Vacuum Leaks

#1

After replacing the radiator on my Dodge Ram 1500 in about 1 hr yesterday, I decided that I was tired of playing in such a spacious engine compartment and started tackling a vacuum leak problem on my Jag.

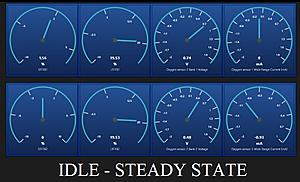

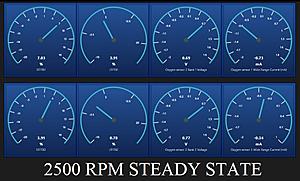

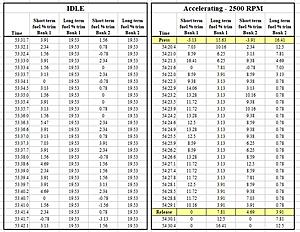

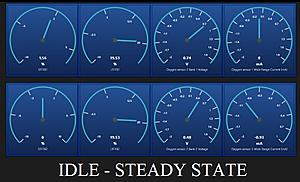

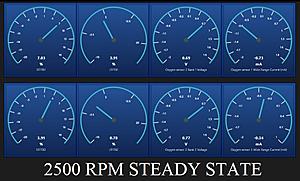

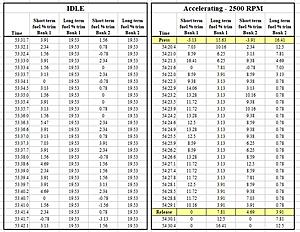

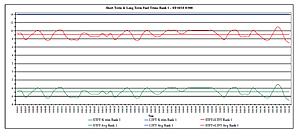

The car has been idling rough when cold and throwing an occasional P0305 (with the accompanying P1316) along with P0420 and P0430 codes intermittently and I decided it was time to look into it further. I ran a real time data stream using a Bluetooth OBD2 module and Car Scan Pro software. Below are the numerical and gauge representations I found at idle (Normal operating temp) and at 2500 RPM.

I think that the numbers confirmed at least one significant vacuum leak.

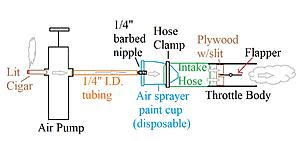

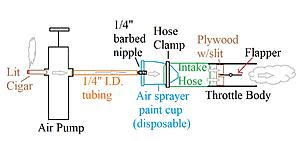

I built a homemade smoke tester using materials I had around the house (sans the cigars) and connected it to the inlet manifold air intake.

I removed the small air box and plugged the hole in the air inlet piping using a PVC pipe plug and electrical tape. I cut a small piece of 1/4 inch plywood (about 2 in x 2 in) to fit into the throttle body and cut a slit in the plywood about midway up to hold the throttle body flapper open. I reached into the throttle body and opened the flap about 1/2 way and inserted my “device”. I then attached the engine smoke tester to the flexible air intake pipe, tightened the ring clamp, lit the cigar and started slowly pumping the air pump and watched for smoke….

I found leaks on the intake manifold brass collet fitting for the Purge Solenoid Valve and at the PVC valve connection to the camshaft cover.

I believe that there is supposed to be a black plastic release ring on the brass collet that allows the hose to release when the ring is pressed down – I have no such ring left in the fitting on my car.

I found a replacement part number for the brass collet, O-ring, and plastic insert - C2S15816 and apparently the brake booster vacuum line and purge solenoid line attach to the manifold with identical fitting, as the part number is the same for both.

There is a pretty good discussion on this forum started by RobinGa back in November, 2016 concerning this very issue. He determined that the brass collet is apparently pressed into the intake manifold and thus difficult to remove, so he simply removed the plastic keeper ring and lower rubber O-ring within the brass collet with needle nose pliers while it was still in the manifold. He then reinserted a new O-ring and plastic keeper ring without having to replace the brass collet. I think I will need to do the same.

The more significant leak was on the PCV valve. The valve on my car has come loose to the point where I can see the sealing O-ring located below the upper seating flange, where the valve sits on the camshaft cover when looking down at it from the engine compartment. It appears that the securing tab(s) have become worn or broken and fail to properly seat the valve snug in an air-tight manner to the cover. The part number for the PCV valve is C2S25648.

I discovered a technical service bulletin (XT303-S928) which discusses the need to replace the PCV valve immediately if the base of the valve is black. If the base is green or grey, the upgrade has already been made. Mine is green, but I saw a few black base valves still for sale on the internet. Needless to say, these older valves are the cheapest – so if someone is thinking of replacing their PCV valves, make sure the base is the correct color.

