got the balancer off! but...

#1

#2

See if this link will help if not contact Walt and see if he can guide you in the right direction.

Link Crank belt pulley loose, how to remove? - Jaguar Forums - Jaguar Enthusiasts Forum

Link Crank belt pulley loose, how to remove? - Jaguar Forums - Jaguar Enthusiasts Forum

The following users liked this post:

wjd03 (10-05-2013)

#3

The following users liked this post:

wjd03 (10-05-2013)

#7

I have never needed to replace the split cone in the damper.

TSB 33-10 recommends only the following..........

"Note: Always replace the timing case oil seal, the damper O-ring, and the

damper retaining bolt with new items any time the damper is removed."

The split cone is not a 'wear-item' and can be reused.

The old bolt can be grooved like a tap to remove debris or galled material and saved in the toolbox. I have had to use mine for a lot of cranks to get the threads clean. I used a cut-off wheel to cut the grooves and a thread file for cleanup.

bob gauff

TSB 33-10 recommends only the following..........

"Note: Always replace the timing case oil seal, the damper O-ring, and the

damper retaining bolt with new items any time the damper is removed."

The split cone is not a 'wear-item' and can be reused.

The old bolt can be grooved like a tap to remove debris or galled material and saved in the toolbox. I have had to use mine for a lot of cranks to get the threads clean. I used a cut-off wheel to cut the grooves and a thread file for cleanup.

bob gauff

The following users liked this post:

plums (10-06-2013)

Trending Topics

#9

Do you mean 303-10?

I have never needed to replace the split cone in the damper.

TSB 33-10 recommends only the following..........

"Note: Always replace the timing case oil seal, the damper O-ring, and the

damper retaining bolt with new items any time the damper is removed."

The split cone is not a 'wear-item' and can be reused.

The old bolt can be grooved like a tap to remove debris or galled material and saved in the toolbox. I have had to use mine for a lot of cranks to get the threads clean. I used a cut-off wheel to cut the grooves and a thread file for cleanup.

bob gauff

TSB 33-10 recommends only the following..........

"Note: Always replace the timing case oil seal, the damper O-ring, and the

damper retaining bolt with new items any time the damper is removed."

The split cone is not a 'wear-item' and can be reused.

The old bolt can be grooved like a tap to remove debris or galled material and saved in the toolbox. I have had to use mine for a lot of cranks to get the threads clean. I used a cut-off wheel to cut the grooves and a thread file for cleanup.

bob gauff

#10

The following users liked this post:

Gus (10-06-2013)

#11

Bob, Thanks for attaching the TSB file but it says:

Caution: Do not use JD 216, crankshaft setting peg, to hold the crankshaft

when tightening or loosening the center bolt of the crankshaft.

- So with the engine in place how do you hold the crank when you are wanting such a high torque to tighten or loosen?

jd

Caution: Do not use JD 216, crankshaft setting peg, to hold the crankshaft

when tightening or loosening the center bolt of the crankshaft.

- So with the engine in place how do you hold the crank when you are wanting such a high torque to tighten or loosen?

jd

#12

#13

I have never needed to replace the split cone in the damper.

TSB 33-10 recommends only the following..........

"Note: Always replace the timing case oil seal, the damper O-ring, and the

damper retaining bolt with new items any time the damper is removed."

The split cone is not a 'wear-item' and can be reused.

bob gauff

TSB 33-10 recommends only the following..........

"Note: Always replace the timing case oil seal, the damper O-ring, and the

damper retaining bolt with new items any time the damper is removed."

The split cone is not a 'wear-item' and can be reused.

bob gauff

Regarding torque when reinstalling: I had a mechanic do the install because I lack the facility. This thing requires major torque, something the mechanic pointed out. He jacked up the passenger side of the car and jammed the flywheel to lock the crank. He then used the jack handle on the torque wrench to get what was needed. This is not a trivial problem.

The following users liked this post:

Gus (10-07-2013)

#14

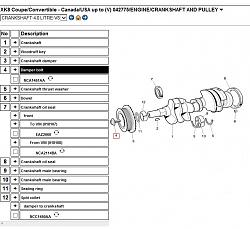

OK, here is what happened....drove home in a rain storm, turned on the AC because it was hot, and the charging light came on, so I cut it off. Next day needed to drive it and charge light was on and felt sluggishness in the steering....soooooo, replaced the serpentine belt. No good there sooooo must be the Alternator.....did that, no better sooooooo replaced the power steering pump, then new belt was not was not turning at all. That's when I realized the damper was the problem. Apparently the damper bolt must have backed out somehow a couple of threads....the damper bolt was damaged in the process (a couple of threads were half eaten...just half) this I found out once I got the bolt out. While the damper became loose, the COLLETT began to wear on the seat of the damper, damaging it and the collet. Been working on this for 8 weeks, and now am getting new parts and going to put her back together.

I hope this chain of events helps someone else in the future,

later

I hope this chain of events helps someone else in the future,

later

#15

This chain is very similar to what I experienced although I got straight to the damper problem so didn't replace the other parts. When everything on the belt goes mucky look for the common thread. What happened is it slips for a short while before completely letting go. This was all detailed in another thread on this forum. Why this happened is a guess but I assume prior work not properly finished but the design itself (the split collett vs. tried and true key lock) is inherently really bad.

To make a long story short, you will need a new damper in addition to the other parts. The damper is expensive and may or not be available. I saw that jagbits had "rebuilt" dampers listed for about half. I did not pursue this as I was fortunate to pick up a used damper from Mr. Avos in Belgium.

To make a long story short, you will need a new damper in addition to the other parts. The damper is expensive and may or not be available. I saw that jagbits had "rebuilt" dampers listed for about half. I did not pursue this as I was fortunate to pick up a used damper from Mr. Avos in Belgium.

#16

yup, i got another damper also- so am going to put back together.the split collet goes into the cone of the damper, but the forward end of the collet leaves a lip on the face of the damper. this leads me to believe that to make the balancer hold tight against the bearing, alot of torque must be applied. does this sound about right? only those who have replaced these parts would know what i am speaking of.

thanks in advance,

thanks in advance,

#17

yup, i got another damper also- so am going to put back together.the split collet goes into the cone of the damper, but the forward end of the collet leaves a lip on the face of the damper. this leads me to believe that to make the balancer hold tight against the bearing, alot of torque must be applied. does this sound about right? only those who have replaced these parts would know what i am speaking of.

thanks in advance,

thanks in advance,

BTW in forum posts it is always helpful to let everyone know where you sourced the difficult parts (ie the damper) and what the cost was. This will be helpful to the next poor soul who has to deal with this.

Last edited by walt_00XKRConv; 10-13-2013 at 09:52 AM.

The following users liked this post:

Norri (10-13-2013)

#18

Use this link and go to page PDF 100 of the form Page 96 and see if that helps.

Link http://www.jagrepair.com/images/Auto...sb_09_2003.pdf

Link http://www.jagrepair.com/images/Auto...sb_09_2003.pdf

#20

If you ever want to drive Sky Line Dr. and end up in Shenandoah Valley send me a note to tell me when and if my car is up and running we can meet up. Ours is sick and in my shop. Replaced a cracked intake manifold, fixed a few other vacuum leaks, replaced, the TB and the left engine shock mount. Just let us know when you have yours on the road again!