Coolant Overflow Tank question

#1

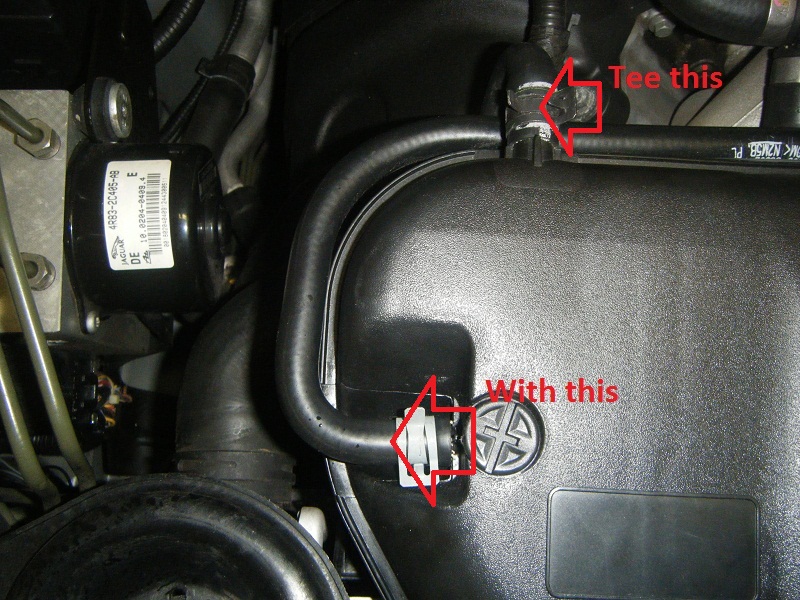

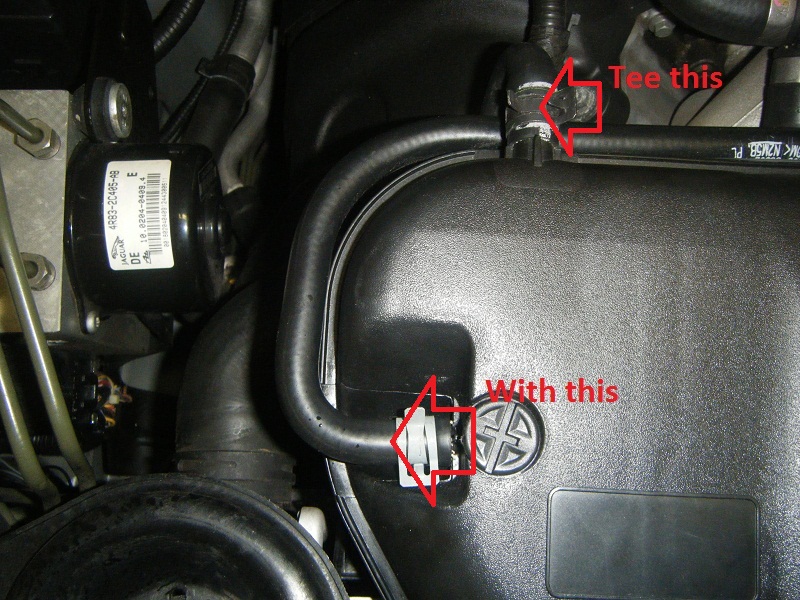

Well I did it today. Probably the worst day I have ever had in the garage. I was removing the throttle body to give it a clean since I was doing plugs, oil change, and fuel filter change, so I figured why not. Well what a pain in the rear that turned out to be. Getting it out wasnt too bad but going to put it back I could not get my hand in the little spot to work to get the coolant lines back on (I was not bypassing them). Well I ended up having to lay across the motor to get enough room to get my hands back there. Well as I was getting back down my shirt caught the clamp for the overflow tube and it was already loose and I could tell it was about to break before. Well when my shirt got it it completed the job and snapped it right off. My question is I wont be able to get a new overflow tank for a little while. I was looking at the hoses coming out of it and was wondering would it still operate properly if I plugged that nipple that broke with say JB Weld to get it nice and sealed then got a tee fitting and teed the hose in with the other hose on the top that comes out? Has anyone one ever did this? If so how long did you run it like that and did it cause any problems? Here are some pics to help show what I'm thinking. I tried to clamp it on what little of the nipple was still left and the pressure was to much and I blew coolant everywhere. Also found out that if your oil cap isnt on all the way you will throw misfire codes like crazy. Another thing I wasnt able to get a video of the throttle body process I just couldn't get my hands and the camera in there good enough to get anything worth using. Trust me its not a task you want to take on if you got bigger hands. Those coolant lines are a pain. I did get footage for a spark plug video so hopefully I can get time to edit that tomorrow and upload it while I'm sleep tomorrow night.

Last edited by vance580; 03-12-2011 at 11:26 PM.

