HURRAY V12 valve riding problem solved

#1

Hi All,

Some readers may have been following my posts concerning a riding inlet valve on my Daimler Double Six. I have solved the problem. It was quite a conundrum and I was sufficiently surprised by the cause, I thought I would right a separate post describing it.

First the background. I am by no way an expert mechanic and I find the complexity of the V12 challenging.

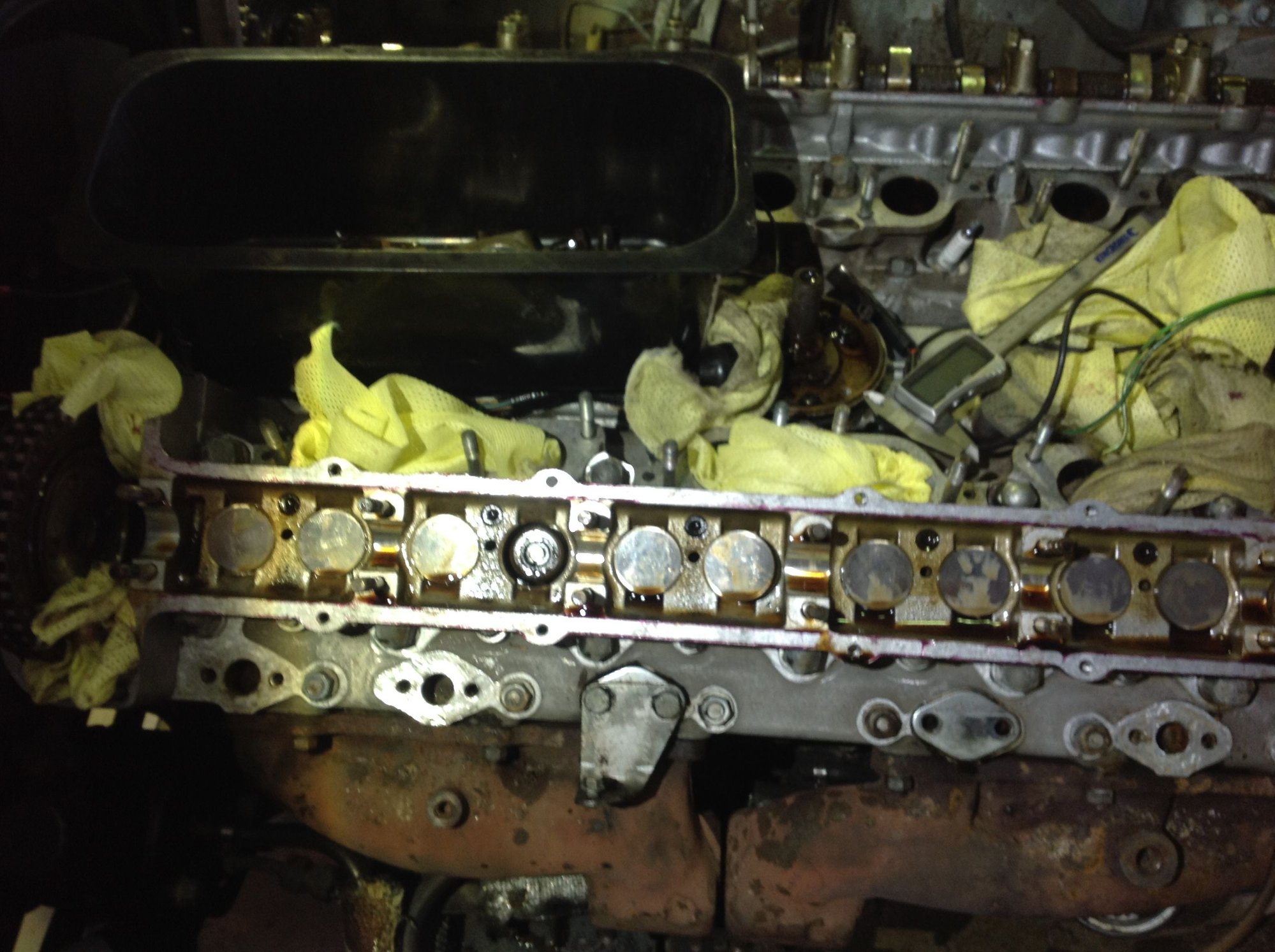

Bought as a barn find, the engine bay of the car was the most disgusting I have ever encountered. Strangely the rest of the car, both exterior and interior were totally original and in good condition.

