so has anyone actually made 500bhp from a v12 pre.he

#481

if you are going to manufacture new cylinder heads , then i would put the injector exactly where it should be(in the combustion chamber,direct injection)!

go big or go home.

also my opinion, multi TBs, are far more tuning problems than two large single TB.

but they do look kool, but so doesn't a supercharger/turbo system!

i have said this before, a modern 4cylinder turbo engine can make great performance/power, and much lighter weight, probably 400lbs less weight over the front wheels. just dont brag about your engine,LOL.

but if pure power and great fuel MPG where important,

my dream choice would still be a AUDI V12 diesel,comes from factory with twin turbochargers, direct injection, light weight(compared to Jag V12)etc.

without taking engine apart, just reprogram computer, redo piping with large intercoolers, use a built GM 4L80E with 6 speed kit!

i'm betting 30mpg would be possible.

now the important part,, 650hp, 800lbs ft.at 1900 rpm, carried to 4000rpm ,would make a great street vehicle, 4000rpm in overdrive,with 2.88 rear would come around 150 mph, but passing accel. would be staggering at 40-120mph!

that with a nice smooth V12 engine mind you!

sorry i'm out of the box AGAIN! LOL.

go big or go home.

also my opinion, multi TBs, are far more tuning problems than two large single TB.

but they do look kool, but so doesn't a supercharger/turbo system!

i have said this before, a modern 4cylinder turbo engine can make great performance/power, and much lighter weight, probably 400lbs less weight over the front wheels. just dont brag about your engine,LOL.

but if pure power and great fuel MPG where important,

my dream choice would still be a AUDI V12 diesel,comes from factory with twin turbochargers, direct injection, light weight(compared to Jag V12)etc.

without taking engine apart, just reprogram computer, redo piping with large intercoolers, use a built GM 4L80E with 6 speed kit!

i'm betting 30mpg would be possible.

now the important part,, 650hp, 800lbs ft.at 1900 rpm, carried to 4000rpm ,would make a great street vehicle, 4000rpm in overdrive,with 2.88 rear would come around 150 mph, but passing accel. would be staggering at 40-120mph!

that with a nice smooth V12 engine mind you!

sorry i'm out of the box AGAIN! LOL.

The following users liked this post:

ronbros (10-29-2015)

#482

reading on the aj6 website. with 6.5 liters 500hp shouldn't be terrible hard. its 75hp a liter. the heads flow incredibly. six intake ports and if you look down them the lack of restriction at .440 lift is a ton. with the oversized liners and broadspeed style pistons. itll have a quench around the right spot.

not to mention, I go to school for engineering, and in an.ideal cylinder has a flat head and the combustion chamber souly in the piston.

not to mention, I go to school for engineering, and in an.ideal cylinder has a flat head and the combustion chamber souly in the piston.

The combustion chambers weren't any problem, and although the engine had super light specially made rods and pistons, the biggest part of everything, were the cams, which you can have reground, if you find the profile somewhere on the net, and their extreme attention to balancing.

The balancing cost around $6000 per engine. If you can assume that the factory crank is fairly well balanced, then all you really need is a gram scale, to balance the piston and rod assemblies within 1 gram, or zero, if you try real hard. Shaving the heads down would be a given. For saying those engines survived what they were put through, I wouldn't be afraid to put a high compression, rumpety rump cammed, and high pressure fuel and large injector V12 out on the street. I'm sure she would turn some heads, at any Jag meet.

I worked on the banned Unfair Advantage Audi Team, so listen to the engineers on this post, of which I am not(just a master tech), and realize that there is a lot of money and work to push that much HP out of a low compression, smogged V12.

I love challenges, and wouldn't hesitate to build an engine. Just keep the one in your car, so you don't turn it into some $300 project for someone else......Best of Luck........Mike

The following 2 users liked this post by mrplow58:

Jonathan-W (10-30-2015),

ronbros (10-29-2015)

#483

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

hey mrplow58, was the Audi car the R-10 diesel racer?

i seen it race at Road America,back in 2007, it won just lazily cruising along!

comin of the 1st to main straight, it would pull away from the 10,000rpm Porsches(Penske cars), like they were standing still, and only turning 4500-5000 rpm.

YUP! they banned them from there on,(lot of politics involved,somebody had some serious push),wonder who?

they started by putting major restrictions on the cars, like choking down the air inlets, then adding big weight amounts, and final BS was reducing the size of the fuel tanks, while petrol was 20% larger, and alcohol greeny cars were almost unlimited!

can you see the politics in the situation.LOL.

i seen it race at Road America,back in 2007, it won just lazily cruising along!

comin of the 1st to main straight, it would pull away from the 10,000rpm Porsches(Penske cars), like they were standing still, and only turning 4500-5000 rpm.

