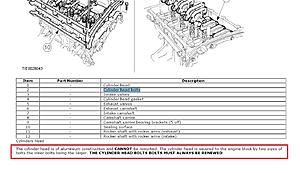

Can I reused the head bolts?

#1

#2

#3

#4

Join Date: May 2008

Location: Great Mills, MD

Posts: 14,200

Likes: 0

Received 3,823 Likes

on

3,142 Posts

All, the reason why that modern day head bolt cannot be reused is a function of how they are torqued. My time in the Navy, I had to learn more about torquing and how it affects the metal than I care to admit to. So, here is the short of the story. When I talk about yield, most of you have seen where bolts have a rating on them that is referred to as strength which is normally something like 50,000 lbs/in2, this is a value that is very close to the strength, but has some different factors that are tossed in. so, this gives you an idea of what sort of numbers we are talking about here.

When you put a metal under stress, it tends to act like taffy, it will stretch and give some. As long as you remain under a point called "yield", the metal will snap back and all is good. It maintains its properties. No crime, no foul.

When you take something to yield, what you will see is the metal will stretch some, but when you release the stress, it will remain elongated. You may have seen this on bolts where up near the head, the bolt has narrowed ever so slightly. When you approach the yield point, the metal will actually get stronger as you are pulling the internal metal structure into a better crystal structure (trying not to get too technical here). But, this is a very fine line. For, if you take it just a little too far, you go from getting stronger to outright failure. This is why when you look at a broken bolt, you can see where the blt has narrowed and then the metal has an end that kinda looks like sugar (these are the crystals).

The head bolts are a "torque to yield" design. By knowing a starting load on the bolt (hence why you torque the bolt to a low torque value initially) and the make up of the joint (ie, length of bolt, head material, gasket material, etc). you can figure out how much you can stretch the bolt to bring it to its maximum strength.

If you were to reuse the same bolts, the bolts have already stretched and not returned. If you use them again, you are going to stretch them a second time and take them to a point that their strength is much less (been stretched too far) and can result in rapid failure once the cylinder starts firing.

The same concept is used for the bolts on very high torque items but instead of trying to turn the nut to increase the torque, we apply an initial torque, then we heat the bolt to a given temperature (the bolt "stretches" due to getting hot), then we torque the bolt a second time to a given value and let the bolt cool. As the bolt attempts to shrink due to cooling off, this causes the bolt to start applying more torque. This is how you torque bolts that go to millions of ft-lbs of torque.

When you put a metal under stress, it tends to act like taffy, it will stretch and give some. As long as you remain under a point called "yield", the metal will snap back and all is good. It maintains its properties. No crime, no foul.

When you take something to yield, what you will see is the metal will stretch some, but when you release the stress, it will remain elongated. You may have seen this on bolts where up near the head, the bolt has narrowed ever so slightly. When you approach the yield point, the metal will actually get stronger as you are pulling the internal metal structure into a better crystal structure (trying not to get too technical here). But, this is a very fine line. For, if you take it just a little too far, you go from getting stronger to outright failure. This is why when you look at a broken bolt, you can see where the blt has narrowed and then the metal has an end that kinda looks like sugar (these are the crystals).

The head bolts are a "torque to yield" design. By knowing a starting load on the bolt (hence why you torque the bolt to a low torque value initially) and the make up of the joint (ie, length of bolt, head material, gasket material, etc). you can figure out how much you can stretch the bolt to bring it to its maximum strength.

If you were to reuse the same bolts, the bolts have already stretched and not returned. If you use them again, you are going to stretch them a second time and take them to a point that their strength is much less (been stretched too far) and can result in rapid failure once the cylinder starts firing.

The same concept is used for the bolts on very high torque items but instead of trying to turn the nut to increase the torque, we apply an initial torque, then we heat the bolt to a given temperature (the bolt "stretches" due to getting hot), then we torque the bolt a second time to a given value and let the bolt cool. As the bolt attempts to shrink due to cooling off, this causes the bolt to start applying more torque. This is how you torque bolts that go to millions of ft-lbs of torque.

Last edited by Thermo; 01-07-2018 at 08:48 AM.

The following users liked this post:

motorcarman (01-07-2018)

#5

#6

Join Date: May 2008

Location: Great Mills, MD

Posts: 14,200

Likes: 0

Received 3,823 Likes

on

3,142 Posts

Thang, no, the bolts cannot be used. They get stretched to the yield point upon torquing them. Running of the engine has nothing to do with the metal changes that occurred when you tightened them. I have heard of people re-using them, but that is done at a risk of a head coming off with the engine running.

Thread

Thread Starter

Forum

Replies

Last Post

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)