Stiegemeier ‘Venom’ supercharger cooler and porting..

#1

I was lucky enough to buy a new-old-stock XJR M90 Eaton supercharger 3 years ago which is on the car. I thus have a spare one, with slight rear needle bearing play but otherwise in good nick.

I have struggled to find anyone in NZ who will port my spare blower.

There is a company in USA who make a water-jacketed snout which cools the front end of the supercharger, where apparently a lot of the heat is generated by the drive gears - I had always assumed it was Boyle’s Law that explained the heat (pressurising a gas heats it up). They say with rear-entry supercharger such as the XJR M90 set-up, the cool air entering the back of the supercharger cools that end , whilst the front drive end gets very hot. Anyway, on bigger American V8 engines such as Mustangs, the water-cooled snout lowers post-supercharger inlet temps by 10-14’C and reduces heat sink significantly. It doesn’t give more power, but prevents power loss by heat sink, which is an issue for me in NZ summer where it is often 30’C or more.

I am tempted to send my Eaton off for a full rebuild and porting, plus the water cooled “Venom” snout, and add a second Bosch electric inter cooler pump into the circuit..

But I will be overcapitalising on my car, especially if I get extractors custom-made which is my intention.

The car will have to be a keeper..

I have struggled to find anyone in NZ who will port my spare blower.

There is a company in USA who make a water-jacketed snout which cools the front end of the supercharger, where apparently a lot of the heat is generated by the drive gears - I had always assumed it was Boyle’s Law that explained the heat (pressurising a gas heats it up). They say with rear-entry supercharger such as the XJR M90 set-up, the cool air entering the back of the supercharger cools that end , whilst the front drive end gets very hot. Anyway, on bigger American V8 engines such as Mustangs, the water-cooled snout lowers post-supercharger inlet temps by 10-14’C and reduces heat sink significantly. It doesn’t give more power, but prevents power loss by heat sink, which is an issue for me in NZ summer where it is often 30’C or more.

I am tempted to send my Eaton off for a full rebuild and porting, plus the water cooled “Venom” snout, and add a second Bosch electric inter cooler pump into the circuit..

But I will be overcapitalising on my car, especially if I get extractors custom-made which is my intention.

The car will have to be a keeper..

#2

Andy, this is probably a question for you, but others may know..

If I get my blower rebuilt, ‘Dyno bob’ Stiegemeier has said he can put a 2.4” pulley on it. I think the standard pulley is 2.8”

My crank pulley is already 10% larger (Powerhouse.co.uk), so if combined with a 2.4” pulley it would be driving the supercharger 28% faster than standard, and potentially that much more air flow.

I don’t know if the MAF and ECU programming would cope with that

1.1 x (2.8/2.4)= 1.28

If I get my blower rebuilt, ‘Dyno bob’ Stiegemeier has said he can put a 2.4” pulley on it. I think the standard pulley is 2.8”

My crank pulley is already 10% larger (Powerhouse.co.uk), so if combined with a 2.4” pulley it would be driving the supercharger 28% faster than standard, and potentially that much more air flow.

I don’t know if the MAF and ECU programming would cope with that

1.1 x (2.8/2.4)= 1.28

Last edited by AL NZ; 01-04-2018 at 07:43 PM.

#4

Supercharger issues are beyond my depth.

With many DIY tips available in this forum and on the web, I bought a supercharger service kit off eBay and with the help of my mechanic we just finished servicing the supercharger on Rose. Already got Andy's timing advance enabled through the ECU. Knew that replacing the upper and lower pulley will give you some 40-50 more horses, but have to manage heat dissipation carefully, possibly working better retrofitting the X300 with the expensive or difficult-to-find oil cooler kit. Am happy with Rose's present performance and do not plan on undertaking other modifications. Rather than chasing for maximum power, I always feel that a relatively low-cost, hassle-free improvement would be to replace the stock differential with a 3.54 or higher ratio so the car might pull like a rocket from standstill and across all power band.

Would love to stick with the X300; more modern (or should I say current) versions of Jaguar seem to have a very different character and adopt a philosophy quite distinct from the past.