#2

Shiat! I'm sorry to hear that bro. I did break that nipple on my S500 coolant tank once. I used the JB weld thinking I can use it temporarily, but the heat in the engine bay and coolant will break it off sooner or later. It only lasted me 24hrs or so, but eventually broke off when I was checking at home. I wouldn't risk it and be stuck on the side of the road VAnce  I really can't think of any other alternative than to just replace it and wait till the part delivers at your home which is another headache.

I really can't think of any other alternative than to just replace it and wait till the part delivers at your home which is another headache.

Good Luck, and thanks in advance for putting the effort in all your work to make the video, look forward to the Plugs change video.

Good Luck, and thanks in advance for putting the effort in all your work to make the video, look forward to the Plugs change video.

Last edited by jag79; 03-12-2011 at 11:54 PM.

#3

My XJ8 did that same evil deed. I got my new tank from www.oemonlineparts.com They beat the dealer price by a bunch even with a new hose and clamps and shipping.

It is a vent to get air out of the cooling system. That screw by the nipple is a bleeder screw. When mine broke, I pluged the hose and the broken nipple, but I didn't take the car anywhere.

It is a vent to get air out of the cooling system. That screw by the nipple is a bleeder screw. When mine broke, I pluged the hose and the broken nipple, but I didn't take the car anywhere.

#4

Yea I figure the JB weld wont hold the nipple that I actually dont have cause I ended up getting it out of the hose and it got lost. I was just gonna use the JB weld to plug the hole there then run a normal tee fitting and tee it with the other hose since they are both at the top of the tank. I'm wondering if that will work. Sorry I couldnt get the throttle body vid for you but it really is a pain. I tried getting my camera at every angle and it just wasnt getting any good video cause of the room.

#5

Yea I figure the JB weld wont hold the nipple that I actually dont have cause I ended up getting it out of the hose and it got lost. I was just gonna use the JB weld to plug the hole there then run a normal tee fitting and tee it with the other hose since they are both at the top of the tank. I'm wondering if that will work. Sorry I couldnt get the throttle body vid for you but it really is a pain. I tried getting my camera at every angle and it just wasnt getting any good video cause of the room.

The tee thing might work you have a 50/50 shot at it. I heard of another product I can't remember the name exactly that HOme depot was selling which was supposedly stronger than the JB weld that was compatible to plastic and rubber bonding

**WTF; that reservoir tank on our STR is like $404 on http://www.oemonlineparts.com/ http://www.oemonlineparts.com/partlo...layCatalogid=0

On this website its selling for $149.58 a lot cheaper http://jaguar-parts.jagbits.com/s%25...252DType--list

Last edited by jag79; 03-13-2011 at 12:23 AM.

#6

Hey no need to apologize amigo, removing the TB is no joke especially doing it alone and using both hands to squeeze in that tight spot with large hands is crazy. By the way did that CRC throttle body cleaner do the job of removing the goo build up in the TB?

The tee thing might work you have a 50/50 shot at it. I heard of another product I can't remember the name exactly that HOme depot was selling which was supposedly stronger than the JB weld that was compatible to plastic and rubber bonding

**WTF; that reservoir tank on our STR is like $404 http://www.oemonlineparts.com/partlo...layCatalogid=0

On this website its selling for $149.58 a lot cheaper http://jaguar-parts.jagbits.com/s%25...252DType--list

The tee thing might work you have a 50/50 shot at it. I heard of another product I can't remember the name exactly that HOme depot was selling which was supposedly stronger than the JB weld that was compatible to plastic and rubber bonding

**WTF; that reservoir tank on our STR is like $404 http://www.oemonlineparts.com/partlo...layCatalogid=0

On this website its selling for $149.58 a lot cheaper http://jaguar-parts.jagbits.com/s%25...252DType--list

The CRC did a really nice job. Sprayed it, then used an old toothbrush to scrub and then wiped and had it spotless in about 10 minutes. Mine was pretty clean to begin with. It wasnt as bad as fergs pics. Just had a small amount of build up that came right off with a toothbrush and the CRC. When I started the car it was all messed up idling all over the place I thought I had screwed something up and was gonna have to rip it apart again. Then I realized I didnt have my oil cap on all the way and as I was screwing it back on everything leveled back out to normal. My check engine light came on and when I hooked up my ELMScan there was misfire codes like crazy. I cleared them and it was purring till that nipple finally gave out and snapped.

#7

Trending Topics

#8

Thanks for the help clubairth1. It was worth a try to see if someone had tried. I figured someone had since I always hear about them breaking. I bit the bullet and called the place I found one at and they are overnighting to me to I'll have it Tuesday. Will have to drive the wifes car till then. Good thing she works midnights so she sleeps while I'm at school and doesnt need her car. I actually came across one in Houston a guy was selling on craigslist in case anyone in the Houston area wants to pic one up as a spare it was only 60 bucks. Here is a link to it.

http://houston.craigslist.org/pts/2249355935.html

http://houston.craigslist.org/pts/2249355935.html

#9

Hey just a couple of thoughts. I've done stuff like this before so I feel for you.

