Caliper Bolt Sheared Off! What should I do? (XJS V12)

#1

Hi

To day I was trying to remove the Bolts that hold the Caliper by using a long breaker bar.

When the Caliper Bolt 'Sheared Off'

The other one is still in place, as I haven't yet tried to remove it.

What do I do now?

Can I just undo the hub nut and pull the whole lot off, or is there anything else to undo?

To day I was trying to remove the Bolts that hold the Caliper by using a long breaker bar.

When the Caliper Bolt 'Sheared Off'

The other one is still in place, as I haven't yet tried to remove it.

What do I do now?

Can I just undo the hub nut and pull the whole lot off, or is there anything else to undo?

The following users liked this post:

paulyling (06-20-2015)

#2

BUGGA.

You guys certainly have some serious issues with that salt, never seen/had that before.

The caliper mout bolts attach to the suspension "vertical" and the disc and hub simple will not come off until the caliper is clear of the area.

Removing the other bolt, if it will remove without breaking, MAY give some room to pivot the caliper on the broken bolt (now a stud) and eventually it may just slide off that "stud", but this is pure theory on my part.

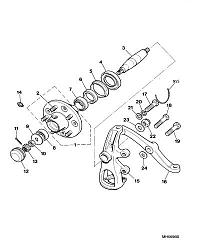

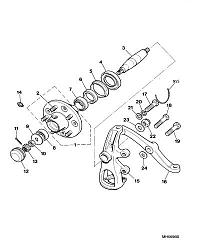

The parts drawing attached may help visualise the make off of what is involed here.

The "EAR" on the vertical that #15 is pionting at is one of the 2 caliper mount "ears".

#18 and 19 are the 2 caliper mount bolts, and #24 is that infamous "shim" that is nearly always missing.

You guys certainly have some serious issues with that salt, never seen/had that before.

The caliper mout bolts attach to the suspension "vertical" and the disc and hub simple will not come off until the caliper is clear of the area.

Removing the other bolt, if it will remove without breaking, MAY give some room to pivot the caliper on the broken bolt (now a stud) and eventually it may just slide off that "stud", but this is pure theory on my part.

The parts drawing attached may help visualise the make off of what is involed here.

The "EAR" on the vertical that #15 is pionting at is one of the 2 caliper mount "ears".

#18 and 19 are the 2 caliper mount bolts, and #24 is that infamous "shim" that is nearly always missing.

Last edited by Grant Francis; 06-10-2015 at 10:57 PM.

The following 3 users liked this post by Grant Francis:

#3

Join Date: Apr 2014

Location: Comox Valley, British Columbia

Posts: 816

Received 222 Likes

on

170 Posts

Cry, scream, drink and repeat.

The same thing happened on my 89. Soak the other bolt with penetrating fluid, let it sit and the use an air chisle (with a pointed tip) if you have it on bolt head to shake it free. Then try to remove.

Once I got second bolt free I tried to pivot off. No deal. I used my die grinder in the hole to clear the metal. Remover caliper and drilled it out. Then heat and easy out. Big pain. Took hours.

The same thing happened on my 89. Soak the other bolt with penetrating fluid, let it sit and the use an air chisle (with a pointed tip) if you have it on bolt head to shake it free. Then try to remove.

Once I got second bolt free I tried to pivot off. No deal. I used my die grinder in the hole to clear the metal. Remover caliper and drilled it out. Then heat and easy out. Big pain. Took hours.

Last edited by Bc xj; 06-10-2015 at 06:39 PM.

The following 4 users liked this post by Bc xj:

#4

BUGGA.

You guys certainly have some serious issues with that salt, never seen/had that before.

The caliper mout bolts attach to the suspension "vertical" and the disc and hub simple will not come off until the caliper is clear of the area.

Removing the other bolt, if it will remove without breaking, MAY give some room to pivot the caliper on the broken bolt (now a stud) and eventually it may just slide off that "stud", but this is pure theory on my part.

The parts drawing attached may help visualise the make off of what is involed here.

Attachment 113680

The "EAR" on the vertical that #15 is pionting at is one of teh 2 caliper mount "ears".

