Group buy: 2pc wortec rotors for steel super brakes on f-type

#22

#25

Someone should call Paul at Wortec and get all the technical details out in the open, direct from the horses mouth, before we all commit a few US grand to something that may not be entirely as represented.

I am far from being the brake rotor expert to be asking technical questions...

#26

I quite like this guy's engineering explanations of a lot of things 'automotive'.

His explanation, as I remember, is that drilled rotors are just not good from any perspective, and the justification for slotted is dubious as the outgassing of pad material is no longer an issue with modern pads.

Which leaves boring old plain rotors....that don't look cool....

#27

https://www.youtube.com/watch?v=78wbht355R8

I quite like this guy's engineering explanations of a lot of things 'automotive'.

His explanation, as I remember, is that drilled rotors are just not good from any perspective, and the justification for slotted is dubious as the outgassing of pad material is no longer an issue with modern pads.

Which leaves boring old plain rotors....that don't look cool....

I quite like this guy's engineering explanations of a lot of things 'automotive'.

His explanation, as I remember, is that drilled rotors are just not good from any perspective, and the justification for slotted is dubious as the outgassing of pad material is no longer an issue with modern pads.

Which leaves boring old plain rotors....that don't look cool....

Having owned a lot of cars with drilled rotors, the cars that had Brembo or OEM drilled rotors never gave me issues, not even after heavy track duty.

Pretty much every Porsche has drilled rotors, on my 911 I had drilled rotors and put them through around ten hard track days with some serious punishment and abuse, did my rotors crack, fail or disintegrate, nope they were fine.

The only one time ever drilled rotors gave me an issue was on some cheap EBC rotors, the issue is not the drilling, but the quality of manufacturing.

Wortec have a strong reputation and cars competing in proper racing series on their drilled rotors, they don't have issues.

Road driving, even hard and fast canyon driving does not even come close to track driving, so whether they are drilled, grooved, blank is never going to be an issue for anyone here buying quality disc.

If your after disc for proper racing and are competing, drop Paul an email he can confirm to you directly what you need because like I say the UK is a small island with 100's of race tracks, we drive our cars very hard here and do track days pretty much monthly, Wortec seem a solid choice and are on small light race cars and then on big heavy cars doing track days like R35 GTR, BMW M4, Mustang and the Wortec drilled rotors show no sign of weakness after several hours of hard track driving.

So Paul can definetely advice you, also remember they are using different stronger more heat efficient materials and then the 12hr bake and 12hr cool down is something pretty much no other brake manufacturer does.

Not all brake rotors are made equal and its fair to say Wortec are the best, but its also why they are not the cheapest.

If you want absolute best braking performance, normally just blank and vented is best.

As my car is a road car, albeit driven hard and the F-Type will do just 1-2 track days per year, I am just going to go with drilled as I know they will be absolutely fine, but look awesome.

Last edited by Gibbo205; 03-01-2018 at 02:51 PM.

#28

Unless I am misreading the explanation, these are drilled after the tempering, not before...

Someone should call Paul at Wortec and get all the technical details out in the open, direct from the horses mouth, before we all commit a few US grand to something that may not be entirely as represented.

I am far from being the brake rotor expert to be asking technical questions...

Someone should call Paul at Wortec and get all the technical details out in the open, direct from the horses mouth, before we all commit a few US grand to something that may not be entirely as represented.

I am far from being the brake rotor expert to be asking technical questions...

)

)https://www.youtube.com/watch?v=78wbht355R8

I quite like this guy's engineering explanations of a lot of things 'automotive'.

His explanation, as I remember, is that drilled rotors are just not good from any perspective, and the justification for slotted is dubious as the outgassing of pad material is no longer an issue with modern pads.

Which leaves boring old plain rotors....that don't look cool....

I quite like this guy's engineering explanations of a lot of things 'automotive'.

His explanation, as I remember, is that drilled rotors are just not good from any perspective, and the justification for slotted is dubious as the outgassing of pad material is no longer an issue with modern pads.

Which leaves boring old plain rotors....that don't look cool....

Here are the questions I posed to Paul:

- Is it correct that the 2 piece rotors you are offering will be drilled and slotted?

- Will the holes be drilled before heat treating? If not, is there a reason whythey arenít?

- With the group buy, can some of the rotors be opted for no holes (slotted only)?

- Will you subsequently offer the rotor plates separately when itís time to replace?

- What would be the shipping cost for 4 sets delivered for pickup at the Port ofBaltimore (US) via surface freight?

- What would be the shipping cost for 1 set delivered to ZIP Code 20904 in the US.