The engine started promptly after a decade and a half of hibernation but ran poorly.

Compression test indicated low compression on LH no.2 cylinder.

After eventually burrowing down to remove the tappet covers a riding ( nil clearance) inlet valve was revealed. There was no question that it was riding as it's bucket was loaded and could not be rotated where all other buckets easily rotated with finger pressure.

Normally I would have simple assumed the riding valve to to be the result of a damaged (tuliped) valve or recessed valve seat, requiring the head removal and rectification. The fact that only one of the 24 was faulty and it was an inlet not exhaust made me suspicious and prevented me from attempting to tear the head off.

In general the overall condition of the cam gear looked good.

My desire to remove the head was low and I was in trepidation of removing the cam for fear of breaking the cam chain tension etc. I read everything available including the excellent Kirby Book.

A contributor, Grant Francis provided excellent advise regarding making a 'special' tool from a piece of wood to lightly tap down between the cam chain sprocket and the head casting to lock the chain in position.

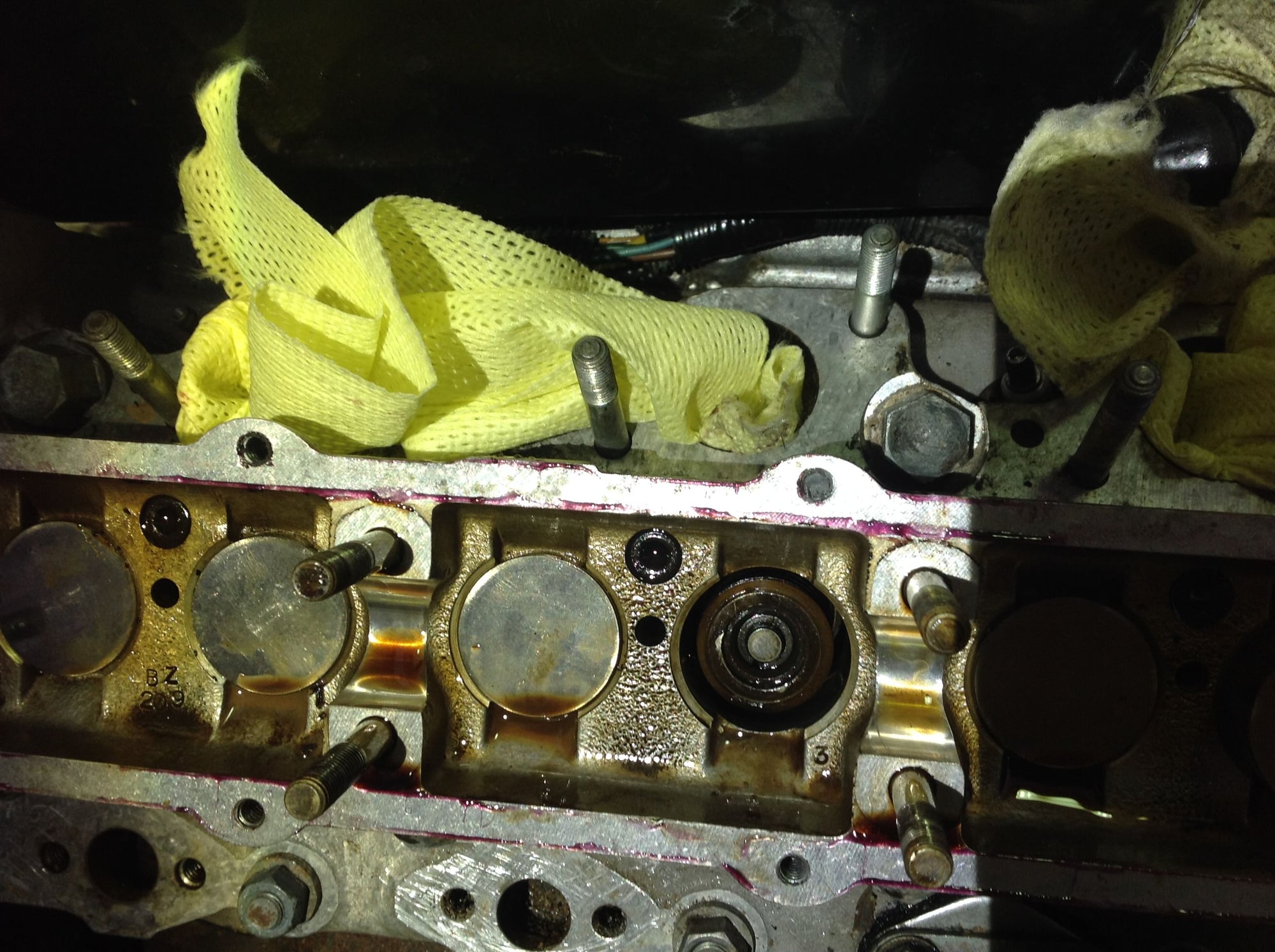

I very judiciously removed the left hand sprocket and hooked it onto it's little hanger.