YUP! they banned them from there on,(lot of politics involved,somebody had some serious push),wonder who?

they started by putting major restrictions on the cars, like choking down the air inlets, then adding big weight amounts, and final BS was reducing the size of the fuel tanks, while petrol was 20% larger, and alcohol greeny cars were almost unlimited!

can you see the politics in the situation.LOL.

Last edited by ronbros; 10-30-2015 at 12:35 PM.

The following users liked this post:

Jonathan-W (10-30-2015)

#484

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

to add, the Audi diesel cars(2009), Daytona/Rolex 24, hauler trucks stopped by the track on way to Sebring, wanted to unload and do some practice laps or just show them!

no such luck, were told dont even open the doors, dont need no stinkin diesels!

right then and there i knew i wanted one of those engines, they were only 5.5L, the street version was 6L, now i hear they stopped making any new ones,DARN!

that will push prices thru the roof!

no such luck, were told dont even open the doors, dont need no stinkin diesels!

right then and there i knew i wanted one of those engines, they were only 5.5L, the street version was 6L, now i hear they stopped making any new ones,DARN!

that will push prices thru the roof!

#485

#488

hey mrplow58, was the Audi car the R-10 diesel racer?

i seen it race at Road America,back in 2007, it won just lazily cruising along!

comin of the 1st to main straight, it would pull away from the 10,000rpm Porsches(Penske cars), like they were standing still, and only turning 4500-5000 rpm.

YUP! they banned them from there on,(lot of politics involved,somebody had some serious push),wonder who?

they started by putting major restrictions on the cars, like choking down the air inlets, then adding big weight amounts, and final BS was reducing the size of the fuel tanks, while petrol was 20% larger, and alcohol greeny cars were almost unlimited!

can you see the politics in the situation.LOL.

i seen it race at Road America,back in 2007, it won just lazily cruising along!

comin of the 1st to main straight, it would pull away from the 10,000rpm Porsches(Penske cars), like they were standing still, and only turning 4500-5000 rpm.

YUP! they banned them from there on,(lot of politics involved,somebody had some serious push),wonder who?

they started by putting major restrictions on the cars, like choking down the air inlets, then adding big weight amounts, and final BS was reducing the size of the fuel tanks, while petrol was 20% larger, and alcohol greeny cars were almost unlimited!

can you see the politics in the situation.LOL.

I think we won 8 out of 11 races, just because we weren't burning our tires up. During the season, they added weight to our car, made our turbo inlet smaller, fuel cell smaller and even made our tires narrower, which turned out to be an advantage, because we weren't putting added stress on our drivetrain. We didn't finish a couple of races, because of breakage, but after they made our tires narrower, that wasn't a problem. Making our fuel cell smaller wasn't a real problem, because we were killing the other teams with fuel mileage anyway.

Strangely enough, the rules were changed, so we could no longer be competitive. The first thing they did was eliminate the all wheel drive, and made a minimum weight we would need to be. GM and Ford got what they wanted. Instead of building better cars, they eliminated us with the rule book. There is a short film somewhere called the unfair advantage. I was the guy with a pony tail, and 2 hearing aids. It was fun kicking the big guys asses though......Be cool....Mike

Last edited by mrplow58; 10-30-2015 at 03:34 PM.

The following 2 users liked this post by mrplow58:

Dave1109971 (10-30-2015),

ronbros (10-30-2015)

