V12 starter issues

#41

Okay, exhaust downpipe is coming loose, but, the steering rack, how do I remove this? The Haynes manual refers to lower mounting bolts, and an upper mounting bolt. I can't find the upper one, where should I be looking, or is this unique to the series 3?

I assume the lower ones refer to the 2 that go on to the subframe? (if I've got my terminology right)

I assume the lower ones refer to the 2 that go on to the subframe? (if I've got my terminology right)

#42

Okay, exhaust downpipe is coming loose, but, the steering rack, how do I remove this? The Haynes manual refers to lower mounting bolts, and an upper mounting bolt. I can't find the upper one, where should I be looking, or is this unique to the series 3?

I assume the lower ones refer to the 2 that go on to the subframe? (if I've got my terminology right)

I assume the lower ones refer to the 2 that go on to the subframe? (if I've got my terminology right)

The lower rack mounts are the 2 you can see easily, 1 on each side on the same horizontal plane. The 3rd is on the RH side, and about 3" above the lower one, and more feelable that visible, until you know exactly where to look. The heat shields for the rack boots are in the way mainly.

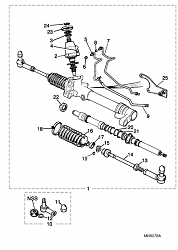

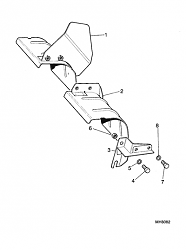

These 3 drawings may help a little.

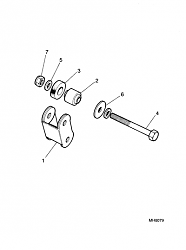

Rack mount bracket for the RH side.

Rack itself, the 2 mount holes are visible above the #22 numbers, NOT what its pointing too.

Rack heat shields, with #1 being the RH side and maybe blocking access to the upper bolt.

The following users liked this post:

NathanDD6 (07-30-2016)

#43

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

Whew, looks like an every tool in the box task. Break out the flex sockets and long extensions !!!

Perhaps a blast at a wash rack or with a power washer pre work would help. Grime ands grease not only unpleasant, but obscures stuff.

Nathan, stay with it, others have done it. Not me, thanks. My band saw at waist level is kicking my behind....

Carl

Perhaps a blast at a wash rack or with a power washer pre work would help. Grime ands grease not only unpleasant, but obscures stuff.

Nathan, stay with it, others have done it. Not me, thanks. My band saw at waist level is kicking my behind....

Carl

The following users liked this post:

NathanDD6 (07-30-2016)

#44

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,738

Received 10,746 Likes

on

7,099 Posts

I've never done the job on a RHD car. Clarify (Grant will know) if the rack must be *removed* or simply lowered out of the way.

If it merely needs to be lowered a bit then remove the 3 mounting bolts and give the rack a jiggle or three. It'll slide downward a few inches. If more is needed you'll have to disconnect the steering column....a little tricky dealing with the pinch bolt....which will let it drop further. At this point it'll be connected to the front suspension by the tie rods, flopping around and likely in your way....grrrr!

If *removal* is needed then add disconnecting and reconnecting the hoses to the list of chores and aggravations.....as well as disconnecting the tire rods.

Just remember that slower is faster when working on these cars

. Just plod along slowly. The car will fight you if you try to hurry.

. Just plod along slowly. The car will fight you if you try to hurry.Cheers

DD

The following users liked this post:

NathanDD6 (07-30-2016)

#45

Yep, I took the rack off, it simply got in my way. Might not bother others.

I then was able to tie the steering column shaft out of the way.

BUT

Remember, my exhaust pipes would NOT come out, so I had to gain as much room as possible.

The second one to play up, engine/trans out, took 6 hours to get it out. Sorted a few oil leaks etc whilst out.

I then was able to tie the steering column shaft out of the way.