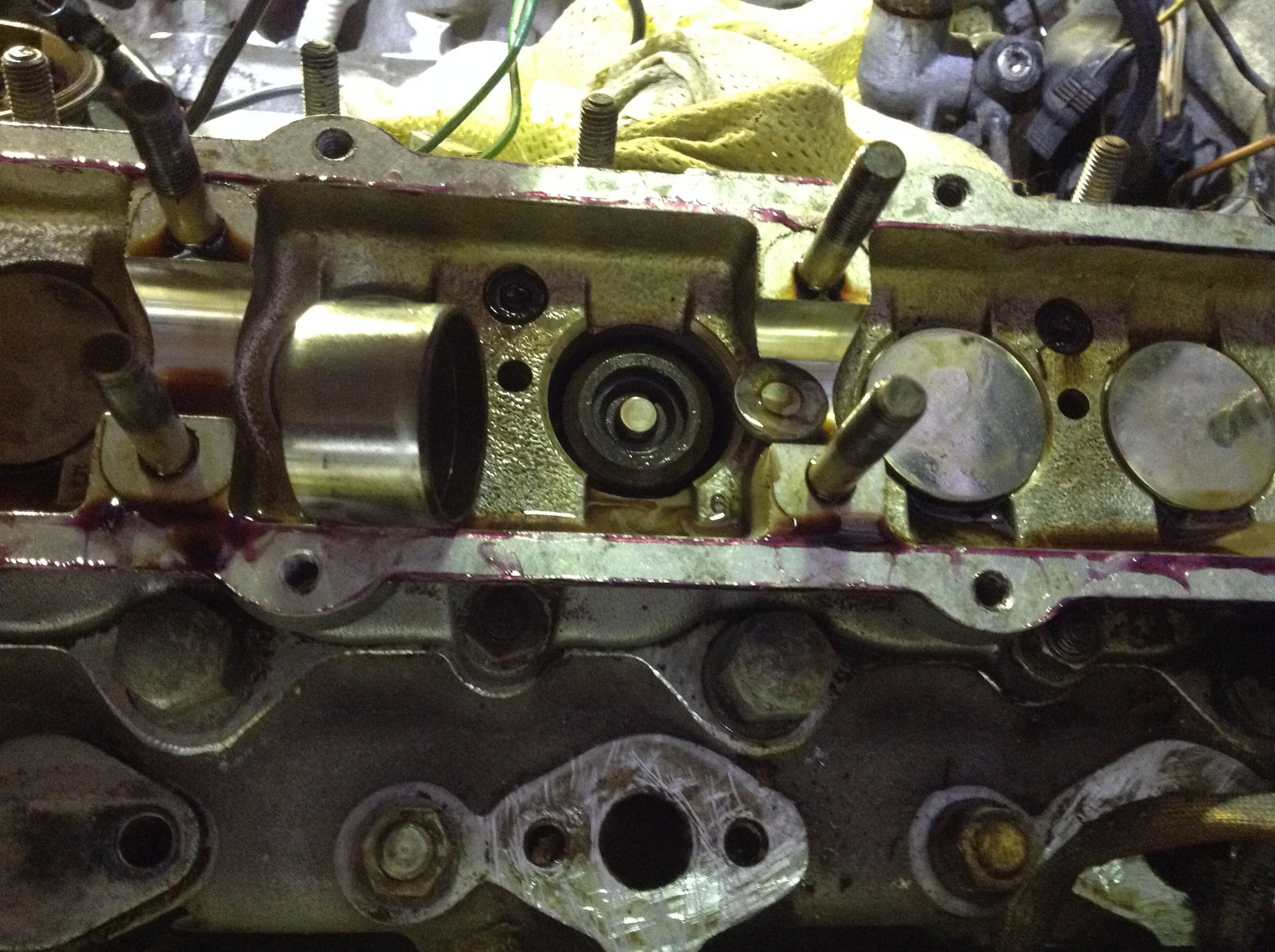

Instantly I noted the bucket on the offending valve was sitting very proud in the head compared to all the others. It appeared to be sitting about .075" above the head casting where the others were flush.

My journey of discovery continued, I carefully removed the bucket and for the first time actually viewed the much discussed shim. On a whim I replaced the shim and slid the bucket back home. To my surprise it smoothly slid all the way home to fit flush and identical to it's 11 other mates.

Hmm, what's going on here?. All I can assume is that the shim has somehow become misplaced and was not sitting in it's recess in the valve spring keeper. Experimentally I was able to reproduce the situation by purposefully incorrectly positioning the shim.

Questions! Could the shim have become misplaced in operation, perhaps by over-revving (seems unlikely with an automatic transmission)? Could the valve have been temporarily stuck open perhaps by injection of foreign matter allowing the shim to move? Could the motor have been incorrectly reassembled after some poor mechanical repairs twenty years ago and when failing to run correctly been abandoned as a bad loss? I don't know.

I measured all the shim thicknesses and was surprised by how even they were ( mostly around .095")

I determined to attempt to reassemble without touching the tensioner. Carefully I moved the sprocket back towards the camshaft and after a little jiggling and firm fingered pressure the sprocket snapped back over the end of the cam shaft. A win!

So that's it for now. I will keep the forum abreast of progress as I continue to reassemble, a rather slow process for a 'backyarder'

Regards all

Al

Some readers may have been following my posts concerning a riding inlet valve on my Daimler Double Six. I have solved the problem. It was quite a conundrum and I was sufficiently surprised by the cause, I thought I would right a separate post describing it.

First the background. I am by no way an expert mechanic and I find the complexity of the V12 challenging.

