Recurring P0171 OBD II CODE

#1

I own a 2004 XJ8 not supercharged, with about 100000 miles. recently, my check engine light came on, and the error codes were for both Bank 1 and 2 Upstream O2 sensors. I replaced both sensors and that appeared to solve the problem. however, within a few drive cycles I started to get the engine light back on and a p0170 code for a bank 1 too lean. When I reset the codes, sometimes it will go a couple of engine Cycles before I get the same engine light, the same po170 code, and and RP warning on the dash. The engine has no noticeable issues and I have not even noticed the RP when driving the car with some moderate aggression. I carefully checked for air leaks in the air intake system, and cleaned the MAF sensor and reinstalled it. I cannot here any obvious air leaks. Any ideas on some possible answers? Is it just a coincidence that this is happening immediately following Upstream O2 sensor replacements? I would love to partake of the collective wisdom of this Jaguar forum.

Thanks in advance

Thanks in advance

#2

Your code scanner - is this one able to monitor fuel trim data?

I have seen in some cases where the MAF can wreak havoc without logging a DTC for it. Cleaning it can help, but won't always work if its actually faulty.

As for vacuum leaks, sometimes these can be too small to hear.

Your best option at this stage before you replace anymore parts, is to use your scanner, or find one that can give you STFT ( Short Term Fuel Trim ) and LTFT ( Long Term Fuel Trim ) data. Once you're able to monitor this, you should be able to decipher where your issue lies. You can do it at idle, but needs to be up to operating temp. The STFT will fluctuate from 0 to positive and negative 5%, if you see it start to go over 5%, you either have a faulty sensor somewhere ( will need to check all DTC's, ) or a vacuum leak. You will need to get some brake clean and spray down the intake, around throttle body, vacuum pipes, etc to see if you notice any change in fuel trim.

Hope this helps, report back what you find.

I have seen in some cases where the MAF can wreak havoc without logging a DTC for it. Cleaning it can help, but won't always work if its actually faulty.

As for vacuum leaks, sometimes these can be too small to hear.

Your best option at this stage before you replace anymore parts, is to use your scanner, or find one that can give you STFT ( Short Term Fuel Trim ) and LTFT ( Long Term Fuel Trim ) data. Once you're able to monitor this, you should be able to decipher where your issue lies. You can do it at idle, but needs to be up to operating temp. The STFT will fluctuate from 0 to positive and negative 5%, if you see it start to go over 5%, you either have a faulty sensor somewhere ( will need to check all DTC's, ) or a vacuum leak. You will need to get some brake clean and spray down the intake, around throttle body, vacuum pipes, etc to see if you notice any change in fuel trim.

Hope this helps, report back what you find.

#3

#4

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,391

Received 12,737 Likes

on

6,379 Posts

Hi 11scotthair11,

Welcome to the Jaguar Forums! It's great to have you with us.

You can download a fairly complete version of the Diagnostic Trouble Code Summaries manual here:

Jaguar X350 DTC Summaries

As you will find, P0170 is not listed in the above manual. It also is not listed in the X350 Workshop Manual or other DTC Summaries manuals I have in my library. This suggests that P0170 was not implemented in the X350, at least not in the early cars. Your scanner may be attempting to make sense of Mode $06 data but misreporting it as P0170. Without any other fuel-trim-related codes, you can only guess what it means.

It is rare for two O2 sensors in different banks to fail simultaneously, so it is likely that whatever was causing the previous codes may still be misbehaving.

If your scanner can read live data, write down your fuel trims, MAF reading at idle, coolant temperature, etc. and post them here and we'll try to help.

Another clue would be if any of the emissions systems readiness monitors are not resetting - can your scanner check the monitors?

Cheers,

Don

Welcome to the Jaguar Forums! It's great to have you with us.

You can download a fairly complete version of the Diagnostic Trouble Code Summaries manual here:

Jaguar X350 DTC Summaries

As you will find, P0170 is not listed in the above manual. It also is not listed in the X350 Workshop Manual or other DTC Summaries manuals I have in my library. This suggests that P0170 was not implemented in the X350, at least not in the early cars. Your scanner may be attempting to make sense of Mode $06 data but misreporting it as P0170. Without any other fuel-trim-related codes, you can only guess what it means.

It is rare for two O2 sensors in different banks to fail simultaneously, so it is likely that whatever was causing the previous codes may still be misbehaving.

If your scanner can read live data, write down your fuel trims, MAF reading at idle, coolant temperature, etc. and post them here and we'll try to help.

Another clue would be if any of the emissions systems readiness monitors are not resetting - can your scanner check the monitors?