#490

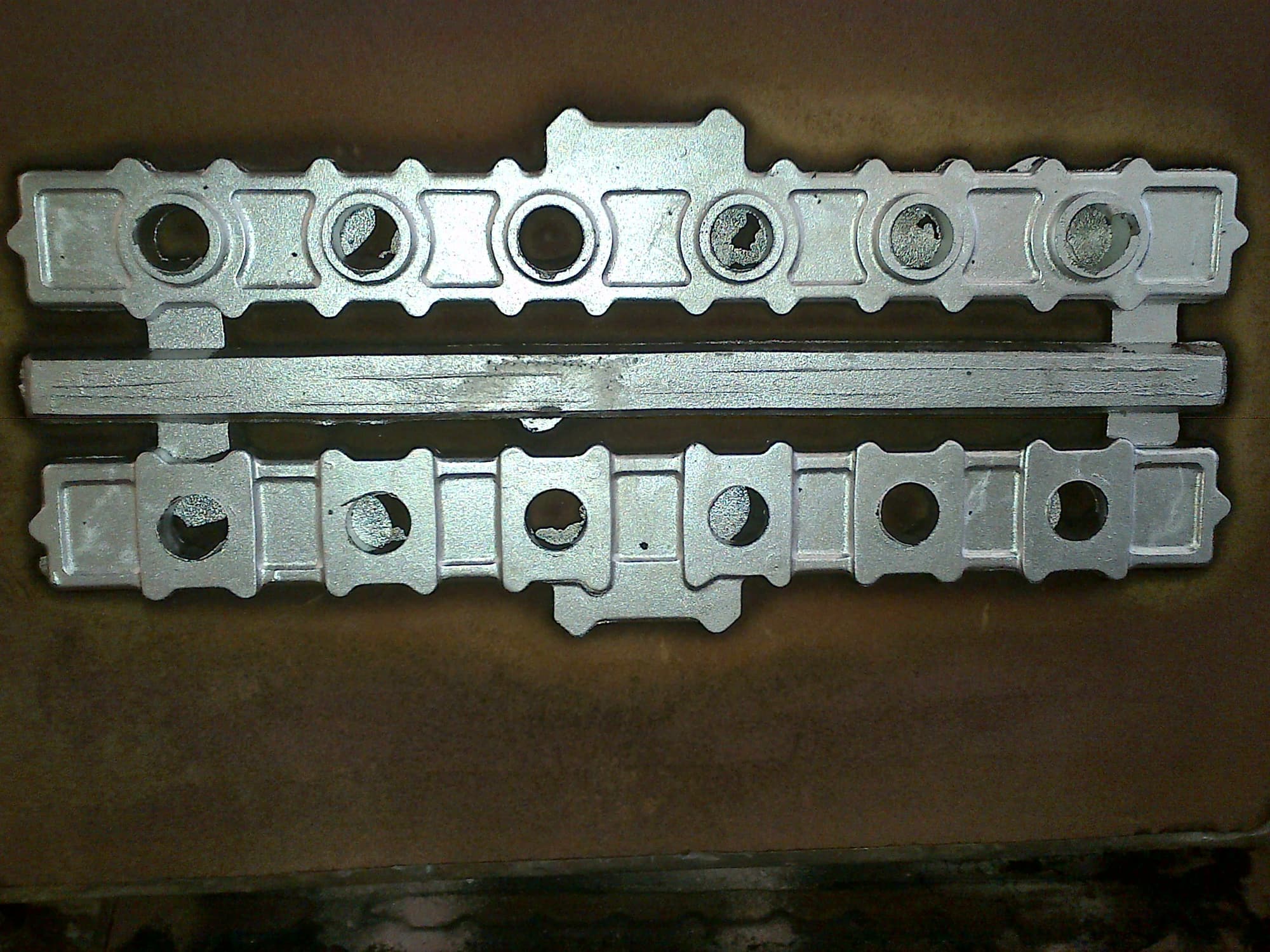

Group C sliders are for Group C engines; Cam carriers are likely to go to Germany where a machine shop owner we know already has a CNC program to machine these babys from billet! The casting will therefore be easy, Cam covers to be done in Mag shortly and in ali maybe in a weeks time.

The TWR Group A manifolds have exceeded our expectations I must say.

The TWR Group A manifolds have exceeded our expectations I must say.

The following users liked this post:

ronbros (10-31-2015)

#491

Hey xjr5006, I am new to this board, but I have a 6.0 NOS crate motor that I want to stroke to 84mm. How do I contact you for more information about the items below? My number is 512/468-3436 (Texas USA)

The 'batch order' is already with the manufacturer; I have available from stock:-

1 x 84mm 2.3 on rope seal (dyno time only )

1 x new group 44 7L crank 2.1 old style back (will have to check if its rope or chevy split lip)

1 x 84mm 2.1 but cut undersize on 1 BE Journal on 110 Lip, so build up that jopurnal or cut them all or have all cut to 2.0 for use with 2 or 2.1 rods with the correct bearings

1 x TWR XJR6 crank + rods + pistons complete + liners good used on 100 lip

1 x set new Gp 44 6.5L pistons

1 x set dyno time 6.5L as above. Both sets can do 7L with top deck machining but not if you are using .6 or .54 cams.

XJRS new cosworth piston set

XJR15 new cosworth piston set

TWR Gp A used cosworth piston set.

New original Gp 44 slide throttles

New TWR throttle sliders if you have deep enough pockets

GP 44 inlets for webers/ throttle bodies (2 inlet ID's)

TWR fabricated versions of the above

XJR7 mag dry sumps

GP 44 Mag belhousing

Kit of all the special parts for XJR7 front end, pulley tensioner water pump all the special parts to go with std weaver pump part including pump shafts.

