Remanufacturing - Automatic Transmissions

#1

On 29th March 2014, UK Region were invited to tour Mackie Automatic Transmissions in Glasgow, Scotland.

Mackie Automatic remanufacture torque converters for use on ZF OEM contracts. They are an "A1" rated supplier, the only company in Europe to receive this accolade. They are also the only Scottish distributor for ZF parts and transmissions.

The tour was a great success and greatly enjoyed by those who attended.

Automatic Transmissions are a mystery to many of us and the information we learned on the day may be of interest to other members around the World.

Owing to the numbers attending, we were divided into three groups for our tour of the facility. Each group was able to see the three principal services offered by Mackie Automatic & Manual Transmissions:

1. Remanufacturing - Automatic Transmissions

2. Remanufacturing - Torque Convertors

3. Servicing, Diagnostics and Repair

The following three posts cover each of these services.Graham

Mackie Automatic remanufacture torque converters for use on ZF OEM contracts. They are an "A1" rated supplier, the only company in Europe to receive this accolade. They are also the only Scottish distributor for ZF parts and transmissions.

The tour was a great success and greatly enjoyed by those who attended.

Automatic Transmissions are a mystery to many of us and the information we learned on the day may be of interest to other members around the World.

Owing to the numbers attending, we were divided into three groups for our tour of the facility. Each group was able to see the three principal services offered by Mackie Automatic & Manual Transmissions:

1. Remanufacturing - Automatic Transmissions

2. Remanufacturing - Torque Convertors

3. Servicing, Diagnostics and Repair

The following three posts cover each of these services.Graham

Last edited by GGG; 03-31-2014 at 11:20 AM.

The following users liked this post:

JimC64 (03-31-2014)

Top Answer

03-31-2014, 11:16 AM

Mackie Automatic Transmissions receive complete vehicles from dealers and individuals for everything from the standard fluid change through fault diagnostics and repair to complete transmission remanufacture.

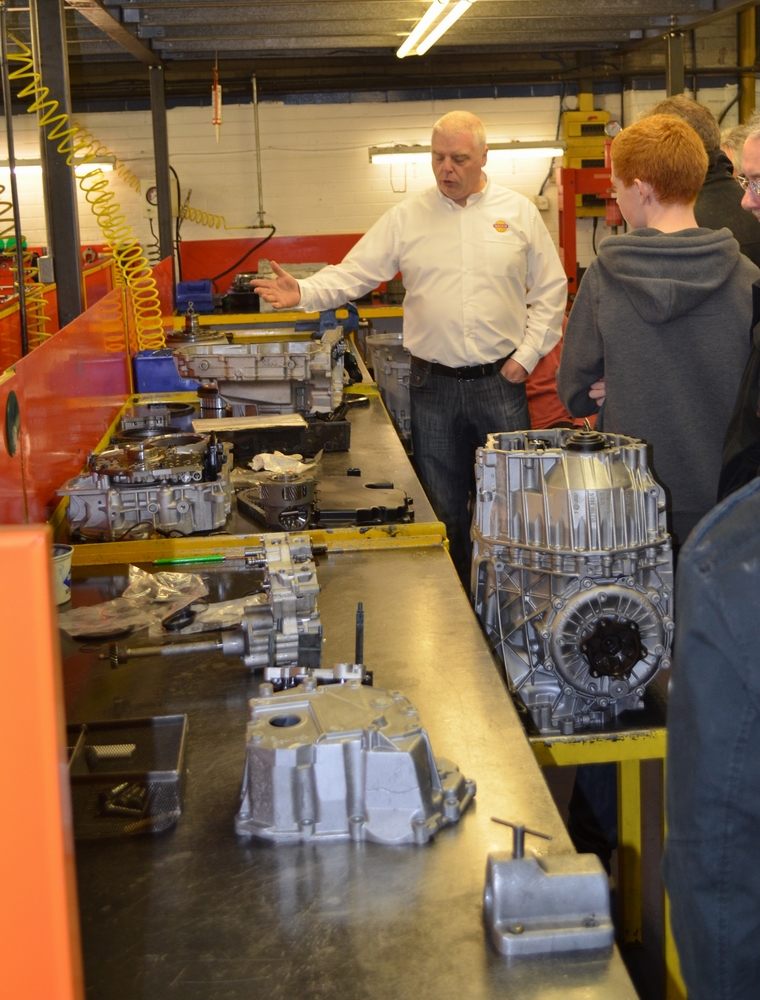

Our host for the day, Managing Director of Mackie Automatic Transmissions, John Mackie explained that many automatic transmission issues are due to:

1. fluid overheating

2. fluid contamination (with engine coolant)

3. software

Autologic is their preferred diagnostics tool.