BUT

Remember, my exhaust pipes would NOT come out, so I had to gain as much room as possible.

The second one to play up, engine/trans out, took 6 hours to get it out. Sorted a few oil leaks etc whilst out.

The following users liked this post:

NathanDD6 (07-30-2016)

#46

Aha, many thanks Grant, Doug and Carl, the ball-joints are off and the special bolt at the top of the starter motor is out, I've bought some dowl-rod to make little plugs for the power steering fluid lines.

I plan to remove the steering rack, that pinch bolt is my next problem, first time ever dealing with one. How does it work? Do I merely just slacken it off and it lets go of the steering pinion or something?

Just the pinch-bolt and the power-steering lines to go, then I'm at the starter

Oh, last one, anyone ever had the starter solenoid in pieces? Can it be taken apart and overhauled?

Many thanks.

I plan to remove the steering rack, that pinch bolt is my next problem, first time ever dealing with one. How does it work? Do I merely just slacken it off and it lets go of the steering pinion or something?

Just the pinch-bolt and the power-steering lines to go, then I'm at the starter

Oh, last one, anyone ever had the starter solenoid in pieces? Can it be taken apart and overhauled?

Many thanks.

#47

Pinch bolt is a bolt and nut.

Remove the nut, jiggle the shaft and the bolt will slide out, DO NOT DROP IT, it is specific to the task.

Refitting the shaft to the pinion head splines is tricky, and getting it all lined up is fiddly. The cotter bolt (pinch bolt to some) slides thru a groove machined in the splined shaft, and you will clearly see this once seperated. Sometimes that groove is 360deg on the spline shaft, sometimes its a simple slot. Slot is fiddly, groove is not so bad.

The rack should be "centralised" before refitting. Simple to do, I will PM you that procedure.

Remove the nut, jiggle the shaft and the bolt will slide out, DO NOT DROP IT, it is specific to the task.

Refitting the shaft to the pinion head splines is tricky, and getting it all lined up is fiddly. The cotter bolt (pinch bolt to some) slides thru a groove machined in the splined shaft, and you will clearly see this once seperated. Sometimes that groove is 360deg on the spline shaft, sometimes its a simple slot. Slot is fiddly, groove is not so bad.

The rack should be "centralised" before refitting. Simple to do, I will PM you that procedure.

The following users liked this post:

NathanDD6 (07-31-2016)

#48

The following users liked this post:

Grant Francis (07-31-2016)

#49

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

Nathan:

Good work. Persistance pays!!! Some term it stubborness. Once I'm my

past professional life, my boss, a "senior VP" went over the reviewe he did for the "more Senior VP". All good, but one, "I was stubborn". Not news to me. But, I questioned that as a fault. We agreed to look in the dictionary. OK, all he synonyms but one were complimentary.

We left it at that. What the heck, I got a raise !!!! And, not long after, a nice promotion. Away from the LA HO to my own in SF.

I've never taken this starter apart. I've done several AC Delco's.

The architecture is quite similar.

The solenoid has two functions. One mechanical and the other electrical. The housing contains a piston. Application of 12 volts cause it to slam forward.

1. Drives a yoke that pushes the pinion forward into the flex plate ring gear.

2. Bridges two studs. One connected to the battery and the other to

the starter motor. That connection can detiorate by arcing. One Delco had a plate that could be reversed and present new fresh metal.

Prepare to bench test. Especialy important in this application. Gotta be sure it's fixed before you fight it back in place.

The motor can be energized apart from the solenoid. If it spins happily, it is exonerated. If not, oh, oh, more to do.

The solenoid can be tested with 12 v and a VOM or test lamp.

Trivia: A past lister on another forum cautioned us on nomenclature.

The device that converts air and fuel into motion is an engine.

The device that converts electricity into motion is a motor.

Clearly our critters make use of each....

Keep plugging.

