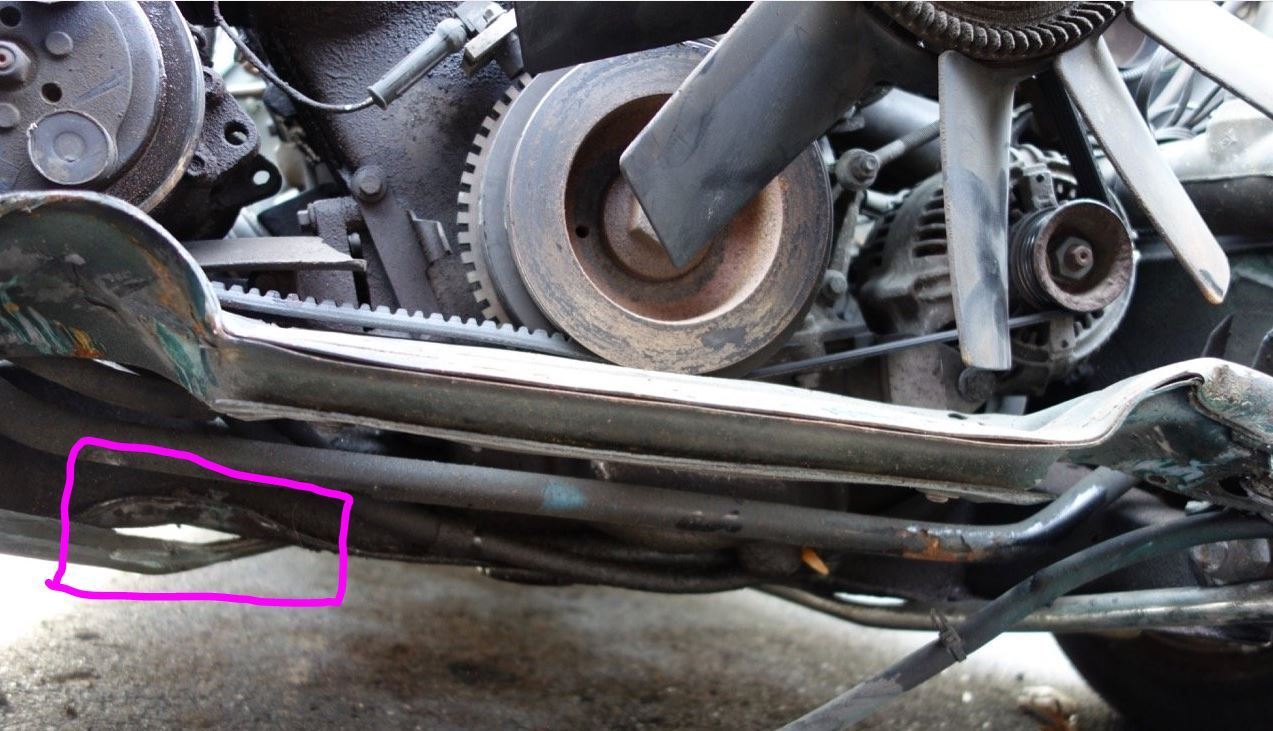

Repair of Subframe (engine cradle) upper control arm bolt holes that are elongated

#21

update-

I ended up taking the engine craddle out, and having the part professionall machined. They did a great job on it. Its back up in place. I lost the order of washers and shins, so today i am trying to sort that out. does anyone have parts numbers and a picture of how it supposed to be assembled?

I am close anyway and I think it will all have to be redone for alignment

I ended up taking the engine craddle out, and having the part professionall machined. They did a great job on it. Its back up in place. I lost the order of washers and shins, so today i am trying to sort that out. does anyone have parts numbers and a picture of how it supposed to be assembled?

I am close anyway and I think it will all have to be redone for alignment

Here's the parts diagram and numbers for the upper wishbone:

XK - Wishbone & Front Hub Assembly.pdf

Only two thicknesses of shim but there can be several fitted on each side.

The chrome domed end washers are now better quality but with a price increase. I paid £2 each in November 2011.

Graham

Last edited by GGG; 03-06-2012 at 05:52 PM.

#22

update-

I ended up taking the engine craddle out, and having the part professionall machined. They did a great job on it. Its back up in place. I lost the order of washers and shins, so today i am trying to sort that out. does anyone have parts numbers and a picture of how it supposed to be assembled?

I am close anyway and I think it will all have to be redone for alignment

I ended up taking the engine craddle out, and having the part professionall machined. They did a great job on it. Its back up in place. I lost the order of washers and shins, so today i am trying to sort that out. does anyone have parts numbers and a picture of how it supposed to be assembled?