- Do yourecommend a specific pad that works particularly well with your rotors(Porterfield, EBC, etc.), or will the OEM pad be a good match?

Last edited by Unhingd; 03-01-2018 at 02:55 PM.

#29

See my questions to Paul below.

Agreed. Brakes are too important a component to just slap something on because they look good (less weight on the other hand... )

)

Agreed, slots alone will easily handle any minimal off-gassing that occurs, but also may provide a small bit of additional bite. For looks, I don't mind having the holes as long as the heat treating occurs after drilling to eliminate the stress points.

Here are the questions I posed to Paul:

Agreed. Brakes are too important a component to just slap something on because they look good (less weight on the other hand...

)

)Agreed, slots alone will easily handle any minimal off-gassing that occurs, but also may provide a small bit of additional bite. For looks, I don't mind having the holes as long as the heat treating occurs after drilling to eliminate the stress points.

Here are the questions I posed to Paul:

Have you asked Paul these buddy, or do you need me to pass onto him?

Though I think it is better you guys email Paul direct with any questions, that way nothing is lost in communications.

I am merely trying to make 2PC an option for our cars, because hey I'd love to save 50lbs of unsprung mass and have nicer looking disc at same time.

Paul emailed me earlier saying he is ordering a genuine front and rear disc for the SVR, so 380mm front, 376mm rear for them to use for their template and weight comparisons.

#30

Already emailed those questions to him. I'll pass along answers to the crew here as soon as I get them. This makes so much more sense than the expense of retrofitting and maintaining ceramics.

#31

#32

He did tell me you guys can have any design you wanted today:

- Drilled

- Drilled and Grooved

- Grooved only

I suspect he could even offer blank.

