Electric series 1 XJ6 project

#21

Carl I believe you are correct about the vacuum canister in the car not being big enough to provide vacuum for the brake booster. I think he is going to need a larger canister with larger hoses. The hoses on my canister are quite small compared to the hose going to the brake booster.

And yeah Roger is right, with no trans in the car, a gps speedo is the way to go here.

And yeah Roger is right, with no trans in the car, a gps speedo is the way to go here.

#22

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,231 Likes

on

939 Posts

The following 2 users liked this post by ronbros:

Roger Mabry (07-09-2017),

someguywithajag (08-20-2017)

#24

thanks for the tips regarding the vacuum system guys, I'll see how it turns out and add another reservoir if the pump can't keep up with my foot.

Ron, that's a sweet mustang - I'm going for a little more useable trunk space though I'm using a power steering pump from an Opel Astra, it seems to be a popular one for conversions

I'm using a power steering pump from an Opel Astra, it seems to be a popular one for conversions

Carl, most batteries up in the trunk, but I'm not going to let that 24 gallons worth of fuel tank space to go waste either... planning to keep the spare tire as well

I did make a little bit of progress today mounting the motor to the subframe. I've decided to try mounting the motor directly to the subframe. As the subframe bushings are rubber isolated, I'm hoping that this will be sufficient to mechanically isolate the two.

I've also decided on a method to mount the power steering pump and vacuum pump adjacent to the motor. This should take advantage of the motor's mechanical isolation via the subframe bushings and also by each pump's own bushings. I'm not the most seasoned hand at fabricating so this part is a little slow going unfortunately

Ron, that's a sweet mustang - I'm going for a little more useable trunk space though

I'm using a power steering pump from an Opel Astra, it seems to be a popular one for conversions

I'm using a power steering pump from an Opel Astra, it seems to be a popular one for conversionsCarl, most batteries up in the trunk, but I'm not going to let that 24 gallons worth of fuel tank space to go waste either... planning to keep the spare tire as well

I did make a little bit of progress today mounting the motor to the subframe. I've decided to try mounting the motor directly to the subframe. As the subframe bushings are rubber isolated, I'm hoping that this will be sufficient to mechanically isolate the two.

I've also decided on a method to mount the power steering pump and vacuum pump adjacent to the motor. This should take advantage of the motor's mechanical isolation via the subframe bushings and also by each pump's own bushings. I'm not the most seasoned hand at fabricating so this part is a little slow going unfortunately

#25

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

1. Cut, weld and grind. It can be frustrating, yet satisfying. In my past repetoire, an HF sourced power metal cutting band saw. An oxy acetylene torch set. A hand held grinder, also HF sourced. I've turned out some fairly decent parts.

2. You might have a look at the two piece drive shaft. It's alignment s critical. And, as your changes are considerable....

Carl

2. You might have a look at the two piece drive shaft. It's alignment s critical. And, as your changes are considerable....

Carl

#26

#27

#28

Thanks!

Batteries are going up front. Looks like I mis typed in haste up above, since the cells package in a nice brick shape, just like the engine bay, this should work out very nicely indeed. With the initial 24kW pack the front end will be pretty close to the weight of the six. The second pack ~90kW will even the weight out to be almost exactly the same as a fully fueled XJ12, so stock springs can keep the original ride quality and height

Batteries are going up front. Looks like I mis typed in haste up above, since the cells package in a nice brick shape, just like the engine bay, this should work out very nicely indeed. With the initial 24kW pack the front end will be pretty close to the weight of the six. The second pack ~90kW will even the weight out to be almost exactly the same as a fully fueled XJ12, so stock springs can keep the original ride quality and height

Last edited by Bry5on; 07-14-2017 at 09:33 AM.

#30

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

Aha, your fab skills are under stated ! Looking great.

However:

1. I hope your drivel line is now a one piece line sans the 'touchy" center U joint.

2. The front motor mount perplexed me a bit. I am not a mechanical engineer, or even close. But, triangulation came in to my lexicon early on. No evidence of it in the front mount. In view of the instant and high

torque inherent in motors as opposed to IC engines, it does need attention. Perhaps, a simple bar???