After retrieving stored and pending codes, these are cleared and the vehicle taken on a 5 to 8 mile drive. Any reset codes are used to diagnose faults.

Reflashing the TCM is a routine procedure and the latest updates are always applied.

Fluid changes are recommended at 25K miles intervals. This is considerably more frequent than most members are applying to their vehicles. A Hot Oil flushing machine is used.

The fluid lines are disconnected on the vehicle at the cooler and the fluid drained. It is then connected to the Hot Oil machine.

The remaining old fluid is pumped out and the transmission refilled with fresh fluid at the correct temperature and volume.

The tour finished with a summary from John Mackie and time for questions.

Not surprisingly, the difference between manufacturer's 'sealed for life' claims for automatic transmissions and Mackie's recommendation for 25K mile fluid changes raised some debate. It is the car manufacturer's (Jaguar included) who claim 'sealed for life'. The transmission manufacturers such as ZF recommend 60K mile fluid changes. John Mackie explained that a more frequent change significantly reduces wear and can more than double the life of an automatic transmission. Not a claim to be taken lightly when Mackie Automatic Transmissions guarantee their remanufactured products for a greater period than the OE manufacturers.

Graham

Our host for the day, Managing Director of Mackie Automatic Transmissions, John Mackie explained that many automatic transmission issues are due to:

1. fluid overheating

2. fluid contamination (with engine coolant)

3. software

Autologic is their preferred diagnostics tool.

After retrieving stored and pending codes, these are cleared and the vehicle taken on a 5 to 8 mile drive. Any reset codes are used to diagnose faults.

Reflashing the TCM is a routine procedure and the latest updates are always applied.

Fluid changes are recommended at 25K miles intervals. This is considerably more frequent than most members are applying to their vehicles. A Hot Oil flushing machine is used.

The fluid lines are disconnected on the vehicle at the cooler and the fluid drained. It is then connected to the Hot Oil machine.

The remaining old fluid is pumped out and the transmission refilled with fresh fluid at the correct temperature and volume.

The tour finished with a summary from John Mackie and time for questions.

Not surprisingly, the difference between manufacturer's 'sealed for life' claims for automatic transmissions and Mackie's recommendation for 25K mile fluid changes raised some debate. It is the car manufacturer's (Jaguar included) who claim 'sealed for life'. The transmission manufacturers such as ZF recommend 60K mile fluid changes. John Mackie explained that a more frequent change significantly reduces wear and can more than double the life of an automatic transmission. Not a claim to be taken lightly when Mackie Automatic Transmissions guarantee their remanufactured products for a greater period than the OE manufacturers.

Graham

#2

Mackie Automatic & Manual Transmissions remanufacture automatic and manual transmissions, gearboxes and torque converters for the public, dealerships and manufacturers.

They accept transmission units delivered to them or take complete vehicles where they will diagnose faults, remove, overhaul and refit the transmission.

Owing to the numbers attending, we were divided into three groups for our tour of the facility. Each group was able to see the three principal services offered by Mackie Automatic & Manual Transmissions:

1. Remanufacturing - Automatic Transmissions

2. Remanufacturing - Torque Convertors

3. Servicing, Diagnosis and Repair

1. Remanufacturing - Automatic Transmissions

The automatic transmission is totally dismantled and every component is cleaned and prepared for inspection.

From this point on, the entire process is scrupulously clean.

Each component (several hundred of them) is then examined and measured. All components that are not deemed 100% perfect are replaced.

All seals, gaskets, filters high failure components are discarded and replaced with new parts.

