Series 2 clunks into reverse?

#1

My series 2 vdp has a series 3 borg warner box fitted as the original torque converter failed. Of late she shifts into reverse with a thump. Park to Drive is not as bad but still not perfectly smooth. I have changed fluid but still the same. If it's any help it doesn't clunk at all when wheels are off the ground. It's as smooth as silk when load is off the ground. Also when the level of fluid is less than the recommended level the changes are noticeably smoother? What could be up?

#3

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,743

Received 10,757 Likes

on

7,101 Posts

#4

#5

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

#6

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,743

Received 10,757 Likes

on

7,101 Posts

With age and miles a 'stack up' of free play/back lash can develop in the transmission, u-joints, and differential. When the transmission is put into gear this free play is suddenly taken up.....typically accompanied by a bit of a metallic clang or clank. This is more of a "I hear it" and less "I feel it" type of thing.

If the sensation is more of a clunk or thud, loose/broken trans mounts or subframe mounts are more likely. The sound would typically not have a clang quality. This would generally be "I feel it" more than "I hear it".

In this case there might be a transmission issue that causes the problem only going into reverse. Internal line pressures (or the like) creating a harsher-than-usual engagement. I don't have the expertise to do much more than speculate on that notion, though.

A u-joint that is worn enough to cause a clank or clang obviously has palpable free-pay and would almost certainly give other symptoms....a vibration while driving, specifically

Cheers

DD

If the sensation is more of a clunk or thud, loose/broken trans mounts or subframe mounts are more likely. The sound would typically not have a clang quality. This would generally be "I feel it" more than "I hear it".

In this case there might be a transmission issue that causes the problem only going into reverse. Internal line pressures (or the like) creating a harsher-than-usual engagement. I don't have the expertise to do much more than speculate on that notion, though.

A u-joint that is worn enough to cause a clank or clang obviously has palpable free-pay and would almost certainly give other symptoms....a vibration while driving, specifically

Cheers

DD

#7

Yes it's more of a thump that you feel as opposed to a clang. Horrible sensation as though I'm doing the old girl harm....so I tend to not use reverse much now. I'll investigate further. I hope it's not a transmission out job. It's only just after getting a refurbished series 3 box. I don't want to go thru all this again...thanks so much folks advice much appreciated as usual.

Trending Topics

#8

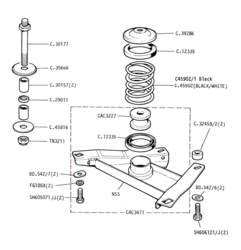

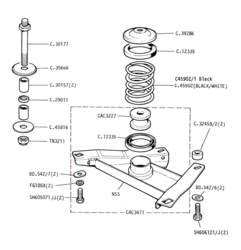

Whilst you are getting involved in all these suggestions add these to the list:

1) The "kickdown" cable is too tight. This WILL affect select line pressure, and it may be that the installing people did not adjust this correctly, as it is a MONGREL task to do.

2) The transmission rear mount is incorrectly assembled, it is a specific procedure, and also may have bits left out, which uninformed mechanics can do.

This parts drawing wil help understand what is what here.

Part # C29011 is usually missing, or fitted where it dont belong.

Part # CAC3227 is the rubber mounting bush, often referred to as the "cotton reel" bush. They wear outm crumble, dissolve in oil, etc.

Since this has only appeared since the trans change, I reckon the first suggestion is the easiest, then move on to the mount.

1) The "kickdown" cable is too tight. This WILL affect select line pressure, and it may be that the installing people did not adjust this correctly, as it is a MONGREL task to do.

2) The transmission rear mount is incorrectly assembled, it is a specific procedure, and also may have bits left out, which uninformed mechanics can do.

This parts drawing wil help understand what is what here.

Part # C29011 is usually missing, or fitted where it dont belong.

Part # CAC3227 is the rubber mounting bush, often referred to as the "cotton reel" bush. They wear outm crumble, dissolve in oil, etc.

Since this has only appeared since the trans change, I reckon the first suggestion is the easiest, then move on to the mount.

#9

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,743

Received 10,757 Likes

on

7,101 Posts

2) The transmission rear mount is incorrectly assembled, it is a specific procedure, and also may have bits left out, which uninformed mechanics can do.

This parts drawing wil help understand what is what here.

Attachment 144648

This parts drawing wil help understand what is what here.

Attachment 144648

Since the trans came from a Series III I wonder if the mounts came from a Series III as well? Probably no reason to do so, but....?

The Series III mounting system is even more convoluted and the parts can be assembled upside down. Ask me how I know.

Cheers

DD

The following users liked this post:

Grant Francis (03-26-2017)

#10

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,743

Received 10,757 Likes

on

7,101 Posts

Frustrating, yes.

There are actually 2 settings to look at/adjust.

The cable actuates a cam inside the transmission. The cam, in turns, moves a valve. The cam and valve must be in the correct position as a base setting, so to speak. This is something normally considered when the detent cable is replaced and/or when the transmission is assembled.

The final adjustment is by the cable and technically should be done with a pressure gauge. However, the ROM shows a physical measurement at the cable which gets you in the ballpark with some experimenting to follow....since nobody except professionals has a trans pressure gauge.

In practice the experimentation method works OK but is nerve jangling because inadvertently going outside the permissible pressure range can mean serious transmission problems. Make just tiny adjustments....like 1/4 turn at a time...and don't go more than a total of maybe 3/4 turn in either direction. Those are my guidelines, not official ones! The adjustment process itself is tricky due to the location of the cable at the throttle body.

Cheers

DD

The following users liked this post:

Grant Francis (03-26-2017)

#11

#12

The following users liked this post:

Grant Francis (03-29-2017)