Air suspension woes, maybe

#1

Bought this car last week, it's absolutely gorgeous, not a mark on it, and the interior wear is limited to slight cracking in the leather on the lower left of the driver's seat. I saw it 3 times before I handed the guy the money, and still didn't pick it up until the next day, when we could get an appointment at the tag office to handle the legalities.

Here's what it looked like a week ago today, the day after the tag office visit, and the 4th day after I'd first seen the car:

And here's today:

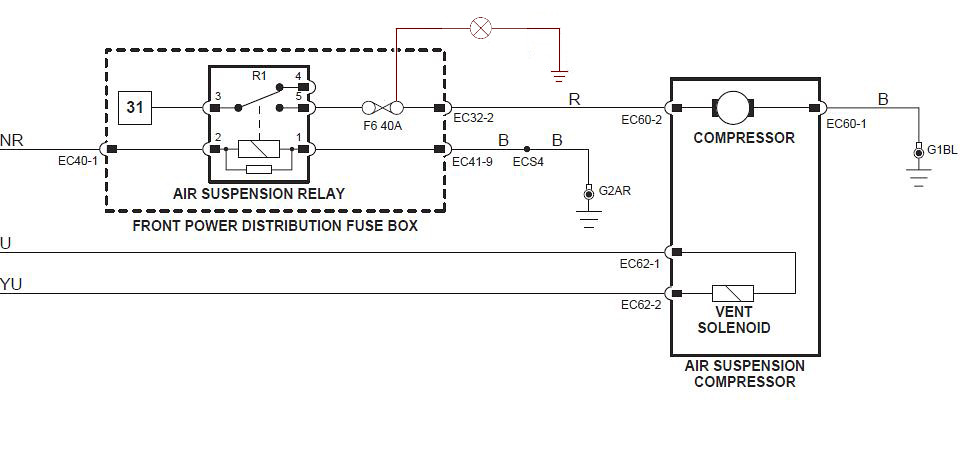

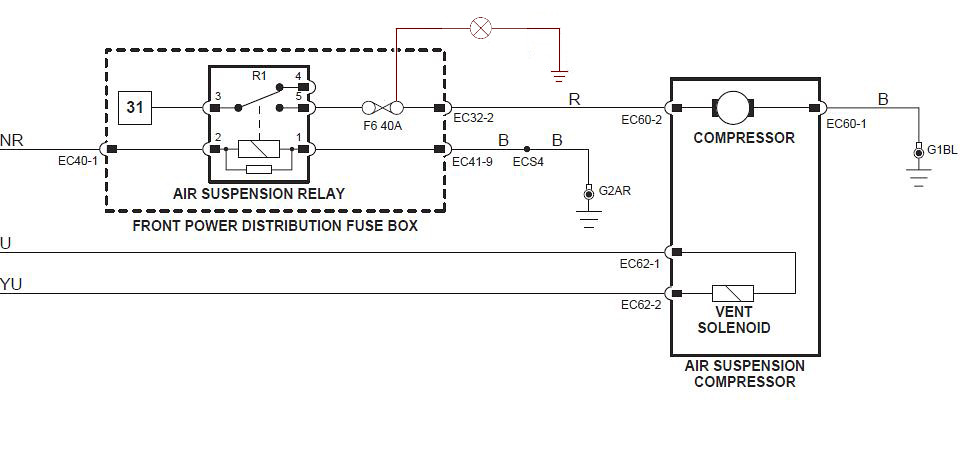

Sitting a lot lower, and I'm trying to find out why. I've read what I'm finding here about the air suspension, and I've got electrical diagrams. One of the things I've determined absolutely is that the compressor is not being activated. Relay and compressor from the electrical diagram:

I applied 12 volts to the socket of the fuse that feeds the compressor and heard the compressor run. I didn't run it but long enough to hear it start, then removed power, as I have no idea what the controller is thinking, even though the car was running. After that, I rigged a test light, taped it to the windshield wiper so I could see it illuminate, wired in two different places; I tapped the fuse output that feeds the compressor, and I tapped the relay wire where the controller energizes the relay, then drove around a while with each connection.

