DIY Repair - Air Bag Light Related to Harness under Driver's Seat ... or not

#1

Hi guys, if any of you remember some of my previous posts, About a year and a half ago, I started getting an intermittent Air Bag indicator for the driver's side. Blinking 2-2 for a couple cycles, then going solid. So I had it taken to the dealer for a diagnosis about 6 months ago after a couple frequent occurrences.

The code 2-2 indicates wiring harness, so they tested the continuity on the pins for the connector just under the driver's seat. All results were within tolerances, so no repairs taken, and they could not get it to repeat.

This is a common area for the air bag indicator to come on, and lately, it has been happening quite frequently, and every time it has, the car has been sitting outside...such as when I am at work. This led me to believe it was heat playing a part in the equation.

Before today, I tried simply applying some dielectric grease to the pins, and plugging/unplugging the harness many times to try to get the connection to be a little better...worked for about 2 weeks, now I am getting some additional lights...twice this morning in fact.

I had a plan though. Something is restricting initial continuity...perhaps tarnish or corrosion, or just plain grime (<- my best technical term)

Check out this pic of the male end of the connector before I started (sorry, best I can do with a Point n Shoot...

See how some of the pins are tin, and some are gold? I have no idea if this is standard or not, and perhaps my service guy did replace a few pins and just didn't mention it to me (and thus not having to charge me)

First, getting to the plug is going to require you to kneel next to the car and fit your massive noggin below the steering wheel to access plugs. Get comfy, put a pillow under your knees, and you'll be good for the next 10 minutes. I took my Wizard kit out, and found the smallest bit I could find. (approximately 3mm wide)

It fit perfectly between these pins and the plastic, and on the lowest speed, I was able to buff-grind off the outside surface of each pin, evident by them getting all shiny. And look at all that dirt/tarnish that came off the surface.

So, I cleaned this out obviously, and then also put a very narrow (pinlike) bit into the female slots, added a dab of dielectric grease on the newly polished pins, and reconnected it. (dieletric grease optional and per preference)

Started and drove the three times after that, no light. This was encouraging, because it was just before I started this little crafty-work and the light was on.

I'll follow up in a month or two, and let you know if the project was successful long-term.

The code 2-2 indicates wiring harness, so they tested the continuity on the pins for the connector just under the driver's seat. All results were within tolerances, so no repairs taken, and they could not get it to repeat.

This is a common area for the air bag indicator to come on, and lately, it has been happening quite frequently, and every time it has, the car has been sitting outside...such as when I am at work. This led me to believe it was heat playing a part in the equation.

Before today, I tried simply applying some dielectric grease to the pins, and plugging/unplugging the harness many times to try to get the connection to be a little better...worked for about 2 weeks, now I am getting some additional lights...twice this morning in fact.

I had a plan though. Something is restricting initial continuity...perhaps tarnish or corrosion, or just plain grime (<- my best technical term)

Check out this pic of the male end of the connector before I started (sorry, best I can do with a Point n Shoot...

See how some of the pins are tin, and some are gold? I have no idea if this is standard or not, and perhaps my service guy did replace a few pins and just didn't mention it to me (and thus not having to charge me)

First, getting to the plug is going to require you to kneel next to the car and fit your massive noggin below the steering wheel to access plugs. Get comfy, put a pillow under your knees, and you'll be good for the next 10 minutes. I took my Wizard kit out, and found the smallest bit I could find. (approximately 3mm wide)

It fit perfectly between these pins and the plastic, and on the lowest speed, I was able to buff-grind off the outside surface of each pin, evident by them getting all shiny. And look at all that dirt/tarnish that came off the surface.

So, I cleaned this out obviously, and then also put a very narrow (pinlike) bit into the female slots, added a dab of dielectric grease on the newly polished pins, and reconnected it. (dieletric grease optional and per preference)

Started and drove the three times after that, no light. This was encouraging, because it was just before I started this little crafty-work and the light was on.