Cheers,

Don

#5

Here's an update on the situation; after reading your posts about the obscurity of an 0170 code, I decided to dig deeper. I borrowed my neighbors OBD reader and it coded out a 0171 confirmed, a 0171pending, and a P1000. I live an hour or so up in the mountains in Utah, and my local resources are limited at best. I called all the "local" national chain part stores to see if they could scan/read for fuel trim data, and only one person I talked to even knew what it was, and none had a capable scanner. couldn't detect any fuel trim changes using the brake clean around the throttle body area or the air intake assembly. But when I shoot the brake clean directly into the air intake, their is a significant fuel trim difference. The only other (maybe coincidental) finding is; after I removed, cleaned, and reinstalled the PCV breather hose, the engine light stayed off for 3 or 4 restarts. Based on my current findings, what is my next logical step? I have a diagnostic circuit tester. Is it possible to test the MAF using that? Please advise...

#6

I own a 2004 XJ8 not supercharged, with about 100000 miles. recently, my check engine light came on, and the error codes were for both Bank 1 and 2 Upstream O2 sensors. I replaced both sensors and that appeared to solve the problem. however, within a few drive cycles I started to get the engine light back on and a p0170 code for a bank 1 too lean. When I reset the codes, sometimes it will go a couple of engine Cycles before I get the same engine light, the same po170 code, and and RP warning on the dash. The engine has no noticeable issues and I have not even noticed the RP when driving the car with some moderate aggression. I carefully checked for air leaks in the air intake system, and cleaned the MAF sensor and reinstalled it. I cannot here any obvious air leaks. Any ideas on some possible answers? Is it just a coincidence that this is happening immediately following Upstream O2 sensor replacements? I would love to partake of the collective wisdom of this Jaguar forum.

Thanks in advance

Thanks in advance

Hi 11scotthair11,

Welcome to the Jaguar Forums! It's great to have you with us.

You can download a fairly complete version of the Diagnostic Trouble Code Summaries manual here:

Jaguar X350 DTC Summaries

As you will find, P0170 is not listed in the above manual. It also is not listed in the X350 Workshop Manual or other DTC Summaries manuals I have in my library. This suggests that P0170 was not implemented in the X350, at least not in the early cars. Your scanner may be attempting to make sense of Mode $06 data but misreporting it as P0170. Without any other fuel-trim-related codes, you can only guess what it means.

It is rare for two O2 sensors in different banks to fail simultaneously, so it is likely that whatever was causing the previous codes may still be misbehaving.

If your scanner can read live data, write down your fuel trims, MAF reading at idle, coolant temperature, etc. and post them here and we'll try to help.

Another clue would be if any of the emissions systems readiness monitors are not resetting - can your scanner check the monitors?

Cheers,

Don

Welcome to the Jaguar Forums! It's great to have you with us.

You can download a fairly complete version of the Diagnostic Trouble Code Summaries manual here:

Jaguar X350 DTC Summaries

As you will find, P0170 is not listed in the above manual. It also is not listed in the X350 Workshop Manual or other DTC Summaries manuals I have in my library. This suggests that P0170 was not implemented in the X350, at least not in the early cars. Your scanner may be attempting to make sense of Mode $06 data but misreporting it as P0170. Without any other fuel-trim-related codes, you can only guess what it means.

It is rare for two O2 sensors in different banks to fail simultaneously, so it is likely that whatever was causing the previous codes may still be misbehaving.

If your scanner can read live data, write down your fuel trims, MAF reading at idle, coolant temperature, etc. and post them here and we'll try to help.

Another clue would be if any of the emissions systems readiness monitors are not resetting - can your scanner check the monitors?

Cheers,

Don

#7

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,391

Received 12,737 Likes

on

6,379 Posts

Thanks for sending the DTC'S. You were right about the 0170 code. Turned out to be exactly what you suggested, a 0171. I'm going to use a multimeter to check the MAF. We'll see where it goes from there. Thanks again for sending the code summaries, much appreciated!

If you have only the P0171 code for Bank 1 (the P is important so don't leave it out), and not a corresponding P0174 lean code for Bank 2, then you need to look at possible causes that can affect only Bank 1. Problems with the MAF or intake air leaks will generally effect both banks.

Problems that can affect only Bank 1 include a leaking PCV valve, which mounts to the Bank 1 camshaft cover, a leaking O-ring on, or crack in, the plastic pipe that connects to the PCV valve, a leak in the Bank 1 exhaust between the exhaust manifold and the catalytic converter, a problem with the wiring for one or both of the Bank 1 oxygen sensors, etc. See the DTC Summaries for any I've forgotten.

Cheers,

Don

Last edited by Don B; 04-11-2018 at 08:59 PM.

Trending Topics

#8

Sounds like you have a similar problem like I have at the moment.