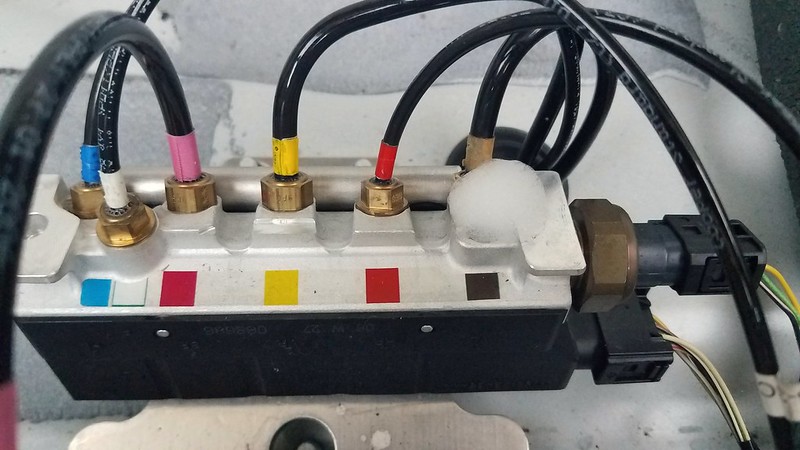

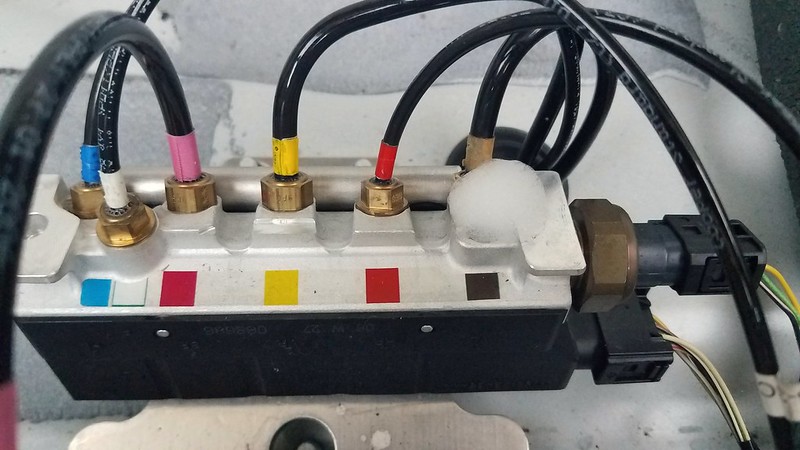

Here's where I tapped off the fuse:

And where I tapped of the relay line, the output from the controller:

The bulb never illuminated at either connection. (Yes, the bulb works if I simply apply 12 volts to it. ) No 12 volts ever at that line means the controller is never asking the compressor to run. Of course, I have no idea at this point how much pressure is in the tank in the trunk, so maybe the tank is full and the compressor is not needed. That means something else is whacked out, since the car is obviously settling, although very slowly. Squirted soapy water onto all of the air connections on the struts and at the valve body and the tank. One of the valve body connections foamed up pretty good, but I think that's the line from the compressor, and if that valve is closed, I just pressurized that line by running the compressor, not sure it's really an issue. None of the struts showed any foaming. (The little tiny bubbles on the one are not an air leak, I just got my soapy solution a little too soapy, so it made suds when I sprayed.)

) No 12 volts ever at that line means the controller is never asking the compressor to run. Of course, I have no idea at this point how much pressure is in the tank in the trunk, so maybe the tank is full and the compressor is not needed. That means something else is whacked out, since the car is obviously settling, although very slowly. Squirted soapy water onto all of the air connections on the struts and at the valve body and the tank. One of the valve body connections foamed up pretty good, but I think that's the line from the compressor, and if that valve is closed, I just pressurized that line by running the compressor, not sure it's really an issue. None of the struts showed any foaming. (The little tiny bubbles on the one are not an air leak, I just got my soapy solution a little too soapy, so it made suds when I sprayed.)

Finally, I don't have any messages about the car being low, but it's low enough to be riding harshly, and I scraped on a speed bump once.

Not sure what I can do now myself before I run it down to the local indie shop and hand him some money... I find it too odd to be believable that the system fails the day I buy it, because this was not happening last week; the car was riding correctly and smoothly. (Unless the guy had a secret "fix the ride-height" button hidden somewhere...) What I know about the suspension history on this particular car is that it has Arnott struts by the previous owner's previous owner, so my guy doesn't have the Arnott paperwork. Carfax doesn't show those, but shows a great deal of good history on the car. I don't think it's the struts, anyway.