I'll follow up in a month or two, and let you know if the project was successful long-term.

Last edited by H20boy; 07-08-2010 at 12:11 AM.

The following 2 users liked this post by H20boy:

Felipe Pr (07-05-2011),

Patrice Konrad (04-13-2023)

#2

#4

My only comment is that dielectric grease is an insulator. It does NOT conduct electricity. If you're putting that on the pins then you are making it more difficult for them to make good contact in the socket.

http://www.wisegeek.com/what-is-dielectric-grease.htm

http://www.wisegeek.com/what-is-dielectric-grease.htm

#6

Found on the internets:

Dielectric grease is a nonconductive grease. Because it is nonconductive it does not enhance the flow electrical current. Electrical conductors should not be coated with dielectric grease prior to being mated. However, dielectric grease is often applied to electrical connectors, particularly ones which contain rubber gaskets, as a way to provide a nonconductive lubricant and sealer for the rubber portions of the connector.

The widest use of dielectric grease is in high-voltage connections associated with spark plugs. The grease is applied to the rubber boot of the plug wire. This helps the rubber boot slide onto the ceramic insulator of the plug. The grease also acts to seal the rubber boot, while at the same time preventing the rubber from becoming stuck to the ceramic. Generally spark plugs are located in areas of high temperature, and the grease is formulated to withstand the temperature range expected.

Another common use of dielectric grease is on the rubber mating surfaces or gaskets of multi-pin electrical connectors used in automotive and marine engines. The grease again acts as a lubricant and a sealant on the nonconductive mating surfaces of the connector. It is not recommended to be applied to the actual electrical conductive contacts of the connector.

The widest use of dielectric grease is in high-voltage connections associated with spark plugs. The grease is applied to the rubber boot of the plug wire. This helps the rubber boot slide onto the ceramic insulator of the plug. The grease also acts to seal the rubber boot, while at the same time preventing the rubber from becoming stuck to the ceramic. Generally spark plugs are located in areas of high temperature, and the grease is formulated to withstand the temperature range expected.

Another common use of dielectric grease is on the rubber mating surfaces or gaskets of multi-pin electrical connectors used in automotive and marine engines. The grease again acts as a lubricant and a sealant on the nonconductive mating surfaces of the connector. It is not recommended to be applied to the actual electrical conductive contacts of the connector.

#7

Dielectric grease is a non conductive material that will seal from moisture and other natural environmental issues. Is it a conductor? NO! and in that environment you do not want a conductive material on the pins to carry a signal from one pin to the other. Using it as Matt did is not a problem, it should eliminate the oxidation and moisture that plague us with the poltergeist effects we often get from our cars. However, if you use it do it moderately.

Trending Topics

#8

I have to respectfully disagree. I have a degree in electrical engineering, so I think I'm qualified to comment on this. You never want to apply dielectric grease to two conductive mating surfaces. That will only increase the resistance of the connection, not make for a better connection. There are other types of lubricants that can be used on electrical connectors that are designed to enhance the conductivity between the pin and the socket, but typically they aren't necessary. The connectors themselves are designed in such a way that the sliding action of the pin within the socket cleans off any oxidation. If you do use a conductive lubricant on the pins you should lubricate each pin individually because you don't want a continuous flow of lubricant from one pin to another. That could result in current leaking from one pin to another and causing all sorts of problems.

#9

I have no problem with that. But as I said used do it moderately. As for your qualifications no contest. However, I have 35 years in the electrical business hands on and supervising people to get the job done.

http://www.crcindustries.com/auto/co..._ss.aspx?ID=85

http://www.crcindustries.com/auto/co..._ss.aspx?ID=85

Last edited by Gus; 06-20-2010 at 05:33 PM.

#10

Well I agree that hands-on experience beats book learning, but I have hands on experience, too. I was an avionics technician in the Marines, and I've worked in the electronics industry for the last 20 years.

OK!!! Enough of the "my d*ck is bigger than your d*ck stuff! LOL! Let's get back to h20boy's airbag problem!