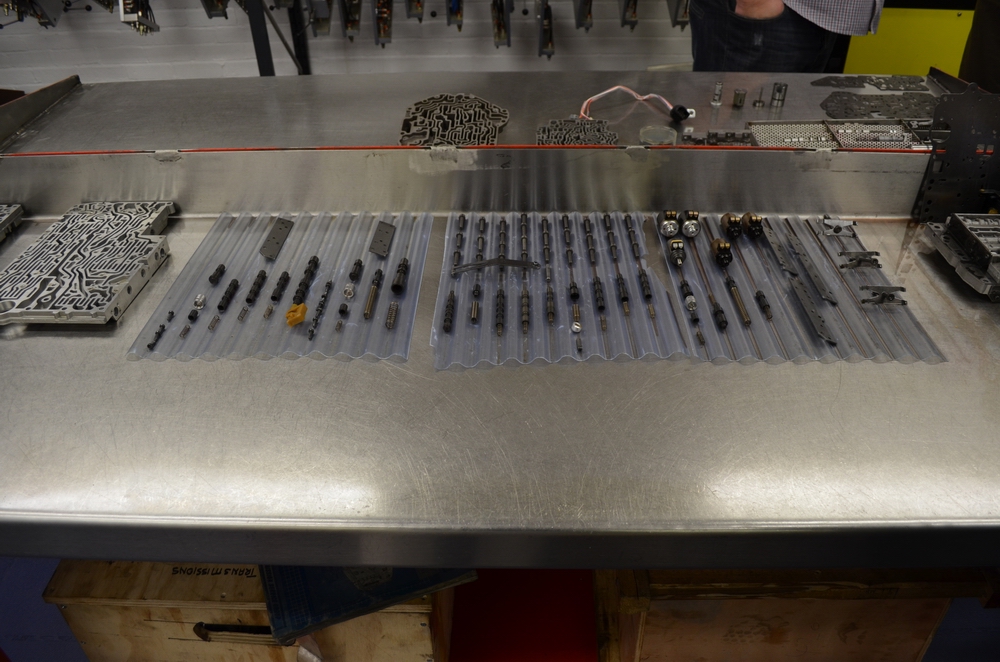

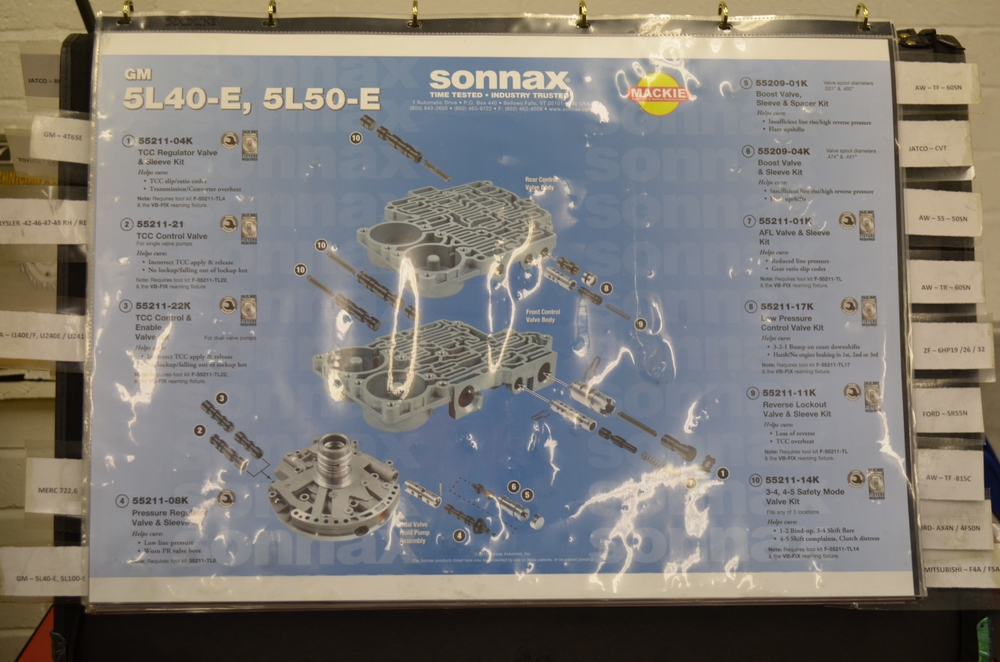

The valve body (control unit) goes through a process that includes ultra-sonic cleaning, vacuum testing, solenoid remanufacturing and final calibration on a unique valve body test station. This ensures that the valve body meets or exceeds the original manufacturer’s specification.

