Should I forget about an AC?

#22

There is going to be a pressure safety switch on your 90 somewhere, I don't know where it is since I have a later model. You will have to jump that connection in order to get power to the compressor. However you don't want to do this with an entirely empty system as you could damage the compressor. The safety switch will be normally be on the low side (suction side) line and you need to jump the switch.

The following users liked this post:

JayJagJay (04-13-2018)

#23

Hey Time Pilot. Got ya. And thanks for that. I will not run it empty, I promise, lol...

I will see if I can find it on the LOW side line then. I have a lot of looking and learning to do with the AC system. Its strange,,, so far, in looking at and over this machine, front to back (and I still have a TON to learn), I almost work on her NOT paying any attention (at all) to the AC system. Like I haven't even considered or seen it yet - or something... So, its like day one, if you know what I mean?

What I thought I read somewhere was that power supply would be constant at the compressor plug (that sounds dumb now that I actually write i), but something in/with the compressor dealt with that,,, not allowing it (the clutch) to kick on without adequate pressure/coolant??? That the compressor, was always with a hot wirea t plug, but would simply not engage if not pressurized. Hmm.

I looked at the "kit"... There is like 10000 O-rings, lol... Jeeeeeeze!

I will see if I can find it on the LOW side line then. I have a lot of looking and learning to do with the AC system. Its strange,,, so far, in looking at and over this machine, front to back (and I still have a TON to learn), I almost work on her NOT paying any attention (at all) to the AC system. Like I haven't even considered or seen it yet - or something... So, its like day one, if you know what I mean?

What I thought I read somewhere was that power supply would be constant at the compressor plug (that sounds dumb now that I actually write i), but something in/with the compressor dealt with that,,, not allowing it (the clutch) to kick on without adequate pressure/coolant??? That the compressor, was always with a hot wirea t plug, but would simply not engage if not pressurized. Hmm.

I looked at the "kit"... There is like 10000 O-rings, lol... Jeeeeeeze!

#24

I worked on mine today, my leak was a bad schrader valve on the low side service port. Someone has been looking for it for a while because there is a ton of dye marker in my system. I was unable to locate the pressure cutoff switch on my 94' maybe it's a Jag thing, so I jumped power into the compressor clutch until I had enough charge to trip the switch I couldn't find.

Here are the correct service fitting locations, not that you can mess that up on the 94 > up cars.

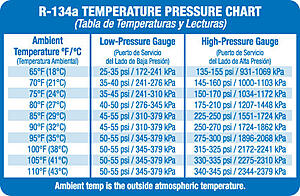

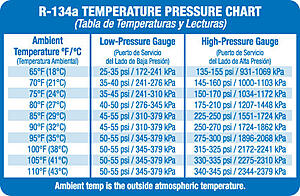

My charging pressures were correct based on the ambient temperature in my garage today but the AC system wasn't putting out exactly what I wanted. I'll have another look at the charge next weekend.

Here are the correct service fitting locations, not that you can mess that up on the 94 > up cars.

My charging pressures were correct based on the ambient temperature in my garage today but the AC system wasn't putting out exactly what I wanted. I'll have another look at the charge next weekend.

The following users liked this post:

JayJagJay (06-23-2018)

#25

Damn TimePilot... Looking good! 41 degrees!?!?! I pray for that kind of result...

I've ordered an o-ring set, vac pump and gauge set, and some r12 - 4 cans. Dryer - or whatever its called and an expansion valve... I should have about 50oz of r12 and hope that will be enough. I decided to stick with the r12... I am scared as hell of touching the expansion valve due to all of the comments about selling the car IF you make a mistake. I've order one anyways, and will most likely just look at it and leave it IN the package, lol... Do folks think I should go after it or leave it alone??? So far I have been mostly lucky with things,,, but yeah, maybe I shouldn't be pushing my luck...? But, if its bad, and I get all that r12 in there (and r12 aint CHEAP) I will have to face losing it all to replace the expansion. I hate these kinds of positions.