Let's get back to h20boy's airbag problem!

OK!!! Enough of the "my d*ck is bigger than your d*ck stuff! LOL!

#12

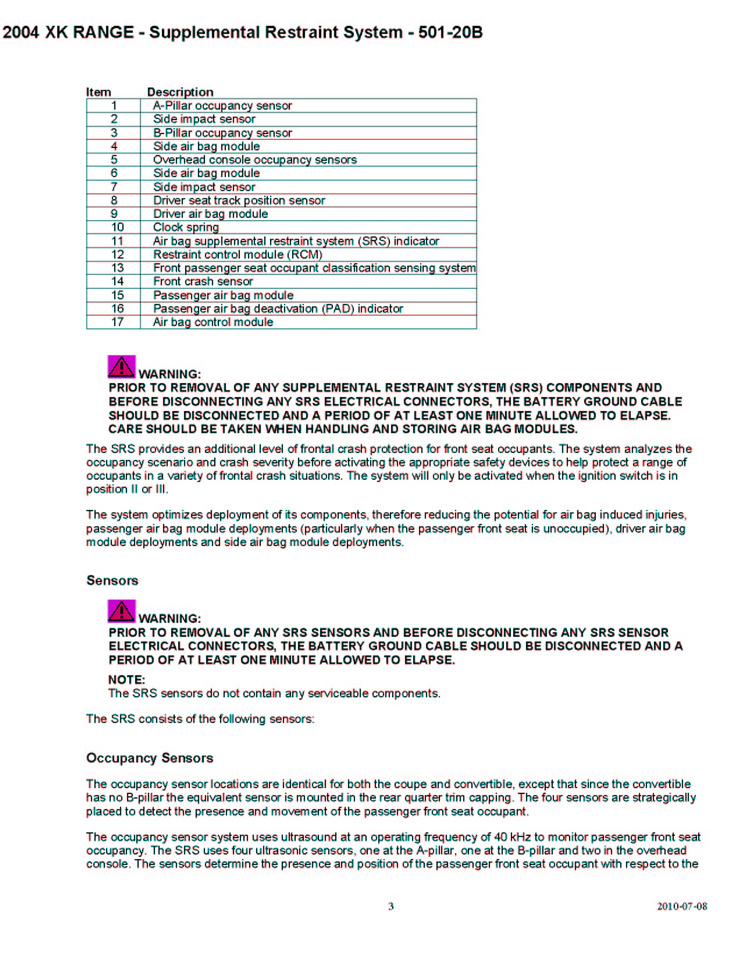

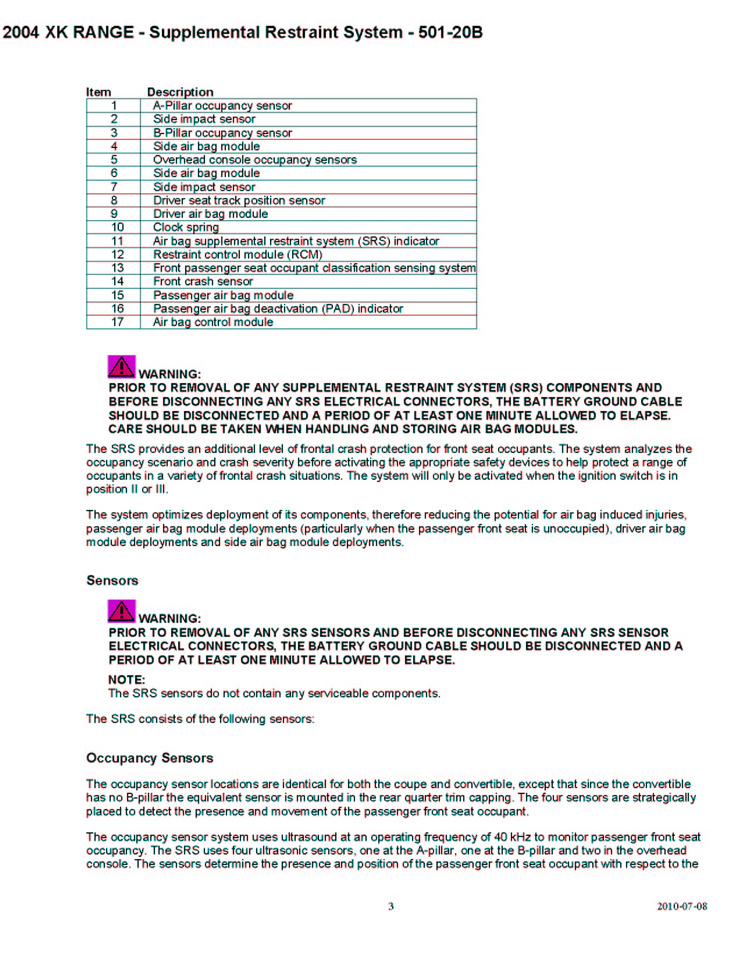