Carl

Good work. Persistance pays!!! Some term it stubborness. Once I'm my

past professional life, my boss, a "senior VP" went over the reviewe he did for the "more Senior VP". All good, but one, "I was stubborn". Not news to me. But, I questioned that as a fault. We agreed to look in the dictionary. OK, all he synonyms but one were complimentary.

We left it at that. What the heck, I got a raise !!!! And, not long after, a nice promotion. Away from the LA HO to my own in SF.

I've never taken this starter apart. I've done several AC Delco's.

The architecture is quite similar.

The solenoid has two functions. One mechanical and the other electrical. The housing contains a piston. Application of 12 volts cause it to slam forward.

1. Drives a yoke that pushes the pinion forward into the flex plate ring gear.

2. Bridges two studs. One connected to the battery and the other to

the starter motor. That connection can detiorate by arcing. One Delco had a plate that could be reversed and present new fresh metal.

Prepare to bench test. Especialy important in this application. Gotta be sure it's fixed before you fight it back in place.

The motor can be energized apart from the solenoid. If it spins happily, it is exonerated. If not, oh, oh, more to do.

The solenoid can be tested with 12 v and a VOM or test lamp.

Trivia: A past lister on another forum cautioned us on nomenclature.

The device that converts air and fuel into motion is an engine.

The device that converts electricity into motion is a motor.

Clearly our critters make use of each....

Keep plugging.

Carl

The following users liked this post:

NathanDD6 (08-01-2016)

#50

Thanks for that Carl, got everything out the way, just the starter to go tomorrow! I'll post how that goes.

Just a little tip for anyone who might stumble across this with the same problem; the steering rack, there are 4 power steering lines, only the 2 bigger ones have to come out in order to drop the rack, the 2 small ones connect back onto the rack out of sight.

The solenoid should be interesting, I'm planning to replace all 12 exhaust gaskets too, little leak here and there.

Just a little tip for anyone who might stumble across this with the same problem; the steering rack, there are 4 power steering lines, only the 2 bigger ones have to come out in order to drop the rack, the 2 small ones connect back onto the rack out of sight.

The solenoid should be interesting, I'm planning to replace all 12 exhaust gaskets too, little leak here and there.

Last edited by NathanDD6; 08-01-2016 at 01:59 PM. Reason: Spelling

#51

#52

The following users liked this post:

NathanDD6 (08-02-2016)

#53

The following users liked this post:

Grant Francis (08-02-2016)

#54

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

Nathan;

Your skills at palpitation will improve.

Getting there.

We are all increasingly curious as to what your work on the bench will reveal.

As an aside, while down and under, use your VOM on the large cable from the firewall post to verify continuity.

And check the smaller one from the starter relay for continuity.

Not so simple, I know as a lot separates the terminus of each.

A mate up top and a test lamp down under may be more practical.

Aside: During my starter travails, the battery cable end at the solenoid was just "melted off'. They are far from robust. The generic cable I bought at the local "real parts store" was of far studier stuff, ends and insulation.

If yours is even questionable. consider a swap. It will never be easier....

And, I added a wire to the small post and fed it topside. An emergency crank feature. Just touch the end to the battery + post and the engine should crank....

The belt and braces thing....

Carl

Your skills at palpitation will improve.

Getting there.

We are all increasingly curious as to what your work on the bench will reveal.

As an aside, while down and under, use your VOM on the large cable from the firewall post to verify continuity.

And check the smaller one from the starter relay for continuity.

Not so simple, I know as a lot separates the terminus of each.

A mate up top and a test lamp down under may be more practical.

Aside: During my starter travails, the battery cable end at the solenoid was just "melted off'. They are far from robust. The generic cable I bought at the local "real parts store" was of far studier stuff, ends and insulation.

If yours is even questionable. consider a swap. It will never be easier....

And, I added a wire to the small post and fed it topside. An emergency crank feature. Just touch the end to the battery + post and the engine should crank....

The belt and braces thing....