The rear most fitting is the connection for the supercharger intercooler circuit. I removed that hose and used it to fill that circuit when I did my coolant exchange. There might be an internal baffle in the tank to prevent the easy intermixing of the two systems. They both share a single POS plastic expansion/reservoir tank. With your T patch perhaps it's something to think about?

When this has happened to me before I have sometimes been able to get a piece of brass tubing of the correct size at a hobby shop and figure a way to slip it over the remaining plastic and glue it in place. Then the hose slips over the short brass nipple. It might work?

I think mine is leaking very, very slightly at that rear spot and I'm trying to get the dealer to look at/acknowledge it. After pulling it off once already as well as listening to these kinds of stories I don't want to touch it again. They must have used the wrong grade of plastic for these tanks. I have others that are milky clear that have worked just fine for 20 years and all the nipples are still intact.

Sh*tty parts! These and the headlamps should be a lifetime warranty because Jaguar really f*cked up and it pisses people off. Not good for your reputation.

I also put a little silicone grease (Napa has it in a tube) on all my coolant fittings so that when you go to remove them they aren't glued on there which leads to breaks like this.

That and errant shirts! Work in the nude dude!

One other thing that's a total PITA is that stupid bleed screw. Once things get hot it's not easy to screw that back in. After my warranty expires I think I'm going to add a T fitting to that front hose and attach a short piece of hose to it with a brass fish tank valve on it. I've done this on several cars and it makes bleeding the bubbles out of the system so much easier. You drop the hose and valve in a container and let the coolant & air bleed out into a nice tidy container. I wish the connection point was higher up on the tank but this still might work OK.

Best of luck.

The rear most fitting is the connection for the supercharger intercooler circuit. I removed that hose and used it to fill that circuit when I did my coolant exchange. There might be an internal baffle in the tank to prevent the easy intermixing of the two systems. They both share a single POS plastic expansion/reservoir tank. With your T patch perhaps it's something to think about?

When this has happened to me before I have sometimes been able to get a piece of brass tubing of the correct size at a hobby shop and figure a way to slip it over the remaining plastic and glue it in place. Then the hose slips over the short brass nipple. It might work?

I think mine is leaking very, very slightly at that rear spot and I'm trying to get the dealer to look at/acknowledge it. After pulling it off once already as well as listening to these kinds of stories I don't want to touch it again. They must have used the wrong grade of plastic for these tanks. I have others that are milky clear that have worked just fine for 20 years and all the nipples are still intact.

Sh*tty parts! These and the headlamps should be a lifetime warranty because Jaguar really f*cked up and it pisses people off. Not good for your reputation.

I also put a little silicone grease (Napa has it in a tube) on all my coolant fittings so that when you go to remove them they aren't glued on there which leads to breaks like this.

That and errant shirts! Work in the nude dude!

One other thing that's a total PITA is that stupid bleed screw. Once things get hot it's not easy to screw that back in. After my warranty expires I think I'm going to add a T fitting to that front hose and attach a short piece of hose to it with a brass fish tank valve on it. I've done this on several cars and it makes bleeding the bubbles out of the system so much easier. You drop the hose and valve in a container and let the coolant & air bleed out into a nice tidy container. I wish the connection point was higher up on the tank but this still might work OK.

Best of luck.

Last edited by Staatsof; 03-13-2011 at 04:17 AM.

#10

Seems there should be a repair for these tanks. I recently bought a plastic welding kit but haven't had time to play with it. In the past I have saved broken plastic pieces such as fan shrouds, electrical boxes ect. Lot of expensive plastic under the hood of todays cars and a front end hit breaks a lot of it. What I have done is basically weld the plastic with a soldering iron and useing a piece of scrap for filler. The kit I bought looks to do the same thing except there are filler rods for different materials and the heat range is adjustable.

What I was thinking may work is to fill up the hole and build up that area in thickness. If it were thick enough a hole could then be drilled and tapped for a brass nipple. Just a thought.

Fortunately mine seems to have survived unscathed. Maybe I can get ahold of one someone replaced to play with?

What I was thinking may work is to fill up the hole and build up that area in thickness. If it were thick enough a hole could then be drilled and tapped for a brass nipple. Just a thought.

Fortunately mine seems to have survived unscathed. Maybe I can get ahold of one someone replaced to play with?

#11

#12

The difference in quality and durability among these plastic coolant overflow tanks from vendor to vendor is astounding. I recently drained, flushed, and refilled the cooling system in my 1999 Dodge Ram pickup. Part of that process involved removing the overflow tank from the radiator (a 10-second task) and thoroughly rinsing it out with a garden hose. The thickness and heft of that Ram plastic tank compared to our S-Type plastic tank is ridiculous. It makes the S-Type tank look like a plastic milk jug in comparison....