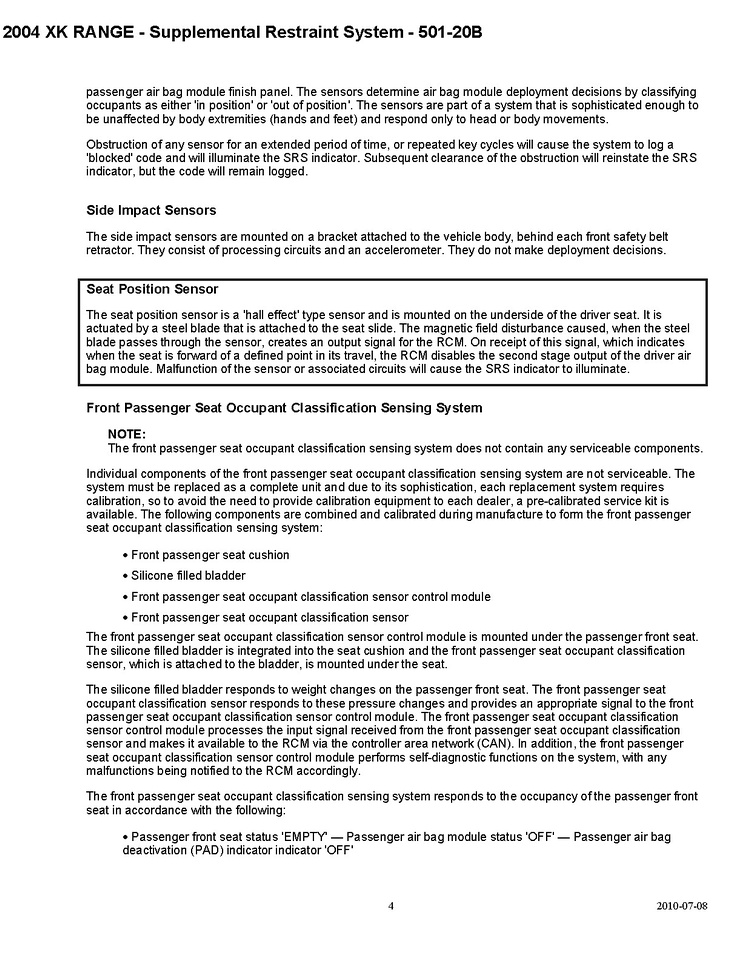

Dangit! I thought I had licked this 2-2 blinking SOB, but apparently not. Ok, I did a little research in the JTIS, and there has to be something else in the SRS system to trigger this code.