Little help for the noob here?

Here's what it looked like a week ago today, the day after the tag office visit, and the 4th day after I'd first seen the car:

And here's today:

Sitting a lot lower, and I'm trying to find out why. I've read what I'm finding here about the air suspension, and I've got electrical diagrams. One of the things I've determined absolutely is that the compressor is not being activated. Relay and compressor from the electrical diagram:

I applied 12 volts to the socket of the fuse that feeds the compressor and heard the compressor run. I didn't run it but long enough to hear it start, then removed power, as I have no idea what the controller is thinking, even though the car was running. After that, I rigged a test light, taped it to the windshield wiper so I could see it illuminate, wired in two different places; I tapped the fuse output that feeds the compressor, and I tapped the relay wire where the controller energizes the relay, then drove around a while with each connection.

Here's where I tapped off the fuse:

And where I tapped of the relay line, the output from the controller:

The bulb never illuminated at either connection. (Yes, the bulb works if I simply apply 12 volts to it.

Finally, I don't have any messages about the car being low, but it's low enough to be riding harshly, and I scraped on a speed bump once.

Not sure what I can do now myself before I run it down to the local indie shop and hand him some money... I find it too odd to be believable that the system fails the day I buy it, because this was not happening last week; the car was riding correctly and smoothly. (Unless the guy had a secret "fix the ride-height" button hidden somewhere...) What I know about the suspension history on this particular car is that it has Arnott struts by the previous owner's previous owner, so my guy doesn't have the Arnott paperwork. Carfax doesn't show those, but shows a great deal of good history on the car. I don't think it's the struts, anyway.

Little help for the noob here?

#2

Join Date: May 2018

Location: Weeki Wachee Florida

Posts: 107

Likes: 0

Received 17 Likes

on

10 Posts

The first easy thing to do is to disconnect each of the connections to the valve black and the strut tops to replace the rubber O rings. That will probably stop the leak we can see in your picture. The compressor should kick in about 5 seconds after starting the car and if one of the struts (probably front) is leaking you will hear it. If you are not getting any error lights for the compressor, its almost certainly a blown strut. One blown strut will cause all corners to drop over a short time as the car attempts to level itself to the lowest corner. Not the end of the world for such a lovely looking car. Let us know what you find

Steve

Steve

#3

#4

wfooshee;

+1 on getting a code reader. There are various models discussed in the forum. I have a Foxwell NT410 with the JLR specific software but any reader that can read the Jaguar specific codes is what you need. Without the Jaguar specific code to start your troubleshooting you could dump all kinds of money into guessing and replacing parts without correcting the root problem. A code reader with Live Data capability will allow you to see when your compressor runs, what the tank pressure is, when the individual solenoid valves open, and the pressure in the lines to each individual air spring.

If not already having done so; read the Air Suspension "Sticky" at the top of this forum page. Good instruction on how the system works.

A leaking air spring is a very common fail mode when temps drop. The front air springs tend to leak more frequently than the rear. Leakage is frequently from the top of the strut where the airbladder seals around the inlet valve. If you happen to have a leak there a little soapy water sprayed will bubble to reveal the leak. Search the forum for more discussion on this.

If you end up having to replace air springs and can afford Bilstein B4's, you might consider going that direction. I've always replaced with Bilstein's and have never had quality issues or problems. RockAuto currently has them for $750.

Good Luck and Best Regards, William

+1 on getting a code reader. There are various models discussed in the forum. I have a Foxwell NT410 with the JLR specific software but any reader that can read the Jaguar specific codes is what you need. Without the Jaguar specific code to start your troubleshooting you could dump all kinds of money into guessing and replacing parts without correcting the root problem. A code reader with Live Data capability will allow you to see when your compressor runs, what the tank pressure is, when the individual solenoid valves open, and the pressure in the lines to each individual air spring.

If not already having done so; read the Air Suspension "Sticky" at the top of this forum page. Good instruction on how the system works.

A leaking air spring is a very common fail mode when temps drop. The front air springs tend to leak more frequently than the rear. Leakage is frequently from the top of the strut where the airbladder seals around the inlet valve. If you happen to have a leak there a little soapy water sprayed will bubble to reveal the leak. Search the forum for more discussion on this.