I plan to replace all of the rings I can find (and thanks to this post TimeP) the schraderz as well. I've also seen new (for less than $200) compressors... I dont have to drive her everyday or anything so maybe I will just start identifying joints with RINGS, open them up a lil, and have things ready for when I have my replacements. I get goofy, so, I'll just wait and see what I have after creating neg pressure and seeing if she holds. On looking things over the expansion looks like the only thing that has never been touched,,, kinda sank into the fire wall and hard to get at, but hoses look kind of new/replaced. We shall see...

Any recommended ORDER OF OPERATIONS considering where I'm at are super welcomed?

I've ordered an o-ring set, vac pump and gauge set, and some r12 - 4 cans. Dryer - or whatever its called and an expansion valve... I should have about 50oz of r12 and hope that will be enough. I decided to stick with the r12... I am scared as hell of touching the expansion valve due to all of the comments about selling the car IF you make a mistake. I've order one anyways, and will most likely just look at it and leave it IN the package, lol... Do folks think I should go after it or leave it alone??? So far I have been mostly lucky with things,,, but yeah, maybe I shouldn't be pushing my luck...? But, if its bad, and I get all that r12 in there (and r12 aint CHEAP) I will have to face losing it all to replace the expansion. I hate these kinds of positions.

I plan to replace all of the rings I can find (and thanks to this post TimeP) the schraderz as well. I've also seen new (for less than $200) compressors... I dont have to drive her everyday or anything so maybe I will just start identifying joints with RINGS, open them up a lil, and have things ready for when I have my replacements. I get goofy, so, I'll just wait and see what I have after creating neg pressure and seeing if she holds. On looking things over the expansion looks like the only thing that has never been touched,,, kinda sank into the fire wall and hard to get at, but hoses look kind of new/replaced. We shall see...

Any recommended ORDER OF OPERATIONS considering where I'm at are super welcomed?

Last edited by JayJagJay; 06-23-2018 at 01:19 PM.

#30

The following 2 users liked this post by Jagboi64:

Greg in France (06-24-2018),

JayJagJay (06-24-2018)

#32

JJJ

Are you just trying to get the hose off the valve? If so, you MUST support the valve body against the torque of the spanner you are using to undo the hose nut. A lockable-jawed wrench may be a good tool for this. A metric spanner may be easiest to find to fit the hose nut well enough, by the way.

Are you just trying to get the hose off the valve? If so, you MUST support the valve body against the torque of the spanner you are using to undo the hose nut. A lockable-jawed wrench may be a good tool for this. A metric spanner may be easiest to find to fit the hose nut well enough, by the way.

The following users liked this post:

JayJagJay (06-24-2018)

#33

I think I'm going to change the o-ring on what I was able to pull apart and hope for the best. If,,, and I mean if, push comes to shove and I need to, I will go back in. As it is now I've removed the cross pipe, the fuel rail, cross rods and still, it just doesn't feel right. Even with the appropriate spanner (19mm I think) and a fair amount of room, applying opposite torque with an adjustable wrench that does grab,,, it just seems as though there is a significant amount of twisty force being transmitted thru the body of the tubing neighboring the expansion valve. Sumpthin ait right. I'm doing what I'm doing with the sense of EXPECTING something to go bad. Ummm, nah. I'm out. lol...

if I have to later I will pull everything in the V ok in my way and give it another shot, until then,,, I'll hope for A.C. with the old valve.

if I have to later I will pull everything in the V ok in my way and give it another shot, until then,,, I'll hope for A.C. with the old valve.

#34

Im late to the party, but here is my 2 cents worth on the XJS AC. It isn’t optional. It’s integration into the fuel system is not to be underestimated. Without it functional and running the temperature of the gasoline will rise constantly with operating time. There is no other cooling available to the fuel, and enormous heat input. All the fuel in the tank is circulated so there’s a really massive heat sink effect in the tank, but once you’ve heated all the fuel in the tank you are constantly vaporizing fuel.