Generally, when you have a bank-specific air-fuel-ration problem the issue must come from a system that the banks don't share. This means it must come from

1) leaks in the exhaust section of the bank until the catalyst (the pipes unite after that and the bank-specific exhaust composition get lost again)

Sucked-in air due to pressure pulsations, even minimal amounts, will continually simulate a slighty oxygen-rich and therefore lean exhaust gas to the lambda probe, dragging the countering fuel trims higher and higher until they max out (depending on operation point, mine maxed out to 25% at low speed/loads and were around 17..20% at around 100km/h only tio rise again at higher speeds -> gas dynamics)

This is operation point specific, at some speeds and loads the effect may not occurr or to a lesser amount due to the dynamic nature of the exhaust pressure pulsations.

This failure is also the most dangerous one in my opinion, because you add a lot of fuel that is not burnt inside the cylinders plus you add oxygen before the catalyst, so that the unburnt fuel will oxidize in the cat depending on how much air is sucked through the leak. This can easily set free a lot of energy inside the cat that may crack or melt it. Additionally, unburnt fuel is a catylyst poison and may damage the chemical catalytic properties of the coating.

2) Injection system

Generally all injectors get the same injection duration signal at a given operation point. If some are worn, plugged or just faulty they will not deliver the amount of fuel intended by the ECM on base of the MAF signal and the added corrections of the lambda probes. So these individual cylinders will run leaner (or potentially also richer if they stick during the closing ramp and therefore effectively open longer than intended) and mess up the overall lambda-reading of all cylinders combined in the one bank's exhaust section because the lambda probe reads their collective mixed gas.

ECM has only one countermeasure to adapt the whole bank's fuel trim to get a correct average over all the 4 cylinders again (well, works with 3 cylinder's too on a V6).

This fault would not necessarily result in hitting the limit of the fuel trims but is depending on the magnitude of injector non-uniformity. When one cylinder is 15% down in fuel delivery, the other 3 cylinders each adding 5% would be compensating that and lambda would be happy in total.

Good thing is that the danger for the catalyst seems smaller than option 1 because the overall air/fuel ratio of the bank fits and most of the unburnt stuff has a good chance to already oxidize directly after mixing of the 4 flows inside the exhaust manifold. Still means increased thermal stress on the catalyst entry, not to mention increased fuel consumption because the faulty cylinder is not only not delivering the power it should, it even has to be dragged along by the remaining 7 to deliver what the driver commands by pedal.

3) Ignition

If your coils or plugs are messed up and don't properly ignite the cylinder contents there is a chance of a similar effect as in option 2, some of the cylinder mixture gets out unburnt and may reach the lambda measuring position with too much oxygen inside.

Most everything that affects the intake side should show on both banks, in my opinion also the crankcase ventilations.

It's true that the part and full load crankcase ventilations are on the left respectively right cylinder head. But the connection below is into the oil space of the engine, connecting to the crankcase below by the timing chain housing and potentially by oil draining ducts.

There is no direct connection between either of the PCV systems on top of the head to the combustion relevant air duct of the respective bank or even the cylinders directly. The blowby gases going through the crankcase find their way up into both camshaft rooms, and depending on the amount and pressure they are feeding into the intake system after MAF again on two different places.

If air were inducted through any of the PCVs it should affect both banks, because it would allow unmetered air into the intake system, which distributes the effect to all participating cylindersand the try to which the lambda control will compensate again.

So when the banks show substantially different equivalence ratios/fuel trims and there is a clear problem on only one bank, priorities should be exhaust, injection and ignition of that bank. This should cover far > 90% of the possible root causes.

If nothing is to be found there than you will have to look for intake leaks extremely close the the cylinders, e.g. directly between intake manifold and cylinder head, which may affect only the cylinders closest to the leak.

Good luck, I wish I had more time to crawl through my engine at the moment.

Generally, when you have a bank-specific air-fuel-ration problem the issue must come from a system that the banks don't share. This means it must come from

1) leaks in the exhaust section of the bank until the catalyst (the pipes unite after that and the bank-specific exhaust composition get lost again)

Sucked-in air due to pressure pulsations, even minimal amounts, will continually simulate a slighty oxygen-rich and therefore lean exhaust gas to the lambda probe, dragging the countering fuel trims higher and higher until they max out (depending on operation point, mine maxed out to 25% at low speed/loads and were around 17..20% at around 100km/h only tio rise again at higher speeds -> gas dynamics)

This is operation point specific, at some speeds and loads the effect may not occurr or to a lesser amount due to the dynamic nature of the exhaust pressure pulsations.

This failure is also the most dangerous one in my opinion, because you add a lot of fuel that is not burnt inside the cylinders plus you add oxygen before the catalyst, so that the unburnt fuel will oxidize in the cat depending on how much air is sucked through the leak. This can easily set free a lot of energy inside the cat that may crack or melt it. Additionally, unburnt fuel is a catylyst poison and may damage the chemical catalytic properties of the coating.