Bought as a barn find, the engine bay of the car was the most disgusting I have ever encountered. Strangely the rest of the car, both exterior and interior were totally original and in good condition.

The engine started promptly after a decade and a half of hibernation but ran poorly.

Compression test indicated low compression on LH no.2 cylinder.

After eventually burrowing down to remove the tappet covers a riding ( nil clearance) inlet valve was revealed. There was no question that it was riding as it's bucket was loaded and could not be rotated where all other buckets easily rotated with finger pressure.

Normally I would have simple assumed the riding valve to to be the result of a damaged (tuliped) valve or recessed valve seat, requiring the head removal and rectification. The fact that only one of the 24 was faulty and it was an inlet not exhaust made me suspicious and prevented me from attempting to tear the head off.

In general the overall condition of the cam gear looked good.

My desire to remove the head was low and I was in trepidation of removing the cam for fear of breaking the cam chain tension etc. I read everything available including the excellent Kirby Book.

A contributor, Grant Francis provided excellent advise regarding making a 'special' tool from a piece of wood to lightly tap down between the cam chain sprocket and the head casting to lock the chain in position.

I very judiciously removed the left hand sprocket and hooked it onto it's little hanger.

Instantly I noted the bucket on the offending valve was sitting very proud in the head compared to all the others. It appeared to be sitting about .075" above the head casting where the others were flush.

My journey of discovery continued, I carefully removed the bucket and for the first time actually viewed the much discussed shim. On a whim I replaced the shim and slid the bucket back home. To my surprise it smoothly slid all the way home to fit flush and identical to it's 11 other mates.