If you end up having to replace air springs and can afford Bilstein B4's, you might consider going that direction. I've always replaced with Bilstein's and have never had quality issues or problems. RockAuto currently has them for $750.

Good Luck and Best Regards, William

The following users liked this post:

Don B (12-22-2020)

#5

Join Date: Nov 2009

Location: The beautiful Mornington Peninsula in OZ

Posts: 2,977

Received 740 Likes

on

623 Posts

The following users liked this post:

wwr (12-19-2020)

#6

Following up with what I've done... I got the back seat out, and the sound deadener material over the suspension control module is torn; someone's been in here before...

Voltmeter checks so the switched line always hot, and the battery line at 0 volts. Fuses on both of those circuits are OK (ohmmeter tested, not just looked at.) Key position makes no difference. I put a fused jumper across the pins for hot and switched on the connector, thus applying 12 volts to both, and when turning on the key, I now get dashboard warnings for air suspension failure and vehicle too low. The controller was not even powering up before I did that... It still never enabled the compressor, as my test light still installed never illuminated, nor did the compressor run.

I know I need a scan tool to go any further, but there's something weird electrically here. The switched line is always hot, and the always hot battery line is 0 volts. I do not want to go physically tracing wires in the harness!!!!

By the way, I have read as much as I could find in the stickies, and what's linked there.

Voltmeter checks so the switched line always hot, and the battery line at 0 volts. Fuses on both of those circuits are OK (ohmmeter tested, not just looked at.) Key position makes no difference. I put a fused jumper across the pins for hot and switched on the connector, thus applying 12 volts to both, and when turning on the key, I now get dashboard warnings for air suspension failure and vehicle too low. The controller was not even powering up before I did that... It still never enabled the compressor, as my test light still installed never illuminated, nor did the compressor run.

I know I need a scan tool to go any further, but there's something weird electrically here. The switched line is always hot, and the always hot battery line is 0 volts. I do not want to go physically tracing wires in the harness!!!!

By the way, I have read as much as I could find in the stickies, and what's linked there.

#7

wfooshee;

Looks like you are handy troubleshooting with a circuit diagram and meter/test lamp. Well done.

Based on what you've learned so far a code reader wouldn't have helped (yet) because the ASM has been disabled.

The ASM must be powered and operative in order to generate, store, and report DTCs.

The switched B+ circuit ( 98s / CR88-2 ) is the wake-up circuit so it may have been hot from you triggering something else as you are working on the car. No B+ directly from the battery ( [6] / CR88-1 ) is likely the 'show-stopper' and why you were able to see the errors on your dash when you powered the ASM. This is the major issue; now you're left to understand why. I think your first task is to get the ASM powered up, then check to see if you have other problems with the system (code reader needed here). But read below before deciding you want to get the ASM running correctly.

I do not have personal experience with non OEM airsprings so input from someone experienced with Arnotts should trump my inputs. If I recall correctly from forum posts, Arnotts are not 100% CATs compatible. I believe the current Arnott offerings have a passive (resistor??) to make the ASM believe it is seeing the Bilstein air valve solenoid. I recall some posts where there were challenges with this retrofit arrangement causing the ASM to generate DTCs prompting the owner to disable the ASM. If airsprings are replaced with coil-overs the compressor is no longer needed and one common means for disabling it is pulling the compressor relay from the engine compartment fuse box.

If I've mis-stated the details of Arnott implementation I expect someone with first-hand knowledge will correct me.

I'm curious to see how this all plays out. Please keep us updated.

Best Regards, William

Looks like you are handy troubleshooting with a circuit diagram and meter/test lamp. Well done.

Based on what you've learned so far a code reader wouldn't have helped (yet) because the ASM has been disabled.

The ASM must be powered and operative in order to generate, store, and report DTCs.

The switched B+ circuit ( 98s / CR88-2 ) is the wake-up circuit so it may have been hot from you triggering something else as you are working on the car. No B+ directly from the battery ( [6] / CR88-1 ) is likely the 'show-stopper' and why you were able to see the errors on your dash when you powered the ASM. This is the major issue; now you're left to understand why. I think your first task is to get the ASM powered up, then check to see if you have other problems with the system (code reader needed here). But read below before deciding you want to get the ASM running correctly.