Carl

However:

1. I hope your drivel line is now a one piece line sans the 'touchy" center U joint.

2. The front motor mount perplexed me a bit. I am not a mechanical engineer, or even close. But, triangulation came in to my lexicon early on. No evidence of it in the front mount. In view of the instant and high

torque inherent in motors as opposed to IC engines, it does need attention. Perhaps, a simple bar???

Carl

#31

Aha, your fab skills are under stated ! Looking great.

However:

1. I hope your drivel line is now a one piece line sans the 'touchy" center U joint.

2. The front motor mount perplexed me a bit. I am not a mechanical engineer, or even close. But, triangulation came in to my lexicon early on. No evidence of it in the front mount. In view of the instant and high

torque inherent in motors as opposed to IC engines, it does need attention. Perhaps, a simple bar???

Carl

However:

1. I hope your drivel line is now a one piece line sans the 'touchy" center U joint.

2. The front motor mount perplexed me a bit. I am not a mechanical engineer, or even close. But, triangulation came in to my lexicon early on. No evidence of it in the front mount. In view of the instant and high

torque inherent in motors as opposed to IC engines, it does need attention. Perhaps, a simple bar???

Carl

Regarding the front motor mount - you picked up on a very good point

in order to be able to install the mount, I couldn't add a welded box section on the bottom. The lower extension will get a bolt in strengthening member (with under tray!) that ties into the lower side of the subframe via some blind rivnuts

in order to be able to install the mount, I couldn't add a welded box section on the bottom. The lower extension will get a bolt in strengthening member (with under tray!) that ties into the lower side of the subframe via some blind rivnutsAnd as promised, the mount installed with vacuum and power steering pumps

Last edited by Bry5on; 07-16-2017 at 11:39 AM.

#34

we'll see how the bracket holds up. Hopefully once it's fully tied in, and along with the rear mount, it should be plenty to withstand the torque.

Hydroboost could be doable, but the conversion is one less thing for me to worry about!

Today was a pretty light day - I started fabricating the under tray/lower support for the motor mount and I also wired up the fuel gauge

I did run into a snafu while I had the center console out to run the reverse trigger wire and remove the shift cable. I probed the reverse light switch to ensure it was getting a proper 12v signal and it was repeatably operational, as this switch is going to be what puts the car into reverse. I then soldered in and heat shrinked a splice off of the switched side to run into the motor inverter. After doing this and hooking everything up, I no longer have a 12v signal into the switch! O_o I looked through the fuse box, checked my wiring for shorts, but found neither a fuse nor a hard short.

Question: which fuse controls this wire and where is it located? It's the same hot wire that also goes to the PRND illumination light

Hydroboost could be doable, but the conversion is one less thing for me to worry about!

Today was a pretty light day - I started fabricating the under tray/lower support for the motor mount and I also wired up the fuel gauge

I did run into a snafu while I had the center console out to run the reverse trigger wire and remove the shift cable. I probed the reverse light switch to ensure it was getting a proper 12v signal and it was repeatably operational, as this switch is going to be what puts the car into reverse. I then soldered in and heat shrinked a splice off of the switched side to run into the motor inverter. After doing this and hooking everything up, I no longer have a 12v signal into the switch! O_o I looked through the fuse box, checked my wiring for shorts, but found neither a fuse nor a hard short.

Question: which fuse controls this wire and where is it located? It's the same hot wire that also goes to the PRND illumination light

#35

#36

Great ideas, both!

I hadn't considered a solar roof but you bet this thing has regenerative braking. The amount of regen is currently software selectable, in addition to there being an input on the inverter board for a brake pressure sensor. Presumably this can be set to provide regen proportional to disc brake effort, maybe even enough to remove the rear brake system entirely...

I wonder if anyone makes a sort of 'roll up' solar panel that I could stash in the trunk..

I hadn't considered a solar roof but you bet this thing has regenerative braking. The amount of regen is currently software selectable, in addition to there being an input on the inverter board for a brake pressure sensor. Presumably this can be set to provide regen proportional to disc brake effort, maybe even enough to remove the rear brake system entirely...

