SU Float Bowl Overflow

#21

AHA, more brain cells light up, thanks to some JD haha.

YES, the new floats are that one piece affair, and YES, the adjustment is by means of the washers under the seat section.

When I did our 4.2 Daimler a looooong time ago I ended up with NO washers under the seat, and using the proper SU tube spanner to tighten that seat, they sealed very well, but they had to be tightened very "firm". No gorilla stuff obviously, but tighter than would be done with washers insitu.

I am still thinking that the fuel is getting past the needle, or the seat threads, and overfilling that bowl. The only issue I am having is that the fuel must be running out of the jet well before it exits from the overflow spout??, which should really "flood" the engine, I think. The overflow is really a release mechanism for a failed needle, or similar, where the full flow of the pump enters the carby, but flooding should also occur and basically stop/stall the engine??.

YES, the new floats are that one piece affair, and YES, the adjustment is by means of the washers under the seat section.

When I did our 4.2 Daimler a looooong time ago I ended up with NO washers under the seat, and using the proper SU tube spanner to tighten that seat, they sealed very well, but they had to be tightened very "firm". No gorilla stuff obviously, but tighter than would be done with washers insitu.

I am still thinking that the fuel is getting past the needle, or the seat threads, and overfilling that bowl. The only issue I am having is that the fuel must be running out of the jet well before it exits from the overflow spout??, which should really "flood" the engine, I think. The overflow is really a release mechanism for a failed needle, or similar, where the full flow of the pump enters the carby, but flooding should also occur and basically stop/stall the engine??.

#22

Grant - it is literally 50 years since I was cursed by SU's so.....

but I reckon the fluid level was at or below the top of the jet even when the bowl overflowed.

If you think about it if petrol could pee out of the jet with a stuck float it could fill a cylinder up with ignition on and engine not running.

but I reckon the fluid level was at or below the top of the jet even when the bowl overflowed.

If you think about it if petrol could pee out of the jet with a stuck float it could fill a cylinder up with ignition on and engine not running.

#23

AHA, more brain cells light up, thanks to some JD haha.

YES, the new floats are that one piece affair, and YES, the adjustment is by means of the washers under the seat section.

When I did our 4.2 Daimler a looooong time ago I ended up with NO washers under the seat, and using the proper SU tube spanner to tighten that seat, they sealed very well, but they had to be tightened very "firm". No gorilla stuff obviously, but tighter than would be done with washers insitu.

I am still thinking that the fuel is getting past the needle, or the seat threads, and overfilling that bowl. The only issue I am having is that the fuel must be running out of the jet well before it exits from the overflow spout??, which should really "flood" the engine, I think. The overflow is really a release mechanism for a failed needle, or similar, where the full flow of the pump enters the carby, but flooding should also occur and basically stop/stall the engine??.

YES, the new floats are that one piece affair, and YES, the adjustment is by means of the washers under the seat section.

When I did our 4.2 Daimler a looooong time ago I ended up with NO washers under the seat, and using the proper SU tube spanner to tighten that seat, they sealed very well, but they had to be tightened very "firm". No gorilla stuff obviously, but tighter than would be done with washers insitu.

I am still thinking that the fuel is getting past the needle, or the seat threads, and overfilling that bowl. The only issue I am having is that the fuel must be running out of the jet well before it exits from the overflow spout??, which should really "flood" the engine, I think. The overflow is really a release mechanism for a failed needle, or similar, where the full flow of the pump enters the carby, but flooding should also occur and basically stop/stall the engine??.

I was very careful when tightening the Needle Valves as without a torque figure to work with I was afraid I would strip the threads!

I'm currently waiting for a Thermostat Housing Gasket as the one supplied was wrong, I have subsequently ordered the correct EAC7045 Gasket. Once I've flushed, drained and refilled, I'll start all the Carb checks again.

I should say that neither Float Bowl was overflowing when I started the Thermostat but, it was running lean. That said I'd only done a short run to and from work and never went above 60 km/h or 2500 rpm.

So to confirm, checks to be done:

1. Check correct Float position for fuel level

2. Check Choke is fully off and Jet is high in the tube

3. Prime fuel system and check fuel level

4. Balance Carbs

5. Check/adjust mixture and rebalance as required

6. Test drive

#24

That sounds about right.