I do not have AC currently and the tank vent to canister appears clogged on my car. Recently took a nice 350mi trip through the country on a nice summer day. 90F ambient. Smelled fuel while cruising, pulled over popped the gas cap off. You know that whoosh that tells you you have a venting issue? The pressure dump from my tank was not like that. It was like purging an air compressor tank. Took a solid thirty seconds to dump all the fuel vapor pressure. Given the size of the tank, and fuel level I would estimate it was under 40-50psi pressure.

With a properly functioning tank venting system the fuel heating up wouldn’t be as dangerous, just hugely wasteful. I’m looking at available fuel coolers for the interim until I restore the AC system. These cars need some fuel cooling.

I do not have AC currently and the tank vent to canister appears clogged on my car. Recently took a nice 350mi trip through the country on a nice summer day. 90F ambient. Smelled fuel while cruising, pulled over popped the gas cap off. You know that whoosh that tells you you have a venting issue? The pressure dump from my tank was not like that. It was like purging an air compressor tank. Took a solid thirty seconds to dump all the fuel vapor pressure. Given the size of the tank, and fuel level I would estimate it was under 40-50psi pressure.

With a properly functioning tank venting system the fuel heating up wouldn’t be as dangerous, just hugely wasteful. I’m looking at available fuel coolers for the interim until I restore the AC system. These cars need some fuel cooling.

The following users liked this post:

JayJagJay (06-24-2018)

#35

Good morning JigJag... That IS concerning. I fully intend to do what I can and need to do to get the A.C. system up and running BUT I do not intend,,, not just now,,, to remove and replace the expansion valve... That was really all that i was saying... That being said,

My fuel recovery system canister situation is a mess, I don't understand it, it will be a focus of mine and I really don't know where to get the information I will need to start to sort it out. I cannot say that I have done a ton of looking and learning, attempting to learn etc just yet - but as of right now I have a bunch of vac lines running down and into that area thru the LH engine bay wall,,, and I don't know for what, to where, and if anything is right about the set up and where the lines are ending up. It's a NEXT thing for me. In fact, I think trouble there is effecting my idle. A vac leak. As it is now my AAV idle bolt is turned all the way down,,, tightly In D or R my idle is about 600. In P or N,,, about 800-850. I would like that lower, maybe??? More,,, although she is running better than I have ever had her to date, I still believe she is running rich, a little bumpy/rough and I want all of that straightened out - post haste... Thing is,,, I have nothing to compare how she runs to a right running 1990 xjs. I don't like that kinda baselessness...

Thanks for your thoughtful well written post... 🤤🤤🤤

My fuel recovery system canister situation is a mess, I don't understand it, it will be a focus of mine and I really don't know where to get the information I will need to start to sort it out. I cannot say that I have done a ton of looking and learning, attempting to learn etc just yet - but as of right now I have a bunch of vac lines running down and into that area thru the LH engine bay wall,,, and I don't know for what, to where, and if anything is right about the set up and where the lines are ending up. It's a NEXT thing for me. In fact, I think trouble there is effecting my idle. A vac leak. As it is now my AAV idle bolt is turned all the way down,,, tightly In D or R my idle is about 600. In P or N,,, about 800-850. I would like that lower, maybe??? More,,, although she is running better than I have ever had her to date, I still believe she is running rich, a little bumpy/rough and I want all of that straightened out - post haste... Thing is,,, I have nothing to compare how she runs to a right running 1990 xjs. I don't like that kinda baselessness...

Thanks for your thoughtful well written post... 🤤🤤🤤

#36

Im late to the party, but here is my 2 cents worth on the XJS AC. It isn’t optional. It’s integration into the fuel system is not to be underestimated. Without it functional and running the temperature of the gasoline will rise constantly with operating time. There is no other cooling available to the fuel, and enormous heat input. All the fuel in the tank is circulated so there’s a really massive heat sink effect in the tank, but once you’ve heated all the fuel in the tank you are constantly vaporizing fuel.