I will attack these two leaks next weekend after I get the replacement parts and fire up the smoker again for further testing. Hopefully this will resolve my vacuum leak issue, since I checked all around the engine during the test and found no other apparent leaks.

The car has been idling rough when cold and throwing an occasional P0305 (with the accompanying P1316) along with P0420 and P0430 codes intermittently and I decided it was time to look into it further. I ran a real time data stream using a Bluetooth OBD2 module and Car Scan Pro software. Below are the numerical and gauge representations I found at idle (Normal operating temp) and at 2500 RPM.

I think that the numbers confirmed at least one significant vacuum leak.

I built a homemade smoke tester using materials I had around the house (sans the cigars) and connected it to the inlet manifold air intake.

I removed the small air box and plugged the hole in the air inlet piping using a PVC pipe plug and electrical tape. I cut a small piece of 1/4 inch plywood (about 2 in x 2 in) to fit into the throttle body and cut a slit in the plywood about midway up to hold the throttle body flapper open. I reached into the throttle body and opened the flap about 1/2 way and inserted my “device”. I then attached the engine smoke tester to the flexible air intake pipe, tightened the ring clamp, lit the cigar and started slowly pumping the air pump and watched for smoke….

I found leaks on the intake manifold brass collet fitting for the Purge Solenoid Valve and at the PVC valve connection to the camshaft cover.

I believe that there is supposed to be a black plastic release ring on the brass collet that allows the hose to release when the ring is pressed down – I have no such ring left in the fitting on my car.

I found a replacement part number for the brass collet, O-ring, and plastic insert - C2S15816 and apparently the brake booster vacuum line and purge solenoid line attach to the manifold with identical fitting, as the part number is the same for both.

There is a pretty good discussion on this forum started by RobinGa back in November, 2016 concerning this very issue. He determined that the brass collet is apparently pressed into the intake manifold and thus difficult to remove, so he simply removed the plastic keeper ring and lower rubber O-ring within the brass collet with needle nose pliers while it was still in the manifold. He then reinserted a new O-ring and plastic keeper ring without having to replace the brass collet. I think I will need to do the same.

The more significant leak was on the PCV valve. The valve on my car has come loose to the point where I can see the sealing O-ring located below the upper seating flange, where the valve sits on the camshaft cover when looking down at it from the engine compartment. It appears that the securing tab(s) have become worn or broken and fail to properly seat the valve snug in an air-tight manner to the cover. The part number for the PCV valve is C2S25648.

I discovered a technical service bulletin (XT303-S928) which discusses the need to replace the PCV valve immediately if the base of the valve is black. If the base is green or grey, the upgrade has already been made. Mine is green, but I saw a few black base valves still for sale on the internet. Needless to say, these older valves are the cheapest – so if someone is thinking of replacing their PCV valves, make sure the base is the correct color.

I will attack these two leaks next weekend after I get the replacement parts and fire up the smoker again for further testing. Hopefully this will resolve my vacuum leak issue, since I checked all around the engine during the test and found no other apparent leaks.

The following users liked this post:

wa3ra (03-05-2018)

#2

A short update - When I got home this evening, I was fooling around with the PCV valve and discovered that the top of the valve (nipple elbow) will rotate within the base. This led me to see if I could tighten the base more fully to the camshaft cover and simply rotate the nipple back in alignment with the hose.

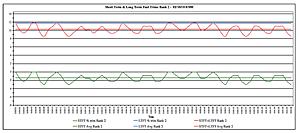

I removed the hose, tightened down the base fully (no more gap) and rotated the nipple back in line with the hose. I reattached the hose and fired up the engine to check the fuel trims. The idle LFTFs dropped slightly from +19.5ish% (pre-tightening) to + 16.5ish% (after tightening) while the STFTs went from +4-0% (pre-tightening) to -5ish% (after). I drove about 2 miles to see if I could get the LTFTs to drop more, now that the STFTs were consistently negative at idle. When I got back, the LFTFs were still around +16% at idle. I may not have driven long enough. Will keep an eye on this when I drive to work tomorrow.

I removed the hose, tightened down the base fully (no more gap) and rotated the nipple back in line with the hose. I reattached the hose and fired up the engine to check the fuel trims. The idle LFTFs dropped slightly from +19.5ish% (pre-tightening) to + 16.5ish% (after tightening) while the STFTs went from +4-0% (pre-tightening) to -5ish% (after). I drove about 2 miles to see if I could get the LTFTs to drop more, now that the STFTs were consistently negative at idle. When I got back, the LFTFs were still around +16% at idle. I may not have driven long enough. Will keep an eye on this when I drive to work tomorrow.

#3

Day 2 Update

Idle LTFTs remained between +14% - +16% after driving to and from work (15 miles each way), no significant changes to STFTs from test data, pre-PCV valve tightening.