Following component checking, everything is laid out ready for rebuilding the valve body.

For those of us less familiar with the parts in the valve body, this graphic gives a clue to how it all goes together.

During the transmission assembly process, all sub-assemblies are pressure-tested to ensure total hydraulic integrity.

The remanufactured valve body is pressure tested

Each individual gear is subjected to testing. A loss on any one results in the valve body being put through the full strip, check and rebuild sequence again.

Final calibration with data acquisition is carried out on a unique valve body test station. This ensures that the valve body meets or exceeds the original manufacturer’s specification.

The subassembly is checked through all gear changes prior to final assembly.

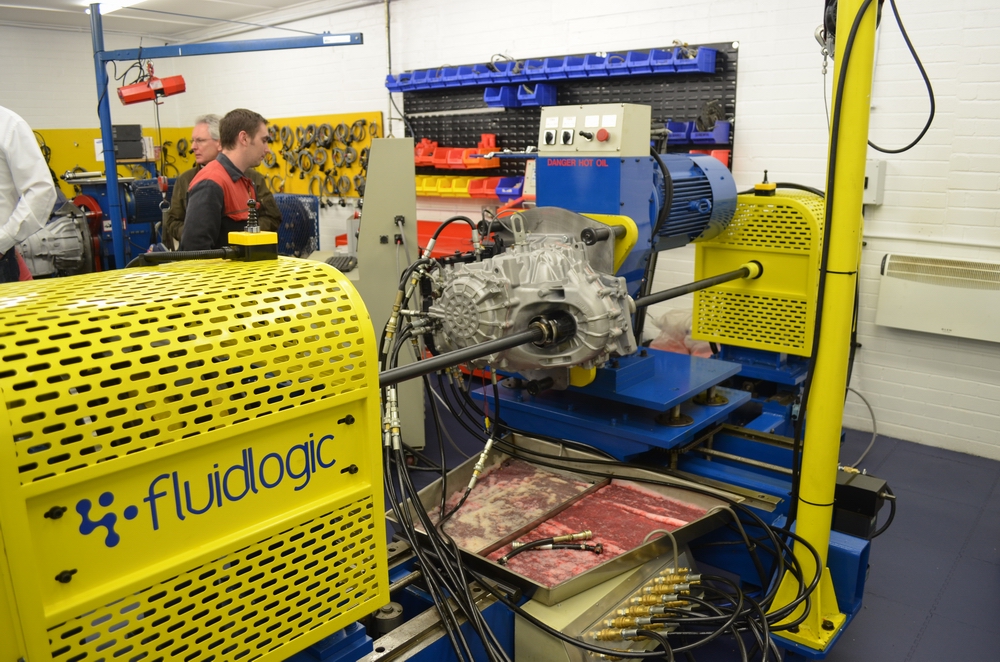

The complete transmission assembly has a final build test on one of two road test simulators that create real life driving situations.

During this stage, the transmission is run at normal operating temperatures for several hours.

The simulator assesses every fundamental part of the remanufactured transmission. Any failed part will instantly be flagged on the test report.

This test procedure almost eliminates any potential failure prior to installation to the vehicle.

The equipment used by Mackie Automatic & Manual Transmissions is exactly the same as that used by the original manufacturers.

Graham

They accept transmission units delivered to them or take complete vehicles where they will diagnose faults, remove, overhaul and refit the transmission.

Owing to the numbers attending, we were divided into three groups for our tour of the facility. Each group was able to see the three principal services offered by Mackie Automatic & Manual Transmissions:

1. Remanufacturing - Automatic Transmissions

2. Remanufacturing - Torque Convertors

3. Servicing, Diagnosis and Repair

1. Remanufacturing - Automatic Transmissions

The automatic transmission is totally dismantled and every component is cleaned and prepared for inspection.

