"XJR 550" project

#101

Ahmedalalousi

In our forum most members are willing to share details about their builds. Unfortunately there are so few technical details published about the AJV8 series of engines, that any modifications we make may or may not work out and we don’t want to share something that fails. To date, Avos has been the most successful at modifying his engine and pushing the envelope.

I have a large file of notes and my original plan clearly laid out how I was going to build up my “super AJ-V8”. In the past year, I have changed that plan a lot! The more I learn about the engine, the more my mindset has changed, and so has the plan. Seems like on these engines, one small detail affects a lot of other parts of the engine. It has become clear to me that before you start your build you will have become an expert on almost every aspect of the engine.

An endless example. The discussion on the forum about heads. There are at least 4 variations of AJV8 heads that I have identified so far. You stated you want to use AJ37 AM heads. They do appear to have better inlet air flow than the AJ-34 heads. But not everyone realizes that the inlets are in a physically different position. Therefore if you want to use AJ-37 heads with an AJ-34 supercharger intake manifold, the ports wont line up. Then what do you do? Custom build an intake manifold? More time, more money. Then you start thinking how much HP is at stake versus how much you want to spend to make it work.

The next logical progression says that if you have to design and fabricate a new intake manifold then why do you have to use the power limiting stock intercoolers? Might as use Laminova intercoolers or something else. Then you start thinking why would I be limited to a Kenny bell twin screw? I can use many other superchargers, like a front fed twin screws and larger displacement. If I go with a front feed I can get rid of the restrictive inlets that feed the throttle body. (Higher HP builds require a larger TB anyways, so if you go with a front fed supercharger, you have a better selection of throttle bodies.)

If you decide to try to go with a front feed SC, then you realize that the stupid AJ series blocks have a water manifold that sits smack dead center in the front of the valley. So you decide it is better to use a remote electric water pump.

One change can drive 50 other small changes.

If you are thinking about using the AM 4.3 or 4.7 as your baseline, carefully study the differences between the AJ-37 and the AJ-34. You may find that the price you have to pay for the AM engine is not worth the money based on the changes you’ll have to make to fit it back into a Jaguar, or the parts you can use from the AM engine to put into a Jag version.

In our forum most members are willing to share details about their builds. Unfortunately there are so few technical details published about the AJV8 series of engines, that any modifications we make may or may not work out and we don’t want to share something that fails. To date, Avos has been the most successful at modifying his engine and pushing the envelope.

I have a large file of notes and my original plan clearly laid out how I was going to build up my “super AJ-V8”. In the past year, I have changed that plan a lot! The more I learn about the engine, the more my mindset has changed, and so has the plan. Seems like on these engines, one small detail affects a lot of other parts of the engine. It has become clear to me that before you start your build you will have become an expert on almost every aspect of the engine.

An endless example. The discussion on the forum about heads. There are at least 4 variations of AJV8 heads that I have identified so far. You stated you want to use AJ37 AM heads. They do appear to have better inlet air flow than the AJ-34 heads. But not everyone realizes that the inlets are in a physically different position. Therefore if you want to use AJ-37 heads with an AJ-34 supercharger intake manifold, the ports wont line up. Then what do you do? Custom build an intake manifold? More time, more money. Then you start thinking how much HP is at stake versus how much you want to spend to make it work.

The next logical progression says that if you have to design and fabricate a new intake manifold then why do you have to use the power limiting stock intercoolers? Might as use Laminova intercoolers or something else. Then you start thinking why would I be limited to a Kenny bell twin screw? I can use many other superchargers, like a front fed twin screws and larger displacement. If I go with a front feed I can get rid of the restrictive inlets that feed the throttle body. (Higher HP builds require a larger TB anyways, so if you go with a front fed supercharger, you have a better selection of throttle bodies.)

If you decide to try to go with a front feed SC, then you realize that the stupid AJ series blocks have a water manifold that sits smack dead center in the front of the valley. So you decide it is better to use a remote electric water pump.

One change can drive 50 other small changes.

If you are thinking about using the AM 4.3 or 4.7 as your baseline, carefully study the differences between the AJ-37 and the AJ-34. You may find that the price you have to pay for the AM engine is not worth the money based on the changes you’ll have to make to fit it back into a Jaguar, or the parts you can use from the AM engine to put into a Jag version.

The following users liked this post:

Panthro (05-29-2016)

#102

#103

#105

Hey Mike!

Wow!How are you?

It's been ages! I remember when you helped diagnose that diff problem ages ago when I still lived in Illinois!