I do not have personal experience with non OEM airsprings so input from someone experienced with Arnotts should trump my inputs. If I recall correctly from forum posts, Arnotts are not 100% CATs compatible. I believe the current Arnott offerings have a passive (resistor??) to make the ASM believe it is seeing the Bilstein air valve solenoid. I recall some posts where there were challenges with this retrofit arrangement causing the ASM to generate DTCs prompting the owner to disable the ASM. If airsprings are replaced with coil-overs the compressor is no longer needed and one common means for disabling it is pulling the compressor relay from the engine compartment fuse box.

If I've mis-stated the details of Arnott implementation I expect someone with first-hand knowledge will correct me.

I'm curious to see how this all plays out. Please keep us updated.

Best Regards, William

The following users liked this post:

Don B (12-22-2020)

Trending Topics

#8

Oddly, after having jumpered the ASM, it now powers up with the car's ignition switch after I removed my jumper. No idea how! I'm not sure it actually switches off, which I didn't consider before going to Texas for a week for a customer job. Hopefully it's still there when I get back!

The 98S circuit being hot is nothing I did. That fuse is hot with the keys in my pocket. The B+ fuse is also hot, as it should be, but no voltage was at CR88-1. That makes me think that someone not understanding what they were doing, may have crossed the wires somewhere. Stupidly, I haven't checked that connector since I removed the jumper. Seeing the system messages after that was a surprise, for sure, as I expected the thing to stay off.

The 98S circuit being hot is nothing I did. That fuse is hot with the keys in my pocket. The B+ fuse is also hot, as it should be, but no voltage was at CR88-1. That makes me think that someone not understanding what they were doing, may have crossed the wires somewhere. Stupidly, I haven't checked that connector since I removed the jumper. Seeing the system messages after that was a surprise, for sure, as I expected the thing to stay off.

Last edited by wfooshee; 12-19-2020 at 09:22 PM.

#9

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,415

Received 12,767 Likes

on

6,395 Posts

Hi wfooshee,

Here's a crazy question: Do you see a small electronic module spliced into the wiring below the ASM with T-taps or Posi-taps? Just wondering if the Arnott Electronic Bypass Module (EBM) was installed on your car? Normally it's just to prevent warning lamps when the Arnott coil conversion kit is installed. But who knows what someone might do just prior to selling a car?

One thing to be aware of is that some air suspension DTCs are stored in modules other than the ASM, such as the ECM, and certain DTCs will cause the air suspension to be disabled until the codes are cleared, and you need a scan tool that can read and clear Chassis (C-prefix) and Network (U-prefix) codes to do that.

I see that you have access to the Electrical Guide. Here's a link to the DTC Summaries:

Jaguar X350 DTC Summaries From 2004

I'll be following your diagnosis with interest!

Cheers,

Don

Here's a crazy question: Do you see a small electronic module spliced into the wiring below the ASM with T-taps or Posi-taps? Just wondering if the Arnott Electronic Bypass Module (EBM) was installed on your car? Normally it's just to prevent warning lamps when the Arnott coil conversion kit is installed. But who knows what someone might do just prior to selling a car?

One thing to be aware of is that some air suspension DTCs are stored in modules other than the ASM, such as the ECM, and certain DTCs will cause the air suspension to be disabled until the codes are cleared, and you need a scan tool that can read and clear Chassis (C-prefix) and Network (U-prefix) codes to do that.

I see that you have access to the Electrical Guide. Here's a link to the DTC Summaries:

Jaguar X350 DTC Summaries From 2004

I'll be following your diagnosis with interest!

Cheers,

Don

Last edited by Don B; 12-22-2020 at 10:36 PM.

The following 4 users liked this post by Don B:

#10

Been away a few days, had to travel for work.

No module spliced in. I haven't been able to get back into the car, yet. It's obvious I'll need to see about getting a scan tool, haven't done that, yet, either. Actually I have a Bluetooth OBD scanner...

Work work work, always getting in the way!

No module spliced in. I haven't been able to get back into the car, yet. It's obvious I'll need to see about getting a scan tool, haven't done that, yet, either. Actually I have a Bluetooth OBD scanner...

Work work work, always getting in the way!

Last edited by wfooshee; 12-24-2020 at 09:54 AM.

