Replacing engine oil cooler hoses.

#1

If any of you folks have done this, please let me know how difficult it is. I can have new ones made up by NAPA. Wondering about accessing the oil cooler. Is it in front of the AC condenser? Also will I have to remove the bottom spoiler. Thanks for any advice.

RagJag

RagJag

#3

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,739

Received 10,749 Likes

on

7,100 Posts

Sidescrollin' is right.

Just went thru this on my V12.....

The fittings will be very tight. Saturate them with penetrating spray for a couple days. I was using a 12" wrench and still needed a 2-foot bar for extra leverage. You'll need a helper to hold a wrench on the oil cooler itself...or divine a way to wedge a wrench in place as I did.

Cheers and good luck

Cheers

DD

Just went thru this on my V12.....

The fittings will be very tight. Saturate them with penetrating spray for a couple days. I was using a 12" wrench and still needed a 2-foot bar for extra leverage. You'll need a helper to hold a wrench on the oil cooler itself...or divine a way to wedge a wrench in place as I did.

Cheers and good luck

Cheers

DD

The following users liked this post:

RagJag (05-13-2015)

#4

Are you sure its the Pipes that are leaking and not the Oil Cooler itself?

In any event I would budget for a New Oil Cooler, which is a very expensive piece of kit in its own right.

Having replaced the Oil Cooler on my XJS V12 it has to rate as one of the most difficult jobs that I have had to do on any Car.

The reason being the Oil Cooler on my Car was made of Aluminium while the connections of the Pipes were made of Steel, which together caused the two

dissimilar metals to corrode and had the effect of Welding them together.

Unless you are very lucky, I very much doubt if you will manage to undo those pipes, as even after Two whole weeks, I could not get mine off.

In the end I bought a New Oil Cooler and had some Pipes made up for me by a local firm who does hydraulic pipes for diggers.

If I ever had to do this again, I would not waste my time in trying to undo corroded connections.

I would simply buy a New Oil Cooler and have some New Pipes made up, although as I used plenty of Copper Grease, when I replaced everything then I

might be luckier next time.

Give it a go by all means, but do not hold your breath on trying to undo those Pipe Connections and also 'Counter Torque' those nuts with a Spanner.

When trying to undo them, the biggest risk of all, it that you might damage one of the other Coolers and so for just that one reason alone and if it were me instead of you.

I would cut the Flexible Pipes off near to the Cooler then get the Oil Cooler out of the Car, where you can then try to undo those Connections.

In any event I would budget for a New Oil Cooler, which is a very expensive piece of kit in its own right.

Having replaced the Oil Cooler on my XJS V12 it has to rate as one of the most difficult jobs that I have had to do on any Car.

The reason being the Oil Cooler on my Car was made of Aluminium while the connections of the Pipes were made of Steel, which together caused the two

dissimilar metals to corrode and had the effect of Welding them together.

Unless you are very lucky, I very much doubt if you will manage to undo those pipes, as even after Two whole weeks, I could not get mine off.

In the end I bought a New Oil Cooler and had some Pipes made up for me by a local firm who does hydraulic pipes for diggers.

If I ever had to do this again, I would not waste my time in trying to undo corroded connections.

I would simply buy a New Oil Cooler and have some New Pipes made up, although as I used plenty of Copper Grease, when I replaced everything then I

might be luckier next time.

Give it a go by all means, but do not hold your breath on trying to undo those Pipe Connections and also 'Counter Torque' those nuts with a Spanner.

When trying to undo them, the biggest risk of all, it that you might damage one of the other Coolers and so for just that one reason alone and if it were me instead of you.

I would cut the Flexible Pipes off near to the Cooler then get the Oil Cooler out of the Car, where you can then try to undo those Connections.

Last edited by orangeblossom; 05-13-2015 at 05:40 AM.

The following 2 users liked this post by orangeblossom:

Greg in France (05-14-2015),

RagJag (05-13-2015)

#5

#6

Thanks to all for the advice. I may not do it at all as it must be quite difficult. Neither the hoses nor the cooler are leaking. I was considering new ones for the original rubber hoses are 20 years old and I fear a rupture as I had in a transmission cooler hose.