I have made good progress with the Challenger- have the 400 block, have the crankshaft, have the pistons, and rods and am working with Comp- and have come up with the first iteration of a cam profile that will allow the 470 cu in engine to rev. Working with a pushrod supplier that can help too. I have two intake manifolds, even though the 6 pack loses close to 80 bhp - I want to find a way to make that work. I have got some very trick Mopar Stage VI Chapman' CNCd cylinder heads an happy I managed to track those down. I went for the Max Wedge style ports -which means the 6 pack intake will have to be adapted. I have a single plane intake also.

I've had to halt some of the progress though, while I look to move to another state. The Jaguar is closer to running- so I put some priority on that.

Its tough when you're working a professional job and doing 60-70 hours a week!

I have family in Chicagoland- and was just there for Thanksgiving. We should meet up sometime!

Wow!How are you?

It's been ages! I remember when you helped diagnose that diff problem ages ago when I still lived in Illinois!

I have made good progress with the Challenger- have the 400 block, have the crankshaft, have the pistons, and rods and am working with Comp- and have come up with the first iteration of a cam profile that will allow the 470 cu in engine to rev. Working with a pushrod supplier that can help too. I have two intake manifolds, even though the 6 pack loses close to 80 bhp - I want to find a way to make that work. I have got some very trick Mopar Stage VI Chapman' CNCd cylinder heads an happy I managed to track those down. I went for the Max Wedge style ports -which means the 6 pack intake will have to be adapted. I have a single plane intake also.

I've had to halt some of the progress though, while I look to move to another state. The Jaguar is closer to running- so I put some priority on that.

Its tough when you're working a professional job and doing 60-70 hours a week!

I have family in Chicagoland- and was just there for Thanksgiving. We should meet up sometime!

#106

#107

Its WAY too cold up here to work on my Jaguar.

Instead I dug up some old dyno files and data I had for the AJV8 supercharged along with some test data that me and some other Jag pals generated recently in the cold fall months.

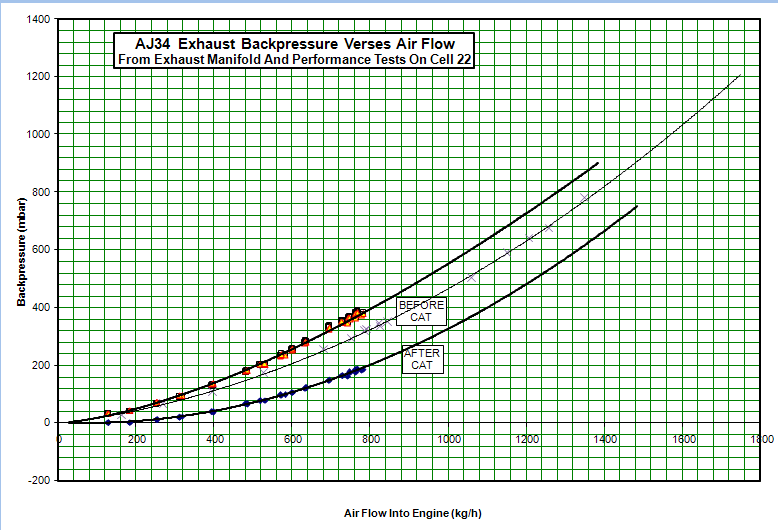

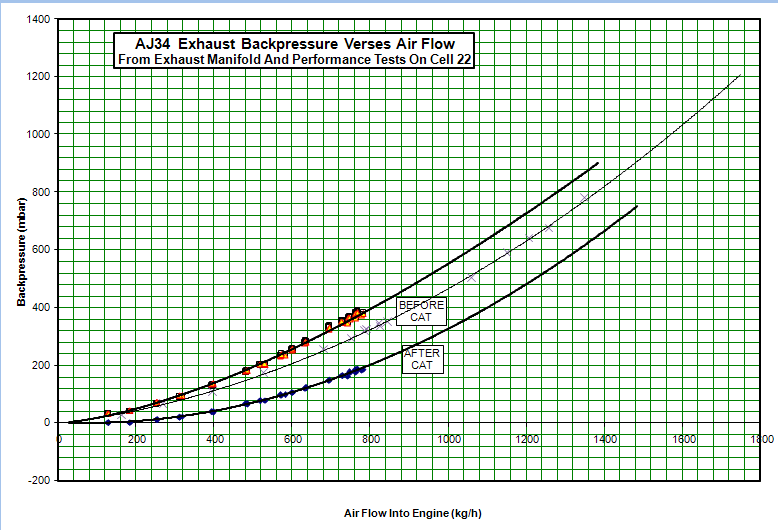

First off lets talk Exhaust back pressure - I heard someone say that 600 mbar back pressure is fine because that's what Avos has and his car still delivers. Where as I'm sure that's true, lower back pressure can always make things better. The other aspect is- it was measured behind the cats, this isn't in line with the rest of the industry so hard to compare- however I found some data.

