Wheel Bearing Replacement

#1

I'm hearing some grinding sounds, like an airplane propeller at speed, when driving from the front of the car and feel some vibration in the wheel. Its not a visible vibration. I believe its the wheel bearings going bad.

Can someone confirm that the process of replacing the bearings match what the XJ40 process is. Someone was kind enough to put together a visual walkthrough that makes me confident enough to think I can do it myself! Check the thread below, Post #6 to be specific.

https://www.jaguarforums.com/forum/x...t-95-a-132643/

I've ordered me up two sets of Timken inner and outer bearings and two Beck Arnley grease seals. Other than some grease (Red Line CV2 Synthetic Grease), I think I'm set. I'll have access to race drivers, but I think that's all I'll need in terms of unusual tools or materials.

Thanks for any advice in advance.

Can someone confirm that the process of replacing the bearings match what the XJ40 process is. Someone was kind enough to put together a visual walkthrough that makes me confident enough to think I can do it myself! Check the thread below, Post #6 to be specific.

https://www.jaguarforums.com/forum/x...t-95-a-132643/

I've ordered me up two sets of Timken inner and outer bearings and two Beck Arnley grease seals. Other than some grease (Red Line CV2 Synthetic Grease), I think I'm set. I'll have access to race drivers, but I think that's all I'll need in terms of unusual tools or materials.

Thanks for any advice in advance.

Last edited by Vee; 03-05-2015 at 03:58 PM.

#2

I'm hearing some grinding sounds, like an airplane propeller at speed, when driving from the front of the car and feel some vibration in the wheel. Its not a visible vibration. I believe its the wheel bearings going bad.

Can someone confirm that the process of replacing the bearings match what the XJ40 process is. Someone was kind enough to put together a visual walkthrough that makes me confident enough to think I can do it myself! Check the thread below, Post #6 to be specific.

https://www.jaguarforums.com/forum/x...t-95-a-132643/

I've ordered me up two sets of Timken inner and outer bearings and two Beck Arnley grease seals. Other than some grease (Red Line CV2 Synthetic Grease), I think I'm set. I'll have access to race drivers, but I think that's all I'll need in terms of unusual tools or materials.

Thanks for any advice in advance.

Can someone confirm that the process of replacing the bearings match what the XJ40 process is. Someone was kind enough to put together a visual walkthrough that makes me confident enough to think I can do it myself! Check the thread below, Post #6 to be specific.

https://www.jaguarforums.com/forum/x...t-95-a-132643/

I've ordered me up two sets of Timken inner and outer bearings and two Beck Arnley grease seals. Other than some grease (Red Line CV2 Synthetic Grease), I think I'm set. I'll have access to race drivers, but I think that's all I'll need in terms of unusual tools or materials.

Thanks for any advice in advance.

The older series have a slightly different front end setup. Removing the wheels and calipers doesn't allow for the rotor to simply pop off. From what I recall, the rotor is bolted through the backside of the hub, so the whole thing comes off the spindle.

Knock them out, clean the old grease out, pack the new bearings and put the races and new bearings in.

The install is a little wishy washy here. From what I saw, it just says tighten until it doesn't wobble...which is kind of vague. Even without doing it the proper way, and checking with a dial indicator, there is a bit more specific way that is safer.

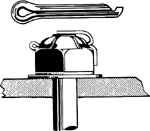

Basically, upon reinstalling, tighten the nut up while spinning the rotor and tighten the nut to about 25 ft/lbs. Back the nut off 1/2 turn, spin the rotor 1/4 turn and then tighten the nut to 2 ft/lbs and install the retainer and cotter pin. This should give you a good .001-.005" clearance.

Also, proper cotter installation does not mean yanking the ends of the cotter pin out the side, the bottom end is cut flush with the end of the nut and the outer end is bent upward along the spindle and over the top of it and then cut off.

After re-fitting the grease cap and applying grease, spin the assembly around until it is clean. Grease will squirt out of the cap as you spin it the first time, keep wiping until it stops, or else you may end of with grease all over the inside of your wheel or worse, your rotors.

The following users liked this post:

afterburner1 (03-17-2015)

#3

You should have no trouble replacing you front wheel bearings - inner, outer and the grease seal. Remove hubs, old bearings, total hub clean, install new bearings and seals and reassemble hubs to spindles and a coupla cold ones should take no more than an hour and a half per side. Properly sized punch and bearing install set are big helps.

#4

i am doing the the rear on my xjs is slightly different than whats in the pictures general concept is the same. i have inboard breaks. the xjs and xj6 platforms are pretty similar. wheel bearings shouldn't be anything too hard. If i get time i might pull my front apart to inspect and grease my front wheel bearings tomorrow when i get into it if i run into anything that might complicated things ill let you know, normally wheel bearings are pretty straight forward, this is my first time on a xjs but done probably 100 or more of various makes and models.

#5

#6

So I realized that perhaps I should change out the rotors while doing this work, since they're the original rotors.

I'm going to pick up Centric High Carbon 125 rotors. Does anyone know who the OEM manufacturer was?

Anything else I should consider swapping out while Im in there doing the work?

I'm going to pick up Centric High Carbon 125 rotors. Does anyone know who the OEM manufacturer was?