Cheers, RagJag

Cheers, RagJag

In that case I would leave well alone as it is very difficult (Make that almost impossible!) to try and undo the connections, while the Oil Cooler is still in the Car.

Not to mention the very high risk of damaging the Condenser, if the Spanner slips.

If you are going to do the job at some future time, then it is probably on the Cards that you may need a New Oil Cooler, 'IF' you can't get the old connections off.

I replaced mine 12 years ago and if I remember correctly, the Oil Cooler just on its own was £200 (UK)

The following 2 users liked this post by orangeblossom:

Greg in France (05-14-2015),

RagJag (05-13-2015)

#7

Ragjag,

My suggestion would be that if there is no leak, do not touch the pipes or the oil cooler!

As has been mentioned, the steel pipes in the ali cooler bosses mean that it it is almost impossible to remove the pipes without wrecking the cooler. I would reckon that 90% of the time, they won't come apart. The pipes are NLA anyway. So go careful as your car could then be off the road if it goes as expected.

Many owners over here fit the bypass block that was fitted to x300 saloons, if their cooler or pipes let go. As the cooler wasn't fitted in some markets or to the saloons, it's generally considered that the AJ16 doesn't need the cooler 99% of the time. The bypass block is NLA but you can find a used one fairly easily. It could get you out of trouble if you get stuck with the pipes.

Good luck

Paul

My suggestion would be that if there is no leak, do not touch the pipes or the oil cooler!

As has been mentioned, the steel pipes in the ali cooler bosses mean that it it is almost impossible to remove the pipes without wrecking the cooler. I would reckon that 90% of the time, they won't come apart. The pipes are NLA anyway. So go careful as your car could then be off the road if it goes as expected.

Many owners over here fit the bypass block that was fitted to x300 saloons, if their cooler or pipes let go. As the cooler wasn't fitted in some markets or to the saloons, it's generally considered that the AJ16 doesn't need the cooler 99% of the time. The bypass block is NLA but you can find a used one fairly easily. It could get you out of trouble if you get stuck with the pipes.

Good luck

Paul

The following users liked this post:

RagJag (05-13-2015)

Trending Topics

#8

#9

Greg

The following 2 users liked this post by Greg in France:

orangeblossom (05-14-2015),

RagJag (05-14-2015)

#10

#11

The following users liked this post:

orangeblossom (05-19-2015)

#12

Unbeknown to me (at the time of purchase) because my knowledge of XJS's was totally Zero.

The PO of what is now my 'Scrapper' must have had a leak in the Engine Oil Cooler, as he had a pipe made up to by pass the Oil Cooler altogether, as he was unable to undo those oil pipe connections.

Not recommended to run without an Oil Cooler, though no doubt some on here may disagree.

When I had the Oil Cooler go, on one of my other Cars, I spend every day for Two whole Weeks! trying to get the leaking oil cooler off.

Its an almost Impossible job (make that an Impossible job) to undo the Connections from the Oil Cooler, as the two dissimilar metals weld themselves together in a way you wouldn't believe!

And even if you tried it, you would need a couple of Jumbo Sized Spanners, even to give it a go.

When the penny finally dropped that I wasn't getting anywhere, I just cut the pipes on either side of the Oil Cooler and scrapped the lot. (pipes, oil cooler, the works!)

Then I bought a new Oil Cooler circa £200! and had some new Oil Pipes made up by a local firm that does Hydraulic Pipes for 'Diggers' which if I remember correctly cost me £25. (Probably £50 or £60 nowadays)

Also I totally did away, with the Metal Bends and just had flexy all the way, which I routed round the engine room to keep them well away from anything hot.

100% successful no problems at all on my Car.

The only Two Connections that shouldn't be a problem to undo are where the Oil Pipes connect to the Engine, so if you have a leak or a weep, where those connections are.