So I learned that out Jags use Air Flow Sensors rather than the old O2 sensor. I found this out while I was exploring the possibility that my sensors were lagging or going bad.

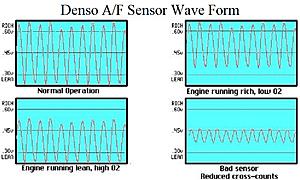

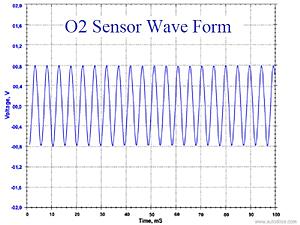

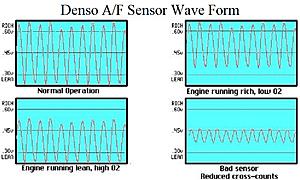

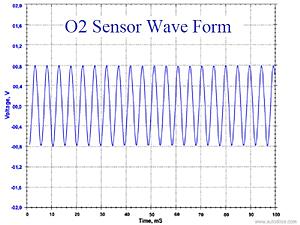

My OBDII data was showing the sensors would never drop below +0 volts and usually hung around +0.4V to +0.7V. After finding the proper wave form for A/F sensors instead of the -1.0V to +1.0V wave form for 02 sensors, it made more sense.

It is no surprise that the data I was seeing from the A/F sensors confirmed that I have an engine running rich. Now to resolve the probable vacuum leak.

I just had both upper and lower intake manifold gaskets replaced and if the source of the leak(s) is not external, the only other likely things I have been able to uncover are leaking intake gaskets, low fuel pressure, clogged fuel injectors, a possible dirty or failing MAF or failing ECU.

The fuel pressure remained between 54-56 psi during tests, so rejected this as a possibility, I replaced the ECU recently and the problem manifested itself prior to replacing the ECU, so I will rule that one out also.

Just thought I would share, so others do not simply Google O2 sensor problems instead of A/F sensor problems if they believe that they could be an issue.

Idle LTFTs remained between +14% - +16% after driving to and from work (15 miles each way), no significant changes to STFTs from test data, pre-PCV valve tightening.

So I learned that out Jags use Air Flow Sensors rather than the old O2 sensor. I found this out while I was exploring the possibility that my sensors were lagging or going bad.

My OBDII data was showing the sensors would never drop below +0 volts and usually hung around +0.4V to +0.7V. After finding the proper wave form for A/F sensors instead of the -1.0V to +1.0V wave form for 02 sensors, it made more sense.

It is no surprise that the data I was seeing from the A/F sensors confirmed that I have an engine running rich. Now to resolve the probable vacuum leak.

I just had both upper and lower intake manifold gaskets replaced and if the source of the leak(s) is not external, the only other likely things I have been able to uncover are leaking intake gaskets, low fuel pressure, clogged fuel injectors, a possible dirty or failing MAF or failing ECU.

The fuel pressure remained between 54-56 psi during tests, so rejected this as a possibility, I replaced the ECU recently and the problem manifested itself prior to replacing the ECU, so I will rule that one out also.

Just thought I would share, so others do not simply Google O2 sensor problems instead of A/F sensor problems if they believe that they could be an issue.

#6

This morning I tackled the vacuum leaks again. I connected my "Do-It-Yourself" engine smoke tester back up to the air intake, but this time I left the small air cleaner inlet box attached to the side of the intake hose. I recognized that this could be a source of un-metered air, since it is past the MAF, if it was somehow leaking.

When I tested the engine, the leak in the Purge Line was no longer present and the leak at the PCV valve connector to the camshaft cover was no longer visible. What I did get, however, was a leak at the connector for the air cleaner box and the intake hose.

I also noted that it was much more difficult to pump smoke into the intake, now that the other leaks had been stopped.

I placed a hose clamp around the air cleaner nipple to intake hose and tested again.

It quickly got difficult to pump any more smoke into the intake, as there was no where for the pressure to go.

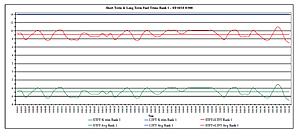

I reset the Long Term Fuel Trims by disconnecting the battery cables and touching them together. After reconnecting the battery, I started up the car. After a short attempt to die at idle (since there were no LTFT values to help set the throttle), the car started to idle normally. I was able to see the LTFTs quickly gain values and after about 15 mins at idle they appeared to have somewhat stabilized.

The good news is that the LTFTs went from +19.5% with STFTs at +1%-3% at idle before fixing the leaks to around +10% with STFTs at -4 to -6% (bank 1) and 0% to -3% (bank 2). I am hoping that the negative STFTs will eventually drive the LTFTs below +10%. It does appear that I may still have a very small leak somewhere in bank 2.