PM if you are seriously interested; these are all serious parts,

1 x 84mm 2.3 on rope seal (dyno time only )

1 x new group 44 7L crank 2.1 old style back (will have to check if its rope or chevy split lip)

1 x 84mm 2.1 but cut undersize on 1 BE Journal on 110 Lip, so build up that jopurnal or cut them all or have all cut to 2.0 for use with 2 or 2.1 rods with the correct bearings

1 x TWR XJR6 crank + rods + pistons complete + liners good used on 100 lip

1 x set new Gp 44 6.5L pistons

1 x set dyno time 6.5L as above. Both sets can do 7L with top deck machining but not if you are using .6 or .54 cams.

XJRS new cosworth piston set

XJR15 new cosworth piston set

TWR Gp A used cosworth piston set.

New original Gp 44 slide throttles

New TWR throttle sliders if you have deep enough pockets

GP 44 inlets for webers/ throttle bodies (2 inlet ID's)

TWR fabricated versions of the above

XJR7 mag dry sumps

GP 44 Mag belhousing

Kit of all the special parts for XJR7 front end, pulley tensioner water pump all the special parts to go with std weaver pump part including pump shafts.

PM if you are seriously interested; these are all serious parts,

#492

#493

Nikolay,

I'm not sure if you are referring to the overall process, or, to the manner in which he is weighing the rod.

That is part of the process involved with "balancing your engine", which, more correctly, is actually the act of balancing your rotating assembly.

These photos seem to show that he is trying to isolate & weigh just the small end of the rod, in order to accurately and individually match the weight distribution of the small end, big end, and shaft of each rod.

The purpose is to make your engine smoother, and it also allows it to rev a bit higher, because all the parts that move quickly are now lighter, and, nothing is out of balance.

The basic process for your connecting rods, and pistons is:

1). weigh, and number each one, and you write down that rod's, or, piston's weight.

2). find the lightest piston and rod of the group

3). use a grinder, file, etc. to take weight off every other piston and rod, until their weight matches the weight of the lightest ones.

I seem to remember xjr5006 posting a series of photos showing the best places to remove weight from the rods. Those photos may even be somewhere in this thread.

At an advanced level, an experienced enthusiast/mechanic may first remove even more weight from the lightest rod and piston in the group, and then making the others match this new lower weight.

Note: be sure to only grind & file the weight from non-stressed areas of the rods and pistons. The best places to start are the seams, and counterweight areas. Knowing when "enough is enough" is the key here. You don't want to compromise the strength of these highly stressed components.

Rods:

Pistons:

The crankshaft should also be balanced, but, that is best handled by a machine shop.

I'm not sure if you are referring to the overall process, or, to the manner in which he is weighing the rod.

That is part of the process involved with "balancing your engine", which, more correctly, is actually the act of balancing your rotating assembly.

These photos seem to show that he is trying to isolate & weigh just the small end of the rod, in order to accurately and individually match the weight distribution of the small end, big end, and shaft of each rod.

The purpose is to make your engine smoother, and it also allows it to rev a bit higher, because all the parts that move quickly are now lighter, and, nothing is out of balance.

The basic process for your connecting rods, and pistons is:

1). weigh, and number each one, and you write down that rod's, or, piston's weight.

2). find the lightest piston and rod of the group

3). use a grinder, file, etc. to take weight off every other piston and rod, until their weight matches the weight of the lightest ones.

I seem to remember xjr5006 posting a series of photos showing the best places to remove weight from the rods. Those photos may even be somewhere in this thread.

At an advanced level, an experienced enthusiast/mechanic may first remove even more weight from the lightest rod and piston in the group, and then making the others match this new lower weight.

Note: be sure to only grind & file the weight from non-stressed areas of the rods and pistons. The best places to start are the seams, and counterweight areas. Knowing when "enough is enough" is the key here. You don't want to compromise the strength of these highly stressed components.

Rods:

Pistons:

The crankshaft should also be balanced, but, that is best handled by a machine shop.

Last edited by JagZilla; 11-12-2015 at 11:05 AM.

#495

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,236 Likes

on

943 Posts

The following users liked this post:

xjsv12 (11-12-2015)

#496

Thanks to all.

I thinking to rebuild my X300s 6.0, and collect information about performance parts and labor.

What i have -

very tired engine, one item

full gasket kit, included O rings, many items

XJR6 pistons (dimensions are the same only diameter is bigger 91mm, it will be 6.1L), twelve item

And long winter ahead ,more then three month

I think this is better thread for my little posting and questions to experienced enthusiasts, like you all.