Steveinfrance has me thinking about this overflow height. I reckon he is spot on.

I will go searching in the shed library tomorrow, and find my SU book. It will have a lot of drawings in it, from memory, and one will show the fuel level as a cross section. I will scan and attach it here once I find it. Might help with things in general.

STEVE, it is about 15 years since I did any SU carbs, and the HS was the easiest to set up by a long stretch.

Steveinfrance has me thinking about this overflow height. I reckon he is spot on.

I will go searching in the shed library tomorrow, and find my SU book. It will have a lot of drawings in it, from memory, and one will show the fuel level as a cross section. I will scan and attach it here once I find it. Might help with things in general.

STEVE, it is about 15 years since I did any SU carbs, and the HS was the easiest to set up by a long stretch.

#26

OK, parts turned up today from Jagdaim in Melbourne in record time!

I got the correct Gasket and also got some new hoses and an Outlet Elbow Header Tank as the old one was a bit corroded.

Put on the new parts together with the new Thermostat and fired up the car and she was running well with a little bit of choke. No Float Bowl Overflow leaks.

I let the car run for a while to warm up and then put the choke back in. This is when the exciting bit happened, the engine got a bit lumpy on idle then slowly died (I was standing over the engine bay). I then attempted to start the car even though there was a little bit of smoke coming from the Air Filter Housing. The engine started straight away but, accelerated to 2500 rpm straight away and I couldn't get it to rev any lower.

I jumped out again to look for something obvious around the Throttle Linkage and noticed that the Lock Nuts either side of the Throttle Cable Bracket were completely loose. I shut the engine down and tightened them up and tried again.

Same thing, engine revved straight to 2500 rpm. I shut the engine down and pulled the Air Filter off and found that half of it had gone up in smoke, literately!

I then suspected that some paper debris may have been holding the Butterfly open so I pulled the Carb Tops off. Nothing found and they were fully closed.

I put the Carbs back together and started the car again, same thing, straight to 2500 rpm. I think there must be an air leak somewhere?

I got the correct Gasket and also got some new hoses and an Outlet Elbow Header Tank as the old one was a bit corroded.

Put on the new parts together with the new Thermostat and fired up the car and she was running well with a little bit of choke. No Float Bowl Overflow leaks.

I let the car run for a while to warm up and then put the choke back in. This is when the exciting bit happened, the engine got a bit lumpy on idle then slowly died (I was standing over the engine bay). I then attempted to start the car even though there was a little bit of smoke coming from the Air Filter Housing. The engine started straight away but, accelerated to 2500 rpm straight away and I couldn't get it to rev any lower.

I jumped out again to look for something obvious around the Throttle Linkage and noticed that the Lock Nuts either side of the Throttle Cable Bracket were completely loose. I shut the engine down and tightened them up and tried again.

Same thing, engine revved straight to 2500 rpm. I shut the engine down and pulled the Air Filter off and found that half of it had gone up in smoke, literately!

I then suspected that some paper debris may have been holding the Butterfly open so I pulled the Carb Tops off. Nothing found and they were fully closed.

I put the Carbs back together and started the car again, same thing, straight to 2500 rpm. I think there must be an air leak somewhere?

#27

Hell, not good.

That air filter has been really soaked in petrol and oil, and basically dissolved. Never seen one in that state on a 6 cylinder before, V12, yes.

That butterfly in the second picture looks to be a long way from closed???.

I think a basic "back to square one" is called for on both carbies.

Release the "Z" clamps on the throttle connecting shaft to isolate each carby. The 2 cold fast idle screws need to be wound well clear of the cam arm, then the 2 throttle stop screws backed off well away from the arm, then rewound until they just contact the arm, then 2 turns down each screw. That will be wrong, but it will start, and then by turning each screw the exact same amount in whatever direction until idle speed is achieved, the balance will be soooooo close.

The choke/cold start idle setting is purely guess work, as each engine requires its own mix of fuel and air when cold. This can be done/sorted once the standard idle/balance/mixture is completed.

The pistons jamming in the bell tower is another common fast idle issue. Spotless cleanliness here in mandatory. Pieces of that filter may well be in the suction chamber (atmospheric side of course), and jamming the piston.

Got called into work today, the joys of retirement, constant calls to duty, so I have not looked for that book today, but will do so tomorrow.