2) Injection system

Generally all injectors get the same injection duration signal at a given operation point. If some are worn, plugged or just faulty they will not deliver the amount of fuel intended by the ECM on base of the MAF signal and the added corrections of the lambda probes. So these individual cylinders will run leaner (or potentially also richer if they stick during the closing ramp and therefore effectively open longer than intended) and mess up the overall lambda-reading of all cylinders combined in the one bank's exhaust section because the lambda probe reads their collective mixed gas.

ECM has only one countermeasure to adapt the whole bank's fuel trim to get a correct average over all the 4 cylinders again (well, works with 3 cylinder's too on a V6).

This fault would not necessarily result in hitting the limit of the fuel trims but is depending on the magnitude of injector non-uniformity. When one cylinder is 15% down in fuel delivery, the other 3 cylinders each adding 5% would be compensating that and lambda would be happy in total.

Good thing is that the danger for the catalyst seems smaller than option 1 because the overall air/fuel ratio of the bank fits and most of the unburnt stuff has a good chance to already oxidize directly after mixing of the 4 flows inside the exhaust manifold. Still means increased thermal stress on the catalyst entry, not to mention increased fuel consumption because the faulty cylinder is not only not delivering the power it should, it even has to be dragged along by the remaining 7 to deliver what the driver commands by pedal.

3) Ignition

If your coils or plugs are messed up and don't properly ignite the cylinder contents there is a chance of a similar effect as in option 2, some of the cylinder mixture gets out unburnt and may reach the lambda measuring position with too much oxygen inside.

Most everything that affects the intake side should show on both banks, in my opinion also the crankcase ventilations.

It's true that the part and full load crankcase ventilations are on the left respectively right cylinder head. But the connection below is into the oil space of the engine, connecting to the crankcase below by the timing chain housing and potentially by oil draining ducts.

There is no direct connection between either of the PCV systems on top of the head to the combustion relevant air duct of the respective bank or even the cylinders directly. The blowby gases going through the crankcase find their way up into both camshaft rooms, and depending on the amount and pressure they are feeding into the intake system after MAF again on two different places.

If air were inducted through any of the PCVs it should affect both banks, because it would allow unmetered air into the intake system, which distributes the effect to all participating cylindersand the try to which the lambda control will compensate again.

So when the banks show substantially different equivalence ratios/fuel trims and there is a clear problem on only one bank, priorities should be exhaust, injection and ignition of that bank. This should cover far > 90% of the possible root causes.

If nothing is to be found there than you will have to look for intake leaks extremely close the the cylinders, e.g. directly between intake manifold and cylinder head, which may affect only the cylinders closest to the leak.

Good luck, I wish I had more time to crawl through my engine at the moment.

#9

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,391

Received 12,737 Likes

on

6,379 Posts

There is no direct connection between either of the PCV systems on top of the head to the combustion relevant air duct of the respective bank or even the cylinders directly. The blowby gases going through the crankcase find their way up into both camshaft rooms, and depending on the amount and pressure they are feeding into the intake system after MAF again on two different places.

If air were inducted through any of the PCVs it should affect both banks, because it would allow unmetered air into the intake system, which distributes the effect to all participating cylindersand the try to which the lambda control will compensate again.

If air were inducted through any of the PCVs it should affect both banks, because it would allow unmetered air into the intake system, which distributes the effect to all participating cylindersand the try to which the lambda control will compensate again.

I think you are correct theoretically, but since I just resolved P0171 on a 2005 S-Type R with 174K miles by replacing the O-ring on the plastic pipe that connects to the PCV valve on Bank 1, my conclusion is that a leak at the PCV valve can communicate directly with some or all of the Bank 1 combustion chambers past valve guides that have become worn. The O-ring on the pipe had hardened and flattened and as I moved the pipe around in the PCV valve fitting I could hear the engine idle change.

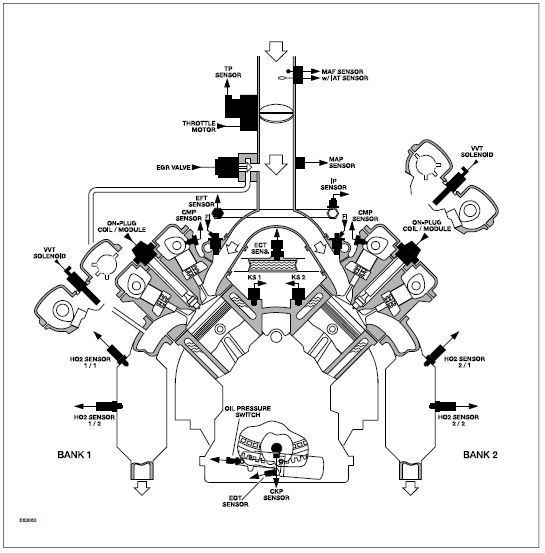

The location of the PCV valve makes the Bank 1 cylinders more likely to inhale air that leaks past the PCV valve or pipe seals and to do so at a level that is not equally distributed throughout the entire crankcase breathing system. The engine diagram from the manual doesn't show the PCV valve, but since it mounts directy to the Bank 1 cam cover, you can see how little there is to prevent leaked air from being inhaled into any Bank 1 cylinder on its intake stroke if the valve guides are worn:

Cheers,

Don

Last edited by Don B; 04-12-2018 at 09:08 AM.

#10

Hmmm, well, all theory is gray, true.

I don't have a schematic or photo without engine cover available to take a quick gance now, but If I remember correctly one of the PCV hoses enters at the throttle body and the other upstream from it. Actually no stratification of blowby gas should survive the turbulence created by the throttle blade up to really serious opening angles.

Just found a pic, full load PCV from bank 1 goes into intake system far after the throttle. Part load PCV enters intake system before throttle.

If valve guides let such an amount of gas pass I would expect to feel oil consumption already drastically increase.

But in all honesty I can't explain the effect you described for one bank

But I'll rather have it working even when I can't fully explain why and assume 11scotthair11 will see it similar.

and assume 11scotthair11 will see it similar.

Since I'm fighting a comparable battle against my still slightly twisted fuel trims I'll definitely go change the O-rings.

Repair can hardly get cheaper than that, both hoses and the PCV valve are around 150€ at Jaguar here, two Viton O-rings are not worth mentioning compared to that from the local industrial parts store.

Do you happen to have the dimensions of the rings?

When I change them I will definitely run some experiments on what happens with fuel trims if I pull off the one or the other PCV line and report back for common brainstorming

Just found a pic, full load PCV from bank 1 goes into intake system far after the throttle. Part load PCV enters intake system before throttle.

If valve guides let such an amount of gas pass I would expect to feel oil consumption already drastically increase.

But in all honesty I can't explain the effect you described for one bank

But I'll rather have it working even when I can't fully explain why

and assume 11scotthair11 will see it similar.

and assume 11scotthair11 will see it similar.Since I'm fighting a comparable battle against my still slightly twisted fuel trims I'll definitely go change the O-rings.

Repair can hardly get cheaper than that, both hoses and the PCV valve are around 150€ at Jaguar here, two Viton O-rings are not worth mentioning compared to that from the local industrial parts store.

Do you happen to have the dimensions of the rings?

When I change them I will definitely run some experiments on what happens with fuel trims if I pull off the one or the other PCV line and report back for common brainstorming

Last edited by Aix; 04-12-2018 at 09:52 AM. Reason: I made no sense :)

#11

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,391

Received 12,737 Likes

on

6,379 Posts

The O-ring I replaced right at the pipe-to-PCV valve joint was 2.5mmX14mm I.D/19mm O.D. I didn't replace any other O-rings because I was working remotely with few tools and just happened to have some O-ring assortments with me. I was actually there to get a tour of a collection of classic cars and found the owner working on his wife's S-Type R trying to identify a coolant leak (octopus hose under the reservoir). He mentioned the P0171 so I had a look at the codes and fuel trims and a quick inspection turned up the leaking PCV pipe.

I'm sure it would be prudent to go through and replace all the breather system O-rings, but as I said I didn't have many tools with me and I really wanted to see the classic car collection (which was fabulous).

Cheers,

Don

I'm sure it would be prudent to go through and replace all the breather system O-rings, but as I said I didn't have many tools with me and I really wanted to see the classic car collection (which was fabulous).

Cheers,

Don

Last edited by Don B; 04-12-2018 at 03:29 PM.

#12

#13

So here's the latest; tested the MAF with a multi -meter. With key on, not started: main power -11.90V, MAF Output-.65V IAT-2.02V