When you plot Exhaust back pressure against engine airflow- you basically get a second order curve. This is very useful- as you can predict what your back pressure will become as you make more power.

You've probably often heard it said that an engine is just an air pump. In many ways this is true.

What is the airflow rate of an AJ33 4.2 supercharged?

Or an AJ27 SC?

The AJ34 SC as an air pump flows about 1350 kg/hr (sorry for all your imperial merchants- you're going to have to convert that yourselves)

The AJ27 SC is at around 1100-1220 kg/hr.

Here you can see Pre cat and post cat. At 1350 kg/hr the Cat of the AJ33 SC account for about 200 mbars, while the ceramic monolith of the stock car would be about another 100 mbars on top of that. The rest of the system on the X100/AJ34 flows about the same as an X308, even though the silencers are different SC vs NA.

The earlier cats of the X308 , AJ26 and AJ27 are less dense and therefore less restrictive. I believe they were 600 cpsi if memory serves and the early cats didn't have the airgap. For the AJ27 SC flow rate of 1200 ish- 200 cpsi cats should reduce this- perhaps to 500 mbar EBP for a stock exhaust.

Oh, stock X308 SC is around 750 mbar EBP, X350 and X100 4.2 SC are at 750-800 mbar but they flow more air.

Convention is to measure in the cat cone, the whole industry does it this way. Its a good reference point for comparisons and benchmarking.

Some cars, have exceptionally low back pressures- like the E39 BMW M5- which is around the 250-300 mbar mark and is still refined and quiet. The M5 5 litre flows a lot less air than an XJR because the XJR must flow enough for the parasitics of the eaton blower itself.

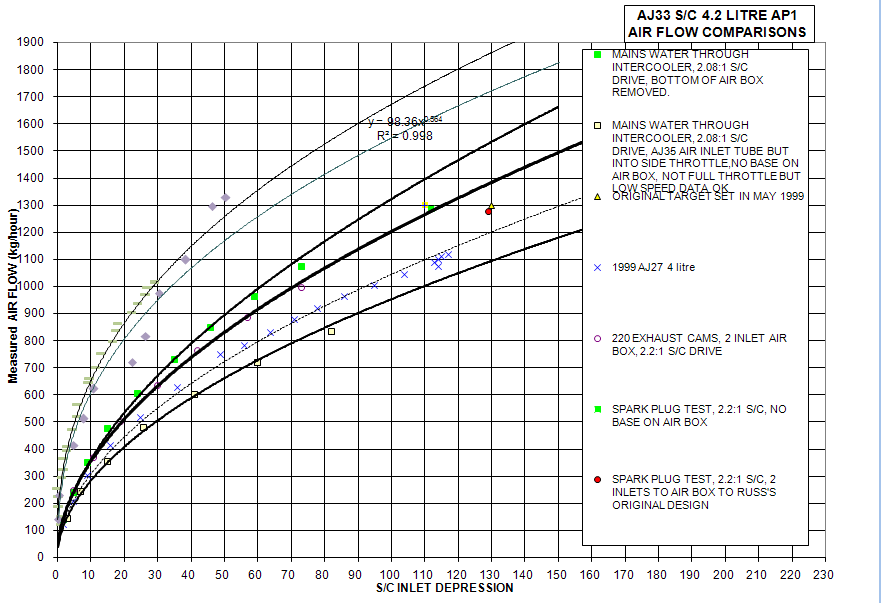

Next lets move onto intake manifold depression or loss

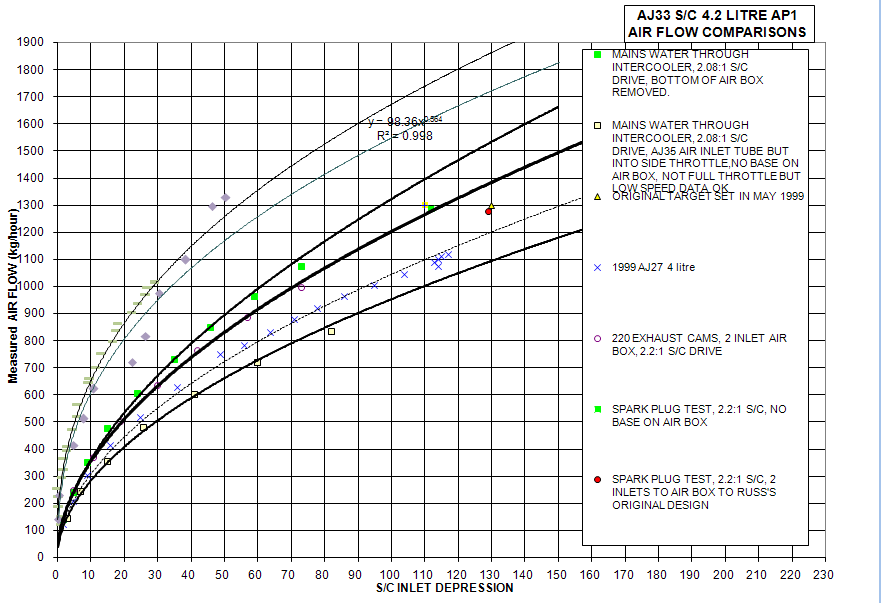

You can see here- different tests that were carried out- again- engine airflow vs Intake restriction.

