Front lower Shock bushing question?

#1

Hi Folks

Just a quick question about the bushing that sits between the front Shock absorber lower fork. (Part no. CAC75851 - Damper bush part) I understand that this is not part of the shock but I'm curious as to what might be involved in changing it out?

Any insights you might have would be very welcome, for example "special tools", press etc. ?

Thanks

BigBoss in Dallas TX

Just a quick question about the bushing that sits between the front Shock absorber lower fork. (Part no. CAC75851 - Damper bush part) I understand that this is not part of the shock but I'm curious as to what might be involved in changing it out?

Any insights you might have would be very welcome, for example "special tools", press etc. ?

Thanks

BigBoss in Dallas TX

#2

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,738

Received 10,746 Likes

on

7,099 Posts

The following users liked this post:

BigBossRadio (05-09-2014)

#3

#4

Yep this the way to go. You can do this job on the car no problem, once you remove the wheel, sway bar link and the shock. Just ensure that you support the spring pan after removing the shock, else the spring may decide to become a projectile!!

The following users liked this post:

BigBossRadio (05-10-2014)

#5

AllenG........ Thanks for that info any ideas on how to make up the puller/Driver?

I guess I'll just have to use my Imagination and come up with one

Again Thanks, It's guys like you here who keep me going on this project

BigBoss in Dallas TX

Again Thanks... It's guys like you here that keep me going on this project

BigBoss In Dallas TX

I guess I'll just have to use my Imagination and come up with one

Again Thanks, It's guys like you here who keep me going on this project

BigBoss in Dallas TX

Again Thanks... It's guys like you here that keep me going on this project

BigBoss In Dallas TX

#6

There are lots of variations so whatever works

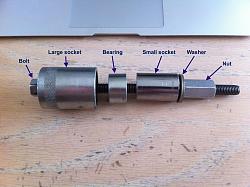

One way is to use a long bolt and use two sockets. A large socket with an ID slightly larger than bushing or bearing. The bolt and large socket are on one side of the bushing and the bolt is pushed through. On the other side of the bushing you would use a smaller socket with an OD that is slightly smaller than the bushing OD. Behind the socket use a washer and a nut.

One way is to use a long bolt and use two sockets. A large socket with an ID slightly larger than bushing or bearing. The bolt and large socket are on one side of the bushing and the bolt is pushed through. On the other side of the bushing you would use a smaller socket with an OD that is slightly smaller than the bushing OD. Behind the socket use a washer and a nut. Holding the head of the bolt to prevent turning, tighten up the nut. As the nut tightens it will push the bushing through the hole and into the large socket. Once the bushing is completely through, take the nut off and all the parts will be free. here's a couple of quick pics i took to illustrate.

As you rotate the nut the bearing or bushing is pushed through the hole.

Once it has cleared the hole, everything will go slack which is the signal that you're done

The following 2 users liked this post by AllanG:

Badbenz94 (06-01-2014),

BigBossRadio (05-10-2014)

#7

Hi Allen

Thanks for the great instructions to install the font Shock damper... That really helped. well today was an interesting one to say the least. I wanted to replace my front shocks so using the instructions Vandenplas408 posted I went about the task... everything went well Till I removed the lower shock mounting bolt and discovered that the Damper Bush was worn away and I had not ordered that part...... It will need to be replaced via the method you explained. The other problem I ran into was having loosened all the shock bolts upper and lower I could not compress it in order to remove it.......... I took a close look at my replacement shock and found it took significant pressure to try and compress it.... does that mean my in situ shock is ok since try as I might I could not compress it to remove it?

Any ideas that might help...........?

Thanks again

BigBoss In Dallas.......

Thanks for the great instructions to install the font Shock damper... That really helped. well today was an interesting one to say the least. I wanted to replace my front shocks so using the instructions Vandenplas408 posted I went about the task... everything went well Till I removed the lower shock mounting bolt and discovered that the Damper Bush was worn away and I had not ordered that part...... It will need to be replaced via the method you explained. The other problem I ran into was having loosened all the shock bolts upper and lower I could not compress it in order to remove it.......... I took a close look at my replacement shock and found it took significant pressure to try and compress it.... does that mean my in situ shock is ok since try as I might I could not compress it to remove it?