#18 and 19 are the 2 caliper mount bolts, and #24 is that infamous "shim" that is nearly always missing.

You guys certainly have some serious issues with that salt, never seen/had that before.

The caliper mout bolts attach to the suspension "vertical" and the disc and hub simple will not come off until the caliper is clear of the area.

Removing the other bolt, if it will remove without breaking, MAY give some room to pivot the caliper on the broken bolt (now a stud) and eventually it may just slide off that "stud", but this is pure theory on my part.

The parts drawing attached may help visualise the make off of what is involed here.

Attachment 113680

The "EAR" on the vertical that #15 is pionting at is one of teh 2 caliper mount "ears".

#18 and 19 are the 2 caliper mount bolts, and #24 is that infamous "shim" that is nearly always missing.

That's not good news!

This looks a real PIA job!

The following users liked this post:

paulyling (06-20-2015)

#5

Cry, scream, drink and repeat.

The same thing happened on my 89. Soak the other bolt with penetrating fluid, let it sit and the use an air chisle (with a pointed tip) if you have it on bolt head to shake it free. Then try to remove.

Once I got second bolt free I tried to pivot off. No deal. I used my die grinder in the hole to clear the metal. Remover caliper and drilled it out. Then heat and easy out. Big pain. Took hours.

The same thing happened on my 89. Soak the other bolt with penetrating fluid, let it sit and the use an air chisle (with a pointed tip) if you have it on bolt head to shake it free. Then try to remove.

Once I got second bolt free I tried to pivot off. No deal. I used my die grinder in the hole to clear the metal. Remover caliper and drilled it out. Then heat and easy out. Big pain. Took hours.

That's really 'Cheered me up!' (Not!)

Just another day at the office! when an XJS goes wrong!

But the other side came off dead easy and this Car has just spent most of its life in the Garage.

Not that the thought is crossing my mind but I wonder how much a Garage/Shop, would want to sort this out?

Probably no change from £1,000!

The following users liked this post:

paulyling (06-20-2015)

#6

Hi and Thanks

That's really 'Cheered me up!' (Not!)

Just another day at the office! when an XJS goes wrong!

But the other side came off dead easy and this Car has just spent most of its life in the Garage.

Not that the thought is crossing my mind but I wonder how much a Garage/Shop, would want to sort this out?

Probably no change from £1,000!

That's really 'Cheered me up!' (Not!)

Just another day at the office! when an XJS goes wrong!

But the other side came off dead easy and this Car has just spent most of its life in the Garage.

Not that the thought is crossing my mind but I wonder how much a Garage/Shop, would want to sort this out?

Probably no change from £1,000!

With that out you can go the chop on it to recover the caliper, hub etc. Chances are you're not going to get the bolt remnants out anyway.

The following 2 users liked this post by baxtor:

orangeblossom (06-11-2015),

paulyling (06-20-2015)

#7

Then Pull the Hub off, and then get some heat around the Top Bolt, so that I can undo it.

Then rock what's left of it backwards and forwards to loosen, what is now a Stud and then Air Chisel it out.

New Caliper, New Bolts Job Done!??????

As the Caliper will be Service Exchange, I can give them one of the old ones off my 'Scrapper' and may even be able to reuse those bolts if I cant get new ones.

I know that it sounds a bit brutal but its either that or spending hours achieving the same result.

Any comments on this would be appreciated before I start.

The following users liked this post:

paulyling (06-20-2015)

Trending Topics

#8

OB

Baxtor is 100% right. For clarity, though I expect you know this; the steering arm is held on by the bolt you have sheered and the bolt into the hub upright top left above it. The caliper is held on by the bolt you have sheered and the bolt it is lock-wired to, a couple of inches DIRECTLY above it.

So you have three to undo, one common to the steering arm and the caliper (the one you have sheered); one holding the steering arm only to the upright (the one not lock-wired) and one holding the caliper only to the upright (the one lockwired to the one you have sheered).

Undo the other lockwired caliper-to-upright bolt and ALSO the bolt not lock-wired holding the steering arm to the upright. At this point the steering arm is in theory removable. BUT, your bolt has sheered because the bolt has corroded itself into the steering arm (not into the caliper threads) so the arm is most unlikely to come off. ALL this is PRECISELY what happened to me when I rebuilt my front suspension.