With many DIY tips available in this forum and on the web, I bought a supercharger service kit off eBay and with the help of my mechanic we just finished servicing the supercharger on Rose. Already got Andy's timing advance enabled through the ECU. Knew that replacing the upper and lower pulley will give you some 40-50 more horses, but have to manage heat dissipation carefully, possibly working better retrofitting the X300 with the expensive or difficult-to-find oil cooler kit. Am happy with Rose's present performance and do not plan on undertaking other modifications. Rather than chasing for maximum power, I always feel that a relatively low-cost, hassle-free improvement would be to replace the stock differential with a 3.54 or higher ratio so the car might pull like a rocket from standstill and across all power band.

Would love to stick with the X300; more modern (or should I say current) versions of Jaguar seem to have a very different character and adopt a philosophy quite distinct from the past.

#5

Well I too can't directly or definitively answer the question posed to Andy .... so that begs the question of why am I bothering

But as I recall Andy has said that any combination of intake/exhaust modifications that exceed a 10% increase in air volume will require his reprogramming the ECU.

And per your quip about just buying a new Jag with 500hp "out of the box".... that's something to consider; how much investment becomes diminishing returns for the X300 XJR? After all, there are so many less expensive alternatives out there that make [much] more power than the AJ16 ever will. So it really comes down to what is possible and economical if you want to keep the X300 for style or other personal reasons.

For me I've come to a peaceful place knowing the X300 XJR will never be a match for even the new Kia's (seriously, check them out, 4.6s 0-60 as I recall), so it then just becomes a goal to have some fun modding the car to a point to get it "better" within reason. At some point "within reason" will be reached for the average owner pretty quickly, especially as the cars continue to age and their value really drops.

Regarding heat soak, I'm going to add the Bosch circulator which I have already in a box, and try to find an X308 intercooler radiator as well as utilize the oil cooler as a secondary. But at some point of investment to control heat soak, I personally think money is better spent strategically on the "Killer Chiller" solution which is about $1000 as a bolt-on kit.

By the time one chases multiple circulators, different intercooler radiators, and a customized water cooled SC snout, etc... plus all the time and expense waiting, shipping and installing these various pieces, you could probably have saved time and money putting in the much more simple "Killer Chiller".

Killer Chiller doesn't have a kit specifically for the X300 XJR, however I have spoken with them and they are familiar with the car and it's multi-manufacturer lineage and think it would be no problem to adapt their "universal" kit and would be excited to help as then they can cite a kit that works.

Might be something to consider:

https://killerchiller.com/

.

But as I recall Andy has said that any combination of intake/exhaust modifications that exceed a 10% increase in air volume will require his reprogramming the ECU.

And per your quip about just buying a new Jag with 500hp "out of the box".... that's something to consider; how much investment becomes diminishing returns for the X300 XJR? After all, there are so many less expensive alternatives out there that make [much] more power than the AJ16 ever will. So it really comes down to what is possible and economical if you want to keep the X300 for style or other personal reasons.

For me I've come to a peaceful place knowing the X300 XJR will never be a match for even the new Kia's (seriously, check them out, 4.6s 0-60 as I recall), so it then just becomes a goal to have some fun modding the car to a point to get it "better" within reason. At some point "within reason" will be reached for the average owner pretty quickly, especially as the cars continue to age and their value really drops.

Regarding heat soak, I'm going to add the Bosch circulator which I have already in a box, and try to find an X308 intercooler radiator as well as utilize the oil cooler as a secondary. But at some point of investment to control heat soak, I personally think money is better spent strategically on the "Killer Chiller" solution which is about $1000 as a bolt-on kit.

By the time one chases multiple circulators, different intercooler radiators, and a customized water cooled SC snout, etc... plus all the time and expense waiting, shipping and installing these various pieces, you could probably have saved time and money putting in the much more simple "Killer Chiller".

Killer Chiller doesn't have a kit specifically for the X300 XJR, however I have spoken with them and they are familiar with the car and it's multi-manufacturer lineage and think it would be no problem to adapt their "universal" kit and would be excited to help as then they can cite a kit that works.

Might be something to consider:

https://killerchiller.com/

.