Any ideas that might help...........?

Thanks again

BigBoss In Dallas.......

Trending Topics

#8

Hi Allen

Thanks for the great instructions to install the font Shock damper... That really helped. well today was an interesting one to say the least. I wanted to replace my front shocks so using the instructions Vandenplas408 posted I went about the task... everything went well Till I removed the lower shock mounting bolt and discovered that the Damper Bush was worn away and I had not ordered that part...... It will need to be replaced via the method you explained. The other problem I ran into was having loosened all the shock bolts upper and lower I could not compress it in order to remove it.......... I took a close look at my replacement shock and found it took significant pressure to try and compress it.... does that mean my in situ shock is ok since try as I might I could not compress it to remove it?

Any ideas that might help...........?

Thanks for the great instructions to install the font Shock damper... That really helped. well today was an interesting one to say the least. I wanted to replace my front shocks so using the instructions Vandenplas408 posted I went about the task... everything went well Till I removed the lower shock mounting bolt and discovered that the Damper Bush was worn away and I had not ordered that part...... It will need to be replaced via the method you explained. The other problem I ran into was having loosened all the shock bolts upper and lower I could not compress it in order to remove it.......... I took a close look at my replacement shock and found it took significant pressure to try and compress it.... does that mean my in situ shock is ok since try as I might I could not compress it to remove it?

Any ideas that might help...........?

Couple of things you can do to check the operation of your shocks.

First, carefully inspect around the shock tube looking for any oil that may have leaked out of the shock. Once they start leaking they lose effectiveness.

Second, compress the shock from the top and you should feel it smoothly compress and once you release it, it should smoothly expand again at a controlled rate.

The shocks can be a little difficult to compress but the secret is to use firm constant pressure and eventually the shock will start to move and will then compress smoothly. Don't try to give yourself a hernia, just firm constant pressure until it compresses.

I find an easy way to do this is to remove the top nut and bushing and then use something that will fit through the hole in the car body like a 10" socket extension. Place the the extension (maybe with a socket if it will fit) on the top bolt of the shock and then use something like a block of wood to help you exert downward force on the extension. You will need to apply a good bit of continuous pressure and then let time and the fluid dynamics in the shock do their thing

The following users liked this post:

BigBossRadio (05-11-2014)

#9

Allen

Thanks for that reply...... I felt like a complete fool yesterday, going to all that effort only to be foiled while trying to remove them..

I will use your method and see how I do BUT I need to get the Spring Damper Bush since I know it's shot.

Again thanks for your help and I will keep you posted.

BigBoss (LittleBoss after yesterday LOL) in Dallas Tx

Thanks for that reply...... I felt like a complete fool yesterday, going to all that effort only to be foiled while trying to remove them..

I will use your method and see how I do BUT I need to get the Spring Damper Bush since I know it's shot.

Again thanks for your help and I will keep you posted.

BigBoss (LittleBoss after yesterday LOL) in Dallas Tx

#10

I cheated when my lower bushing fell apart. I unbolted the bottom of the shock and got it out of the way. After fighting with it for too long, since all the rubber was torn away, I used a new blade in the recip/sawzall, slid the blade in the hole, and made 2 cuts about, 1/4" apart, most of the way through the old outer sleeve of the bushing. A punch and a hammer tapped out the cut portion, and the rest easily came out.

The following users liked this post:

BigBossRadio (05-12-2014)

#11

#12

Watch as the inner sleeve sits proud of the outer, so try not to compress against that sleeve which may cause the rubber to rip - the whole reason I had to replace mine. I also use a little lube.

I used some copper grease on the shank of the shock bolt to prevent it from seizing up in the inner sleeve. It's an old habit from owning MGBs. The kinpin bolts on those cars are notorious for seizing up in the bush sleeves.