I have a huge amount of room to play with between the outermost (plastic chrome) grill and the radiator, for instance. Under the AC dryer area.

Last edited by JayJagJay; 06-24-2018 at 08:17 AM.

#37

Hello All... Real quick guys... This is what I am looking at... Should I get/do this??? The price is very good. Now, I have what looks like the factory original, heavy as a bag of cement and takes up HUGE space.

https://www.ebay.com/itm/AC-Compress...4383.l4275.c10

https://www.ebay.com/itm/AC-Compress...4383.l4275.c10

#38

JJJ

Forget the fuel cooler. Jaguar themselves eliminated it on later V12 models.

A very good choice to leave the old valve in place; it will be fine.

Aircon: new compressor, new dryer, new condenser (unless the old one is in excellent condition) and new pipes (again unless the existing ones are very good) will all be needed.

I would speak to the aircon guy about a compressor before buying anything. You need to be sure the OEM pipes can fit to the compressor OK (or new ones made up can fit to it OK). A decent aircon guy can make new pipes using the old hard fittings as the attachment to the back of the OEM compressor if needed, or fit new type fittings as long as there is room in the V. The OEM fittings are not as modern cars now use, and space is limited if your cruise control is in the V.

You do not want to splash the cash and find you have packaging problems!

It is not at all hard to get them fitted, and then find your local aircon guy to evacuate and charge the system.

Tank venting: I am sympathetic with JigJag, but a non-functioning tank breather system will produce very high pressure differentials quite regardless of ambient temps. On the XJS fuel temp in the tank is not greatly different, if at all, cooler or no cooler, which is why later Jaguar cars eliminated it. If your tank is not whooshing (in or out) when you open the cap, you are OK. If you are allowed by your local regs, the tank breather system can be very easily simplified to dump the cannister and front-end stuff.

About that cooler photo, the LAST thing you want is a large rad full of petrol right at the front of the car, ready to incinerate you and the unlucky person you accidentally hit at 10 MPH - even if it is his fault! Keep everything as simple as you can, get the car right, and then, and only then, worry about the frills!

Forget the fuel cooler. Jaguar themselves eliminated it on later V12 models.

A very good choice to leave the old valve in place; it will be fine.

Aircon: new compressor, new dryer, new condenser (unless the old one is in excellent condition) and new pipes (again unless the existing ones are very good) will all be needed.

I would speak to the aircon guy about a compressor before buying anything. You need to be sure the OEM pipes can fit to the compressor OK (or new ones made up can fit to it OK). A decent aircon guy can make new pipes using the old hard fittings as the attachment to the back of the OEM compressor if needed, or fit new type fittings as long as there is room in the V. The OEM fittings are not as modern cars now use, and space is limited if your cruise control is in the V.

You do not want to splash the cash and find you have packaging problems!

It is not at all hard to get them fitted, and then find your local aircon guy to evacuate and charge the system.

Tank venting: I am sympathetic with JigJag, but a non-functioning tank breather system will produce very high pressure differentials quite regardless of ambient temps. On the XJS fuel temp in the tank is not greatly different, if at all, cooler or no cooler, which is why later Jaguar cars eliminated it. If your tank is not whooshing (in or out) when you open the cap, you are OK. If you are allowed by your local regs, the tank breather system can be very easily simplified to dump the cannister and front-end stuff.

About that cooler photo, the LAST thing you want is a large rad full of petrol right at the front of the car, ready to incinerate you and the unlucky person you accidentally hit at 10 MPH - even if it is his fault! Keep everything as simple as you can, get the car right, and then, and only then, worry about the frills!

Last edited by Greg in France; 06-24-2018 at 09:44 AM.

The following users liked this post:

JayJagJay (06-24-2018)

#39

I’m currently getting my A/C back to life.

