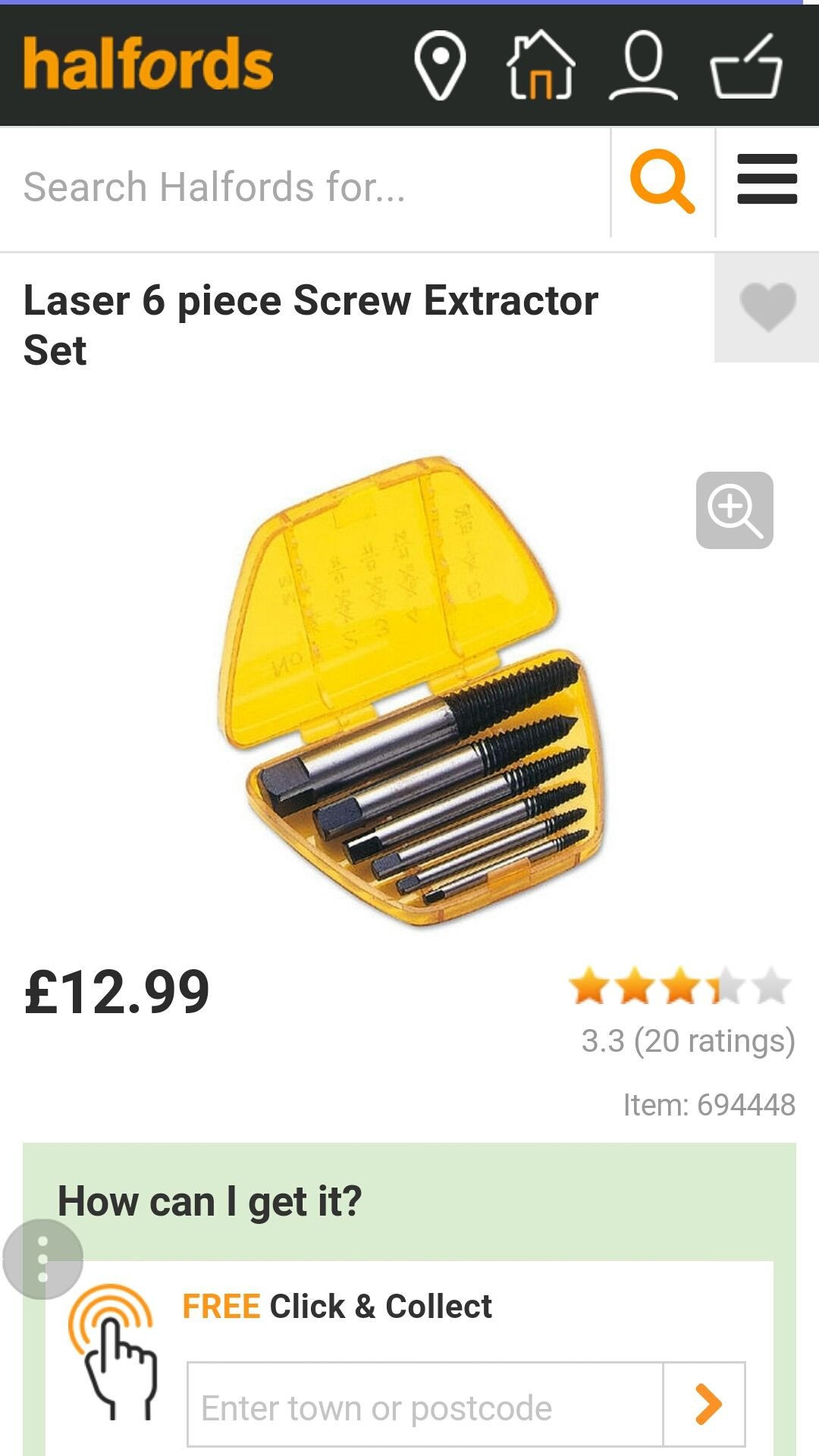

If that doesn't work, then I would say to stop by your local large tool shop and see if you can find some easy-outs that are meant for rounded nuts. Put the largest one that will fit inside the well in the wheel and then while push the wrench in, try and loosen the lugnut. The easy-out has teeth on the inside of it that will bite into the metal left on the nut and hopefully you have enough metal there that the lugnut will back itself out.

The final act is what a shop will do in that you are getting an impact hammer (normally pneumatically powered), but you will put the chisel end down along side the wheel stud and attempt to split the lug nut into a few pieces.

If that doesn't work, then I would say to stop by your local large tool shop and see if you can find some easy-outs that are meant for rounded nuts. Put the largest one that will fit inside the well in the wheel and then while push the wrench in, try and loosen the lugnut. The easy-out has teeth on the inside of it that will bite into the metal left on the nut and hopefully you have enough metal there that the lugnut will back itself out.

The final act is what a shop will do in that you are getting an impact hammer (normally pneumatically powered), but you will put the chisel end down along side the wheel stud and attempt to split the lug nut into a few pieces.

#3

My first thought was to try and hammer a socket over it but was concerned i might flatten it even more luckily both wheels have near brand new tyres on so its not desperately urgent to fix right away. I was also toying with idea of welding a bar to whats left of the nut but dont want to damage the wheel. Do u know if its possible to buy an easy out tool in the uk ?

#6

Join Date: May 2008

Location: Great Mills, MD

Posts: 14,197

Likes: 0

Received 3,823 Likes

on

3,142 Posts

#7

Trending Topics

#8

Hi has anyone had a problem with their wheel nuts snapping when trying to change a wheel. I have had 2 snap while trying to paint my brake calipers. Any one got any ideas how to remove them. They have snapped really low down so that the actual stud is showing out the top.

Walter

#9

Getting those broken lugnuts off is a bear no matter what tools you have -especially without damaging the wheel. The problem is a combination of 2 things: (1) The crappy Jaguar lugnuts, wrapped in a cheesey tin cap that strips out so easy and (2) the tire shop mechanics with their impact wrenches set on "KILL." It seems most tire shops just set their wrenches on somewhere between 100- 150 ft. lbs. of torque, and use that setting on all cars. The spec for the X-type is 76 ft. lbs. When the nuts are grossly overtightened, you're obviously going to have problems. Also, you can get one piece Lexus/ Toyota/ Scion lug nuts off ebay that work much better. They will require a 20 mm lugwrench instead of the 19 mm one in your trunk, but otherwise fit perfect. I replaced the entire set on mine. I use a torque wrench set on 76 lbs., and no problems. You will have to remind the tire shop guys though.