I wonder if anyone makes a sort of 'roll up' solar panel that I could stash in the trunk..

#37

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

#38

Roll up Solar Panels are a thing, available online or in Camping stores.

The idea of solar panels is poo-pood on the DIY electric car forum as not justifiable given the weight, wind resistence, complexity and 'minimal' output. possibly just to help charge the 12v battery but not really for range extension. I think a good system can output reasonable wattage and a roll up/ ultra thin panel could remove the wind resistance factor.

Its something i had considered for my project, either the roll up kind or i was thinking about making the trunk/ boot lid, front bonnet and guards out of fibreglass and inlaying individual solar cells to maximuse the use of space. Its currently at the bottom of the list under 'cool but time consuming/ impractical' ideas.

The idea of solar panels is poo-pood on the DIY electric car forum as not justifiable given the weight, wind resistence, complexity and 'minimal' output. possibly just to help charge the 12v battery but not really for range extension. I think a good system can output reasonable wattage and a roll up/ ultra thin panel could remove the wind resistance factor.

Its something i had considered for my project, either the roll up kind or i was thinking about making the trunk/ boot lid, front bonnet and guards out of fibreglass and inlaying individual solar cells to maximuse the use of space. Its currently at the bottom of the list under 'cool but time consuming/ impractical' ideas.