But for now, I am claiming VICTORY!!

I have to share that I was able to find and monitor these issues with equipment that cost me less than $15 total.

I purchased an ELM327 bluetooth OBDII reader on Amazon for less than $10.

I then went online and found Car Scanner Pro software for my phone and laptop for the outrageous price of $2.99. This software lets you monitor ECU data real time, provides freeze frame data for DTCs and of course allows you to reset the CEL for PXXXX codes. There is more sophisticated equipment out there, but for less than $15 this combo met my needs perfectly!!

When I tested the engine, the leak in the Purge Line was no longer present and the leak at the PCV valve connector to the camshaft cover was no longer visible. What I did get, however, was a leak at the connector for the air cleaner box and the intake hose.

I also noted that it was much more difficult to pump smoke into the intake, now that the other leaks had been stopped.

I placed a hose clamp around the air cleaner nipple to intake hose and tested again.

It quickly got difficult to pump any more smoke into the intake, as there was no where for the pressure to go.

I reset the Long Term Fuel Trims by disconnecting the battery cables and touching them together. After reconnecting the battery, I started up the car. After a short attempt to die at idle (since there were no LTFT values to help set the throttle), the car started to idle normally. I was able to see the LTFTs quickly gain values and after about 15 mins at idle they appeared to have somewhat stabilized.

The good news is that the LTFTs went from +19.5% with STFTs at +1%-3% at idle before fixing the leaks to around +10% with STFTs at -4 to -6% (bank 1) and 0% to -3% (bank 2). I am hoping that the negative STFTs will eventually drive the LTFTs below +10%. It does appear that I may still have a very small leak somewhere in bank 2.

But for now, I am claiming VICTORY!!

I have to share that I was able to find and monitor these issues with equipment that cost me less than $15 total.

I purchased an ELM327 bluetooth OBDII reader on Amazon for less than $10.

I then went online and found Car Scanner Pro software for my phone and laptop for the outrageous price of $2.99. This software lets you monitor ECU data real time, provides freeze frame data for DTCs and of course allows you to reset the CEL for PXXXX codes. There is more sophisticated equipment out there, but for less than $15 this combo met my needs perfectly!!

Last edited by PanamaJag; 03-10-2018 at 12:04 PM.

#7

Trending Topics

#8

So, while I claimed victory yesterday, I got to thinking about un-metered air flow and it dawned on me that if the MAF sensor was dirty, it could allow air to pass through without accurately accounting for the total amount.

I purchased a can of MAF sensor cleaner and Throttle Body cleaner from Walmart this morning and gave both a good cleaning. Reset the LTFTs again and tested her out.

After reaching normal temp on the car, I observed a slight increase in calculated average air flow (about 3% increase after taking into account changes in atmospheric pressure and temp) from the last data I had grabbed earlier.

But I did see a noticeable difference in the smoothness of idle and response to the throttle. I should have thought of this earlier.....

I purchased a can of MAF sensor cleaner and Throttle Body cleaner from Walmart this morning and gave both a good cleaning. Reset the LTFTs again and tested her out.

After reaching normal temp on the car, I observed a slight increase in calculated average air flow (about 3% increase after taking into account changes in atmospheric pressure and temp) from the last data I had grabbed earlier.

But I did see a noticeable difference in the smoothness of idle and response to the throttle. I should have thought of this earlier.....

#9

#10

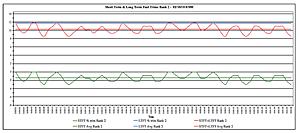

After correcting 3 observed leaks I have gotten the LTFTs down to around +10% average at idle with STFTs averaging -2% to -6% at idle. The LTFTs still drop to around 0% at 2500 RPM and STFTs return to around +0% also...

So I am at a point of letting things ride to see if the negative STFTs drive the LTFTs down over time. If not, the LTFTs are not as horrendous as the were, but still not optimal.

I have started to monitor MAF sensor air flow rate and intake manifold absolute pressure, but not sure what "good" numbers for these two look like.

Currently the "Idle" average MAF air flow rate is 3.88 g/sec and average Intake Manifold Absolute Pressure is 5.97 psi.

- a little more investigation on the web is called for.

#11

The following users liked this post:

PanamaJag (03-12-2018)

Thread

Thread Starter

Forum

Replies

Last Post

Jeeves12

X-Type ( X400 )

3

09-01-2021 06:52 PM

jaguars4r

XJ XJ8 / XJR ( X308 )

14

11-07-2012 08:02 AM

The Coupe

XK8 / XKR ( X100 )

6

03-20-2012 08:37 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)