You will find that once the other steering arm and caliper bolt is undone, the arm complete with the sheered bolt will rotate a tiny bit about the sheered 'stud' each way before it fouls a bit of car and cannot rotate further. This proves that the threads are free and it is the stud/upright hole that is tight. Undo the ball joint at the other end of the steering arm where it attaches to the rack.

Then, what I did was to get the small angle grinder and carefully cut through the steering arm down the side of the hole in it where the sheered bolt goes through. This is not too tricky to do and once done, the grip of the hole in the arm on the sheered bolt comes loose and it can all come off. Then the stud can be undone with a huge set of grips.

Buy a steering arm from Grublogger (etc) for a few quid and rebuild! The bolt should be available from Grublogger. It is METRIC FINE THREAD, NOT UNF. Test the bolt goes easily into its threads before you start.

This is all quite doable and I think the best way to proceed. On reassembly, copper grease the barrel of the bolt, assemble the top arm bolt tight and top caliper bolt, then with a feeler gauge find out the gap between the caliper and the steering arm at the lower bolt hole (the one you have sheered). Once found loosen off the two tight bolts, insert shims to the correct depth between the caliper and the arm and then refit all three bolts and lockwire the caliper bolts. Good luck.

Greg

Baxtor is 100% right. For clarity, though I expect you know this; the steering arm is held on by the bolt you have sheered and the bolt into the hub upright top left above it. The caliper is held on by the bolt you have sheered and the bolt it is lock-wired to, a couple of inches DIRECTLY above it.

So you have three to undo, one common to the steering arm and the caliper (the one you have sheered); one holding the steering arm only to the upright (the one not lock-wired) and one holding the caliper only to the upright (the one lockwired to the one you have sheered).

Undo the other lockwired caliper-to-upright bolt and ALSO the bolt not lock-wired holding the steering arm to the upright. At this point the steering arm is in theory removable. BUT, your bolt has sheered because the bolt has corroded itself into the steering arm (not into the caliper threads) so the arm is most unlikely to come off. ALL this is PRECISELY what happened to me when I rebuilt my front suspension.

You will find that once the other steering arm and caliper bolt is undone, the arm complete with the sheered bolt will rotate a tiny bit about the sheered 'stud' each way before it fouls a bit of car and cannot rotate further. This proves that the threads are free and it is the stud/upright hole that is tight. Undo the ball joint at the other end of the steering arm where it attaches to the rack.

Then, what I did was to get the small angle grinder and carefully cut through the steering arm down the side of the hole in it where the sheered bolt goes through. This is not too tricky to do and once done, the grip of the hole in the arm on the sheered bolt comes loose and it can all come off. Then the stud can be undone with a huge set of grips.

Buy a steering arm from Grublogger (etc) for a few quid and rebuild! The bolt should be available from Grublogger. It is METRIC FINE THREAD, NOT UNF. Test the bolt goes easily into its threads before you start.

This is all quite doable and I think the best way to proceed. On reassembly, copper grease the barrel of the bolt, assemble the top arm bolt tight and top caliper bolt, then with a feeler gauge find out the gap between the caliper and the steering arm at the lower bolt hole (the one you have sheered). Once found loosen off the two tight bolts, insert shims to the correct depth between the caliper and the arm and then refit all three bolts and lockwire the caliper bolts. Good luck.

Greg

Last edited by Greg in France; 06-11-2015 at 03:21 AM.

The following 3 users liked this post by Greg in France:

#9

OB

Baxtor is 100% right. For clarity, though I expect you know this; the steering arm is held on by the bolt you have sheered and the bolt into the hub upright top left above it. The caliper is held on by the bolt you have sheered and the bolt it is lock-wired to, a couple of inches DIRECTLY above it.

So you have three to undo, one common to the steering arm and the caliper (the one you have sheered); one holding the steering arm only to the upright (the one not lock-wired) and one holding the caliper only to the upright (the one lockwired to the one you have sheered).

