Best Way To Jack Front Tires

#1

A newbie here looking for help from the DIY guys (and gals).

Question:

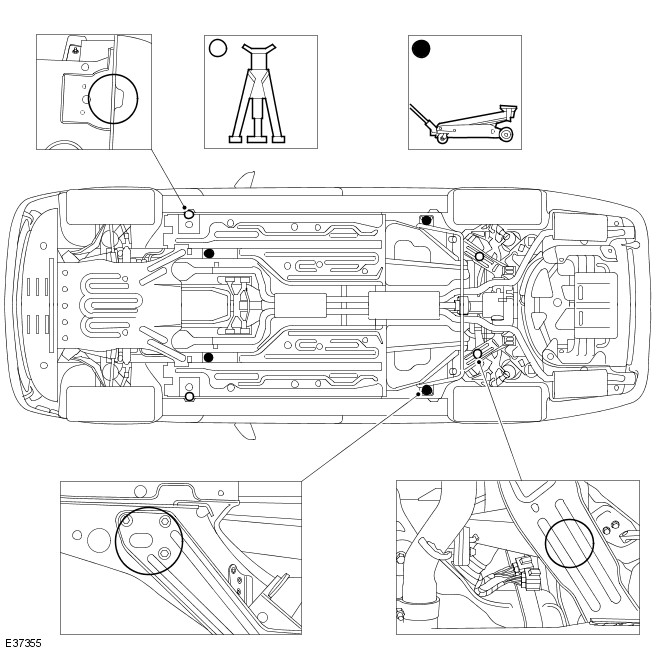

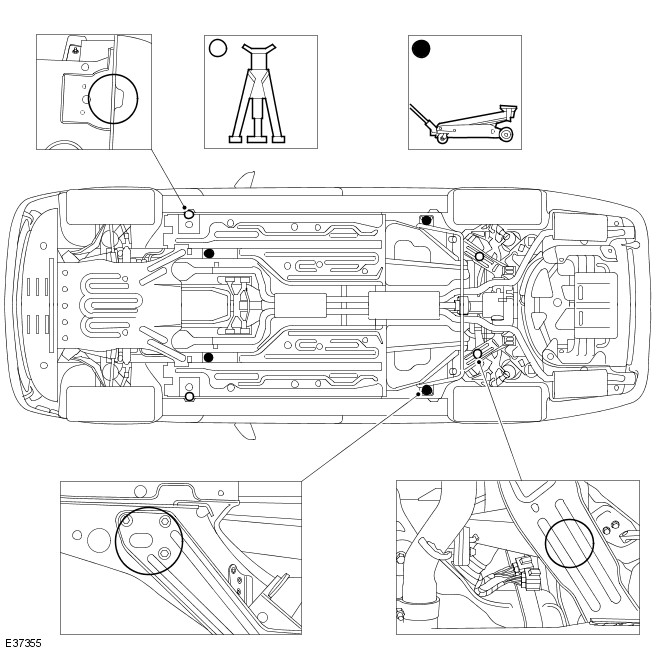

Where on this picture is the crossmember? Is it the part labeled A or B? Can it support the weight of the car if a floor jack is put under it to raise both front tires?

Background:

I am trying to change out my front brake pads. This is my first car project, and I would not consider myself mechanically inclined. I prepared by watching lots of Youtube videos on changing out the brakes - ChrisFix is a great channel. I have all the tools i need. I managed to put the car on ramps and got the plastic belly pan off.

From the Youtube videos, it seems the easiest way to raise the front two tires of a car is putting the floor jack under the front crossmember and then using jack stands. I know where the two front jack points are. There's also some commentary on how it's an aluminum body and this makes things different regarding crossmember support.

Any help, especially if you've done this regularly on your own XJ8 :-), would be appreciated.

Question:

Where on this picture is the crossmember? Is it the part labeled A or B? Can it support the weight of the car if a floor jack is put under it to raise both front tires?

Background:

I am trying to change out my front brake pads. This is my first car project, and I would not consider myself mechanically inclined. I prepared by watching lots of Youtube videos on changing out the brakes - ChrisFix is a great channel. I have all the tools i need. I managed to put the car on ramps and got the plastic belly pan off.

From the Youtube videos, it seems the easiest way to raise the front two tires of a car is putting the floor jack under the front crossmember and then using jack stands. I know where the two front jack points are. There's also some commentary on how it's an aluminum body and this makes things different regarding crossmember support.

Any help, especially if you've done this regularly on your own XJ8 :-), would be appreciated.

#2

Below is where you should put the floor jack and stands if you're doing this in your driveway/garage. You should never use the subframe to lift the vehicle at any time, or damage can occur. Should be look at the solid black dots for jack points with the floor jack.

Lifting Points—Floor Jack and Axle Stands

CAUTIONS:

Lifting Points—Floor Jack and Axle Stands

CAUTIONS:

- If the vehicle is to be lifted using floor jacks, two jacks must be used to raise either the front or rear of the vehicle. If one jack only is used, excessive body twist may occur.