From this point on, the entire process is scrupulously clean.

Each component (several hundred of them) is then examined and measured. All components that are not deemed 100% perfect are replaced.

All seals, gaskets, filters high failure components are discarded and replaced with new parts.

The valve body (control unit) goes through a process that includes ultra-sonic cleaning, vacuum testing, solenoid remanufacturing and final calibration on a unique valve body test station. This ensures that the valve body meets or exceeds the original manufacturer’s specification.

Following component checking, everything is laid out ready for rebuilding the valve body.

For those of us less familiar with the parts in the valve body, this graphic gives a clue to how it all goes together.

During the transmission assembly process, all sub-assemblies are pressure-tested to ensure total hydraulic integrity.

The remanufactured valve body is pressure tested

Each individual gear is subjected to testing. A loss on any one results in the valve body being put through the full strip, check and rebuild sequence again.

Final calibration with data acquisition is carried out on a unique valve body test station. This ensures that the valve body meets or exceeds the original manufacturer’s specification.

The subassembly is checked through all gear changes prior to final assembly.

The complete transmission assembly has a final build test on one of two road test simulators that create real life driving situations.

During this stage, the transmission is run at normal operating temperatures for several hours.

The simulator assesses every fundamental part of the remanufactured transmission. Any failed part will instantly be flagged on the test report.

This test procedure almost eliminates any potential failure prior to installation to the vehicle.

The equipment used by Mackie Automatic & Manual Transmissions is exactly the same as that used by the original manufacturers.

Graham

The following 2 users liked this post by GGG:

Nergion (04-19-2019),

SleekJag12 (09-02-2022)

#3

Remanufacturing Torque Converters

Mackie Automatic Transmissions torque converters are supplied with a life time warranty for the vehicle that they are installed in.

To start the process, the two welded halves of the converter are cut apart by specialist lathe operators.

After washing and examination, the unit is re-machined in one of three adapted high-specification lathes to refinish the joining faces.

Mackie Automatic Transmissions remanufacture torque convertors from the BW66 of the early 1970's through to the current 6HP26.

Through this period, the torque converter has developed from a simple 'fluid flywheel' through increasingly sophisticated 'lock up clutches'.

Note the two beakers on the workbench. The one on the right contains new transmission fluid. The one on the left has typical contaminated fluid from a transmission in for service.

Mackie Automatic Transmissions identify where there is a pattern in OE torque converters failures and develop improvements to increase reliability in their units.

The bonded friction lining is removed and a new one is re-bonded to the lock-up plate. This highly specialized process is made possible by a unique bonding machine.

The torque converter is welded back together, with accuracy to a few tenths of a thousandth of an inch.

The unit is leak tested to ensure the integrity of the weld is correct and rebalanced to meet or exceed the original manufacturer’s specifications.

This equipment test for glycol contamination. Not an applicable part of the process once a transmission has been stripped and cleaned.

The torque converter is shot-blasted to restore a perfect satin steel finish. A coating of anti-rust and an etching identification number is applied to the finished unit.

The remanufactured torque convertor is guaranteed for the life of the vehicle in which it is fitted.

Graham

Mackie Automatic Transmissions torque converters are supplied with a life time warranty for the vehicle that they are installed in.

To start the process, the two welded halves of the converter are cut apart by specialist lathe operators.

After washing and examination, the unit is re-machined in one of three adapted high-specification lathes to refinish the joining faces.

Mackie Automatic Transmissions remanufacture torque convertors from the BW66 of the early 1970's through to the current 6HP26.

Through this period, the torque converter has developed from a simple 'fluid flywheel' through increasingly sophisticated 'lock up clutches'.

Note the two beakers on the workbench. The one on the right contains new transmission fluid. The one on the left has typical contaminated fluid from a transmission in for service.

Mackie Automatic Transmissions identify where there is a pattern in OE torque converters failures and develop improvements to increase reliability in their units.

The bonded friction lining is removed and a new one is re-bonded to the lock-up plate. This highly specialized process is made possible by a unique bonding machine.