Undo the other lockwired caliper-to-upright bolt and ALSO the bolt not lock-wired holding the steering arm to the upright. At this point the steering arm is in theory removable. BUT, your bolt has sheered because the bolt has corroded itself into the steering arm (not into the caliper threads) so the arm is most unlikely to come off. ALL this is PRECISELY what happened to me when I rebuilt my front suspension.

You will find that once the other steering arm and caliper bolt is undone, the arm complete with the sheered bolt will rotate a tiny bit about the sheered 'stud' each way before it fouls a bit of car and cannot rotate further. This proves that the threads are free and it is the stud/upright hole that is tight. Undo the ball joint at the other end of the steering arm where it attaches to the rack.

Then, what I did was to get the small angle grinder and carefully cut through the steering arm down the side of the hole in it where the sheered bolt goes through. This is not too tricky to do and once done, the grip of the hole in the arm on the sheered bolt comes loose and it can all come off. Then the stud can be undone with a huge set of grips.

Buy a steering arm from Grublogger (etc) for a few quid and rebuild! The bolt should be available from Grublogger. It is METRIC FINE THREAD, NOT UNF. Test the bolt goes easily into its threads before you start.

This is all quite doable and I think the best way to proceed. On reassembly, copper grease the barrel of the bolt, assemble the top arm bolt tight and top caliper bolt, then with a feeler gauge find out the gap between the caliper and the steering arm at the lower bolt hole (the one you have sheered). Once found loosen off the two tight bolts, insert shims to the correct depth between the caliper and the arm and then refit all three bolts and lockwire the caliper bolts. Good luck.

Greg

Baxtor is 100% right. For clarity, though I expect you know this; the steering arm is held on by the bolt you have sheered and the bolt into the hub upright top left above it. The caliper is held on by the bolt you have sheered and the bolt it is lock-wired to, a couple of inches DIRECTLY above it.

So you have three to undo, one common to the steering arm and the caliper (the one you have sheered); one holding the steering arm only to the upright (the one not lock-wired) and one holding the caliper only to the upright (the one lockwired to the one you have sheered).

Undo the other lockwired caliper-to-upright bolt and ALSO the bolt not lock-wired holding the steering arm to the upright. At this point the steering arm is in theory removable. BUT, your bolt has sheered because the bolt has corroded itself into the steering arm (not into the caliper threads) so the arm is most unlikely to come off. ALL this is PRECISELY what happened to me when I rebuilt my front suspension.

You will find that once the other steering arm and caliper bolt is undone, the arm complete with the sheered bolt will rotate a tiny bit about the sheered 'stud' each way before it fouls a bit of car and cannot rotate further. This proves that the threads are free and it is the stud/upright hole that is tight. Undo the ball joint at the other end of the steering arm where it attaches to the rack.

Then, what I did was to get the small angle grinder and carefully cut through the steering arm down the side of the hole in it where the sheered bolt goes through. This is not too tricky to do and once done, the grip of the hole in the arm on the sheered bolt comes loose and it can all come off. Then the stud can be undone with a huge set of grips.

Buy a steering arm from Grublogger (etc) for a few quid and rebuild! The bolt should be available from Grublogger. It is METRIC FINE THREAD, NOT UNF. Test the bolt goes easily into its threads before you start.

This is all quite doable and I think the best way to proceed. On reassembly, copper grease the barrel of the bolt, assemble the top arm bolt tight and top caliper bolt, then with a feeler gauge find out the gap between the caliper and the steering arm at the lower bolt hole (the one you have sheered). Once found loosen off the two tight bolts, insert shims to the correct depth between the caliper and the arm and then refit all three bolts and lockwire the caliper bolts. Good luck.

Greg

Thanks, but first I've got another little problem to sort out!

I've got my other Car 'Cherry Blossom' up on my Car lifter, and the Motor on the Lifter has Cut Out.

I think it could be more than a fuse but I don't want to leave it up in the air, just in case something 'something else!' happens.

#10

OB,

Really sorry to hear of your troubles. It's not unusual for the bolts to be tight as PO's often lubricate them and then just whack them up really tight rather than use the proper torque setting as per the manual.