#11

I'm a bit over my head in figuring out what I need for a scan tool and software. From what I'm reading, SDD seems to be for Windows XP 32-bit only, and I don't know where I'd get an XP system. I could spin up a virtual XP box, but getting USB connectivity to that would probably be very iffy, maybe more so on a 64-bit Win10 host. I will probably just take it to a local indie shop I know that has a good Jag reputation and see if he can find anything in it, and if it's weird electrical, I'm kinda leaning towards hitting up rockauto.com for the Arnott coilovers. It seems like getting a scan tool is nearly halfway to the coilovers anyway, unless I'm missing a deal somewhere.

#12

Wfoosee,

I have not post for a while but I am glad to add my input. STOP DIAGNOSE. YOU NEED ALL NEW SHOCKS AND COMPRESSOR DUE TO AGE. There is reason why majority the higher end luxury vehicles equipped with air shock system. They ride much better. I installed coil springs for my friend 2004 Jaguar and that was a huge mistake. Ride was stiff in a bad way. I would not recommend buying used air shocks since most of them are over a decade old and all dry rodded. I have purchased both used front and rear air shocks as back up. I tested all of them by pressurized with air to 80 PSI and left them out door in the cold weather. I checked them the next day and one of the used shock deflated. With the headache of worrying leaking air shocks, I bought all new air shocks from EBAY.

These are made in China and cost only $430.00 per pair. They are identical in everyway to the OEM. The only different is the bottom rubber protective sleeve, which is a bit longer. It equipped with adaptive driving harness just like OEM. I bet my lunch that these copy made or manufactured by the same suppliers that manufactured parts for the OEM shock. However, you cannot ask for absolute perfect for the price. The four top bolts were not 90 degree perpendicular and I had to bend them to fit. $1,000.00 for all four corners are worth it.

I also replaced air compressor with EBAY air compressor as well and it works perfect. This is my first winter with no more deflating air suspension.

I have not post for a while but I am glad to add my input. STOP DIAGNOSE. YOU NEED ALL NEW SHOCKS AND COMPRESSOR DUE TO AGE. There is reason why majority the higher end luxury vehicles equipped with air shock system. They ride much better. I installed coil springs for my friend 2004 Jaguar and that was a huge mistake. Ride was stiff in a bad way. I would not recommend buying used air shocks since most of them are over a decade old and all dry rodded. I have purchased both used front and rear air shocks as back up. I tested all of them by pressurized with air to 80 PSI and left them out door in the cold weather. I checked them the next day and one of the used shock deflated. With the headache of worrying leaking air shocks, I bought all new air shocks from EBAY.

These are made in China and cost only $430.00 per pair. They are identical in everyway to the OEM. The only different is the bottom rubber protective sleeve, which is a bit longer. It equipped with adaptive driving harness just like OEM. I bet my lunch that these copy made or manufactured by the same suppliers that manufactured parts for the OEM shock. However, you cannot ask for absolute perfect for the price. The four top bolts were not 90 degree perpendicular and I had to bend them to fit. $1,000.00 for all four corners are worth it.

I also replaced air compressor with EBAY air compressor as well and it works perfect. This is my first winter with no more deflating air suspension.

Last edited by annamiata; 01-01-2021 at 09:28 PM. Reason: more input

#13

NT510 Foxwell, & icarsoft 910 are a couple of inexpensive readers.

They read many of the specific Jaguar codes, besides the suspension ones.

I have one of each, &. prefer the Foxwell, but keep one in each Jaguar.

The fancy computer setup is my next step, but finances are the fly in the ointment.

They read many of the specific Jaguar codes, besides the suspension ones.

I have one of each, &. prefer the Foxwell, but keep one in each Jaguar.

The fancy computer setup is my next step, but finances are the fly in the ointment.

The following users liked this post:

Don B (01-25-2021)

#15

Well, Alexa was WRONG!!!! LRII arrived today. Get it in the car, it tells me there is no communication with the air suspension module.

Back to old-fashioned electrical troubleshooting, tracing wires and stuff, finding where the electrons are stopping.

Parking brake is weird, too, would not release, saw parking brake fault on the dash. I drove the car forward and backward a few feet and it popped free, now I see "Cannot apply park brake," No codes on the park brake module. Not too worried baout the park prake, unless I find that it didn't fully release when it popped loose, but first the air suspension. If wires start making me crazy, I may spring for the coilovers. (See what I did there? )

)

Back to old-fashioned electrical troubleshooting, tracing wires and stuff, finding where the electrons are stopping.