#39

#40

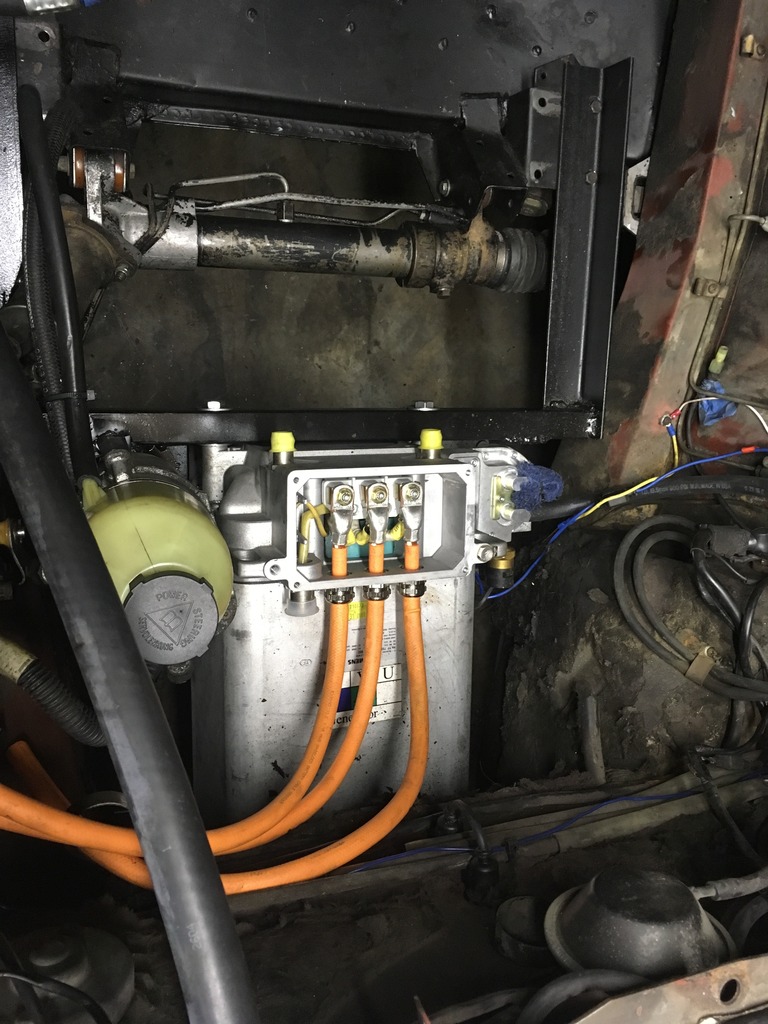

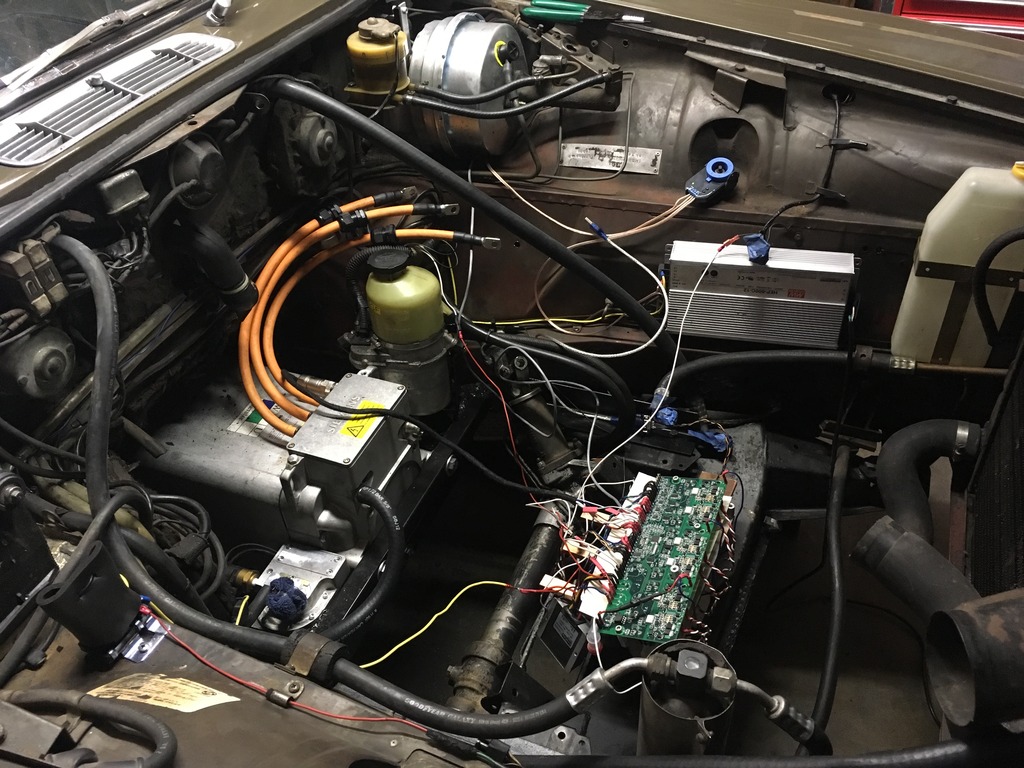

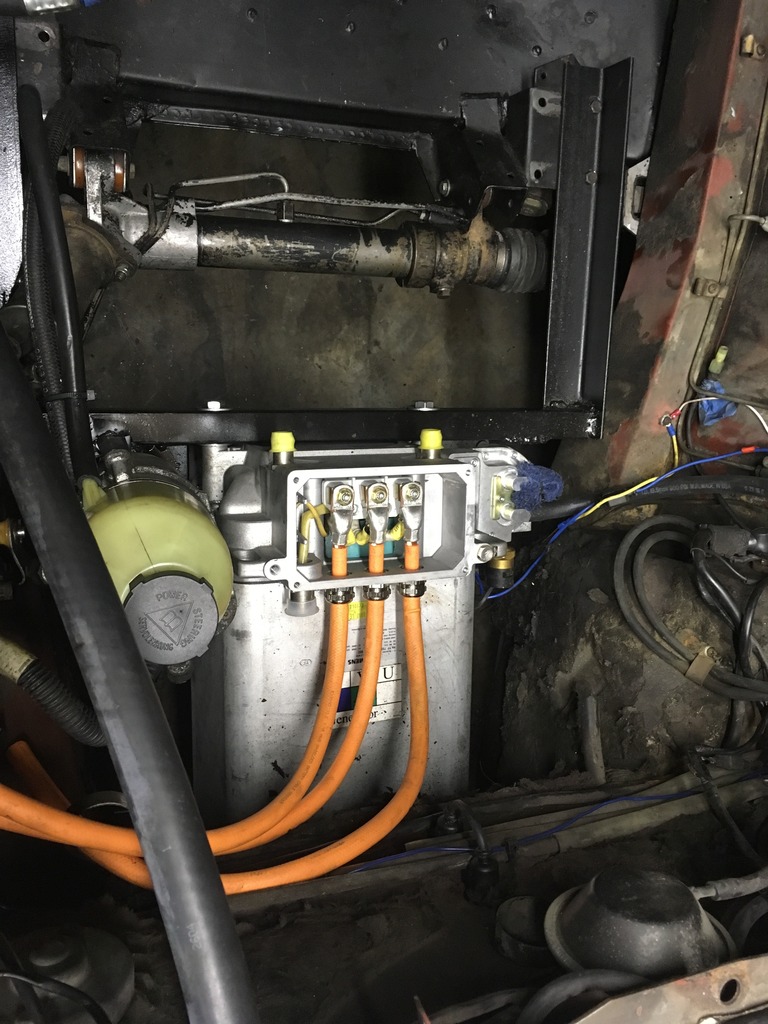

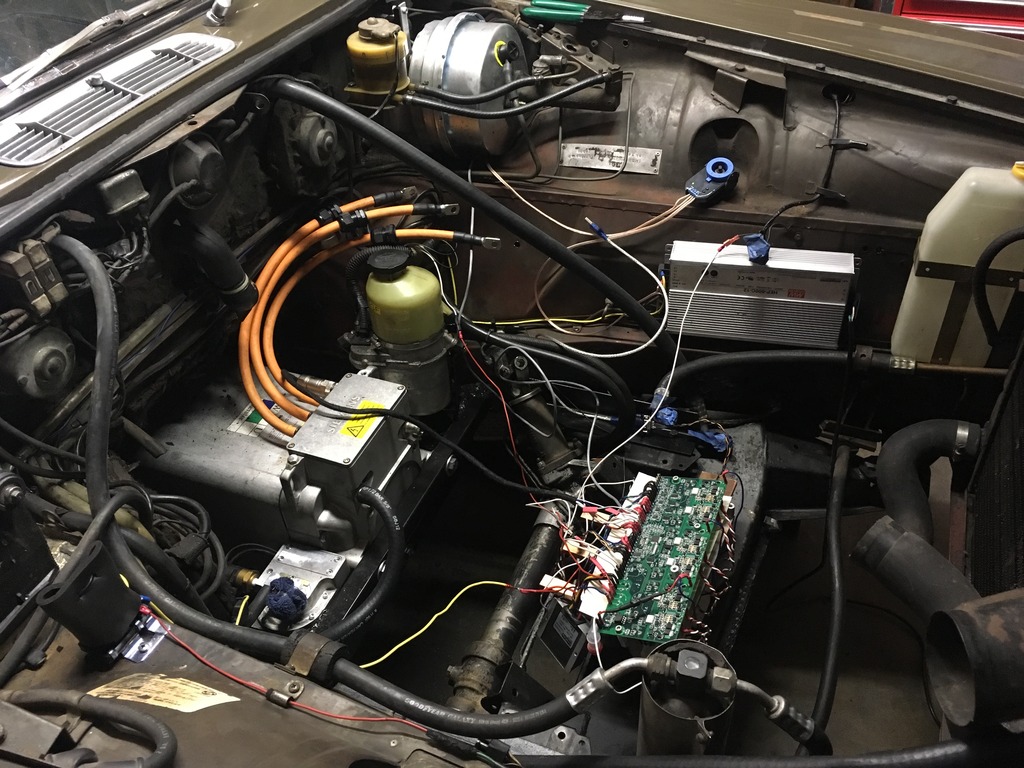

Progress! Lengthened driveshaft is in and fits like a glove. I've also got the inverter complete and started wiring it up to the car for testing without a high voltage DC bus. Here's a video showing the start sequence and what happens on the dash during that time:

and some photos to accompany the video

and some photos to accompany the video