#6

Al quoted me correctly. I think if you increase airflow by much more than 10%, you risk reducing the level of enrichment beyond the leanest mixture for best torque. This is because the airflow meter is already at the limit of its range. Airflow can be increased but fuel flow will not, without reprogramming the ECU, or "tricking" it into delivering more fuel. If you want more power than is possible with one of my crank sensor brackets, a 10% bigger crank pulley, a revised air cleaner assembly and a revised exhaust system (listed in order of cost effectiveness, then you will have to consider a bigger supercharger, such as the Eaton m112, that I have fitted. This won't overcome the airflow measurement issue, but will make the cost of the solution more worthwhile.

#7

Thanks Andy and Al.

I have considered the killer chiller but worry it will be a hassle to fit.

So Andy, on a std XJR, does the MAF reach its maximum measurable flow, or is there some reserve?

I already have your reprogrammed EPROMs and the Powerhouse 110% drive pulley. I have gone back to std XJR air filter box with a paper filter. I am seriously considering a set of exhaust extractors made to your pipe specs -going to see the guy in the next week or so.

I think the Stiegemeier Venom cooler (water-cooled drive snout) for the Eaton is a great idea, and won’t give more power necessarily, but will keep things cool. However he offers it with a smaller pulley which would push more air. It could be spec’ed with std pulley, and I just stick to the Powerhouse 110% crank pulley.

I am assuming (perhaps wrongly) that a ported supercharger with cooling but not overdriven will just make the airflow more efficient, with necessarily increasing the amount of air flow significantly. This would presumably be further enhanced with extractors.

If I did all these measures and the MAF limits were exceeded, would that matter if I never used wide open throttle at high revs? I rarely go beyond 4000 rpm, so if I modified all these bolt-on parts for more midrange power, but never revved high enough to exceed the MAF measurable upper limit, would that be ‘safe’?

In the end, I like the XJR for what it is, and am not trying to turn it into something it isn’t. It is not a new 911 or Ferrari, it is a fast 20 year old saloon which is nicest driven at about 80%. It has a lovely supple but sporty ride, minimal body roll, and great for open road driving.

..edit...afterthought... would a simple aftermarket plug-in OBD Bluetooth thingie be able to tell me instantaneous MAF airflow so I could see at what point (if at all) my MAF reaches its limit?

I have considered the killer chiller but worry it will be a hassle to fit.

So Andy, on a std XJR, does the MAF reach its maximum measurable flow, or is there some reserve?

I already have your reprogrammed EPROMs and the Powerhouse 110% drive pulley. I have gone back to std XJR air filter box with a paper filter. I am seriously considering a set of exhaust extractors made to your pipe specs -going to see the guy in the next week or so.

I think the Stiegemeier Venom cooler (water-cooled drive snout) for the Eaton is a great idea, and won’t give more power necessarily, but will keep things cool. However he offers it with a smaller pulley which would push more air. It could be spec’ed with std pulley, and I just stick to the Powerhouse 110% crank pulley.

I am assuming (perhaps wrongly) that a ported supercharger with cooling but not overdriven will just make the airflow more efficient, with necessarily increasing the amount of air flow significantly. This would presumably be further enhanced with extractors.

If I did all these measures and the MAF limits were exceeded, would that matter if I never used wide open throttle at high revs? I rarely go beyond 4000 rpm, so if I modified all these bolt-on parts for more midrange power, but never revved high enough to exceed the MAF measurable upper limit, would that be ‘safe’?

In the end, I like the XJR for what it is, and am not trying to turn it into something it isn’t. It is not a new 911 or Ferrari, it is a fast 20 year old saloon which is nicest driven at about 80%. It has a lovely supple but sporty ride, minimal body roll, and great for open road driving.

..edit...afterthought... would a simple aftermarket plug-in OBD Bluetooth thingie be able to tell me instantaneous MAF airflow so I could see at what point (if at all) my MAF reaches its limit?

Last edited by AL NZ; 01-05-2018 at 04:13 PM.

Trending Topics

#8

I'd be very curious as well. I'm retrofitting the XJR engine to a Daimler DS420 limo (kerb weight 5900lbs!) so I'm after all the mid range torque I can get.