#13

Yes exactly this!! I always use copper anti seize on the bolts shanks on the suspension. Many owners will replace the wishbone bushings but not lubricate the bolt only to find later that the new bushings fail after a relatively short life. The pivot bolt seizes inside the bushing and the shearing force this creates can cause the rubber to crack and/or delaminate.

The following users liked this post:

BigBossRadio (05-12-2014)

#14

Hi Mgb4tim and Allen

Thanks for including that extra pies of info and Data..... I will be sure to do that because I would never have thought to do that and having had the opportunity to look closely at the one that's there now I'm sure the previous installed never bothered to do that.

Again Thanks Guys

Your help keeps me working on that piece of my To-Do list

BigBoss In Dallas

Thanks for including that extra pies of info and Data..... I will be sure to do that because I would never have thought to do that and having had the opportunity to look closely at the one that's there now I'm sure the previous installed never bothered to do that.

Again Thanks Guys

Your help keeps me working on that piece of my To-Do list

BigBoss In Dallas

#15

Hi AllenG

Just a quick up date, My new Spring Damper bushes, new Sway Bar Link rods and Sway bar doughnut bushings arrived this evening. So with the help of the pictures you posted earlier and the helpful tip to use copper anti-seize for the rod...... I should be set to do the job in the AM..

Again Thanks you so much for all your help

BigBoss in Dallas, TX

Just a quick up date, My new Spring Damper bushes, new Sway Bar Link rods and Sway bar doughnut bushings arrived this evening. So with the help of the pictures you posted earlier and the helpful tip to use copper anti-seize for the rod...... I should be set to do the job in the AM..

Again Thanks you so much for all your help

BigBoss in Dallas, TX

The following users liked this post:

AllanG (05-15-2014)

#16

Sometimes you have to adjust the height of the jack under the spring pan to allow the shocks to compress ...anyway that's what I found when I did mine last month. I also replaced the lower bushings but thankfully a mate loaned me a bushing removal tool - worked on the same principle as the excellent illustrations above but even with this I had to use a breaker bar on the nut to get it started ..

good luck

Larry

good luck

Larry

The following users liked this post:

BigBossRadio (05-16-2014)

#17

Lawerence

Greetings from Dallas. Thanks for that tidbit. I did manage to change out the shock last sunday, that's when I discovered that I need to replace the Spring Damper bushing....... So I should not have any problem getting the shock and sway bar link out of the way while I do it. Glad to hear you borrowed that tool from your friend.

Anyway I'll keep you posted

BigBoss in Dallas TX

Greetings from Dallas. Thanks for that tidbit. I did manage to change out the shock last sunday, that's when I discovered that I need to replace the Spring Damper bushing....... So I should not have any problem getting the shock and sway bar link out of the way while I do it. Glad to hear you borrowed that tool from your friend.

Anyway I'll keep you posted

BigBoss in Dallas TX

#18

#20

Hi all you good folks

After replacing the spring damper bushing and sway bar link yesterday, I took the cat out for a spin this morning and I'm very happy to report a dramatic improvement. No more banging and knocking when I hit rough spots on the roads....... I suspect the cause of the problem was the very badly shot SPRING DAMPER BUSHING...... who would of thought?

By the way special thanks to AllenG for the puller/pusher tool idea and also to MGB4Tim, I used his sawsall idea to cut through the old outer sleve, that did the trick. Pressing in the new one took some persuading and patience....

Again thanks to you all......

BigBoss in Dallas

After replacing the spring damper bushing and sway bar link yesterday, I took the cat out for a spin this morning and I'm very happy to report a dramatic improvement. No more banging and knocking when I hit rough spots on the roads....... I suspect the cause of the problem was the very badly shot SPRING DAMPER BUSHING...... who would of thought?

By the way special thanks to AllenG for the puller/pusher tool idea and also to MGB4Tim, I used his sawsall idea to cut through the old outer sleve, that did the trick. Pressing in the new one took some persuading and patience....

Again thanks to you all......

BigBoss in Dallas

Thread

Thread Starter

Forum

Replies

Last Post

MC36

US Lower Atlantic

0

09-01-2015 07:34 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)