- When using a floor jack to jack up the rear of the vehicle, the jack head must be aimed at the NVH bar securing bolts to aviod fuel tank damage or body damage.

- When using a floor jack, a cushioned pad must be utilized to avoid body damage.

- When using axle stands, a cushioned pad must be utilized to avoid damage to the body or rear subframe assembly.

#3

#4

Hi

I'm a new member myself, but I just went through all this. Instructions say that for a flat tire in an emergency situation, you can jack up just one wheel high enough that it barely clears the ground, leaving the other 3 wheels in contact with the ground to prevent warping the frame.

Otherwise, I think I am stuck buying a second jack this weekend. Not sure you can do it any other way, realistically. I need to do some work underneath, and so jack stands are necessary. So, 2 floorjacks seem unavoidable, so its back to Harbor Freight.

I'm a new member myself, but I just went through all this. Instructions say that for a flat tire in an emergency situation, you can jack up just one wheel high enough that it barely clears the ground, leaving the other 3 wheels in contact with the ground to prevent warping the frame.

Otherwise, I think I am stuck buying a second jack this weekend. Not sure you can do it any other way, realistically. I need to do some work underneath, and so jack stands are necessary. So, 2 floorjacks seem unavoidable, so its back to Harbor Freight.

#5

Hi

I'm a new member myself, but I just went through all this. Instructions say that for a flat tire in an emergency situation, you can jack up just one wheel high enough that it barely clears the ground, leaving the other 3 wheels in contact with the ground to prevent warping the frame.

Otherwise, I think I am stuck buying a second jack this weekend. Not sure you can do it any other way, realistically. I need to do some work underneath, and so jack stands are necessary. So, 2 floorjacks seem unavoidable, so its back to Harbor Freight.

I'm a new member myself, but I just went through all this. Instructions say that for a flat tire in an emergency situation, you can jack up just one wheel high enough that it barely clears the ground, leaving the other 3 wheels in contact with the ground to prevent warping the frame.

Otherwise, I think I am stuck buying a second jack this weekend. Not sure you can do it any other way, realistically. I need to do some work underneath, and so jack stands are necessary. So, 2 floorjacks seem unavoidable, so its back to Harbor Freight.

#6

Hi Dave,

I am hoping that all cars have basic structural support parts that can take a jack placed under them. A basic obvious example is tires :-). The front crossmember is conventionally supposed to be another.

I know that people have been able to use the floor jack under the front crossmember in older Jags. My concern is that the 2004 XJ8 was the first aluminum body construction, so it might not have followed the usual structure design as 2003 and earlier.

-Sax

I am hoping that all cars have basic structural support parts that can take a jack placed under them. A basic obvious example is tires :-). The front crossmember is conventionally supposed to be another.

I know that people have been able to use the floor jack under the front crossmember in older Jags. My concern is that the 2004 XJ8 was the first aluminum body construction, so it might not have followed the usual structure design as 2003 and earlier.

-Sax

The following users liked this post:

saxandliz (04-08-2017)

Trending Topics

#9

You CAN do one side at a time, just need to make sure you put the jack in the right spot.

The older jags such as the X300, XJ40, Series 1-3 have a more beefy subframe and can handle the weight, but that is only if you absolutely have to jack at that point. I wouldn't recommend it all the time. If you can jack it from the side jacking points, that is recommended.

The older jags such as the X300, XJ40, Series 1-3 have a more beefy subframe and can handle the weight, but that is only if you absolutely have to jack at that point. I wouldn't recommend it all the time. If you can jack it from the side jacking points, that is recommended.

#10

I have a lift now but before I did I used this setup from harbor freight. It's a low profile long reach jack with the attachment you see on top. I came in from the side. Also the bar extended long enough to lift one side (front and back lifting points.

You need the low profile jack and the longer reach one is better, for this to work but it worked well.

http://www.harborfreight.com/2-ton-l...ump-62310.html

http://www.harborfreight.com/steel-f...eam-60762.html

Spend the money. It's your health, safety and life we're talking about.

You need the low profile jack and the longer reach one is better, for this to work but it worked well.

http://www.harborfreight.com/2-ton-l...ump-62310.html

http://www.harborfreight.com/steel-f...eam-60762.html

Spend the money. It's your health, safety and life we're talking about.

Last edited by Sean W; 03-22-2017 at 09:48 AM.

#11

DO NOT single point jack under the front or rear Xmember. Totally different animal from a XJ40 or X302. 2 jacks or 1 wheel. If your not opening the fluid system (front pads and rotors), its easier and faster to just do 1 wheel at a time. If your doing rears, you may have to "screw" the pistons in requiring relieving the pressure. Read up on the rears prior to starting. Also read up on bleeding. Not the funnest job to get the air out.

#12

Thanks to everybody who chimed in! Part of my anxiety in all this is my complete lack of experience doing any sort of mechanical work.