It Should be fairly easy to undo them and put some sort of compound on the threads ie 'Plumbers Mate' and then screw them back, which was how I reassembled them.

The Old Oil Cooler is still in my 'Scrapper' where it clearly shows the 'dreaded joints' you were talking about and I think I've still got the Oil Cooler, that I cut out of my other Car.

So I will try and get you some photos ASAP.

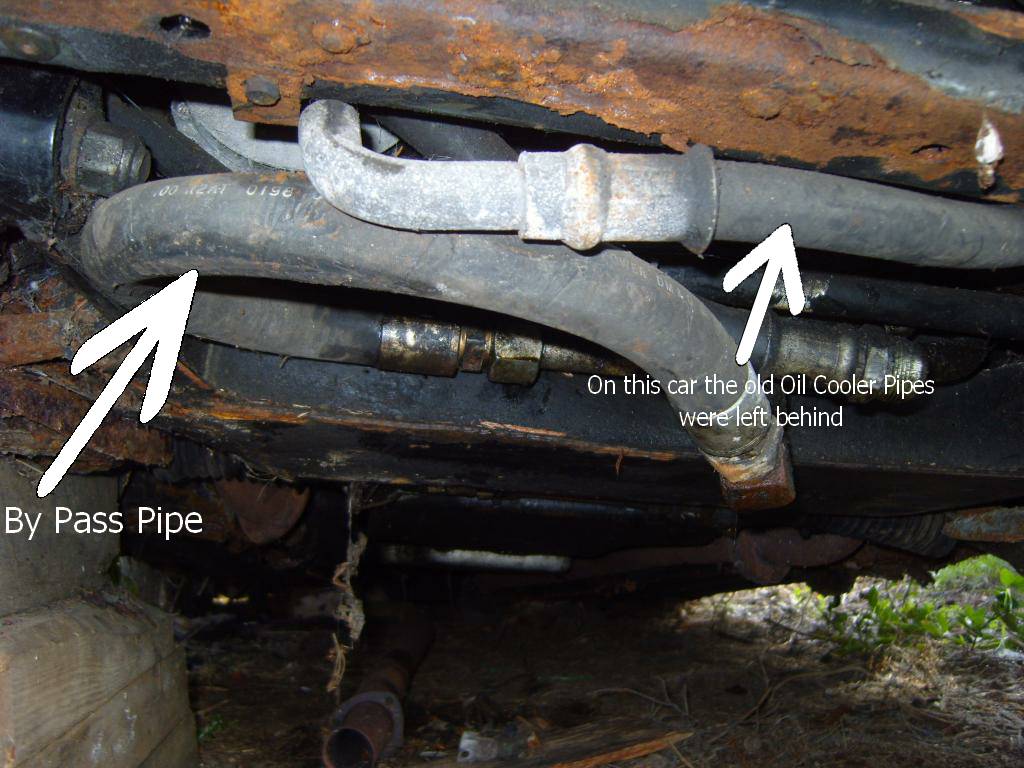

Photo: of 'The Controversial Oil Bypass Pipe' which I found on my 'Scrapper'

When I replaced the Oil Cooler on one of my other XJS's I did away with all those metal bends you see in the Photo and went 'Flexy' all the way, while making sure there they were long enough to avoid any kinks and keeping the Flexy Oil Pipes well away from any heat.