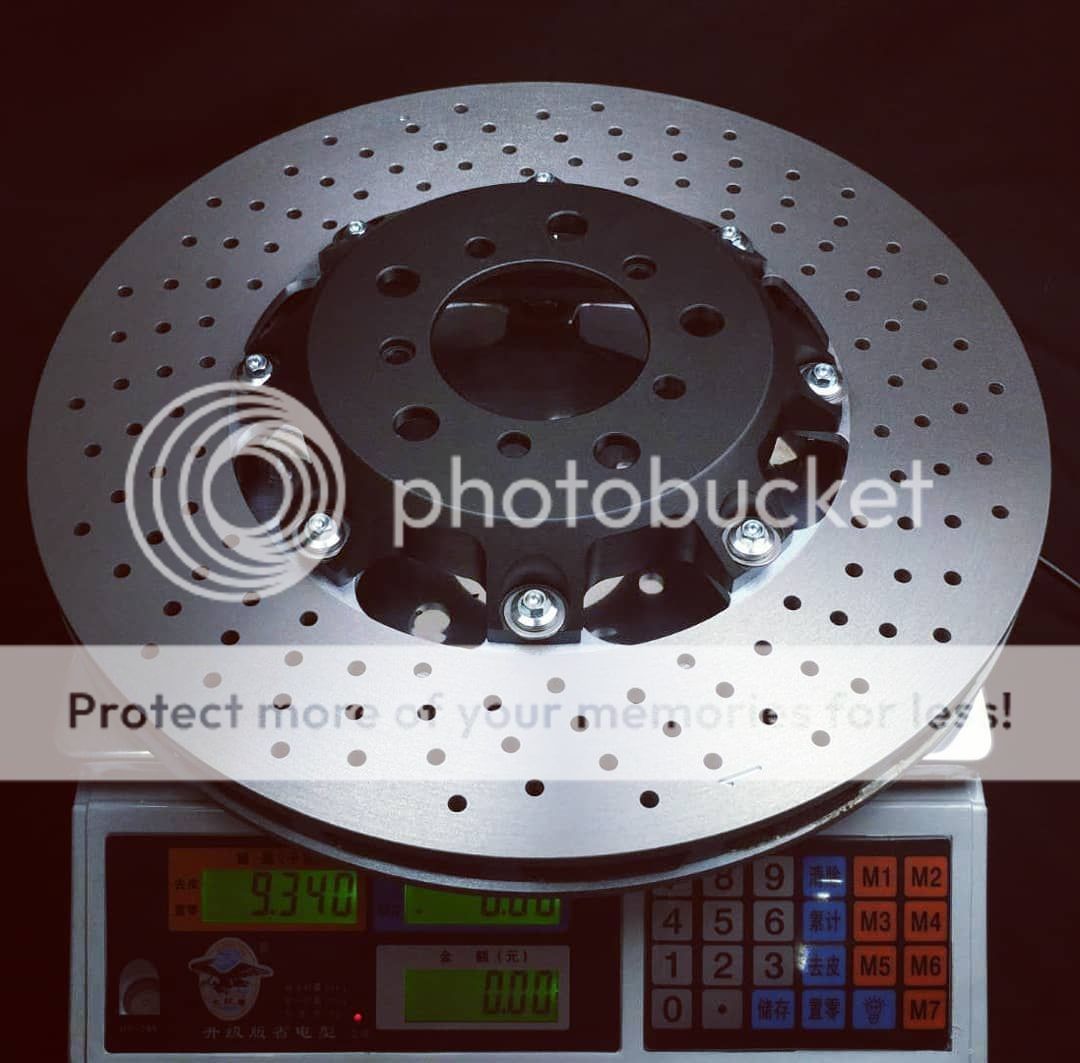

My plan is to just have mine in this style:

Once all done, we could be saving as much as 50lbs, which is just as much as the ceramics save with nowhere near the expense.

The following users liked this post:

Unhingd (03-01-2018)

#34

#35

Would there be any issue using ANY (non ceramic type) brake pad made for the F-Type such as the Porterfield low dust pads I bought? (not yet installed).

I am on the fence, but probably easily convinced cause I'll be putting off doing my pads. Pretty rotors, less dust are things fantasies are made of .... oh yeah and that weight thing also.

I am on the fence, but probably easily convinced cause I'll be putting off doing my pads. Pretty rotors, less dust are things fantasies are made of .... oh yeah and that weight thing also.

Last edited by Burt Gummer; 03-01-2018 at 04:31 PM.

#36

#37

#38

Paul@Wortec

1. As we machine froma blank casting we can have any configuration of surface designs.....plain,milled holes or slots.....as you realise making one off designs is more costlyso if we can agree on a limited range that would be preferable.

2. The rotors are rough machined before heat treating then full machined afteras this gives the best finish for strength and durability. Everyone has anopinion on holes or no holes etc etc but we are fortunate to have theexperience of all designs. the best performance on our current range is thethermal slot design and suncut edge. But holes only is a good option for noiseand performance.

3. Yes..... as said above but please limit to 2-3 designs

4. Yes replacement rotors will be kept in stock (blank)

5. When we have finished designs and weights I can quote all options.......butour air freight costs are very good.

6. Let me check in the morning....(9.00pm in UK now)

7. a) EBC yellow suff is agood compound ( there are reports of poor pad build quality but the compoundworks well) for more aggressive use try pagid RS29, but expect higher noise androtor wear....

b) carbon lorain have some options that work well......

c) for another option try ferodo Ds2300 as a good road option...

d) if this product takes off we can look at making our own compounds in a pad tofit your calipers, but we would need to make 30-50 sets to warrant theinvestment.

The next stage is for us to produce a test set of rotors to finalise designsand advise finished weights. then we can give all info, then we can takedeposits on the first batch..........

1. As we machine froma blank casting we can have any configuration of surface designs.....plain,milled holes or slots.....as you realise making one off designs is more costlyso if we can agree on a limited range that would be preferable.

2. The rotors are rough machined before heat treating then full machined afteras this gives the best finish for strength and durability. Everyone has anopinion on holes or no holes etc etc but we are fortunate to have theexperience of all designs. the best performance on our current range is thethermal slot design and suncut edge. But holes only is a good option for noiseand performance.

3. Yes..... as said above but please limit to 2-3 designs

4. Yes replacement rotors will be kept in stock (blank)

5. When we have finished designs and weights I can quote all options.......butour air freight costs are very good.

6. Let me check in the morning....(9.00pm in UK now)

7. a) EBC yellow suff is agood compound ( there are reports of poor pad build quality but the compoundworks well) for more aggressive use try pagid RS29, but expect higher noise androtor wear....

b) carbon lorain have some options that work well......

c) for another option try ferodo Ds2300 as a good road option...

d) if this product takes off we can look at making our own compounds in a pad tofit your calipers, but we would need to make 30-50 sets to warrant theinvestment.

The next stage is for us to produce a test set of rotors to finalise designsand advise finished weights. then we can give all info, then we can takedeposits on the first batch..........

NOT trashcan lids.

Last edited by Unhingd; 03-01-2018 at 06:09 PM.

#39

Definitely not trashcan lids. Not being counted among the idle rich, I'm not sure I can swing it in this first batch. Not sure I can't, but need to figure out how many months of a rice and beans diet I live with.

#40

My local track is pretty hard on brakes, but I haven't had the F-Type out there yet. My last trip out there was in a car with far less than half the power of the F-Type (less power than my motorcycle!) and maybe 600 pounds lighter, and I could feel fade at the end of a 20 minute session. It didn't have trashcan lids though