Anything else I should consider swapping out while Im in there doing the work?

#7

Well I'm glad I chose to replace the rotors...they were pretty rusty.

I only got to one side because I had the wrong sized bearings! That killed of a lot of valuable time!

Luckily the local Advanced Auto carried the right sizes. Unfortunately I ended up losing the Timken bearings and am now riding on National brand? They appeared fine.

Unfortunately I was only able to complete one wheel. The old grease seal was quite a pain to remove. It stayed on the stub axle carrier. I didn't realize it was just a rubber seal. I ended up pulling off a thin metal piece as well... I can't find that part illustrated anywhere, so I'm hoping it was part of the rubber seal.

Not sure I was able to get the wheel to spin as freely as before...I may just have to invest in a magnetic dial indicator. I feel like the wheel is too tight. I compared it to the other side, and the amount of threads remaining is about the same, so I'm in the ballpark.

I only got to one side because I had the wrong sized bearings! That killed of a lot of valuable time!

Luckily the local Advanced Auto carried the right sizes. Unfortunately I ended up losing the Timken bearings and am now riding on National brand? They appeared fine.

Unfortunately I was only able to complete one wheel. The old grease seal was quite a pain to remove. It stayed on the stub axle carrier. I didn't realize it was just a rubber seal. I ended up pulling off a thin metal piece as well... I can't find that part illustrated anywhere, so I'm hoping it was part of the rubber seal.

Not sure I was able to get the wheel to spin as freely as before...I may just have to invest in a magnetic dial indicator. I feel like the wheel is too tight. I compared it to the other side, and the amount of threads remaining is about the same, so I'm in the ballpark.

Trending Topics

#8

Well I managed to do the other tire. The stub axle looked a little worse than the drivers side, but I couldn't feel any damage to the steel, so I lubed it up and wrapped it up!

I learned a few things that I'd like to share.

1. You'll only be able to remove the front half of the rotor, which means you'll lose a little bit of fluid, and it also means you'll have to bleed the brakes when you reassemble them. (don't forget to clamp the line before unbolting the caliper halves)

Removing the caliper as a whole would avoid that mess, however (a) it's a great way to clean up the brake calipers and (b) there doesn't seem to be an easy way to access the bolts that hold the entire assembly together.

2. It's impossible to remove the ABS sensor without disconnecting the lower ball joint. I didn't bother. The brake cleaner, apparently, did not damage the sensor. Please take the opportunity to give it a thorough cleaning, since you'll never get better access to it.

3. Don't waste money on a grease packer. The palm of hand method works great. It didn't take long for me to get good at it. I learned that smearing a dallop of grease, low, wide and flat on your palm works great. A high, vertical dallop doesn't work as well.

4. You'll want a can of brake cleaner per wheel.

5. OEM bearings were indeed Timken. Made in England. New Timkens had varying countries of origin. The ones I had (but didn't use due to the fact they were the wrong size) came from Poland and Italy. National brand is Made in the USA.

6. Installing the grease seal is easy if you use a flat block, or board. Using a hammer to tap it in is completely useless. I couldn't get it to work. By starting the seal in on one side of the circle and then laying a flat piece of scrap wood and pressing down on it got it in in no time.

7. Make sure you have a cheap wire brush on hand to clean off the hub and especially the ABS ring. Wire brush made short work on the grime. Make sure you anti-seize it all.

I think that was all.

I learned a few things that I'd like to share.

1. You'll only be able to remove the front half of the rotor, which means you'll lose a little bit of fluid, and it also means you'll have to bleed the brakes when you reassemble them. (don't forget to clamp the line before unbolting the caliper halves)

Removing the caliper as a whole would avoid that mess, however (a) it's a great way to clean up the brake calipers and (b) there doesn't seem to be an easy way to access the bolts that hold the entire assembly together.

2. It's impossible to remove the ABS sensor without disconnecting the lower ball joint. I didn't bother. The brake cleaner, apparently, did not damage the sensor. Please take the opportunity to give it a thorough cleaning, since you'll never get better access to it.

3. Don't waste money on a grease packer. The palm of hand method works great. It didn't take long for me to get good at it. I learned that smearing a dallop of grease, low, wide and flat on your palm works great. A high, vertical dallop doesn't work as well.

4. You'll want a can of brake cleaner per wheel.

5. OEM bearings were indeed Timken. Made in England. New Timkens had varying countries of origin. The ones I had (but didn't use due to the fact they were the wrong size) came from Poland and Italy. National brand is Made in the USA.

6. Installing the grease seal is easy if you use a flat block, or board. Using a hammer to tap it in is completely useless. I couldn't get it to work. By starting the seal in on one side of the circle and then laying a flat piece of scrap wood and pressing down on it got it in in no time.

7. Make sure you have a cheap wire brush on hand to clean off the hub and especially the ABS ring. Wire brush made short work on the grime. Make sure you anti-seize it all.

I think that was all.

The following 3 users liked this post by Vee:

Thread

Thread Starter

Forum

Replies

Last Post

BrentGardner

XJ XJ6 / XJ8 / XJR ( X350 & X358 )

26

04-17-2024 05:19 PM

Doberman_Fan

S-Type / S type R Supercharged V8 ( X200 )

22

12-24-2019 06:21 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)