I am close anyway and I think it will all have to be redone for alignment

#23

#24

This design of upper wishbone bush has been on Jaguars models for a long time. Once they wear, it's not too long before the internal steel tube in the bush seizes onto the fulcrum pin. Ignore it much longer and the fulcrum pin can seize in the front crossmember.

This was annoying with the older steel crossmember but jono's experience shows the potential for a more disastrous result with the aluminium unit in the XK8/R.

From XJ40 through X300, XJ8 and previous XK8, there's not one Jaguar I've had which hasn't needed the wishbone bushes replaced. I check them visually every time the front wheels are off (you can easily see whether the ends are starting to break up) and more thoroughly at each service.

With the load off the suspension, slacken the locknut and put a socket and bar on the hexagon to make sure the fulcrum pin rotates. If it's OK, tighten up the locknut again. If not, it's time for replacement.

Graham

#25

I was very careful to count and replace the shims on either end of the fulcrum pin (Upper wishbone bolt) and replace them. The problem was I was replacing them on a different (used) subframe. I think these shims vary to address manufacturing tolerances with the body and subframe. I was able to precision align but my steering wheel is about 5 degrees off center - which may or may not be related...

#26

hey guys. I did get it bored 2mm and sleeved with a bushing. They did a great job. I'm defiantly glad I left it to the pros. we test drove it last night and it does need a lower ball joint on the other side and there looks to be a crack in the plastic thermostat housing. I see the update version of that part from jagbits is aluminum.

Other than that, the car is great. I knew the owner of the machine shop and he did the job for 350 CAD. I was happy with that and I think its better than new. There is nothing to say the bushing won't wear the aluminum because it is stronger. I seams to me the control arm mount sound be a bolt on bracket, but then again, I'm defiantly not an engineer.

I want to thank very one on here for advice and support. It was a big help

cheers

Other than that, the car is great. I knew the owner of the machine shop and he did the job for 350 CAD. I was happy with that and I think its better than new. There is nothing to say the bushing won't wear the aluminum because it is stronger. I seams to me the control arm mount sound be a bolt on bracket, but then again, I'm defiantly not an engineer.

I want to thank very one on here for advice and support. It was a big help

cheers

#27

I was very careful to count and replace the shims on either end of the fulcrum pin (Upper wishbone bolt) and replace them. The problem was I was replacing them on a different (used) subframe. I think these shims vary to address manufacturing tolerances with the body and subframe. I was able to precision align but my steering wheel is about 5 degrees off center - which may or may not be related...

It's usually changes in horizontal alignment affects steering wheel position so the 5 degrees off centre is more likely to be related to wheel alignment.

I always have alignment checked after anything on the front suspension has been disturbed. A slight misalignment can soon scrub a tyre down. This is even more important when you've swapped the cross member.

Graham

The following users liked this post:

thenaz007 (03-09-2012)

#28

My aligment is off as well and I am sending it in on Saturday to be corrected. I need to replace the ball joint first to get a proper alignment.

One other question for the field. There is a bit of play in my front shock bushings. I the cost of them is the same as the entire shock (from the places I have looked). Has anyone found a different solution?

One other question for the field. There is a bit of play in my front shock bushings. I the cost of them is the same as the entire shock (from the places I have looked). Has anyone found a different solution?

#29

My aligment is off as well and I am sending it in on Saturday to be corrected. I need to replace the ball joint first to get a proper alignment.

One other question for the field. There is a bit of play in my front shock bushings. I the cost of them is the same as the entire shock (from the places I have looked). Has anyone found a different solution?

One other question for the field. There is a bit of play in my front shock bushings. I the cost of them is the same as the entire shock (from the places I have looked). Has anyone found a different solution?

XK8 - Front Shock Absorber.pdf

From £20 to £30 for the lower bush ($31 - $47) against £140 to £170 for the entire shock assembly ($220 - $267) in the UK.

Looking at costs from a couple of US suppliers for the lower bush, they must come gold plated over there!

Graham

Last edited by GGG; 03-07-2012 at 10:54 AM.

#30

I had a little trouble finding the shock bushings - I was thinking $80 US but that may have been for two. I found Bilstein replacement shocks with bushings for $96 US. These are aftermarket, but Bilstein also makes the OEM version. They seem fine but I am not Speed Racer. I believe it is more work ($) to replace the shock than the bushing.

#31

Thread

Thread Starter

Forum

Replies

Last Post

Fraser Mitchell

XJ XJ6 / XJ8 / XJR ( X350 & X358 )

9

10-01-2015 04:06 AM

Doug Dooren

XJ XJ8 / XJR ( X308 )

0

08-30-2015 08:51 AM

smokin_hobo

F-Type ( X152 )

8

08-29-2015 12:13 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)