Hmm, what's going on here?. All I can assume is that the shim has somehow become misplaced and was not sitting in it's recess in the valve spring keeper. Experimentally I was able to reproduce the situation by purposefully incorrectly positioning the shim.

Questions! Could the shim have become misplaced in operation, perhaps by over-revving (seems unlikely with an automatic transmission)? Could the valve have been temporarily stuck open perhaps by injection of foreign matter allowing the shim to move? Could the motor have been incorrectly reassembled after some poor mechanical repairs twenty years ago and when failing to run correctly been abandoned as a bad loss? I don't know.

I measured all the shim thicknesses and was surprised by how even they were ( mostly around .095")

I determined to attempt to reassemble without touching the tensioner. Carefully I moved the sprocket back towards the camshaft and after a little jiggling and firm fingered pressure the sprocket snapped back over the end of the cam shaft. A win!

So that's it for now. I will keep the forum abreast of progress as I continue to reassemble, a rather slow process for a 'backyarder'

Regards all

Al

The following 2 users liked this post by Alan Lindsay:

Grant Francis (07-02-2018),

littlelic69 (07-11-2018)

#3

The following users liked this post:

Coventrywood (07-06-2018)

#4

Yes over revving can dislodge the shim, from the retainer. Kawasaki's KZ 900 used large shims, and they sat on the top of the bucket, and the cam rode directly on the shims. Occasionally when over revved they would spit a shim, out of place, and usually tear up the bucket , cam, head, etc. When they made the KZ 650, they used a small shim, that fit into a recessed area in the underside of the bucket, to eliminate the friction, of the cam rubbing on the shim, claiming that's what was the cause of spitting shims. It worked a little better, but every now and then, the KZ 650 would dislodge a shim for whatever reason, and usually did similar damage, with the exception of holding the valve open, and slamming it into a piston. But again only on a very rare occasion. Just a little insight into very high revving engines. I believe if memory serves me right the red line was 9000, and both would easily go past it. Thus the possibility of spitting a shim.

The following users liked this post:

ronbros (07-08-2018)

#5

hi Jacobra,

ahh, the mention of Kwaka 9s makes me go all misty for my lost youth. Always a pommie bike rider I had to respect the 900s. I spent my life playing catch up to them with my Trident though it was a lot better through the twisty bits.

i do remember those shims on top of the buckets and the tool that allowed you to change a shim with the cam in place.

I never recall a spat out shim and the motors were pretty bullet proof, great bikes

of course back in the late seventies I could only dream of owning a jag but I remember pretty good looking E Tyoes for sale for a few grand

al

ahh, the mention of Kwaka 9s makes me go all misty for my lost youth. Always a pommie bike rider I had to respect the 900s. I spent my life playing catch up to them with my Trident though it was a lot better through the twisty bits.

i do remember those shims on top of the buckets and the tool that allowed you to change a shim with the cam in place.

I never recall a spat out shim and the motors were pretty bullet proof, great bikes

of course back in the late seventies I could only dream of owning a jag but I remember pretty good looking E Tyoes for sale for a few grand

al

The following users liked this post:

89 Jacobra (07-02-2018)

#6

Well done Alan.

Also, the shim could have been dislodged at your fire up, as the Inlet valve may have had a small rust ridge, from sitting so long, and the valve wa a tad lazy returning to closed. Like you, dunno.

I would cover ALL those Inlet track holes, coz anything down there will have you removing the head/s no matter what.

Tag that tool. hire it out, make a $ or 2, HAHAHA>

Also, the shim could have been dislodged at your fire up, as the Inlet valve may have had a small rust ridge, from sitting so long, and the valve wa a tad lazy returning to closed. Like you, dunno.

I would cover ALL those Inlet track holes, coz anything down there will have you removing the head/s no matter what.

Tag that tool. hire it out, make a $ or 2, HAHAHA>

Thread

Thread Starter

Forum

Replies

Last Post

jagxkrtoofast

XK8 / XKR ( X100 )

164

09-30-2013 04:00 AM

Cadillac

Wheels / Tires, Suspension & handling

0

01-07-2011 05:17 AM

Innovative Detailing

Detailing / Car care

11

07-07-2010 03:13 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)