I suspect that Greg's suggestion might be your only answer. However, the desire in me to try and remedy the situation without cutting anything would make me try Grant's suugestion of removing the other caliper bolt and wiggling the caliper, but to then use an Ezy-out or similar to try and take out the sheared bolt whilst the caliper is still in situ. You've nothing to lose but your time.

Interestingly, Jaguar moved away from lock-wired caliper bolts on later models and moved to a form of self-loctited bolt. I'm not sure if the torque setting changed at that time so check depending on which type of bolt you get.

Remember to keep the threads dry and use the proper torques setting on reassembly.

Good luck

Paul

Really sorry to hear of your troubles. It's not unusual for the bolts to be tight as PO's often lubricate them and then just whack them up really tight rather than use the proper torque setting as per the manual.

I suspect that Greg's suggestion might be your only answer. However, the desire in me to try and remedy the situation without cutting anything would make me try Grant's suugestion of removing the other caliper bolt and wiggling the caliper, but to then use an Ezy-out or similar to try and take out the sheared bolt whilst the caliper is still in situ. You've nothing to lose but your time.

Interestingly, Jaguar moved away from lock-wired caliper bolts on later models and moved to a form of self-loctited bolt. I'm not sure if the torque setting changed at that time so check depending on which type of bolt you get.

Remember to keep the threads dry and use the proper torques setting on reassembly.

Good luck

Paul

The following users liked this post:

orangeblossom (06-11-2015)

#11

OB,

Really sorry to hear of your troubles. It's not unusual for the bolts to be tight as PO's often lubricate them and then just whack them up really tight rather than use the proper torque setting as per the manual.

I suspect that Greg's suggestion might be your only answer. However, the desire in me to try and remedy the situation without cutting anything would make me try Grant's suugestion of removing the other caliper bolt and wiggling the caliper, but to then use an Ezy-out or similar to try and take out the sheared bolt whilst the caliper is still in situ. You've nothing to lose but your time.

Interestingly, Jaguar moved away from lock-wired caliper bolts on later models and moved to a form of self-loctited bolt. I'm not sure if the torque setting changed at that time so check depending on which type of bolt you get.

Remember to keep the threads dry and use the proper torques setting on reassembly.

Good luck

Paul

Really sorry to hear of your troubles. It's not unusual for the bolts to be tight as PO's often lubricate them and then just whack them up really tight rather than use the proper torque setting as per the manual.

I suspect that Greg's suggestion might be your only answer. However, the desire in me to try and remedy the situation without cutting anything would make me try Grant's suugestion of removing the other caliper bolt and wiggling the caliper, but to then use an Ezy-out or similar to try and take out the sheared bolt whilst the caliper is still in situ. You've nothing to lose but your time.

Interestingly, Jaguar moved away from lock-wired caliper bolts on later models and moved to a form of self-loctited bolt. I'm not sure if the torque setting changed at that time so check depending on which type of bolt you get.

Remember to keep the threads dry and use the proper torques setting on reassembly.

Good luck

Paul

Cheers! but what is an 'Easy Out?' something I've never heard of!

#12

Of course you could simply undo the 2 bolts that hold the 2 halves of the caliper together, then the outer half will fall off, the disc rotor will fall off, and working romm becomes much bigger.

Once off the car, bolt it back together, and use it as a core unit for the new/rebuilt you are going to get anyway.

Easy Out, is similar to a thread tap, but more of a spiral, and Left Handed, and is used to remove a broken stud, once a hole is drilled of suitable size down the guts of said stud. Biggest drawback is that they are made of hardened steel, and IF you snap one off in said stud, I will not require a telephone to hear your vocabulary extension.

Once off the car, bolt it back together, and use it as a core unit for the new/rebuilt you are going to get anyway.

Easy Out, is similar to a thread tap, but more of a spiral, and Left Handed, and is used to remove a broken stud, once a hole is drilled of suitable size down the guts of said stud. Biggest drawback is that they are made of hardened steel, and IF you snap one off in said stud, I will not require a telephone to hear your vocabulary extension.