Parking brake is weird, too, would not release, saw parking brake fault on the dash. I drove the car forward and backward a few feet and it popped free, now I see "Cannot apply park brake," No codes on the park brake module. Not too worried baout the park prake, unless I find that it didn't fully release when it popped loose, but first the air suspension. If wires start making me crazy, I may spring for the coilovers. (See what I did there?

#17

OK, the "no communication" tells me that the AS module isn't powered up. I pretty much already knew that from before, when I discovered that the B+ line is dead, and the switched line is always hot, both of which states are incorrect. As I reported in Post 6, I was able to jumper the B+ and switched connectors and power the module up, at which time I got faults on the dash. My report in post 8 was incorrect, though. I assumed since the faults stayed that the unit was still up. The LR-II showed me that there was no module with the "No communication" status.

So this morning I removed the back seat, again, and jumpered the connectors, plugged in the LR-II and started the car. A few DTCs showed, which I cleared, wanting to see what came back and was current. (I didn't want to chase something that might have been sitting there for 12 years.) The one that kept coming back was C2302 Levelling plausibility error. The actual level readings were all very low, as expected. Reservoir pressure was 7.3 bar, so considering the compressor hadn't run in over a month, I felt good about that. I put the car in drive and shuffled around the parking lot, nothing happened. Parked and shut it off. Restarted, and THE CAR LEVELED! Boom! I also heard the compressor run, and the reservoir pressure came up to 8.7 bar. Got out and looked at the car, it looks great! Sitting just as it should. Cleared the DTC, it stayed cleared instead of coming right back. Cool!

I drove over to a friend's house for a visit, he was aware of what was going on so I showed him how it looks now. At that point I was thinking that I had some kind of electrical power supply fault, but the system works, and I was happy. I still needed to figure out the fault because I don't want to just leave my jumper across those two pins, leaving the module thinking the car is always on!

On the way home, the side mirrors looked a bit odd, showing me the road not far behind the car, so I adjusted them up. When I got home I saw why... the nose was way high! For some reason the system raised the nose to 75, 80 mm!!! The rear is OK, although slightly low on the right. So now what??? The system obviously isn't working. And the C2302 is back.

I though maybe the leveling sensors weren't working, but the LR-II gives me a reading for all four corners that matches the attitude of the car. Frustrating, because when I left for my friend's house, and when I arrived there, the height and ride were perfect. Now the fronts are effectively maximum extension, and when the front wheels clear a bump that would drop the wheels, there is a very harsh effect which I assume is the strut extension limit being reached, so the car is parked again. 20 minutes of glory!!!

EDIT: Went out and cranked it up again a couple of hours later, with the jumper, and the right rear came up to normal but the fronts stayed high. I was also able to clear the C2302 and it stayed cleared while I was out there. I also saw over 10 bar in the reservoir at one point. The rear is now at normal height, but the fronts are way up in the air, like a redneck pickup truck.

So this morning I removed the back seat, again, and jumpered the connectors, plugged in the LR-II and started the car. A few DTCs showed, which I cleared, wanting to see what came back and was current. (I didn't want to chase something that might have been sitting there for 12 years.) The one that kept coming back was C2302 Levelling plausibility error. The actual level readings were all very low, as expected. Reservoir pressure was 7.3 bar, so considering the compressor hadn't run in over a month, I felt good about that. I put the car in drive and shuffled around the parking lot, nothing happened. Parked and shut it off. Restarted, and THE CAR LEVELED! Boom! I also heard the compressor run, and the reservoir pressure came up to 8.7 bar. Got out and looked at the car, it looks great! Sitting just as it should. Cleared the DTC, it stayed cleared instead of coming right back. Cool!

I drove over to a friend's house for a visit, he was aware of what was going on so I showed him how it looks now. At that point I was thinking that I had some kind of electrical power supply fault, but the system works, and I was happy. I still needed to figure out the fault because I don't want to just leave my jumper across those two pins, leaving the module thinking the car is always on!