at idle; main power-14.20V MAF 1.29V, IAT-2.39V

AT 2000 RPM; MAIN POWER-14.37V MAF-1.69V, IAT- 2.49V. When I unplug the MAF, aside from a brief idle change that returns to normal in 2-3 seconds, no noticeable performance changes. Maybe idle's slightly more rough. I had no luck at all using brake clean or propane to find vacuum leaks. I used the lit cigar method also, and found a leak on the intake end of the PCV HOSE. I REPLACED THE O- RINGS ON BOTH ENDS OF THE HOUSE WITH NO POSITIVE RESULTS (0171 CODE). THEN I GOT A NEW P1646 CODE for a bank 1 upstream O2 sensor. I decided to try a 02 sensor switch, side to side. The bank one (same as 0171 lean) sensor was fried!. A very thin, tough layer of carbon was virtually fused to the metal of the sensor. I let it sit in gasoline for 8 hours, then still had a hard time getting the carbon off. It now causes a P1647 code in bank 2, so i presume that t's shot. (It had only been installed maybe 10 days earlier. When I looked at the spark plugs on bank one, they were similarly "fried", but still very functional. Bank 2 plugs and sensor look normal. When I push on the brake while driving, i can hear a brief release of air on the driver side of engine bay. It doesn't happen when parked. So I'm totally stumped at this point. I can hear a constant hissing around the PCV when the engine is running, but I didn't detect vacuum leaks around it with any method. Are the MAF voltages within normal limits? Any thoughts of where to go from here? I am going to have to get another new 02 sensor and new plugs, at least. Please advise.

at idle; main power-14.20V MAF 1.29V, IAT-2.39V

AT 2000 RPM; MAIN POWER-14.37V MAF-1.69V, IAT- 2.49V. When I unplug the MAF, aside from a brief idle change that returns to normal in 2-3 seconds, no noticeable performance changes. Maybe idle's slightly more rough. I had no luck at all using brake clean or propane to find vacuum leaks. I used the lit cigar method also, and found a leak on the intake end of the PCV HOSE. I REPLACED THE O- RINGS ON BOTH ENDS OF THE HOUSE WITH NO POSITIVE RESULTS (0171 CODE). THEN I GOT A NEW P1646 CODE for a bank 1 upstream O2 sensor. I decided to try a 02 sensor switch, side to side. The bank one (same as 0171 lean) sensor was fried!. A very thin, tough layer of carbon was virtually fused to the metal of the sensor. I let it sit in gasoline for 8 hours, then still had a hard time getting the carbon off. It now causes a P1647 code in bank 2, so i presume that t's shot. (It had only been installed maybe 10 days earlier. When I looked at the spark plugs on bank one, they were similarly "fried", but still very functional. Bank 2 plugs and sensor look normal. When I push on the brake while driving, i can hear a brief release of air on the driver side of engine bay. It doesn't happen when parked. So I'm totally stumped at this point. I can hear a constant hissing around the PCV when the engine is running, but I didn't detect vacuum leaks around it with any method. Are the MAF voltages within normal limits? Any thoughts of where to go from here? I am going to have to get another new 02 sensor and new plugs, at least. Please advise.

#14

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,391

Received 12,737 Likes

on

6,379 Posts

So here's the latest; tested the MAF with a multi -meter. With key on, not started: main power -11.90V, MAF Output-.65V IAT-2.02V

at idle; main power-14.20V MAF 1.29V, IAT-2.39V

AT 2000 RPM; MAIN POWER-14.37V MAF-1.69V, IAT- 2.49V. When I unplug the MAF, aside from a brief idle change that returns to normal in 2-3 seconds, no noticeable performance changes. Maybe idle's slightly more rough. I had no luck at all using brake clean or propane to find vacuum leaks. I used the lit cigar method also, and found a leak on the intake end of the PCV HOSE. I REPLACED THE O- RINGS ON BOTH ENDS OF THE HOUSE WITH NO POSITIVE RESULTS (0171 CODE). THEN I GOT A NEW P1646 CODE for a bank 1 upstream O2 sensor. I decided to try a 02 sensor switch, side to side. The bank one (same as 0171 lean) sensor was fried!. A very thin, tough layer of carbon was virtually fused to the metal of the sensor. I let it sit in gasoline for 8 hours, then still had a hard time getting the carbon off. It now causes a P1647 code in bank 2, so i presume that t's shot. (It had only been installed maybe 10 days earlier. When I looked at the spark plugs on bank one, they were similarly "fried", but still very functional. Bank 2 plugs and sensor look normal. When I push on the brake while driving, i can hear a brief release of air on the driver side of engine bay. It doesn't happen when parked. So I'm totally stumped at this point. I can hear a constant hissing around the PCV when the engine is running, but I didn't detect vacuum leaks around it with any method. Are the MAF voltages within normal limits? Any thoughts of where to go from here? I am going to have to get another new 02 sensor and new plugs, at least. Please advise.