Let me know your email address, and I will scan the whole HS8 section and send to you.

That air filter has been really soaked in petrol and oil, and basically dissolved. Never seen one in that state on a 6 cylinder before, V12, yes.

That butterfly in the second picture looks to be a long way from closed???.

I think a basic "back to square one" is called for on both carbies.

Release the "Z" clamps on the throttle connecting shaft to isolate each carby. The 2 cold fast idle screws need to be wound well clear of the cam arm, then the 2 throttle stop screws backed off well away from the arm, then rewound until they just contact the arm, then 2 turns down each screw. That will be wrong, but it will start, and then by turning each screw the exact same amount in whatever direction until idle speed is achieved, the balance will be soooooo close.

The choke/cold start idle setting is purely guess work, as each engine requires its own mix of fuel and air when cold. This can be done/sorted once the standard idle/balance/mixture is completed.

The pistons jamming in the bell tower is another common fast idle issue. Spotless cleanliness here in mandatory. Pieces of that filter may well be in the suction chamber (atmospheric side of course), and jamming the piston.

Got called into work today, the joys of retirement, constant calls to duty, so I have not looked for that book today, but will do so tomorrow.

Let me know your email address, and I will scan the whole HS8 section and send to you.

Last edited by Grant Francis; 09-05-2012 at 06:02 AM.

#28

Grant you are of course correct, the butterfly does seem to have a gap at the top, and therefore probably the bottom too!

Unfortunately, I'm only getting a couple of hours each evening before darkness closes in as I have my Renault taking up garage space at the moment.

There is very little info in the Haynes Workshop Manual about setting up the throttle linkage so I'll disconnect it at the Throttle end to rule it out. I'll probably need to pull the Carbs off if I can't get the Butterfly to close fully.

Unfortunately, I'm only getting a couple of hours each evening before darkness closes in as I have my Renault taking up garage space at the moment.

There is very little info in the Haynes Workshop Manual about setting up the throttle linkage so I'll disconnect it at the Throttle end to rule it out. I'll probably need to pull the Carbs off if I can't get the Butterfly to close fully.

#29

Ok, finally got a bit of time to get some work done and it was all positive!

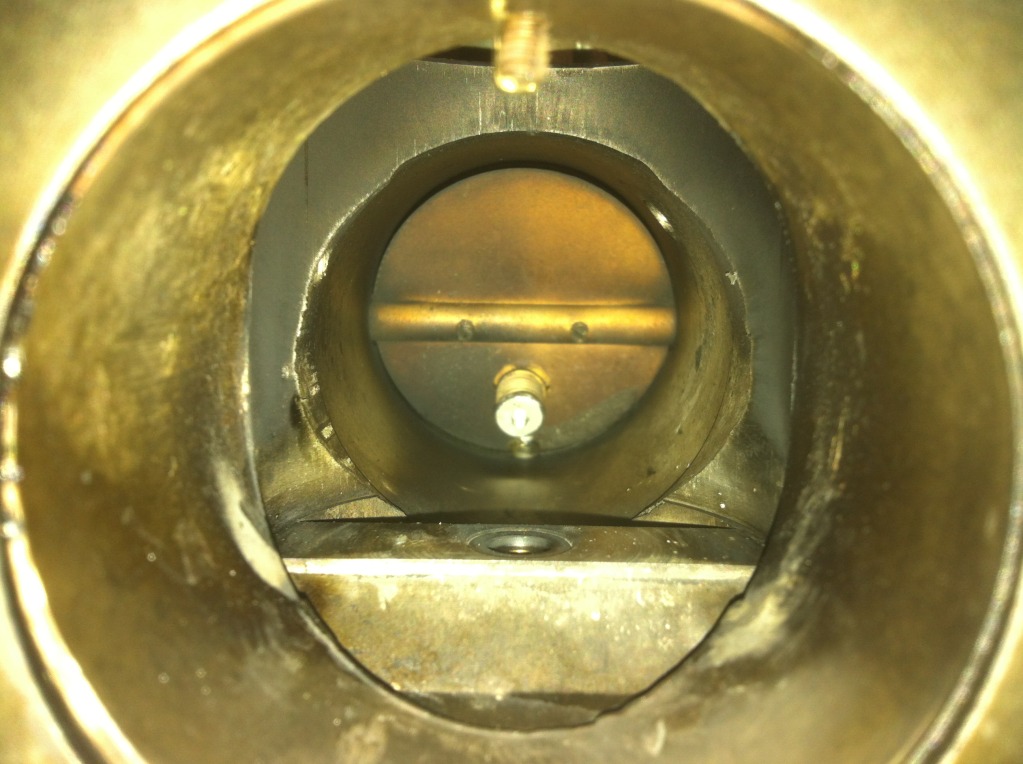

I pulled the Carbs off today so I could inspect the Throttle Butterfly Plate properly and this is what I found:

The Throttle Plate was being held open by a bit of paper from the Air Filter and a strange piece of plastic (see below for a close up).

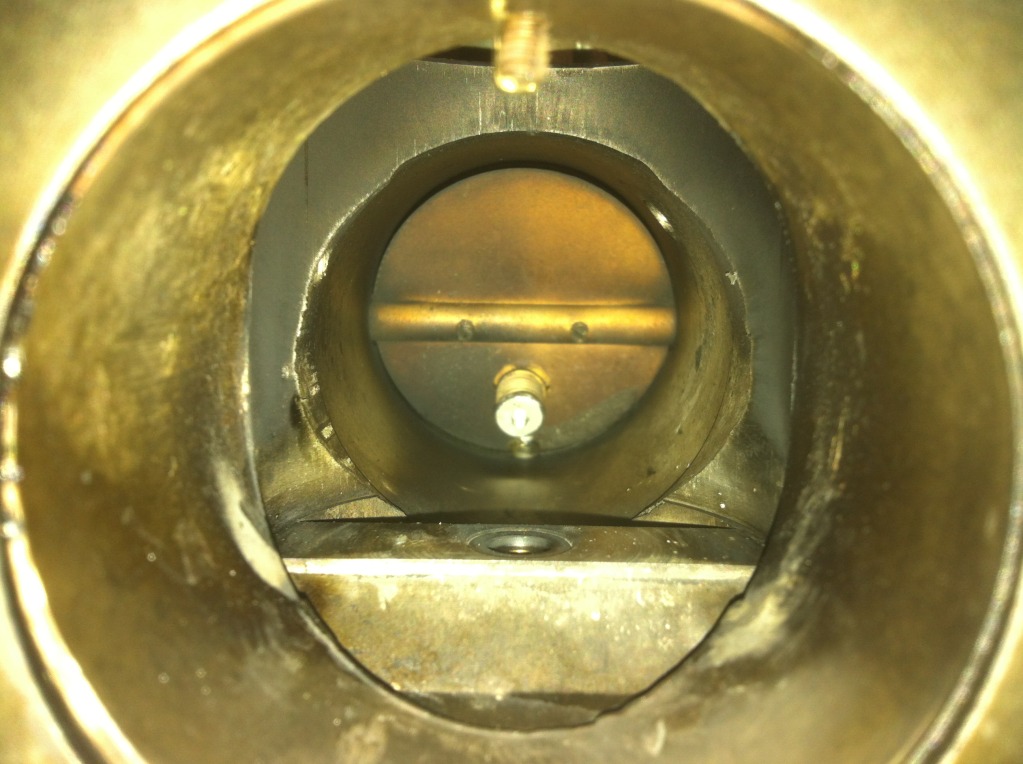

I also noticed that the Button on the Throttle Plate of the good Carb had been soldered shut but the faulty Carb had lost all of it's solder. So I decided to pull the Throttle Plate out, give it a good clean and re-solder it shut again.

Here's the Throttle Plate refitted with new solder in place:

I then refitted the Carbs, set up the Choke and fired her up. I needed a bit of choke and the idle was pretty lumpy so I adjusted the Throttle Stops (equally) to get the idle speed a little higher before putting the choke in.

I idle went very lumpy with the Choke in so I richened up the mixture a bit and the revs climbed a bit, so I richened it up a little further and the revs climbed again but it was a lot smoother. I could no readjust the idle to around 650 rpm.

I could now fine tune the mixture using the Piston Lift Pin method. The rear Carb needed a fair bit more but the front Carb wasn't a million miles off. I then rebalanced the Carbs (they were almost there anyway) and rechecked everything.