#13

The repair of the plastic nipple is very much complicated by the physical placement of the nipples. Someone mentioned the plastic welding kits. Great idea but you have no access to about half of the nipple. Same problem with other repair techniques. Where it breaks is usually close to the body of the tank. Leaving you little choice.

.

.

.

.

.

.

#14

Well I ended up having to lay across the motor to get enough room to get my hands back there. Well as I was getting back down my shirt caught the clamp for the overflow tube and it was already loose and I could tell it was about to break before. Well when my shirt got it it completed the job and snapped it right off.

Here you go, Vance!

http://www.northerntool.com/shop/too..._357638_357638

What's that old saw about an ounce of prevention? Sounds like close to what you'll be sinking into your new tank!

I desparately need one of these for the Exc....I've been using plywood scraps across the engine..but still uncomfortable and lots of creaks and groans..not all coming from me!

Sorry for your misfortune, but look at it this way: It was gonna crap-out anyway, you just helped choose the time!

#15

Here you go, Vance!

http://www.northerntool.com/shop/too..._357638_357638

What's that old saw about an ounce of prevention? Sounds like close to what you'll be sinking into your new tank!

I desparately need one of these for the Exc....I've been using plywood scraps across the engine..but still uncomfortable and lots of creaks and groans..not all coming from me!

Sorry for your misfortune, but look at it this way: It was gonna crap-out anyway, you just helped choose the time!

http://www.northerntool.com/shop/too..._357638_357638

What's that old saw about an ounce of prevention? Sounds like close to what you'll be sinking into your new tank!

I desparately need one of these for the Exc....I've been using plywood scraps across the engine..but still uncomfortable and lots of creaks and groans..not all coming from me!

Sorry for your misfortune, but look at it this way: It was gonna crap-out anyway, you just helped choose the time!

Thats actually a really good idea. That would of worked perfect for getting back there. I need to come up with an idea like this so I can retire. I actually found the tank for 150 overnighted which wasnt too bad. Maybe I'll use the old one to see how much it would cost to fab up a metal tank and keep that for the next time it breaks.

#16

#17

#18

#19

One possible repair depending on access is to use a mag wheel type air valve. The type that secures with a nut on the stem that compresses two rubber washers. Just remove the valve core.

Drill out the hole to the right size, smooth the hole, slip the stem and one of the washers in, slip the other washer on the outside, screw down with the nut.

If you are really paranoid, coat the gasket mating surfaces with silicone.

Drill out the hole to the right size, smooth the hole, slip the stem and one of the washers in, slip the other washer on the outside, screw down with the nut.

If you are really paranoid, coat the gasket mating surfaces with silicone.

#20

Yes, access IS the problem. These tanks are also make from a very inappropriate form of plastic so I don't know that drilling would work anyway? Just buy a new one and be more careful in the future. I have to wonder if the used route isn't asking for trouble?

On a couple of my other cars the tanks are made from a clear and more flexible plastic that can absorb some abuse like this. One even has a metal tube inside of the plastic nipple.

A couple of week ago three of us did a major service on a friends 2001 V8 Jag and it involved removing a couple of vacuum lines as well as coolant lines that had "special" twist off connectors. Even with the warnings of a tech ahead of time one of them simply broke in a very clean fashion where the connector meets the plastic, yes that's correct, plastic ribbed tubing. The car is 10 years old with 40K miles and after that much time all of these "great idea" connectors become fragile.

Have you also noticed that with so many different styles of these newer connector designs that if you don't know EXACTLY how each one comes off then you're putting the wrong kind of stress on them and frequently you're not exactly "rewarded" for your efforts in the most helpful way?

My friend was lucky in that it could be patched because getting to the other end of the hose was hours of work and probably additional stressed & broken plastic parts.

On a couple of my other cars the tanks are made from a clear and more flexible plastic that can absorb some abuse like this. One even has a metal tube inside of the plastic nipple.

A couple of week ago three of us did a major service on a friends 2001 V8 Jag and it involved removing a couple of vacuum lines as well as coolant lines that had "special" twist off connectors. Even with the warnings of a tech ahead of time one of them simply broke in a very clean fashion where the connector meets the plastic, yes that's correct, plastic ribbed tubing. The car is 10 years old with 40K miles and after that much time all of these "great idea" connectors become fragile.

Have you also noticed that with so many different styles of these newer connector designs that if you don't know EXACTLY how each one comes off then you're putting the wrong kind of stress on them and frequently you're not exactly "rewarded" for your efforts in the most helpful way?

My friend was lucky in that it could be patched because getting to the other end of the hose was hours of work and probably additional stressed & broken plastic parts.