On the way home, the side mirrors looked a bit odd, showing me the road not far behind the car, so I adjusted them up. When I got home I saw why... the nose was way high! For some reason the system raised the nose to 75, 80 mm!!! The rear is OK, although slightly low on the right. So now what??? The system obviously isn't working. And the C2302 is back.

I though maybe the leveling sensors weren't working, but the LR-II gives me a reading for all four corners that matches the attitude of the car. Frustrating, because when I left for my friend's house, and when I arrived there, the height and ride were perfect. Now the fronts are effectively maximum extension, and when the front wheels clear a bump that would drop the wheels, there is a very harsh effect which I assume is the strut extension limit being reached, so the car is parked again. 20 minutes of glory!!!

EDIT: Went out and cranked it up again a couple of hours later, with the jumper, and the right rear came up to normal but the fronts stayed high. I was also able to clear the C2302 and it stayed cleared while I was out there. I also saw over 10 bar in the reservoir at one point. The rear is now at normal height, but the fronts are way up in the air, like a redneck pickup truck.

Last edited by wfooshee; 01-09-2021 at 09:18 PM.

#18

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,415

Received 12,767 Likes

on

6,395 Posts

Hi wfooshee,

You're making progress!

A couple of thoughts come to mind.

First of all, C2302 is one of the classic codes triggered when the compressor fails to fully pressurize the system within the time allotted by the ASM. I can't remember if you have replaced the piston ring/seal in your compressor, but if not, put that on your list of things to do. The ring is made of PTFE (Teflon) and typically wears out long before the compressor itself. While you have the compressor apart, remove the desiccant bed and clean the rust off of the leaf valve and partially reactivate the desiccant beads by putting them in a 500 degree oven overnight, and remove the exhaust valve and pressure relief valve and clean all the rust out of them.

Regarding the front end, it would be worth trying this: loosen one of the front air spring air hose fittings and allow most of the air to escape. Assuming your pressure-retention valves are working, some air will remain to prevent the bladders from fully collapsing. Restart the engine and see if the system levels itself again. If your compressor piston ring is worn it may take two or three engine cycles to fully raise the suspension again. System calibration glitches are fairly common and are sometimes cured by this method.

I'll be very curious to hear what you figure out about the power supplies to the ASM and what may have caused the differences between your posts #6 and #8.

Cheers,

Don

You're making progress!

A couple of thoughts come to mind.

First of all, C2302 is one of the classic codes triggered when the compressor fails to fully pressurize the system within the time allotted by the ASM. I can't remember if you have replaced the piston ring/seal in your compressor, but if not, put that on your list of things to do. The ring is made of PTFE (Teflon) and typically wears out long before the compressor itself. While you have the compressor apart, remove the desiccant bed and clean the rust off of the leaf valve and partially reactivate the desiccant beads by putting them in a 500 degree oven overnight, and remove the exhaust valve and pressure relief valve and clean all the rust out of them.

Regarding the front end, it would be worth trying this: loosen one of the front air spring air hose fittings and allow most of the air to escape. Assuming your pressure-retention valves are working, some air will remain to prevent the bladders from fully collapsing. Restart the engine and see if the system levels itself again. If your compressor piston ring is worn it may take two or three engine cycles to fully raise the suspension again. System calibration glitches are fairly common and are sometimes cured by this method.

I'll be very curious to hear what you figure out about the power supplies to the ASM and what may have caused the differences between your posts #6 and #8.

Cheers,

Don

The following 3 users liked this post by Don B:

#19

Well, post #8 was an assumption. I had no air suspension warnings before I jumpered the pins as reported in post 6. When I removed the jumper and started the car, I expected to return to no warnings, but they remained, leading me to just assume the module was awake. The LR-II showed that it wasn't.

It's too cold to be outside digging in a wiring harness. I'll probably see about that compressor kit, though.

It's too cold to be outside digging in a wiring harness. I'll probably see about that compressor kit, though.

#20

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,415

Received 12,767 Likes

on

6,395 Posts

Regarding the kit, I highly recommend the one from our member Andy at bagpipingandy.com. He is a precision machinist who was the first to come up with the new piston ring and he manufactures them himself. I've installed several of his kits and the quality is consistently perfect. There are clone kits on eBay but we've had at least one report of the quality being suspect. Wabco now also sells a kit, but the last time I checked it was more expensive than Andy's.

The following 4 users liked this post by Don B: