XJR6-AJ16S knowledge

#1

Calling out to all engine experts! I'm sure I'm going to be running into a lot of questions as I start work on my project, so thank you in advance for any and all help you guys hand over.

This project is going to be putting an AJ16S with a Getrag 290 5-speed and then attempting to shoehorn them into a Datsun 280z.

To start off the questions (and get me going on buying up anything I need):

1 - Is there anything outside of the ECU that is required to run the engine? It seems like the ECU does fuel and ignition duties, but are there any security metrics that the ECU needs to see in order to fire the engine? (I see we have a member than can tweak these ECUs, and from a developer level at that. Access like that is *priceless*!)

2 - Is there a recommended engine rebuild kit available? Not looking to open the bottom end, but I usually doe heads-up on my projects, so I try to at least replace all the basic gaskets that are difficult to do with an installed engine.

3 - I'm looking to remove the air-water intercooler from the engine and create my own piping to run an air-air setup in it's place. Are there any sensors or obstacles associated with the water cooler that I should be aware of?

4 - Give me any and all secrets to unlocking the potential of this engine! Modifications, replacements, upgrades... I want to know them all! I've seen from some research that the heads on the AJ line were not very good, in terms of flow. Is this true? Any guides to reworking them?

I'll have hundreds more, I'm sure. Thank you all!

This project is going to be putting an AJ16S with a Getrag 290 5-speed and then attempting to shoehorn them into a Datsun 280z.

To start off the questions (and get me going on buying up anything I need):

1 - Is there anything outside of the ECU that is required to run the engine? It seems like the ECU does fuel and ignition duties, but are there any security metrics that the ECU needs to see in order to fire the engine? (I see we have a member than can tweak these ECUs, and from a developer level at that. Access like that is *priceless*!)

2 - Is there a recommended engine rebuild kit available? Not looking to open the bottom end, but I usually doe heads-up on my projects, so I try to at least replace all the basic gaskets that are difficult to do with an installed engine.

3 - I'm looking to remove the air-water intercooler from the engine and create my own piping to run an air-air setup in it's place. Are there any sensors or obstacles associated with the water cooler that I should be aware of?

4 - Give me any and all secrets to unlocking the potential of this engine! Modifications, replacements, upgrades... I want to know them all! I've seen from some research that the heads on the AJ line were not very good, in terms of flow. Is this true? Any guides to reworking them?

I'll have hundreds more, I'm sure. Thank you all!

The following users liked this post:

Mkii250 (08-25-2022)

#2

#4

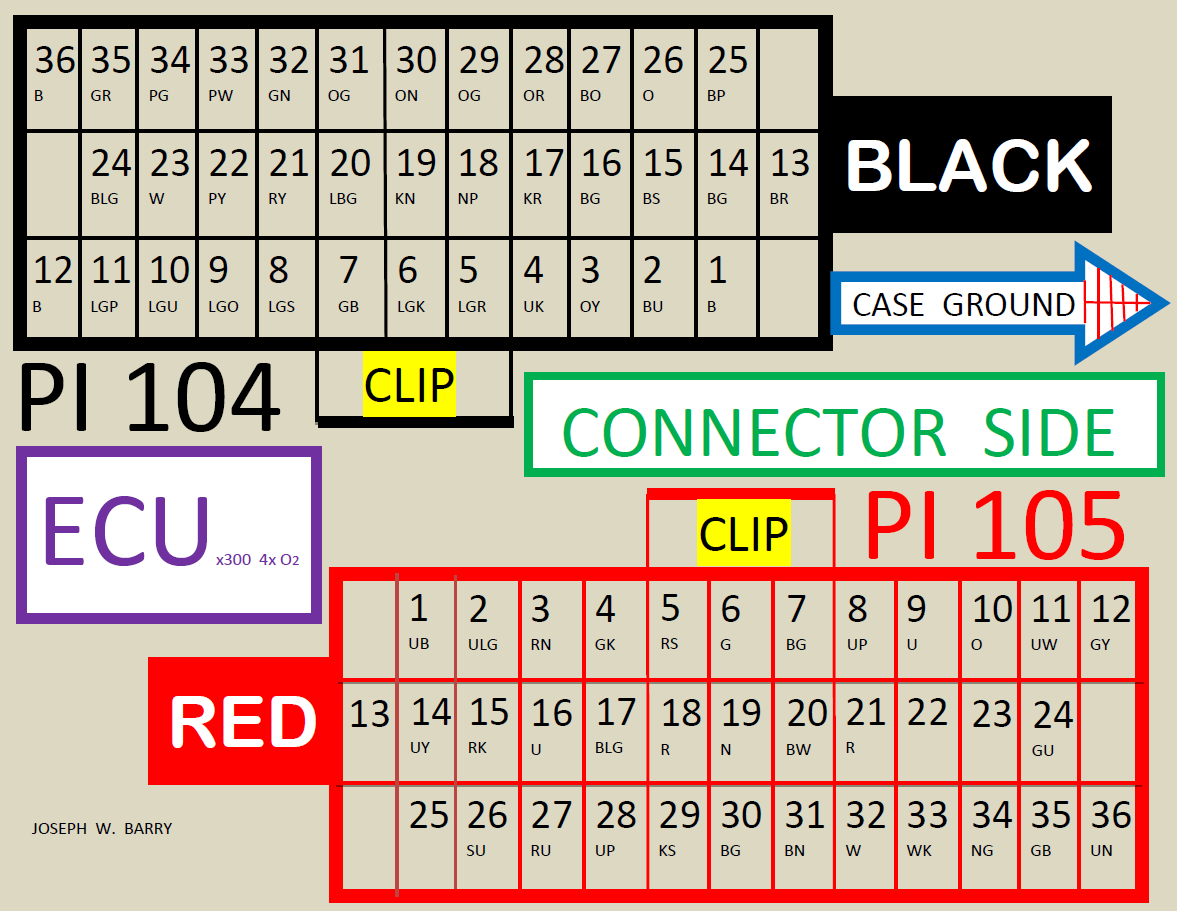

look up x300 wiring diagram

andy makes conversions for GEMS to run standalone. i think he can delete federal stuff like egr and upstream sensors too

most aj6 power making knowledge is with a certain guy who gets banned on every forum. you can still find him on amoc.

iíll give you the basics.

coarse thread head bolts. stud conversion needed

OE composite head gasket is not great, no remaining stock. aftermarket is junk. no MLS upgrade options

hair dryer for a blower, poor intercooler setup. there is somebody making their own air to air, itís going in an old xj coupe

andy makes conversions for GEMS to run standalone. i think he can delete federal stuff like egr and upstream sensors too

most aj6 power making knowledge is with a certain guy who gets banned on every forum. you can still find him on amoc.

iíll give you the basics.

coarse thread head bolts. stud conversion needed

OE composite head gasket is not great, no remaining stock. aftermarket is junk. no MLS upgrade options

hair dryer for a blower, poor intercooler setup. there is somebody making their own air to air, itís going in an old xj coupe

Last edited by xalty; 08-24-2022 at 08:26 PM.

The following users liked this post:

XJRengineer (08-28-2022)

#5

#7

If you are going to fit an air-air inter-cooling system, you should think about where you are going to mount the throttle body relative to the supercharger. If you mount the throttle on the inlet to the supercharger, then the pipework to and from the air-air inter-cooler will need to cope with manifold depression as well as boost pressure. If you mount the throttle after the inter-cooler, the parasitic work , at part throttle will be increased. Either way, make sure that you have a supercharger bypass system.

The inlet valve seats throat cut is not well-matched to the ports, so there is plenty of scope to improve the blending of the valve seat throat to the ports. I re-cut the seat and fitted bigger valves.

I recommend fitting a bigger air cleaner, as the standard part is too restrictive. If you have the appetite, the throttle body is also far too small, if mounted upstream of the supercharger, but fitting a bigger one requires designing a customer adaptor.

The inlet valve seats throat cut is not well-matched to the ports, so there is plenty of scope to improve the blending of the valve seat throat to the ports. I re-cut the seat and fitted bigger valves.

I recommend fitting a bigger air cleaner, as the standard part is too restrictive. If you have the appetite, the throttle body is also far too small, if mounted upstream of the supercharger, but fitting a bigger one requires designing a customer adaptor.

The following users liked this post:

Cafcpete (08-28-2022)

Trending Topics

#8

Alex , are you in Kansas City ?

Considered the radiator size ?

Uprate the differential ?

Battery upsize room ?

The fuel pumps enable is by a ground provided by the ECU to the control half of the fuel pumps relays

You can find it and the second fuel pump relay a command ground any why you like like a dedicated small current switch to ground

The fuel pumps run in 2 stages where the second fuel pump does not come on until 4000 RPM with the original design

If you have both fuel pumps running in the starting sequence it may be too much for the fuel pressure regulator to bypass and have a overfueling cylinder charge situation at that point

I don't see why you couldn't use the original to Jaguar ECU controlled / provided ground , but you may have to only install 1 large capacity fuel pump with your existing tank

Considered using a normal aspirated AJ16 instead ?

They are much cheaper to find

In removing the transmission, there is a 0 - ring high on the engine block that you should consider replacing while it is apart

To get the engine to regulate properly you do not need the rear Cats only the Fwd ones just below the exhaust manifolds

Final emissions passing would require the aft Cats depending on your area regulations

Considered the radiator size ?

Uprate the differential ?

Battery upsize room ?

The fuel pumps enable is by a ground provided by the ECU to the control half of the fuel pumps relays

You can find it and the second fuel pump relay a command ground any why you like like a dedicated small current switch to ground

The fuel pumps run in 2 stages where the second fuel pump does not come on until 4000 RPM with the original design

If you have both fuel pumps running in the starting sequence it may be too much for the fuel pressure regulator to bypass and have a overfueling cylinder charge situation at that point

I don't see why you couldn't use the original to Jaguar ECU controlled / provided ground , but you may have to only install 1 large capacity fuel pump with your existing tank

Considered using a normal aspirated AJ16 instead ?

They are much cheaper to find

In removing the transmission, there is a 0 - ring high on the engine block that you should consider replacing while it is apart

To get the engine to regulate properly you do not need the rear Cats only the Fwd ones just below the exhaust manifolds

Final emissions passing would require the aft Cats depending on your area regulations

Last edited by Parker 7; 08-28-2022 at 06:46 PM.

#9

Your fuel pump enable provided ground is

pin Black 19 is # 1 fuel pump

Notice the # 2 fuel pump enable ground goes through a module located in the trunk which may be hard to find / purchase

It takes 2 relays to power the ECU one being a small ignition positive relay at point 32 double hash circle on the right side of the print

And a large ECU controlled relay which is controlled by the ECU and brings power back into the ECU and some of your sensors and power sitting on your injectors

Last edited by Parker 7; 08-28-2022 at 03:46 PM.

The following users liked this post:

XJRengineer (08-29-2022)

#10

For a small charge, I can provide a document with details of all the engine harness connections that are required. Please contact me directly (andystodart4@gmail.com).

In my previous post about port modifications, I should have said that I also removed the boss around the exhaust valve guide, after temporarily partially pressing out the valve guide. This modification significantly improves the flow coefficient for the exhaust port, thereby reducing the pumping work during the exhaust stroke. I have lots of photos of the inlet and exhaust port modifications that I performed.

In my previous post about port modifications, I should have said that I also removed the boss around the exhaust valve guide, after temporarily partially pressing out the valve guide. This modification significantly improves the flow coefficient for the exhaust port, thereby reducing the pumping work during the exhaust stroke. I have lots of photos of the inlet and exhaust port modifications that I performed.

#11

Sorry for my absence! I was out of town attending a wedding, so I'm going to try and go through all of this knowledge. It's incredible there's so much! Talk about good problems to have!

I have definitely been reading through this man's work, and will no doubt be employing his experience and help very soon. This car is going to be running in California, so I'll be keeping some emissions helpers and such for the inception of this monster, then go from there.

I'll have to look up this certain individual... Not interested in the drama, but I can always take in the gems of knowledge!

Stud conversion, easy-peasy. Added to the checklist.

Shame on the gaskets, I'll have to start looking around and see if I can get some quality ones made.

I am caught in a battle between keeping the engine fairly original, and going crazy with power adders. The Datsun is very small, and very light... even a tired 322hp/378ftlbs would be *plenty* for the chassis... A hairdrier might not be the worst thing.

Thank you for all your input! Great start to my list.

Check! Added to my list. Thank you!

I think for this setup, the aft-charger option makes the most sense. For initial stages (aka get it running/driving) the parasitic draw sounds like the much easier workaround. As for bypass... sir, that's the charm of boost! Having a purge valve hissing at your lane neighbor is what it's about!

I've had some pretty good success doing my own porting in manifolds and such in the past... I'm excited to tackle this challenge and create some pictures of a cleaned up union in the intake tract. I'll leave the valves as-is for now (maybe...), but it's definitely good to know there's room to do it there.

Air cleaner will be aftermarket, as the Datsun's definitely will not be properly suited to the upgraded engine. I think I'll use an OEM setup from a Hellcat or some-such, to help disguise it and keep a CARB-approved box in it for inspection. I have a Scat Pack with an OEM box, and I think I can get it to fit in the Datsun nose area.

Thank you for all your input!

Radiator size is still under research, but I have a feeling I'll be a bit limited once the AJ16 is stuffed in. I'll have to do a quick mock-fit with it dangling from the hoist, measure what space I have left, then determine if I have to start chopping the firewall and/or how much rad room I can have.

Going to be using the OEM Datsun rear end to start... Other S30 Datsun experts say that 350-ish HP is about the limit for the OEM design. LSD is going to be a requirement down the line, especially if I want to start seriously tracking the car. The axle stubs are also weak, and going to be strained by a disc conversion, so that's all going to be a "go easy and wait-n-see" approach. Basically, break the weakest link and upgrade as I go.

Battery is easy... I get a stellar deals on yellow top Optimas through work.

That's a lot of info regarding the fuel pump, and I'm glad you mentioned it! Original plan was just a fuel cell built into the area where the spare currently sits. I figured just a simple, in-tank high-performance pump would suffice; I already have an aftermarket adjustable FPR that has a pretty sturdy capacity, as well as a lot of the OEM stuff converted to braided lines with AN fittings. I'll look into these points a bit more, and decide what might be best. It would be really nice to be able to hide the whine of a powerful fuel pump and keep the car as a sneaky sleeper. (Never race a guy who's fuel pump is louder than your exhaust, right?) I've added the note to research this to my list!

I did consider an NA AJ16, and they are quite abundant near me... However, I'm not shy of challenge, and it's a vein where I'm being childish and saying bigger is better! I want the whine and performance of a supercharger, even if it is a small/weak one. I am aware how much easier the NA would be, though.

I am aware how much easier the NA would be, though.

Engine block o-ring added to list!

That is *excellent* news about the cats! Thank you very much! I'm thinking dual exhaust might be the goal, and it might make sense to try to combine fore and aft cats into two single high performance units. I'll have to model up some ideas and see.

Thank you very much for all the help!

I will be in contact with you very soon for ECM needs, the mentioned document, and details about doing this valve job. I'm very glad to see you're still active here, and willing to help. This project will be MUCH easier for it.

As a final question, does anyone happen to know the rough dimensions of the AJ16S? I have a scale attachment for the engine hoist, so I'm going to have a fairly accurate guess of how much weight is changing between the two, but I am a bit nervous on physical size!