The torque converter is welded back together, with accuracy to a few tenths of a thousandth of an inch.

The unit is leak tested to ensure the integrity of the weld is correct and rebalanced to meet or exceed the original manufacturer’s specifications.

This equipment test for glycol contamination. Not an applicable part of the process once a transmission has been stripped and cleaned.

The torque converter is shot-blasted to restore a perfect satin steel finish. A coating of anti-rust and an etching identification number is applied to the finished unit.

The remanufactured torque convertor is guaranteed for the life of the vehicle in which it is fitted.

Graham

The following 2 users liked this post by GGG:

Sean W (01-21-2020),

SleekJag12 (09-02-2022)

#4

Mackie Automatic Transmissions receive complete vehicles from dealers and individuals for everything from the standard fluid change through fault diagnostics and repair to complete transmission remanufacture.

Our host for the day, Managing Director of Mackie Automatic Transmissions, John Mackie explained that many automatic transmission issues are due to:

1. fluid overheating

2. fluid contamination (with engine coolant)

3. software

Autologic is their preferred diagnostics tool.

After retrieving stored and pending codes, these are cleared and the vehicle taken on a 5 to 8 mile drive. Any reset codes are used to diagnose faults.

Reflashing the TCM is a routine procedure and the latest updates are always applied.

Fluid changes are recommended at 25K miles intervals. This is considerably more frequent than most members are applying to their vehicles. A Hot Oil flushing machine is used.

The fluid lines are disconnected on the vehicle at the cooler and the fluid drained. It is then connected to the Hot Oil machine.

The remaining old fluid is pumped out and the transmission refilled with fresh fluid at the correct temperature and volume.

The tour finished with a summary from John Mackie and time for questions.

Not surprisingly, the difference between manufacturer's 'sealed for life' claims for automatic transmissions and Mackie's recommendation for 25K mile fluid changes raised some debate. It is the car manufacturer's (Jaguar included) who claim 'sealed for life'. The transmission manufacturers such as ZF recommend 60K mile fluid changes. John Mackie explained that a more frequent change significantly reduces wear and can more than double the life of an automatic transmission. Not a claim to be taken lightly when Mackie Automatic Transmissions guarantee their remanufactured products for a greater period than the OE manufacturers.

Graham

Our host for the day, Managing Director of Mackie Automatic Transmissions, John Mackie explained that many automatic transmission issues are due to:

1. fluid overheating

2. fluid contamination (with engine coolant)

3. software

Autologic is their preferred diagnostics tool.

After retrieving stored and pending codes, these are cleared and the vehicle taken on a 5 to 8 mile drive. Any reset codes are used to diagnose faults.

Reflashing the TCM is a routine procedure and the latest updates are always applied.

Fluid changes are recommended at 25K miles intervals. This is considerably more frequent than most members are applying to their vehicles. A Hot Oil flushing machine is used.

The fluid lines are disconnected on the vehicle at the cooler and the fluid drained. It is then connected to the Hot Oil machine.

The remaining old fluid is pumped out and the transmission refilled with fresh fluid at the correct temperature and volume.

The tour finished with a summary from John Mackie and time for questions.

Not surprisingly, the difference between manufacturer's 'sealed for life' claims for automatic transmissions and Mackie's recommendation for 25K mile fluid changes raised some debate. It is the car manufacturer's (Jaguar included) who claim 'sealed for life'. The transmission manufacturers such as ZF recommend 60K mile fluid changes. John Mackie explained that a more frequent change significantly reduces wear and can more than double the life of an automatic transmission. Not a claim to be taken lightly when Mackie Automatic Transmissions guarantee their remanufactured products for a greater period than the OE manufacturers.

Graham

The following 12 users liked this post by GGG:

Bigg Will (09-08-2016),

CorStevens (02-16-2018),

ibblue2 (10-21-2018),

jaguarcraver (03-31-2014),

Jon89 (02-16-2018),

and 7 others liked this post.

Thread

Thread Starter

Forum

Replies

Last Post

FS[NorthEast]: 2008 XKR Portfolio Convertable

Knomad

PRIVATE For Sale / Trade or Buy Classifieds

0

09-22-2015 04:36 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)