The following users liked this post:

orangeblossom (06-11-2015)

#13

OB,

Just as Grant has described. They look as in the pic below. You drill a hole then turn it into the hole anticlockwise (LH thread) which tightens in the bolt and hopefully then turns out the bolt. Can be quite effective. I've broken a couple of the very small ones over the years by being a bit brutal but never broken one of the larger ones. If it did break flush with the broken stud then you're not really any worse off, and if it did break proud then you could just back it out anyway. Useful addition to the toolbox and not expensive.

If you can drill a hole nice and square in the centre of the broken bolt, then I think its worth a try. Sometimes even the force of drilling a hole can help to break the grip of the bolt threads a bit anyway.

Good luck

Paul

Just as Grant has described. They look as in the pic below. You drill a hole then turn it into the hole anticlockwise (LH thread) which tightens in the bolt and hopefully then turns out the bolt. Can be quite effective. I've broken a couple of the very small ones over the years by being a bit brutal but never broken one of the larger ones. If it did break flush with the broken stud then you're not really any worse off, and if it did break proud then you could just back it out anyway. Useful addition to the toolbox and not expensive.

If you can drill a hole nice and square in the centre of the broken bolt, then I think its worth a try. Sometimes even the force of drilling a hole can help to break the grip of the bolt threads a bit anyway.

Good luck

Paul

The following users liked this post:

orangeblossom (06-11-2015)

#14

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,743

Received 10,757 Likes

on

7,101 Posts

The following users liked this post:

orangeblossom (06-11-2015)

#15

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,743

Received 10,757 Likes

on

7,101 Posts

If a bolt head shears off I'd be inclined to say the bolt was seized and not just "really tight" !

Cheers

DD

The following users liked this post:

orangeblossom (06-11-2015)

#16

Of course you could simply undo the 2 bolts that hold the 2 halves of the caliper together, then the outer half will fall off, the disc rotor will fall off, and working romm becomes much bigger.

Once off the car, bolt it back together, and use it as a core unit for the new/rebuilt you are going to get anyway.

Easy Out, is similar to a thread tap, but more of a spiral, and Left Handed, and is used to remove a broken stud, once a hole is drilled of suitable size down the guts of said stud. Biggest drawback is that they are made of hardened steel, and IF you snap one off in said stud, I will not require a telephone to hear your vocabulary extension.

Once off the car, bolt it back together, and use it as a core unit for the new/rebuilt you are going to get anyway.

Easy Out, is similar to a thread tap, but more of a spiral, and Left Handed, and is used to remove a broken stud, once a hole is drilled of suitable size down the guts of said stud. Biggest drawback is that they are made of hardened steel, and IF you snap one off in said stud, I will not require a telephone to hear your vocabulary extension.

I might just give it a try you never know they just might undo!

#17

#18

#19

OB,

Just as Grant has described. They look as in the pic below. You drill a hole then turn it into the hole anticlockwise (LH thread) which tightens in the bolt and hopefully then turns out the bolt. Can be quite effective. I've broken a couple of the very small ones over the years by being a bit brutal but never broken one of the larger ones. If it did break flush with the broken stud then you're not really any worse off, and if it did break proud then you could just back it out anyway. Useful addition to the toolbox and not expensive.

If you can drill a hole nice and square in the centre of the broken bolt, then I think its worth a try. Sometimes even the force of drilling a hole can help to break the grip of the bolt threads a bit anyway.

Good luck

Paul

Just as Grant has described. They look as in the pic below. You drill a hole then turn it into the hole anticlockwise (LH thread) which tightens in the bolt and hopefully then turns out the bolt. Can be quite effective. I've broken a couple of the very small ones over the years by being a bit brutal but never broken one of the larger ones. If it did break flush with the broken stud then you're not really any worse off, and if it did break proud then you could just back it out anyway. Useful addition to the toolbox and not expensive.

If you can drill a hole nice and square in the centre of the broken bolt, then I think its worth a try. Sometimes even the force of drilling a hole can help to break the grip of the bolt threads a bit anyway.

Good luck

Paul

Its a great idea but there's no room for a Drill and I would imagine those bolts are high tensile steel, so in any event it would be a PIA Job.

#20

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

The following users liked this post:

orangeblossom (06-11-2015)