And again, thank you all very much!

look up x300 wiring diagram

andy makes conversions for GEMS to run standalone. i think he can delete federal stuff like egr and upstream sensors too

most aj6 power making knowledge is with a certain guy who gets banned on every forum. you can still find him on amoc.

i’ll give you the basics.

coarse thread head bolts. stud conversion needed

OE composite head gasket is not great, no remaining stock. aftermarket is junk. no MLS upgrade options

hair dryer for a blower, poor intercooler setup. there is somebody making their own air to air, it’s going in an old xj coupe

andy makes conversions for GEMS to run standalone. i think he can delete federal stuff like egr and upstream sensors too

most aj6 power making knowledge is with a certain guy who gets banned on every forum. you can still find him on amoc.

i’ll give you the basics.

coarse thread head bolts. stud conversion needed

OE composite head gasket is not great, no remaining stock. aftermarket is junk. no MLS upgrade options

hair dryer for a blower, poor intercooler setup. there is somebody making their own air to air, it’s going in an old xj coupe

I'll have to look up this certain individual... Not interested in the drama, but I can always take in the gems of knowledge!

Stud conversion, easy-peasy. Added to the checklist.

Shame on the gaskets, I'll have to start looking around and see if I can get some quality ones made.

I am caught in a battle between keeping the engine fairly original, and going crazy with power adders. The Datsun is very small, and very light... even a tired 322hp/378ftlbs would be *plenty* for the chassis... A hairdrier might not be the worst thing.

Thank you for all your input! Great start to my list.

If you are going to fit an air-air inter-cooling system, you should think about where you are going to mount the throttle body relative to the supercharger. If you mount the throttle on the inlet to the supercharger, then the pipework to and from the air-air inter-cooler will need to cope with manifold depression as well as boost pressure. If you mount the throttle after the inter-cooler, the parasitic work , at part throttle will be increased. Either way, make sure that you have a supercharger bypass system.

The inlet valve seats throat cut is not well-matched to the ports, so there is plenty of scope to improve the blending of the valve seat throat to the ports. I re-cut the seat and fitted bigger valves.

I recommend fitting a bigger air cleaner, as the standard part is too restrictive. If you have the appetite, the throttle body is also far too small, if mounted upstream of the supercharger, but fitting a bigger one requires designing a customer adaptor.

The inlet valve seats throat cut is not well-matched to the ports, so there is plenty of scope to improve the blending of the valve seat throat to the ports. I re-cut the seat and fitted bigger valves.

I recommend fitting a bigger air cleaner, as the standard part is too restrictive. If you have the appetite, the throttle body is also far too small, if mounted upstream of the supercharger, but fitting a bigger one requires designing a customer adaptor.

I've had some pretty good success doing my own porting in manifolds and such in the past... I'm excited to tackle this challenge and create some pictures of a cleaned up union in the intake tract. I'll leave the valves as-is for now (maybe...), but it's definitely good to know there's room to do it there.

Air cleaner will be aftermarket, as the Datsun's definitely will not be properly suited to the upgraded engine. I think I'll use an OEM setup from a Hellcat or some-such, to help disguise it and keep a CARB-approved box in it for inspection. I have a Scat Pack with an OEM box, and I think I can get it to fit in the Datsun nose area.

Thank you for all your input!

Alex , are you in Kansas City ?

Considered the radiator size ?

Uprate the differential ?

Battery upsize room ?

The fuel pumps enable is by a ground provided by the ECU to the control half of the fuel pumps relays

You can find it and the second fuel pump relay a command ground any why you like like a dedicated small current switch to ground

The fuel pumps run in 2 stages where the second fuel pump does not come on until 4000 RPM with the original design

If you have both fuel pumps running in the starting sequence it may be too much for the fuel pressure regulator to bypass and have a overfueling cylinder charge situation at that point

I don't see why you couldn't use the original to Jaguar ECU controlled / provided ground , but you may have to only install 1 large capacity fuel pump with your existing tank

Considered using a normal aspirated AJ16 instead ?