at idle; main power-14.20V MAF 1.29V, IAT-2.39V

AT 2000 RPM; MAIN POWER-14.37V MAF-1.69V, IAT- 2.49V. When I unplug the MAF, aside from a brief idle change that returns to normal in 2-3 seconds, no noticeable performance changes. Maybe idle's slightly more rough. I had no luck at all using brake clean or propane to find vacuum leaks. I used the lit cigar method also, and found a leak on the intake end of the PCV HOSE. I REPLACED THE O- RINGS ON BOTH ENDS OF THE HOUSE WITH NO POSITIVE RESULTS (0171 CODE). THEN I GOT A NEW P1646 CODE for a bank 1 upstream O2 sensor. I decided to try a 02 sensor switch, side to side. The bank one (same as 0171 lean) sensor was fried!. A very thin, tough layer of carbon was virtually fused to the metal of the sensor. I let it sit in gasoline for 8 hours, then still had a hard time getting the carbon off. It now causes a P1647 code in bank 2, so i presume that t's shot. (It had only been installed maybe 10 days earlier. When I looked at the spark plugs on bank one, they were similarly "fried", but still very functional. Bank 2 plugs and sensor look normal. When I push on the brake while driving, i can hear a brief release of air on the driver side of engine bay. It doesn't happen when parked. So I'm totally stumped at this point. I can hear a constant hissing around the PCV when the engine is running, but I didn't detect vacuum leaks around it with any method. Are the MAF voltages within normal limits? Any thoughts of where to go from here? I am going to have to get another new 02 sensor and new plugs, at least. Please advise.

Regarding your MAFS tests, I am not aware of any Jaguar documentation that specifies what the voltages should be from the sensor, although your battery power of 11.9V is low - either because your battery was depleted, or there is resistance in the battery power and/or ground circuits in the vehicle. Your voltages with the engine running of 14.2-14.37V are probably OK, if not a little low.

The only MAFS pinpoint tests I am aware of start on page 2462 of the Workshop Manual, but they assume you have had a MAFS-related diagnostic trouble code flagged, and focus on the supply voltage, ground, and connection to the ECM, not the MAFS output.

The easiest way to get a sense of the MAFS performance is to use a scanner with Live Data capability and watch the MAFS signal. As a general rule of thumb, the MAFS signal will be in grams/second, about the same as or a little more than the displacement of the engine in liters, so your 4.2L should read something like 4-6 g/sec at idle. As you rev the engine, the signal should climb to 20-30 g/sec or more.

Regarding your search for an air leak, did you test around the top and bottom sides of the Bank 1 exhaust manifold?

Regarding the O2S that was carboned up, is it possible the sensor was not torqued properly and exhaust gasses have been blowing out the O2S port?

Regarding the hiss of air on the driver's side, that could be from the brake booster. Did you check the brake booster vacuum hose for leaks?

Cheers,

Don

The following users liked this post:

AD2014 (04-20-2018)

#15

I have found on my 2005 XJR .... if I get code P0170 since its been running good with no issues; I have felt that it might be a clogged or sticking injectors.

I have had this 2 different times and just reset and put in a fuel additive/cleaner and seems to work. Second trip code was a year later which was about two months ago and still off.

It's worth a try for $5 of a good injector cleaner.

I have had this 2 different times and just reset and put in a fuel additive/cleaner and seems to work. Second trip code was a year later which was about two months ago and still off.

It's worth a try for $5 of a good injector cleaner.

#16

Hi 11scotthair11, seems our cars are behaving quite similar at the moment.

Mine, too, had the hissing around the PCV and developed slightly uncomfortable fuel trims. The hissing also changed when slightly pushing on the PCV valve.

The hose from the valve was also quite brittle and obviously already taped in the past, so I changed the whole crankcase ventilation stuff yesterday evening, also the part load breather on bank 2, just for completeness. Cleaned all the surfaces that seal to the o-rings, too, to make sure they are sealed.

Good thing was that this was by far the easiest and fasted job I ever had to do on this Jag, 10 minutes and all was changed.

Bad thing is that, same as in your case, it didn't change anything to the better. The hissing is still there, although it can no longer be manipulated by pressing the PCV valve. I just chose to consider this an improvement.

But to put cream on top I now have misfiring DTCs in the system, sugared up with reported injector circuit problems.

If you find the silver bullet to solve this, please share. I promise I also will !

Mine, too, had the hissing around the PCV and developed slightly uncomfortable fuel trims. The hissing also changed when slightly pushing on the PCV valve.

The hose from the valve was also quite brittle and obviously already taped in the past, so I changed the whole crankcase ventilation stuff yesterday evening, also the part load breather on bank 2, just for completeness. Cleaned all the surfaces that seal to the o-rings, too, to make sure they are sealed.

Good thing was that this was by far the easiest and fasted job I ever had to do on this Jag, 10 minutes and all was changed.

Bad thing is that, same as in your case, it didn't change anything to the better. The hissing is still there, although it can no longer be manipulated by pressing the PCV valve. I just chose to consider this an improvement.

But to put cream on top I now have misfiring DTCs in the system, sugared up with reported injector circuit problems.

If you find the silver bullet to solve this, please share. I promise I also will !