I'll have to fabricate an exhaust for it anyway, so I'd be interested in details of exhaust modifications I can do that won't compromise low end torque. I typically drive the car up long mountain grades that can be 20km of unbroken 7% that go from basically sea level up to 4500' elevation, then down and back up over the next mountain range, so I'm interested being able to make the speed limit going up those hills.

I'll have to fabricate an exhaust for it anyway, so I'd be interested in details of exhaust modifications I can do that won't compromise low end torque. I typically drive the car up long mountain grades that can be 20km of unbroken 7% that go from basically sea level up to 4500' elevation, then down and back up over the next mountain range, so I'm interested being able to make the speed limit going up those hills.

#10

Nope, not a wedding car. The last thing I want to do is deal with Bridezilla and her mother!

Mine is a late DS420, I bought it in Japan and brought it to Canada. It was the only LHD car built that year, so rather unique. I take it to car shows on the west coast ( Vancouver and Victoria) and occasional pleasure trips. I will admit to taking it to the junkyard once because it has a huge trunk. I was able to fit the gas tank of a Lincoln Town Car inside!

The original engine is a low compression XK 4.2, rated at 164hp. Not enough for a car of that weight going over the Canadian Rockies. I bought a rusty 1995 XJR and took it apart and will fit that engine and transmission. The AJ16 is very close in dimensions to the XK engine, so it looks right in the DS420 engine bay. A V8 would be nice, but the electronics get very complicated due to all the modules being networked. In comparison, the AJ16 is very simple and I can have the factory stand alone engine and transmission controllers run with only a few inputs faked easily for missing components, such as ABS and traction control. I don't think I could do that for a V8.

Right now I'm at the stage of starting to pull out the 4.2, then I have to fabricate new motor mounts.

I did consider a V12, but the engine bay of the DS420 is surprisingly narrow and I only would have had 1/2" to spare over the air filter housings. The engine would have needed to be lifted to change air filters! The 5.3 in Canadian emissions was 262HP, so not a huge improvement over a modified 4.2. Then I wanted an overdrive transmission and that would have been a lot of money. I bought the XJR for $1,000 with 130,000km on it, that was a much better deal and I get more power/torque with better fuel economy in the process.

Mine is a late DS420, I bought it in Japan and brought it to Canada. It was the only LHD car built that year, so rather unique. I take it to car shows on the west coast ( Vancouver and Victoria) and occasional pleasure trips. I will admit to taking it to the junkyard once because it has a huge trunk. I was able to fit the gas tank of a Lincoln Town Car inside!

The original engine is a low compression XK 4.2, rated at 164hp. Not enough for a car of that weight going over the Canadian Rockies. I bought a rusty 1995 XJR and took it apart and will fit that engine and transmission. The AJ16 is very close in dimensions to the XK engine, so it looks right in the DS420 engine bay. A V8 would be nice, but the electronics get very complicated due to all the modules being networked. In comparison, the AJ16 is very simple and I can have the factory stand alone engine and transmission controllers run with only a few inputs faked easily for missing components, such as ABS and traction control. I don't think I could do that for a V8.

Right now I'm at the stage of starting to pull out the 4.2, then I have to fabricate new motor mounts.

I did consider a V12, but the engine bay of the DS420 is surprisingly narrow and I only would have had 1/2" to spare over the air filter housings. The engine would have needed to be lifted to change air filters! The 5.3 in Canadian emissions was 262HP, so not a huge improvement over a modified 4.2. Then I wanted an overdrive transmission and that would have been a lot of money. I bought the XJR for $1,000 with 130,000km on it, that was a much better deal and I get more power/torque with better fuel economy in the process.

The following 2 users liked this post by Jagboi64:

AL NZ (01-07-2018),

someguywithajag (04-10-2018)