A quick test drive and all appears to be well (we've been there before) but, I haven't checked the fuel level or adjusted the Floats. That said, nothing is overflowing at the moment.....

I pulled the Carbs off today so I could inspect the Throttle Butterfly Plate properly and this is what I found:

The Throttle Plate was being held open by a bit of paper from the Air Filter and a strange piece of plastic (see below for a close up).

I also noticed that the Button on the Throttle Plate of the good Carb had been soldered shut but the faulty Carb had lost all of it's solder. So I decided to pull the Throttle Plate out, give it a good clean and re-solder it shut again.

Here's the Throttle Plate refitted with new solder in place:

I then refitted the Carbs, set up the Choke and fired her up. I needed a bit of choke and the idle was pretty lumpy so I adjusted the Throttle Stops (equally) to get the idle speed a little higher before putting the choke in.

I idle went very lumpy with the Choke in so I richened up the mixture a bit and the revs climbed a bit, so I richened it up a little further and the revs climbed again but it was a lot smoother. I could no readjust the idle to around 650 rpm.

I could now fine tune the mixture using the Piston Lift Pin method. The rear Carb needed a fair bit more but the front Carb wasn't a million miles off. I then rebalanced the Carbs (they were almost there anyway) and rechecked everything.

A quick test drive and all appears to be well (we've been there before) but, I haven't checked the fuel level or adjusted the Floats. That said, nothing is overflowing at the moment.....

#31

Good news.

I will crack a fresh JD, and begin celebrating.

Told ya the HS8 carbies are SOOO simple.

Once set, and that can take a little time to get the "fine tune" just right, no touch for many a mile.

I ran, and still run, foam air filter elements, home made of course. Simply wash in solvent, dry and refit. The V12 ones are 12 years old and sweet.

I will crack a fresh JD, and begin celebrating.

Told ya the HS8 carbies are SOOO simple.

Once set, and that can take a little time to get the "fine tune" just right, no touch for many a mile.

I ran, and still run, foam air filter elements, home made of course. Simply wash in solvent, dry and refit. The V12 ones are 12 years old and sweet.

#32

#33

Haynes manuals are a joke, actually you could write a better Manual than Haynes, because you actually did the job and documented it!

check eBay and other local sources for the Factory Shop Manual for the Series 1 in CD. The Jaguar Daimler Heritage Trust offers the Factory Manuals worldwide, they are miles better than the Haynes or Chilton.

check eBay and other local sources for the Factory Shop Manual for the Series 1 in CD. The Jaguar Daimler Heritage Trust offers the Factory Manuals worldwide, they are miles better than the Haynes or Chilton.

#34

I wanted to double check the Float levels and give the Needle Valve a good tightening as I was still getting a little bit of overflow still on the rear Carb Float Bowl.

They were sitting way too high because I had used the washer from the older style Needle Valve that was fitted previously. I removed the washer and tightened the Needle Valve on both Float Bowls and refitted everything.

I fired up the engine and it was running well so I went for a test drive which involved some traffic and clear motorway driving and again the car performed well. Very smooth.

Once home I left the engine running and checked the the Overflow Outlets on both Carbs and once again the rear had fuel trickling out.

I am beginning to think I need a new Float Blow Top Housing?....

There doesn't seem to be a part number available for a new one so I will probably have to source a second hand one. My Carb Model Number is: AUD397, just incase someone has one locally.

They were sitting way too high because I had used the washer from the older style Needle Valve that was fitted previously. I removed the washer and tightened the Needle Valve on both Float Bowls and refitted everything.

I fired up the engine and it was running well so I went for a test drive which involved some traffic and clear motorway driving and again the car performed well. Very smooth.

Once home I left the engine running and checked the the Overflow Outlets on both Carbs and once again the rear had fuel trickling out.

I am beginning to think I need a new Float Blow Top Housing?....

There doesn't seem to be a part number available for a new one so I will probably have to source a second hand one. My Carb Model Number is: AUD397, just incase someone has one locally.

Thread

Thread Starter

Forum

Replies

Last Post

chatmanx

S-Type / S type R Supercharged V8 ( X200 )

0

09-11-2015 07:17 PM

aktell

MKI / MKII S type 240 340 & Daimler

2

09-10-2015 02:55 PM

1964Daimler

MKI / MKII S type 240 340 & Daimler

4

09-09-2015 04:50 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)