disaster after changing secondary tensioner?

#21

Spotting any bent valve with an endoscope may not be really possible. One way would be to remove the intake manifold, position the valves (one by one) fully closed, shine light into the intake and look for any light patches inside the cylinder with the endoscope. This would only give you the status of the intake valves. There is no point in trying to use an endoscope, the compression test will tell you straight away.

The following users liked this post:

RA110623 (06-09-2019)

#22

You can check the compression on a cold engine, the readings will just be somewhat lower as compared to the readings on a hot engine. But this does not matter in your case - you just need to see if you have very low or zero readings on some cylinders. Otherwise, the compression test should be done with the throttle in the wide open position. You can remove the intake tube and, in some way, jam the throttle butterfly fully open.

Spotting any bent valve with an endoscope may not be really possible. One way would be to remove the intake manifold, position the valves (one by one) fully closed, shine light into the intake and look for any light patches inside the cylinder with the endoscope. This would only give you the status of the intake valves. There is no point in trying to use an endoscope, the compression test will tell you straight away.

Spotting any bent valve with an endoscope may not be really possible. One way would be to remove the intake manifold, position the valves (one by one) fully closed, shine light into the intake and look for any light patches inside the cylinder with the endoscope. This would only give you the status of the intake valves. There is no point in trying to use an endoscope, the compression test will tell you straight away.

I noticed when I turned the crankshaft clockwise it was heavier to turn it could it be because the exhaust camshaft over tightened so there's more load on the entire engine?

#23

#24

ist still possible that I have bent valves? I know the compression test will show if there's bent or no but just curious since both side are the same.

I don't have compression gauge will get one soon .

also the right side plastic secondary tensioner looks brand new! no cracks no wear the left side was bare metal so should i change it or keep it?

#25

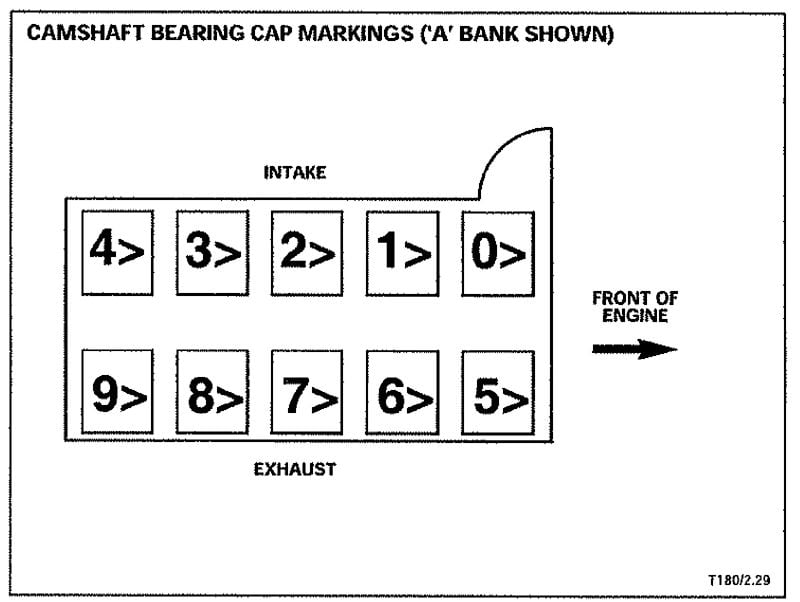

The over-tighten, if not significant but say 20-30%, would not cause the camshaft to bind. However, incorrect orientation of the caps (front/back) as well as incorrect sequence (numbering) can cause serious binding of the camshaft, even camshaft breaking. Perhaps you should double-check this. The caps on the intake cam are numbered 0 to 4 from the front of the engine; the exhaust cam caps are numbered from 5 to 9, also from the front of the engine. The ">" sign should point forwards on all caps.

#26

The over-tighten, if not significant but say 20-30%, would not cause the camshaft to bind. However, incorrect orientation of the caps (front/back) as well as incorrect sequence (numbering) can cause serious binding of the camshaft, even camshaft breaking. Perhaps you should double-check this. The caps on the intake cam are numbered 0 to 4 from the front of the engine; the exhaust cam caps are numbered from 5 to 9, also from the front of the engine. The ">" sign should point forwards on all caps.