#11

#12

AL NZ,

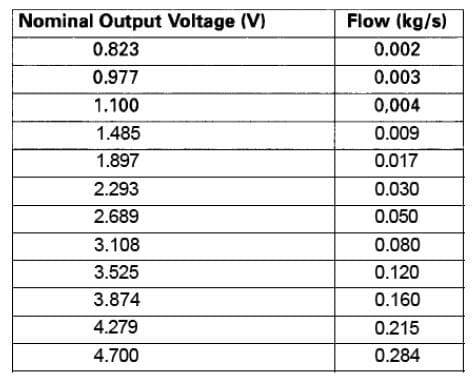

The standard air flow meter will only read up to 1018kg/hr and the standard engine just about reaches this airflow. There is no "reserve" . A scan too, will attempt to display the airflow in grammes/sec, but there is something wrong with the output from the engine ECU, so the data is always out by a factor of 10. If you log the data, you can of course post-process it into the correct units. I have an Eaton M112 supercharger running at 2.5:1 drive ratio. In theory this is 24.4% higher displacement per engine rev than the Eaton M90 running at the standard 2.5: 1 drive ratio. With my Eaton M112 setup, I don't exceed the 1018kg/hr limit until the engine is doing about 4000rpm at wide open thriottle. Therefore I think it extremely unlikely that any M90 based installation, even if fitted with a smaller SC pulley to give a 28% increased drive ratio, will exceed the airflow limit until about 4000rpm. If you keep below 4000rpm at wide open throtle, I think what you are proposing would be "safe". I would be wary of exceeding 5000rpm at any throttle opening with a 28% higher drive ratio, because by then the supercharger will be spinning faster, than even those installations that use a 10% bigger crank pulley and run the engine to its rev limit of 5,950rpm.

The standard air flow meter will only read up to 1018kg/hr and the standard engine just about reaches this airflow. There is no "reserve" . A scan too, will attempt to display the airflow in grammes/sec, but there is something wrong with the output from the engine ECU, so the data is always out by a factor of 10. If you log the data, you can of course post-process it into the correct units. I have an Eaton M112 supercharger running at 2.5:1 drive ratio. In theory this is 24.4% higher displacement per engine rev than the Eaton M90 running at the standard 2.5: 1 drive ratio. With my Eaton M112 setup, I don't exceed the 1018kg/hr limit until the engine is doing about 4000rpm at wide open thriottle. Therefore I think it extremely unlikely that any M90 based installation, even if fitted with a smaller SC pulley to give a 28% increased drive ratio, will exceed the airflow limit until about 4000rpm. If you keep below 4000rpm at wide open throtle, I think what you are proposing would be "safe". I would be wary of exceeding 5000rpm at any throttle opening with a 28% higher drive ratio, because by then the supercharger will be spinning faster, than even those installations that use a 10% bigger crank pulley and run the engine to its rev limit of 5,950rpm.

The following users liked this post:

AL NZ (01-07-2018)

#13

AL NZ,

The standard air flow meter will only read up to 1018kg/hr and the standard engine just about reaches this airflow. There is no "reserve" . A scan too, will attempt to display the airflow in grammes/sec, but there is something wrong with the output from the engine ECU, so the data is always out by a factor of 10. If you log the data, you can of course post-process it into the correct units. I have an Eaton M112 supercharger running at 2.5:1 drive ratio. In theory this is 24.4% higher displacement per engine rev than the Eaton M90 running at the standard 2.5: 1 drive ratio. With my Eaton M112 setup, I don't exceed the 1018kg/hr limit until the engine is doing about 4000rpm at wide open thriottle. Therefore I think it extremely unlikely that any M90 based installation, even if fitted with a smaller SC pulley to give a 28% increased drive ratio, will exceed the airflow limit until about 4000rpm. If you keep below 4000rpm at wide open throtle, I think what you are proposing would be "safe". I would be wary of exceeding 5000rpm at any throttle opening with a 28% higher drive ratio, because by then the supercharger will be spinning faster, than even those installations that use a 10% bigger crank pulley and run the engine to its rev limit of 5,950rpm.

The standard air flow meter will only read up to 1018kg/hr and the standard engine just about reaches this airflow. There is no "reserve" . A scan too, will attempt to display the airflow in grammes/sec, but there is something wrong with the output from the engine ECU, so the data is always out by a factor of 10. If you log the data, you can of course post-process it into the correct units. I have an Eaton M112 supercharger running at 2.5:1 drive ratio. In theory this is 24.4% higher displacement per engine rev than the Eaton M90 running at the standard 2.5: 1 drive ratio. With my Eaton M112 setup, I don't exceed the 1018kg/hr limit until the engine is doing about 4000rpm at wide open thriottle. Therefore I think it extremely unlikely that any M90 based installation, even if fitted with a smaller SC pulley to give a 28% increased drive ratio, will exceed the airflow limit until about 4000rpm. If you keep below 4000rpm at wide open throtle, I think what you are proposing would be "safe". I would be wary of exceeding 5000rpm at any throttle opening with a 28% higher drive ratio, because by then the supercharger will be spinning faster, than even those installations that use a 10% bigger crank pulley and run the engine to its rev limit of 5,950rpm.