They are much cheaper to find

In removing the transmission, there is a 0 - ring high on the engine block that you should consider replacing while it is apart

To get the engine to regulate properly you do not need the rear Cats only the Fwd ones just below the exhaust manifolds

Final emissions passing would require the aft Cats depending on your area regulations

Considered the radiator size ?

Uprate the differential ?

Battery upsize room ?

The fuel pumps enable is by a ground provided by the ECU to the control half of the fuel pumps relays

You can find it and the second fuel pump relay a command ground any why you like like a dedicated small current switch to ground

The fuel pumps run in 2 stages where the second fuel pump does not come on until 4000 RPM with the original design

If you have both fuel pumps running in the starting sequence it may be too much for the fuel pressure regulator to bypass and have a overfueling cylinder charge situation at that point

I don't see why you couldn't use the original to Jaguar ECU controlled / provided ground , but you may have to only install 1 large capacity fuel pump with your existing tank

Considered using a normal aspirated AJ16 instead ?

They are much cheaper to find

In removing the transmission, there is a 0 - ring high on the engine block that you should consider replacing while it is apart

To get the engine to regulate properly you do not need the rear Cats only the Fwd ones just below the exhaust manifolds

Final emissions passing would require the aft Cats depending on your area regulations

Going to be using the OEM Datsun rear end to start... Other S30 Datsun experts say that 350-ish HP is about the limit for the OEM design. LSD is going to be a requirement down the line, especially if I want to start seriously tracking the car. The axle stubs are also weak, and going to be strained by a disc conversion, so that's all going to be a "go easy and wait-n-see" approach. Basically, break the weakest link and upgrade as I go.

Battery is easy... I get a stellar deals on yellow top Optimas through work.

That's a lot of info regarding the fuel pump, and I'm glad you mentioned it! Original plan was just a fuel cell built into the area where the spare currently sits. I figured just a simple, in-tank high-performance pump would suffice; I already have an aftermarket adjustable FPR that has a pretty sturdy capacity, as well as a lot of the OEM stuff converted to braided lines with AN fittings. I'll look into these points a bit more, and decide what might be best. It would be really nice to be able to hide the whine of a powerful fuel pump and keep the car as a sneaky sleeper. (Never race a guy who's fuel pump is louder than your exhaust, right?) I've added the note to research this to my list!

I did consider an NA AJ16, and they are quite abundant near me... However, I'm not shy of challenge, and it's a vein where I'm being childish and saying bigger is better! I want the whine and performance of a supercharger, even if it is a small/weak one.

I am aware how much easier the NA would be, though.

I am aware how much easier the NA would be, though.Engine block o-ring added to list!

That is *excellent* news about the cats! Thank you very much! I'm thinking dual exhaust might be the goal, and it might make sense to try to combine fore and aft cats into two single high performance units. I'll have to model up some ideas and see.

Thank you very much for all the help!

For a small charge, I can provide a document with details of all the engine harness connections that are required. Please contact me directly (andystodart4@gmail.com).

In my previous post about port modifications, I should have said that I also removed the boss around the exhaust valve guide, after temporarily partially pressing out the valve guide. This modification significantly improves the flow coefficient for the exhaust port, thereby reducing the pumping work during the exhaust stroke. I have lots of photos of the inlet and exhaust port modifications that I performed.

In my previous post about port modifications, I should have said that I also removed the boss around the exhaust valve guide, after temporarily partially pressing out the valve guide. This modification significantly improves the flow coefficient for the exhaust port, thereby reducing the pumping work during the exhaust stroke. I have lots of photos of the inlet and exhaust port modifications that I performed.

As a final question, does anyone happen to know the rough dimensions of the AJ16S? I have a scale attachment for the engine hoist, so I'm going to have a fairly accurate guess of how much weight is changing between the two, but I am a bit nervous on physical size!

And again, thank you all very much!

#12

A supercharged AJ16 engine weighs about 240kg. I've got a couple of spares engines in my garage, so I should be able to measure them next weekend, if nobody else has replied first. It is a very long engine, as it has very generous bore spacing and 90mm bores. The stroke is 102mm so it is also a very tall engine.