I thinking to rebuild my X300s 6.0, and collect information about performance parts and labor.

What i have -

very tired engine, one item

full gasket kit, included O rings, many items

XJR6 pistons (dimensions are the same only diameter is bigger 91mm, it will be 6.1L), twelve item

And long winter ahead ,more then three month

I think this is better thread for my little posting and questions to experienced enthusiasts, like you all.

#497

I dont know if the XJR6 pistons will work, 91mm will with std liners bored out but never heard of anyone doing it. 92mm yes but not 91mm. I would get a piston and use the 1 wrist pin though 1/2 of both to check deck height before getting 12 of these. If all is good then try for +40 to get 92mm A little bit more power for no more money.

Wondering why you are not considering re -using the original pistons? A very much cheaper option. If the reason for going 91 was also to get better compression ratio consider just getting higher comp pistons.

The best performance increase you can get would be buy buying a load of flap wheels and opening the inlet ports out to the gasket blending them in as far as the valve guide, dont even have to take the heads off to do this. The later heads are pretty dreadful in this area, you will see what I mean when you take the inlet manifolds off. From memory the gasket is 35mm and your ports 10mm down could be as small as 30mm. Doing this is actually a very straightforward DIY job, 30 and 35mm flap wheels and a good drill, I have done an engine in 4 hours so allow yourself a days work. Suck the rubbish out with a vacuum cleaner. but turn the engine over to make sure the valve is closed before you start. Headers are good value as the cast iron jobbys are very poor.

If you want value for money re ring the std pistons, do the flap wheel job and invest in a decent set of headers. If you want to go further then add on better inlets (like mine, LoL) Good Luck.

BTW tired engine? enlighten us more, these engines at 100,000 will still have cross hatching visible down the bores,

Wondering why you are not considering re -using the original pistons? A very much cheaper option. If the reason for going 91 was also to get better compression ratio consider just getting higher comp pistons.

The best performance increase you can get would be buy buying a load of flap wheels and opening the inlet ports out to the gasket blending them in as far as the valve guide, dont even have to take the heads off to do this. The later heads are pretty dreadful in this area, you will see what I mean when you take the inlet manifolds off. From memory the gasket is 35mm and your ports 10mm down could be as small as 30mm. Doing this is actually a very straightforward DIY job, 30 and 35mm flap wheels and a good drill, I have done an engine in 4 hours so allow yourself a days work. Suck the rubbish out with a vacuum cleaner. but turn the engine over to make sure the valve is closed before you start. Headers are good value as the cast iron jobbys are very poor.

If you want value for money re ring the std pistons, do the flap wheel job and invest in a decent set of headers. If you want to go further then add on better inlets (like mine, LoL) Good Luck.

BTW tired engine? enlighten us more, these engines at 100,000 will still have cross hatching visible down the bores,

Last edited by xjr5006; 11-12-2015 at 10:04 PM.

#498

I've seen these for sale in the UK.. Not a bad price?

Jaguar XJ V12 Exhaust Manifold and Jaguar XJ V12 Exhaust Headers

My assumption is that ceramic coating these would do wonders for the under hood temps. Anyone got any other stainless header suppliers?

Jaguar XJ V12 Exhaust Manifold and Jaguar XJ V12 Exhaust Headers

My assumption is that ceramic coating these would do wonders for the under hood temps. Anyone got any other stainless header suppliers?

#499

Maybe, maybe not - or could be a waste of money? Roger Bywater states the following & I for one don't have sufficient knowledge to bet against him:

2. Can you supply multi-branch exhaust manifolds for my Jaguar V12?

Well we could - but the trouble is that there isn't enough space to install pipes of the right dimensions to work properly. If the dimensions are wrong then the system can actually have a negative effect. There is virtually no overlap of exhaust pulses into the cast three-into-one manifolds of the V12 (and 6 cylinder engines) so replacing them with separate pipes doesn't reap much improvement for the cost and trouble involved. As the TT system keeps each group of three separate for a considerable distance it provides the most viable solution.

Rgds.

A.

2. Can you supply multi-branch exhaust manifolds for my Jaguar V12?

Well we could - but the trouble is that there isn't enough space to install pipes of the right dimensions to work properly. If the dimensions are wrong then the system can actually have a negative effect. There is virtually no overlap of exhaust pulses into the cast three-into-one manifolds of the V12 (and 6 cylinder engines) so replacing them with separate pipes doesn't reap much improvement for the cost and trouble involved. As the TT system keeps each group of three separate for a considerable distance it provides the most viable solution.

Rgds.

A.

#500

The other benefits of course would be a hefty weight saving along with better heat dissipation.