#14

AL NZ,

The standard air flow meter will only read up to 1018kg/hr and the standard engine just about reaches this airflow. There is no "reserve" . A scan too, will attempt to display the airflow in grammes/sec, but there is something wrong with the output from the engine ECU, so the data is always out by a factor of 10. If you log the data, you can of course post-process it into the correct units. I have an Eaton M112 supercharger running at 2.5:1 drive ratio. In theory this is 24.4% higher displacement per engine rev than the Eaton M90 running at the standard 2.5: 1 drive ratio. With my Eaton M112 setup, I don't exceed the 1018kg/hr limit until the engine is doing about 4000rpm at wide open thriottle. Therefore I think it extremely unlikely that any M90 based installation, even if fitted with a smaller SC pulley to give a 28% increased drive ratio, will exceed the airflow limit until about 4000rpm. If you keep below 4000rpm at wide open throtle, I think what you are proposing would be "safe". I would be wary of exceeding 5000rpm at any throttle opening with a 28% higher drive ratio, because by then the supercharger will be spinning faster, than even those installations that use a 10% bigger crank pulley and run the engine to its rev limit of 5,950rpm.

The standard air flow meter will only read up to 1018kg/hr and the standard engine just about reaches this airflow. There is no "reserve" . A scan too, will attempt to display the airflow in grammes/sec, but there is something wrong with the output from the engine ECU, so the data is always out by a factor of 10. If you log the data, you can of course post-process it into the correct units. I have an Eaton M112 supercharger running at 2.5:1 drive ratio. In theory this is 24.4% higher displacement per engine rev than the Eaton M90 running at the standard 2.5: 1 drive ratio. With my Eaton M112 setup, I don't exceed the 1018kg/hr limit until the engine is doing about 4000rpm at wide open thriottle. Therefore I think it extremely unlikely that any M90 based installation, even if fitted with a smaller SC pulley to give a 28% increased drive ratio, will exceed the airflow limit until about 4000rpm. If you keep below 4000rpm at wide open throtle, I think what you are proposing would be "safe". I would be wary of exceeding 5000rpm at any throttle opening with a 28% higher drive ratio, because by then the supercharger will be spinning faster, than even those installations that use a 10% bigger crank pulley and run the engine to its rev limit of 5,950rpm.

Today I am having some remedial exhaust work done, where some non-mandrel-bent pipe was unfortunately welded in after my front driveshaft yoke was fitted - I believe the slight “crimps’ in the pipes may restrict full flow. I’ll see how that helps. Then I want to investigate extractors. Lastly, I am trying to work out whether just to send my spare Eaton front drive to Stiegemeier in USA for the ‘Venom’ water-cooled front drive to keep things cool, or go the whole hog and send the whole spare supercharger for rebuild and porting as well..

#15

#16

#17

#18

#19

Would that be the current operating data maps and can the maps be modified and retain the firmware ? Thinking in terms of a second valve that shifts to full open and shifting the maps up a bit as this valve is commanded open . No place to pipe in after the butterfly though unless on the bottom . Looking for less restrictive flow this way as the butterfly is a limited opening . Is the N/A and S/C butterfly the same size and can the fwd and aft edges be feathered for a smoother air flow at max opening if it is fully 90 degrees

Last edited by Lady Penelope; 01-09-2018 at 06:25 PM.

Thread

Thread Starter

Forum

Replies

Last Post

princemarko

XJ XJ8 / XJR ( X308 )

22

01-13-2019 12:57 PM

ttwotees

S-Type / S type R Supercharged V8 ( X200 )

39

04-11-2011 12:59 PM

ttwotees

S-Type / S type R Supercharged V8 ( X200 )

125

08-06-2010 03:48 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)