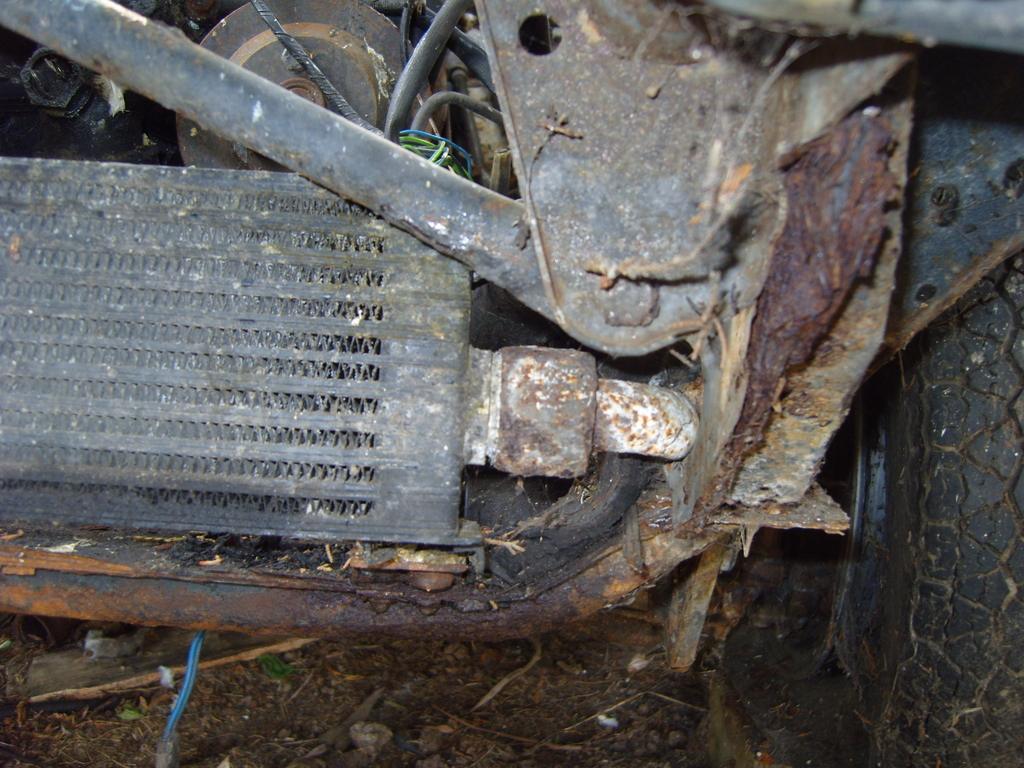

The Oil Cooler on my 'Scrapper' showing the 'dreaded connections' that Weld themselves together because of dissimilar metals.

You could always try slicing the nut through sideways, in a couple of places using a 'Dremel' then just replace the Hoses, where having these made by a local firm that make up Hydraulic Hoses will save you a small fortune and should be just as good as OEM.

In any event this is a PIA Job, where you either have to do it yourself or be prepared to pay a Garage/Shop some really 'Big Bucks' to have it done for you.

The Parts alone won't be far shy of £500-£600 (UK) and probably the same again for the Labour.

So its really worth having a go yourself, as then all you need to buy is the Oil Cooler and then get some hoses made up, which more often than not they will do while you wait.

Last edited by orangeblossom; 05-20-2015 at 07:11 AM.

The following 2 users liked this post by orangeblossom:

RagJag (05-24-2015),

TheWarlock (05-23-2015)

#13

The following users liked this post:

orangeblossom (05-24-2015)

#14

One of the toughest jobs. Pipes will most surely be 'bonded'...no way to loosen without breaking something. I sent away for a used coole with pipes for my '93. You have to be careful with year. They sent me a '94...a 2 piece hose. Mine was one piece. I ended up using the used cooler leaving the pipes intact. I cut the pipes at convenient places and used Transmission Hose and clamps to connect to my old hose which I left in place. And yes, you have to take the lower grill off...

#15

PTJS mentioned a bypass device to be used to eliminate the cooler. Do any of you have one for sale or know where I may find one. I would like to remove the cooler because I do believe it is unnecessary on a 4 liter engine making only about 270 HP and carrying almost 9 quarts of engine oil in the sump. I don't live in Death Valley.

I also think the cooler blocks some of the radiator air flow and if not, at least only transfers heat from the oil to the coolant. Jump in if you have thoughts to share.

RagJag

I also think the cooler blocks some of the radiator air flow and if not, at least only transfers heat from the oil to the coolant. Jump in if you have thoughts to share.

