Torque specs for rear suspension bump stop bolts

#1

Finished replacing the rear shocks, and I removed the rear suspension bump stop to provide a little more access, which it did.

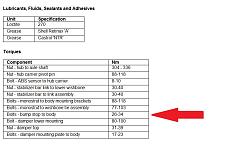

I found all the torque specs for all the other fasteners related to this work in the Service Manual, but I just can't seem to find the specs for the four bolts that hold this bracket to the inner body/fender.

This is the last part I need to reinstall to have it all buttoned up...

Anyone know?

.

I found all the torque specs for all the other fasteners related to this work in the Service Manual, but I just can't seem to find the specs for the four bolts that hold this bracket to the inner body/fender.

This is the last part I need to reinstall to have it all buttoned up...

Anyone know?

.

#2

About... that... ... ... tight!

What a job Al! Congrats. You got it all put back right, following all the torque specs. That must have been a lot of torquing! I'm sorry I don't know the spec for the bump stop, although not normally being a load bearing piece, "good and tight" ought to do it. Unless that is unacceptable to you. The bolts are pretty big aren't they? Ironic that after all that heavy work you are missing that one last spec!

What a job Al! Congrats. You got it all put back right, following all the torque specs. That must have been a lot of torquing! I'm sorry I don't know the spec for the bump stop, although not normally being a load bearing piece, "good and tight" ought to do it. Unless that is unacceptable to you. The bolts are pretty big aren't they? Ironic that after all that heavy work you are missing that one last spec!

The following users liked this post:

al_roethlisberger (08-18-2014)

#3

You can check at the Whitworth Steel Bolt Torque Specifications Table - Engineer's Handbook

and at plenty other sites.

The values are valied for new bolts and depend on many factors:

bolt mechanical property classes (the two small numbers on a bolt with a dot between them)

working temperature

type of load

type of fastening (dry/wet/glue)

type of thread

length of bolt

bolt's coating

..

..

..

and so on

the bolts you work on are big and old, clean both male/female threads, do them "good" using a medium thread lock material, so to undo them some day...

and at plenty other sites.

The values are valied for new bolts and depend on many factors:

bolt mechanical property classes (the two small numbers on a bolt with a dot between them)

working temperature

type of load

type of fastening (dry/wet/glue)

type of thread

length of bolt

bolt's coating

..

..

..

and so on

the bolts you work on are big and old, clean both male/female threads, do them "good" using a medium thread lock material, so to undo them some day...

The following users liked this post:

al_roethlisberger (08-18-2014)

#4

The following users liked this post:

al_roethlisberger (08-18-2014)

#5

About... that... ... ... tight!

What a job Al! Congrats. You got it all put back right, following all the torque specs. That must have been a lot of torquing! I'm sorry I don't know the spec for the bump stop, although not normally being a load bearing piece, "good and tight" ought to do it. Unless that is unacceptable to you. The bolts are pretty big aren't they? Ironic that after all that heavy work you are missing that one last spec!

What a job Al! Congrats. You got it all put back right, following all the torque specs. That must have been a lot of torquing! I'm sorry I don't know the spec for the bump stop, although not normally being a load bearing piece, "good and tight" ought to do it. Unless that is unacceptable to you. The bolts are pretty big aren't they? Ironic that after all that heavy work you are missing that one last spec!

Thanks, boy you aren't kidding.... I don't look forward to ever doing this again, but I do think it will go a bit faster next time. Hopefully next time is at least 3+ish years away (based on 20k+ miles a year).

The LH side took me a few hours to get out, but I was able to pull the RH side in about an hour. So there was definitely a learning curve.

Reinstalling both sides only took a couple hours each, with the LH taking a bit longer, again benefiting from the initial learning curve.

It may have been helpful if I had a lift, but I'm not sure it would have changed things that much. I think even an experienced shop would have a couple hours per side in this work though. Just cranking/uncranking on the spring compressors takes quite a bit of time.

Much like the comments about "if only Jaguar had put an access hatch in the rear package shelf for the fuel pump".... if only Jaguar had put some access holes above these shocks, it would save a world of effort. I think the fuel tank is immediately above the shocks, but I bet a creative engineer could have worked it out if they had decided to

.

Last edited by al_roethlisberger; 08-18-2014 at 05:49 AM.

Thread

Thread Starter

Forum

Replies

Last Post

philwarner

XJ6 & XJ12 Series I, II & III

16

09-05-2015 10:05 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)