#27

The over-tighten, if not significant but say 20-30%, would not cause the camshaft to bind. However, incorrect orientation of the caps (front/back) as well as incorrect sequence (numbering) can cause serious binding of the camshaft, even camshaft breaking. Perhaps you should double-check this. The caps on the intake cam are numbered 0 to 4 from the front of the engine; the exhaust cam caps are numbered from 5 to 9, also from the front of the engine. The ">" sign should point forwards on all caps.

#28

From left? The numbers you provided are not what the caps usually have. On the exhaust cam caps, they should be 5, 6, 7, 8, 9 from front to back.

#29

#30

Have we been back to basics

check the crankshaft timing as I did with Xjack & MS help me look for timing alignment on the flywheel

then set the flats on the cams

reading back to the beginning you changed the tensioner while under pressure from the valves

so I would think to get the timing set up so as to be on the compression stroke (both valves closed)

then there is no load (pressure) on the cam and just check everything is timed and aligned properly.

then you know it cant be mechanical

then do a compression test and go from there

whenever you replace a part (tensioner in this case ) do all, as you do with plugs, or oil and filter, it just takes that maybe factor out.

ok keep going bit by bit and watch the back

keep going bit by bit and watch the back

check the crankshaft timing as I did with Xjack & MS help me look for timing alignment on the flywheel

then set the flats on the cams

reading back to the beginning you changed the tensioner while under pressure from the valves

so I would think to get the timing set up so as to be on the compression stroke (both valves closed)

then there is no load (pressure) on the cam and just check everything is timed and aligned properly.

then you know it cant be mechanical

then do a compression test and go from there

whenever you replace a part (tensioner in this case ) do all, as you do with plugs, or oil and filter, it just takes that maybe factor out.

ok

keep going bit by bit and watch the back

keep going bit by bit and watch the back

#32

#33

compression test results

bank B from front to rear. 180 psi -185psi - 185psi -190 psi

bank A from front to rear 185 psi- 185psi -190psi 190 psi

thanks God I think I have good compression numbers.

what you think guys ? next step put everything back together or there's more things to check before putting back the fuel pump relay and ignition coils?

thanks.

bank B from front to rear. 180 psi -185psi - 185psi -190 psi

bank A from front to rear 185 psi- 185psi -190psi 190 psi

thanks God I think I have good compression numbers.

what you think guys ? next step put everything back together or there's more things to check before putting back the fuel pump relay and ignition coils?

thanks.

#34

Join Date: Feb 2013

Location: Trying to escape Central Florida

Posts: 4,636

Received 1,769 Likes

on

1,303 Posts

#35

update. i installed everything back together spark plugs torqued at 28nm, ignition coils and air intake air filter and fuel relay i started the car and now the engine sound very good I didn't rev up the engine the engine became smoother after the temperature raised up to the quarter on the gauge turned off the car after about 3 minutes .

I believe i did the job as it should but I lost the 2 bolts of the air intake

thanks a lot for you guys.

I believe i did the job as it should but I lost the 2 bolts of the air intake

thanks a lot for you guys.

#36

Join Date: Feb 2013

Location: Trying to escape Central Florida

Posts: 4,636

Received 1,769 Likes

on

1,303 Posts

#37

i did sand 2 of my ignition coils i was going to change it anyway with good used denso or new set from eBay which is for 90$ and comes with 100000 warranty but the engine now works fine and no much of vibration I think it's normal to have little vibration at cold start with old cars .

#38

Join Date: Feb 2013

Location: Trying to escape Central Florida

Posts: 4,636

Received 1,769 Likes

on

1,303 Posts

#39

maybe, I will check it next month. i noticed oil leakage from left side of the engine . the cam cover is leaking from the upper side I'm sure the the cam cover gasket have something wrong

#40

Join Date: Feb 2013

Location: Trying to escape Central Florida

Posts: 4,636

Received 1,769 Likes

on

1,303 Posts