RagJag

The following users liked this post:

orangeblossom (06-10-2015)

#16

PTJS mentioned a bypass device to be used to eliminate the cooler. Do any of you have one for sale or know where I may find one. I would like to remove the cooler because I do believe it is unnecessary on a 4 liter engine making only about 270 HP and carrying almost 9 quarts of engine oil in the sump. I don't live in Death Valley.

I also think the cooler blocks some of the radiator air flow and if not, at least only transfers heat from the oil to the coolant. Jump in if you have thoughts to share.

RagJag

I also think the cooler blocks some of the radiator air flow and if not, at least only transfers heat from the oil to the coolant. Jump in if you have thoughts to share.

RagJag

Its pretty simple really, just a length of Hydraulic Hose the same size as the hydraulic pipes already on the Oil Cooler.

With fittings to suit the metal pipes that are left behind, at the point where they can be undone.

The Photo shows a 'by pass pipe' connected to a V12 but the same applies to a 4.0L XJS.

These are not Stock, you just can't go out and buy one.

But any Shop that does Hydraulic Pipes for Diggers and Excavators can make you one up in 10 minutes. (for around $50-$100)

All they will need to know is the length of the pipe you need and the size and type of fittings you want on the ends.

Probably best to take the Car to show them.

The following users liked this post:

RagJag (06-11-2015)

#17

I haven't checked mine but living in Houston I can't imagine not having a good functioning oil cooler. Would it be easier to just block off the existing fittings and putting a thermostatic Mocal sandwich plate and fitting a new Setrab cooler? Probably cheaper than OEM.

Mocal Oil Control System Products- Automotive Performance Plumbing & Cooling

I used a kit on my Subie BRZ when I went to a supercharger. Works well.

Mocal Oil Control System Products- Automotive Performance Plumbing & Cooling

I used a kit on my Subie BRZ when I went to a supercharger. Works well.

The following users liked this post:

RagJag (06-12-2015)

#18

#19

In the facelift V12 the oil goes out of the oil filter head, to the cooler and then back from the cooler to the oil filter head. There are two steel pipes that lead the oil along the B bank side under the exhaust manifold. At the front of the engine, the steel pipes join the flexibles that lead to the cooler. If an oil cooler line got completely blocked, oil would (a) return directly to the sump via the oil pressure bypass valve and be picked up again by the oil pump and (b) inside the oil filter head there is another pressure-activated valve which allows excess oil to go directly back into the oil lube system, thereby short circuiting the cooler completely. So the engine would get oil even if the cooler was 100% blocked.

On an early HE (eg mine) and all earlier models the oil has so called "bypass" cooling, whereby only a portion of the oil goes through the cooler. On this system, oil once through the filter, goes either (a) directly to the lube system or (b) any excess goes through the oil pressure relief valve and to the cooler. In this case there is only ONE steel pipe from the oil filter head along the B bank under the exhaust. At the front it joins a flexible to the cooler, and the flexible FROM the cooler goes directly back into the front A bank corner of the sandwich plate where it feeds the cooled oil directly into the oil pump. The oil pump thus draws oil from two sources, the sump and the oil cooler return.

There is much discussion about how much oil goes through the bypass system's oil cooler. I intend to test the temperature of the bypass cooler this summer - thereby proving (ie: if it gets hot oil is going through it) whether it does much cooling or not. Preliminary results indicate oil does go though, I hope to have more data soon.

So I would expect, even if the oil cooler was 100% blocked on a 6 cylinder car, the same 'emergency oil short circuiting' system exists on the 6 cylinder engine.

Greg

Last edited by Greg in France; 06-18-2015 at 02:05 AM.

The following users liked this post:

RagJag (06-18-2015)

#20

You can actually use the aluminum/steel joint combination to your advantage.

Aluminum has a much greater coefficient of expansion as compared to typical steels.

Depending on whether the aluminum forms the male or female thread, you can respectively spray the aluminum with a can of liquid air or spray the steel with

liquid air.

Aluminum has a much greater coefficient of expansion as compared to typical steels.

Depending on whether the aluminum forms the male or female thread, you can respectively spray the aluminum with a can of liquid air or spray the steel with

liquid air.