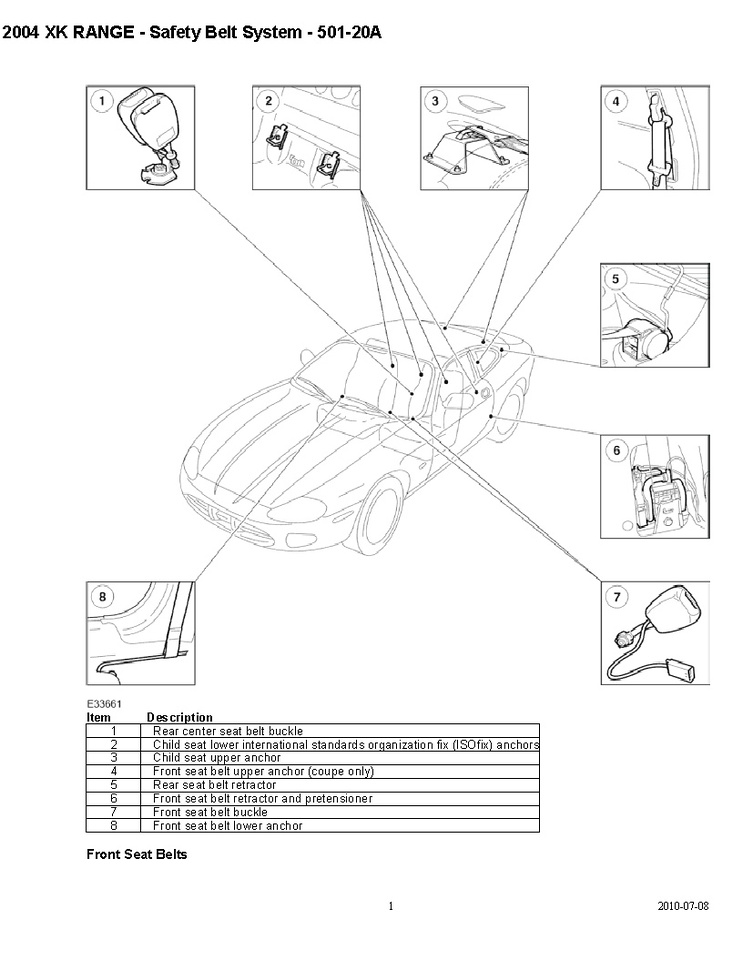

I've got two more items to check, and they sound promising...considering I've spilled more than a couple big drinks in those flimsy cup holders, onto myself, along the side of the seat between the center console and the seat...so I am thinking its either the seat position sensor, or more likely...the seat belt buckle sensor next to my cupholders.

Gonna take out the seat this weekend, and give everything a good cleaning where those metal contact sensors are...but how am I going to clean the seat belt buckle? I've got brake cleaner, TB cleaner, and WD 40...no way I can disassemble it... thinking of shooting a cleaner into it. Bad idea?

I've got two more items to check, and they sound promising...considering I've spilled more than a couple big drinks in those flimsy cup holders, onto myself, along the side of the seat between the center console and the seat...so I am thinking its either the seat position sensor, or more likely...the seat belt buckle sensor next to my cupholders.

Gonna take out the seat this weekend, and give everything a good cleaning where those metal contact sensors are...but how am I going to clean the seat belt buckle? I've got brake cleaner, TB cleaner, and WD 40...no way I can disassemble it... thinking of shooting a cleaner into it. Bad idea?

Last edited by H20boy; 07-08-2010 at 12:34 AM.

#15

Well, I pulled my driver seat out tonight, and flipped her like a girlfriend I had once in college. Anyhoo, that seat position sensor, I could not figure it out! I couldn't find the 'steel blade attached to the seat slide', it must be in between the rails. So, I just cleaned the connectors, and reinstalled.

Since I've had the seat back, forth, back, forth removing and reinstalling the bolts, the light hasn't returned. Perhaps the healthy exercise of the seat cleaned whatever is on/or around that steel blade and the 'sensor' it goes in. I'll watch it carefully, and let you know if it returns. It was becoming an every other day event. Since I had the seat forward and back a couple times before tonight, the light has not returned.

Tonight, I just felt like taking it out to see if I could figure out how that sensor works.