Sean, I tried the cross beam extender from HB, but I couldn't get it to lift just the front. I didn't want to come in from the side. I wanted both wheels off so I could turn the steering to provide easy access.

I ended up getting regular jack stands from Harbor Freight (I had initially bought high lift jack stands from Craftsman). I lifted up the front one side at a time. Quickly placing the jack stand on the driver's side with the wheel about an inch off the ground, I moved to do the passenger side. I used rubber/ plastic pads on the jack stands.

Took about 3 hours to do the passenger side brake pad change, and 1.5 hours to do the driver's side. I took my time cleaning out all the brake dust I could, and struggled with my new piston compression tool which decided to get cross threaded half way through the job.

For anybody who has never used any thing more than a screwdriver before in their life, you can change your own brake pads.

-Sax

Sean, I tried the cross beam extender from HB, but I couldn't get it to lift just the front. I didn't want to come in from the side. I wanted both wheels off so I could turn the steering to provide easy access.

I ended up getting regular jack stands from Harbor Freight (I had initially bought high lift jack stands from Craftsman). I lifted up the front one side at a time. Quickly placing the jack stand on the driver's side with the wheel about an inch off the ground, I moved to do the passenger side. I used rubber/ plastic pads on the jack stands.

Took about 3 hours to do the passenger side brake pad change, and 1.5 hours to do the driver's side. I took my time cleaning out all the brake dust I could, and struggled with my new piston compression tool which decided to get cross threaded half way through the job.

For anybody who has never used any thing more than a screwdriver before in their life, you can change your own brake pads.

-Sax

#13

Before I bought a lift, for brakes, I just used what I sent you in a pic to do the left side first, front and back, then the right side front and back.

When lifting the front or rear only, coming in from the side poses no risk, but if for whatever reason, you're uncomfortable doing it, your way works fine.

I would however caution against it if your constantly jacking your vehicle up to work on it. Once in awhile, I think the ole girl can handle it.

Glad you got your brake pads changed. Nice work Sax.

When lifting the front or rear only, coming in from the side poses no risk, but if for whatever reason, you're uncomfortable doing it, your way works fine.

I would however caution against it if your constantly jacking your vehicle up to work on it. Once in awhile, I think the ole girl can handle it.

Glad you got your brake pads changed. Nice work Sax.

#14

Hi Sean,

At some point I will probably own a lift. By the way, which model did you get and was it expensive?

Can you also clarify if you used the cross beam attachment screwed in lengthwise onto the floor jack head and not at a right angle as pictured? I was skeptical because the screw holds the cross beam in place and does not allow free rotation on the head.

-Sax

At some point I will probably own a lift. By the way, which model did you get and was it expensive?

Can you also clarify if you used the cross beam attachment screwed in lengthwise onto the floor jack head and not at a right angle as pictured? I was skeptical because the screw holds the cross beam in place and does not allow free rotation on the head.

-Sax

#15

Hi Sean,

At some point I will probably own a lift. By the way, which model did you get and was it expensive?

Can you also clarify if you used the cross beam attachment screwed in lengthwise onto the floor jack head and not at a right angle as pictured? I was skeptical because the screw holds the cross beam in place and does not allow free rotation on the head.

-Sax

At some point I will probably own a lift. By the way, which model did you get and was it expensive?

Can you also clarify if you used the cross beam attachment screwed in lengthwise onto the floor jack head and not at a right angle as pictured? I was skeptical because the screw holds the cross beam in place and does not allow free rotation on the head.

-Sax

This was the lift I bought. Garage too small for a full height but this fits all my needs and it was long enough for the Super V8 and win enough to easily work on exhaust, all suspension and transmission. Cost around $2k shipped to my garage.

#16

#17

Some things to think about. If you have a third stall, you can go with a full lift, either a two post or four post. Two post are a bit of a pain because you have to park far enough forward so the post doesn't interfere with the door.

Four post full lifts solve that problem but create others. Your wheels aren't suspended with a four post lift, making it useless for brake and suspension work.

I don't like working under full size lifts. As a former mechanic I still have neck problems from years of looking up.

So given the size of the car and it's weight, combined with garage space issues, I went with the mid-rise which lifts 38 inches and can handle 6k lbs.

You can lift it in virtually 1 inch increments which is convenient for engine work and minimizes back pain (less bending at the fender)

You do need a compressor for these types of lift (maybe all types?) as they are air locked into position - see manual - to prevent them from coming down.

The roll bars between the two sides prevent the use of a creeper, or at least limit it but I use a 1-1/2 inch mechanics pad anyway so no issue for me.

Anyway - some things to consider.

Their are other mid rise lifts out there. They're almost all Chinese built. Not sure about the Atlas lifts. You can check out a boat load of lifts @ Greg Smiths.

I didn't buy from them because of their dictatorial shipping policy and better pricing at the time with Redline. Also, Redline helped me coordinate getting from the cartage shipper to my house. Greg Smith has a bit of a screw you attitude with that. Maybe they've changed though.

The following users liked this post:

paydase (04-15-2017)