R12 is banned in Europe (and has been for many years), so I’m converting g to R134a.

My A/C specialist tells me all that needs to be done is change of oil, which means the system shall be flushed. I’m changing the condenser and of course filter/dryer while I’m at it, but otherwise I change nothing. Ed Abbott (former Jaguar Engineer in the period) has confirmed on FB, that his XJ-S has been converted in same way w/o any issues.

R134a will run warmer, which is why I was told to check the condenser. All fins were loose, so it was easy to decide it needed replacement. Charge weight need to be reduced with 10-15%, which means it Will be fælled with 960 gram.

R12 is banned in Europe (and has been for many years), so I’m converting g to R134a.

My A/C specialist tells me all that needs to be done is change of oil, which means the system shall be flushed. I’m changing the condenser and of course filter/dryer while I’m at it, but otherwise I change nothing. Ed Abbott (former Jaguar Engineer in the period) has confirmed on FB, that his XJ-S has been converted in same way w/o any issues.

R134a will run warmer, which is why I was told to check the condenser. All fins were loose, so it was easy to decide it needed replacement. Charge weight need to be reduced with 10-15%, which means it Will be fælled with 960 gram.

The following users liked this post:

JayJagJay (06-24-2018)

#40

Understood Greg... I like the way you keep it simple and me grounded. Honestly.

I have purchased the things I need to do the aircon (if push comes to shove I will take her somewhere). I figured now, with ol 3 cars, I can use it on them all and Vac and Mani set will pay for themselves in two-three uses. Vac pump, decent manifold set, mineral oil (I'd removed the compresor completely the first time I rebuilt the fuel rail, changed cap, plugs, rotor and cleaned out the V), dryer --- pipes and hoses look good on her ---- I simply CANNOT afford new ones right now. And, although its more expensive, I am going to stick with the r12 this time around. If I need a new compressor, condenser (I pulled, cleaned and degreased the condenser last year too - it looks good),,, after I get things together I will do that then if needed. I have no choice. Money is tight.

I have a gas smell. It comes and goes but is there. I want to simplify the canister. MORE, I need to see what going on with it all together in them mean time. I get NO whoooosh... Never have, not once. I nickeled some spots (leaks) on the tank last year, epoxied the whole under side - pulling it completely, and will admit, it didn't go back IN exactly as it came OUT, lol... There was one steel part of tank vent tubing that I had NO idea where it went. I guess Ill need to get back in there. Anyways.

I will be back once I get the set up to start sealing and testing the system - expansion valve RIGHT where it is .... Holding off on new compressor.

.... Holding off on new compressor.

Thanks all. See ya on the flip side.

I have purchased the things I need to do the aircon (if push comes to shove I will take her somewhere). I figured now, with ol 3 cars, I can use it on them all and Vac and Mani set will pay for themselves in two-three uses. Vac pump, decent manifold set, mineral oil (I'd removed the compresor completely the first time I rebuilt the fuel rail, changed cap, plugs, rotor and cleaned out the V), dryer --- pipes and hoses look good on her ---- I simply CANNOT afford new ones right now. And, although its more expensive, I am going to stick with the r12 this time around. If I need a new compressor, condenser (I pulled, cleaned and degreased the condenser last year too - it looks good),,, after I get things together I will do that then if needed. I have no choice. Money is tight.

I have a gas smell. It comes and goes but is there. I want to simplify the canister. MORE, I need to see what going on with it all together in them mean time. I get NO whoooosh... Never have, not once. I nickeled some spots (leaks) on the tank last year, epoxied the whole under side - pulling it completely, and will admit, it didn't go back IN exactly as it came OUT, lol... There was one steel part of tank vent tubing that I had NO idea where it went. I guess Ill need to get back in there. Anyways.

I will be back once I get the set up to start sealing and testing the system - expansion valve RIGHT where it is

.... Holding off on new compressor.

.... Holding off on new compressor.Thanks all. See ya on the flip side.