Carl

#55

#56

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

Nathan:

Whoah!!! What blobs ???

And what of the bench test. Not hard with a clean starter and a battery and some wires and a cable on the bench. Gotta establish:

1. There is a fault.

2 It is the solenoid.

3. It is the starter motor .

4. Or both?

5. Or merely lousy dirty wires and connectors.

6. Or a parted wire or cable.

Carl

Whoah!!! What blobs ???

And what of the bench test. Not hard with a clean starter and a battery and some wires and a cable on the bench. Gotta establish:

1. There is a fault.

2 It is the solenoid.

3. It is the starter motor .

4. Or both?

5. Or merely lousy dirty wires and connectors.

6. Or a parted wire or cable.

Carl

#57

All fixed, and running much smoother, don't know what I did right to be honest, but she's engaging and spinning well.

Re the 2 blobs of solder, it is pretty tough solder, managed to melt it ever so slightly with the blowtorch and an old screwdriver, couldn't get the cap off as a result.

PS when you do a bench test, make sure the jumper cables actually work, any guesses how I know?

All good now, just gonna get the crack in the downpipe welded up, dad has a friend at the airport.

Thank you all for your help, I really really appreciate it

Re the 2 blobs of solder, it is pretty tough solder, managed to melt it ever so slightly with the blowtorch and an old screwdriver, couldn't get the cap off as a result.

PS when you do a bench test, make sure the jumper cables actually work, any guesses how I know?

All good now, just gonna get the crack in the downpipe welded up, dad has a friend at the airport.

Thank you all for your help, I really really appreciate it

The following users liked this post:

Grant Francis (08-07-2016)

#58

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

Nathan:

At times the path is murky, but if one r4eacxhes trhe desired destination, that is what counts!!

Kudos in spades!!!

I am messing with a "mix and match" parts from Jaguar's and MGB's. Objective, 7" outter head lamps.

Why, well fresh Halogen seal beams in lieu of ancient originals. Sans one, result of a prior adventure .

I feel pretty good as I "fixed" my old Chinese semi-copy of a classic Delta 14" band saw. Help and research carried the day!!

Carl

,

At times the path is murky, but if one r4eacxhes trhe desired destination, that is what counts!!

Kudos in spades!!!

I am messing with a "mix and match" parts from Jaguar's and MGB's. Objective, 7" outter head lamps.

Why, well fresh Halogen seal beams in lieu of ancient originals. Sans one, result of a prior adventure .

I feel pretty good as I "fixed" my old Chinese semi-copy of a classic Delta 14" band saw. Help and research carried the day!!

Carl

,

The following users liked this post:

NathanDD6 (08-07-2016)

#59

#60

All fixed, and running much smoother, don't know what I did right to be honest, but she's engaging and spinning well.

Re the 2 blobs of solder, it is pretty tough solder, managed to melt it ever so slightly with the blowtorch and an old screwdriver, couldn't get the cap off as a result.

PS when you do a bench test, make sure the jumper cables actually work, any guesses how I know?

All good now, just gonna get the crack in the downpipe welded up, dad has a friend at the airport.

Thank you all for your help, I really really appreciate it

Re the 2 blobs of solder, it is pretty tough solder, managed to melt it ever so slightly with the blowtorch and an old screwdriver, couldn't get the cap off as a result.

PS when you do a bench test, make sure the jumper cables actually work, any guesses how I know?

All good now, just gonna get the crack in the downpipe welded up, dad has a friend at the airport.

Thank you all for your help, I really really appreciate it

WELL DONE.

Sooooo the solder blobs were the mongrels after all, same as mine.

I agree with TOUGH solder, no idea of the % stuff used there, but my BIG solder iron also had issues, but did the flow eventually.

CONGRATULATIONS AGAIN.

The following users liked this post:

NathanDD6 (08-11-2016)

or a steel rod and the blowtorch, fun times!

or a steel rod and the blowtorch, fun times!