Good luck with your project. it sounds interesting.

Good luck with your project. it sounds interesting.

#13

#14

#15

#16

Edit: I just measured and HOO BOY is that going to be close! The original engine is about 25" long, 24" tall, and 22ish inches wide. I'm nearly certain I'll need a cowl hood, and it seems like I'll probably have to do a wider, slimmer radiator with pusher fans... Good thing I love a challenge.

Last edited by Zaguar; 08-29-2022 at 08:33 PM.

#17

If you get length dimensions you would have to ensure it is from a NA or SC engine as the SC has an extra pulley on the crankshaft for the blower

A air to air intercooler would be much larger and you already have a installation done for you with the original liquid coolant to air intercooler

Some have put a higher flow capacity electric pump ( Bosch # X ) in place of the original which can be expensive, this is needed for the intercooler beyond the engine block common mechanical water pump

Your ordinal Datsun engine was cast iron so you have an even weight trade so you might get away with your original front springs

A air to air intercooler would be much larger and you already have a installation done for you with the original liquid coolant to air intercooler

Some have put a higher flow capacity electric pump ( Bosch # X ) in place of the original which can be expensive, this is needed for the intercooler beyond the engine block common mechanical water pump

Your ordinal Datsun engine was cast iron so you have an even weight trade so you might get away with your original front springs

Last edited by Parker 7; 08-30-2022 at 09:45 PM.

#18

I offer a specification for tuned exhaust primary pipes lengths and diameters, and secondary diameters, from a computer simulation in GT Power software to optimise peak power at 5,000rpm.

If you were to keep the air-water-air inter-cooling, then I would recommend replacing the Hella pump with a Bosch pump , as it increases coolant flow from 7litres/min to 11litres/min.

If you decide to change to air-air inter-cooling and mount the throttle downstream of the inter-cooler, then the bypass valve for the supercharger will experience boost pressure. This does not happen in the standard installation. I do not know if the vacuum capsule is designed to be exposed to boost pressure.

Please also note that the bypass valve does not perform the same function as a "dump valve", or a wastegate in a turbocharged engine. The bypass valve operates in a closed circuit, to minimise pumping work by the supercharger when the engine is operating at part load. The air passing through the bypass circuit should be recirculated in order to achieve good fueling control, as the air being recirculated has already been measured by the air flow meter. If the throttle is mounted downstream of the inter-cooler, there is a risk that the recirculated air could flow "backwards" through the air meter, depending on the details of your bespoke installation. Personally, It is not clear why you wish to replace the air-water-air inter-cooling system with air-air. It seems a lot of work, and introduces several problems, not present with the standard installation. Air-air inter-cooling a supercharged engine is more complicated than air-air inter-cooling a turbocharged engine, due to the function of the bypass system.

If you were to keep the air-water-air inter-cooling, then I would recommend replacing the Hella pump with a Bosch pump , as it increases coolant flow from 7litres/min to 11litres/min.

If you decide to change to air-air inter-cooling and mount the throttle downstream of the inter-cooler, then the bypass valve for the supercharger will experience boost pressure. This does not happen in the standard installation. I do not know if the vacuum capsule is designed to be exposed to boost pressure.

Please also note that the bypass valve does not perform the same function as a "dump valve", or a wastegate in a turbocharged engine. The bypass valve operates in a closed circuit, to minimise pumping work by the supercharger when the engine is operating at part load. The air passing through the bypass circuit should be recirculated in order to achieve good fueling control, as the air being recirculated has already been measured by the air flow meter. If the throttle is mounted downstream of the inter-cooler, there is a risk that the recirculated air could flow "backwards" through the air meter, depending on the details of your bespoke installation. Personally, It is not clear why you wish to replace the air-water-air inter-cooling system with air-air. It seems a lot of work, and introduces several problems, not present with the standard installation. Air-air inter-cooling a supercharged engine is more complicated than air-air inter-cooling a turbocharged engine, due to the function of the bypass system.

#19

#20