The following users liked this post:

Don B (04-24-2018)

#17

#18

Well, some hissing in the PCV valve may be normal. After all there is flow through the valve through an tight, spring and diaphragm-controlled gap.

But it made sense, and also based on Don B's contribution above I therefore changed the whole stuff. Fuel trims were totally unimpressed.

They actually were not bad before (within +/- 3%) and if anything then bank 2 became a bit better and bank 1 a bit worse.

Sorry, don't want to hijack the thread for my green beast, but maybe the effects observed by several different cars contribute to a solution for all of us.

But it made sense, and also based on Don B's contribution above I therefore changed the whole stuff. Fuel trims were totally unimpressed.

They actually were not bad before (within +/- 3%) and if anything then bank 2 became a bit better and bank 1 a bit worse.

Sorry, don't want to hijack the thread for my green beast, but maybe the effects observed by several different cars contribute to a solution for all of us.

The following users liked this post:

Don B (04-24-2018)

#19

I am now a firm believer in the seemingly random nuance of vacuum leaks. As mentioned previously, due to geographical considerations, I don't have access to anything but basic OBD II diagnostic tests, such as fuel trims, etc. So I was relegated to diagnosis by trial and error, and the limited info available from a multi meter.

. I had absolutely no luck with the carb cleaner/ propane methods of leak detection. Using the "cigar" method, I did detect a small leak where the PCV hose connects to the top of the throttle body. I changed out the o- rings on both ends of the PCV hose. The cigar re-test suggested that the leak had been fixed. but it had no effect on the persistent P0171 code. I also checked the upper and lower exhaust manifold ares for leaks with no luck. I had basically resigned myself to an expensive trip to the dealership, but I thought I'd try one more time. I sprayed the carb cleaner around the all the vacuum hoses add I had done many times before, but this time with a stone cold engine. I immediately noticed an idle change when I sprayed near the PCV/ throttle body connection. I had already changed out o-rings there, and the other end of the hose, too. Closer inspection revealed that the connector on top of the throttle body did not fit in perfectly straight. This was probably do to some dimensional shrinkage due to advancef the age of hose plastic. I added another o ring to the connector so it had a very snug fit into the throttle body. When I started the car, both the P0171 code and the mil was gone. I've been replaced the fouled O2 sensor on bank 1 Upstream. The P1646 code also resolved itself. I guess the moral to my long-winded story is that vacuum leaks can and might behave differently in different temperature environments, and it would be wise to test for vacuum leaks at various engine temperatures. So finally my long quest to resolve this problem is over, but I think there are also questions to be asked about the fix itself. Such as if the vacuum leak was located on top of the throttle body, why did it not affect both Bank 1 and bank 2 equally and simultaneously as logic would suggest? Just food for thought, I suppose. I thank you all for your wise and generous advice to me in helping me resolve this without an expensive trip to the dealership. This forum is a wonderful source of knowledge and experience for us relative novices. Much appreciated!

Kindest regards,

Scott

. I had absolutely no luck with the carb cleaner/ propane methods of leak detection. Using the "cigar" method, I did detect a small leak where the PCV hose connects to the top of the throttle body. I changed out the o- rings on both ends of the PCV hose. The cigar re-test suggested that the leak had been fixed. but it had no effect on the persistent P0171 code. I also checked the upper and lower exhaust manifold ares for leaks with no luck. I had basically resigned myself to an expensive trip to the dealership, but I thought I'd try one more time. I sprayed the carb cleaner around the all the vacuum hoses add I had done many times before, but this time with a stone cold engine. I immediately noticed an idle change when I sprayed near the PCV/ throttle body connection. I had already changed out o-rings there, and the other end of the hose, too. Closer inspection revealed that the connector on top of the throttle body did not fit in perfectly straight. This was probably do to some dimensional shrinkage due to advancef the age of hose plastic. I added another o ring to the connector so it had a very snug fit into the throttle body. When I started the car, both the P0171 code and the mil was gone. I've been replaced the fouled O2 sensor on bank 1 Upstream. The P1646 code also resolved itself. I guess the moral to my long-winded story is that vacuum leaks can and might behave differently in different temperature environments, and it would be wise to test for vacuum leaks at various engine temperatures. So finally my long quest to resolve this problem is over, but I think there are also questions to be asked about the fix itself. Such as if the vacuum leak was located on top of the throttle body, why did it not affect both Bank 1 and bank 2 equally and simultaneously as logic would suggest? Just food for thought, I suppose. I thank you all for your wise and generous advice to me in helping me resolve this without an expensive trip to the dealership. This forum is a wonderful source of knowledge and experience for us relative novices. Much appreciated!

Kindest regards,

Scott

The following 2 users liked this post by 11scotthair11:

Don B (04-25-2018),

Rancheroguy (04-26-2018)