Since I've had the seat back, forth, back, forth removing and reinstalling the bolts, the light hasn't returned. Perhaps the healthy exercise of the seat cleaned whatever is on/or around that steel blade and the 'sensor' it goes in. I'll watch it carefully, and let you know if it returns. It was becoming an every other day event. Since I had the seat forward and back a couple times before tonight, the light has not returned.

Tonight, I just felt like taking it out to see if I could figure out how that sensor works.

#16

I've been putting Vaseline on the battery terminals for years. Had the ABS light issue for the last year. Recently I've been working on the car and disconnecting the battery. I did not refresh the Vaseline. Guess what? The ABS/traction warning no longer appears! I was all set to tackle the ABS solder solution.

I have some contact cleaner work in my future!

Can you recommend something conductive to spray on the terminals after the clean?

Silicone spray. I also use this great penetrant/corrosion called CorrosionX. Got it at a local boat store/chandler.

I have some contact cleaner work in my future!

Can you recommend something conductive to spray on the terminals after the clean?

Silicone spray. I also use this great penetrant/corrosion called CorrosionX. Got it at a local boat store/chandler.

#17

It isn't necessary to apply anything to battery terminals or the pins in electrical connectors. The metal to metal contact is more than adequate for proper contact. I used to work on the avionics on jets in the Marine Corps. We didn't spray anything into the connectors. If McDonnell Douglas is satisfied with the electrical properties of metal to metal contact, I am to. In fact, spraying anything conductive into a connector could result in current from one pin bleeding over to other pins in the connector. That could be very bad.

In regards to putting Vaseline on the battery terminals, that was to prevent corrosion on the outer part of the terminal. I don't know if there is a difference between modern batteries and old batteries, but I haven't seen corrosion on a battery terminal in years. Maybe the posts and connectors are being made with something non-corrosive these days.

In regards to putting Vaseline on the battery terminals, that was to prevent corrosion on the outer part of the terminal. I don't know if there is a difference between modern batteries and old batteries, but I haven't seen corrosion on a battery terminal in years. Maybe the posts and connectors are being made with something non-corrosive these days.

#18

Just thought I add, from my personal experience. First of all, Great JOB! I always love seeing people do things like this themselves. Secondly, the pins are replaceable, fairly easily I might add. I have made a few wiring harness's and would like to add that, there is a specialty tool to re-pin it, though I made my own from some hooks and paper clips with a tiny little screwdriver. Whatever I could use to get at the clip in the back that holds the pin.

Last edited by viscoussquirrel; 07-10-2010 at 06:48 PM.

#19

One complete week...not a single air bag light. Will follow up after a month, and 3 months with hopefully the same observation.

Whatever I did, seems to have worked for the moment. Here's are the tasks which I performed.

Whatever I did, seems to have worked for the moment. Here's are the tasks which I performed.

- I sprayed contact cleaner into my seat belt buckle. I couldn't reach the harness that it connects to the seat module so no cleaning it.

- I disconnected all harness connectors visible beneath the seat (about 3 of them) and sprayed the contact cleaner onto all pins and sockets.

- I cleaned the screw-drive (from the seat frame) that passes within 1-2 mm of my driver seat track position sensor; it had dirt, fuzz, and hair stuck to it. Just in case.

- My driver seat track position sensor was so close to the screw-drive thing, it actually touched it very easily with just a little nudge, so I moved it away (bent it back) from this metal rod so it wouldn't 'accidentally' make contact, which may have caused the sensor to fault?

#20

Join Date: Sep 2008

Location: Damon /Houston, Texas

Posts: 7,254

Received 2,183 Likes

on

1,355 Posts

I guess I should have read this thread earlier Matt. The biggest issue with drivers seat srs light is not the connector under the seat(except Stypes that break) but the connector on the side airbag itself. UNder warranty we replaced the bag but only because we dont get paid if nothing is replaced. But the action of disconnecting and reconnecting as the flying spagetti monster stated is useally enough to clean and reestablish the best connection....So if it happens again pull the seat back cover up to access the air bag connector, disconnect and reconnect it....