It follows a 2nd order or even power curve.

The intake is pretty restrictive. I would echo the fact that roughly a 3 inch or 76mm diameter is pretty stingy. 3.5 inches is better. When Mina Gallery talk of keeping it to 3 inches for 'throttle response' - they are talking more bollox than Plums talks, basically and I lost respect for them. Throttle response is effected by the volume from the back of the intake valves to the throttle blade itself along with reciprocating mass of the engine and rotational inertia.

On the In-man-dep plot- you can see two very good intake systems- to the left and above- an Aston Martin Vantage- which I helped design and a benchmark Audi Turbo RS6. There are the dots in grey. The Audi data is a bit poor but you get an indication. The intakes there are of much lower restriction than the X308 or X100 unfortunately.

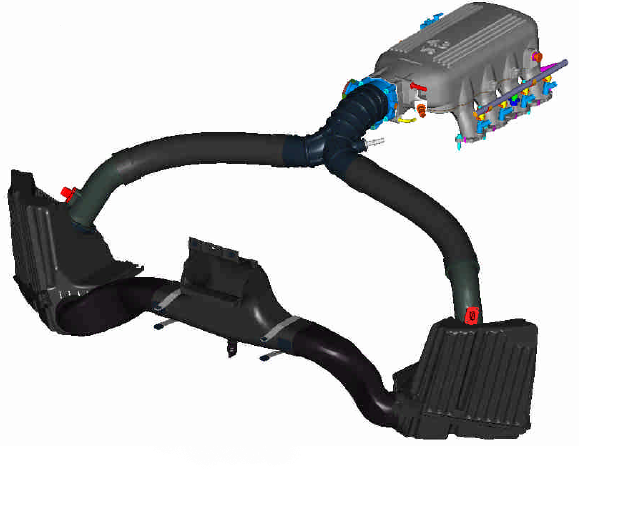

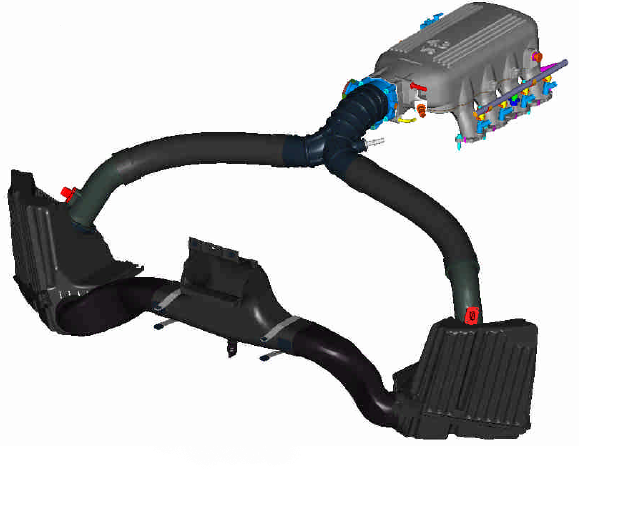

Its the reason why the last of the AJ34 S/C in the X150s have a totally different design of intake system and a lot less loss. This also requires a dual MAF intake-which is a hassle to integrate but not impossible, even on our 16 bit systems.

I have a question for 2007-2009 XKR 4.2 owners- where is your brake master cylinder and power steering reservoir mounted on your cars? And for that matter, the oil level dip stick? I have some ideas which I wont go into now, but probably a long shot. An AJV8 4.8 litre fitted with a TVS2300 but keeping the restrictive intake made 50-70 bhp more peak power with a better intake system.

Unfortunately the kind of engine airflow to get serious power- a good target is 1700-1900 kg/hr, but an appreciatible amount of this is lost as parasitics to the blower. The M112 consumes about 70 bhp at peak power- you see this manifest itself as heat in the intercooler tanks.

The TVS blower runs cooler. The measured tank temps of the Aj33 4.2 S/C are about 150-160 deg C at peak power. Too high here and you'll end up retarding your ignition, losing power here due to too high charge temps.

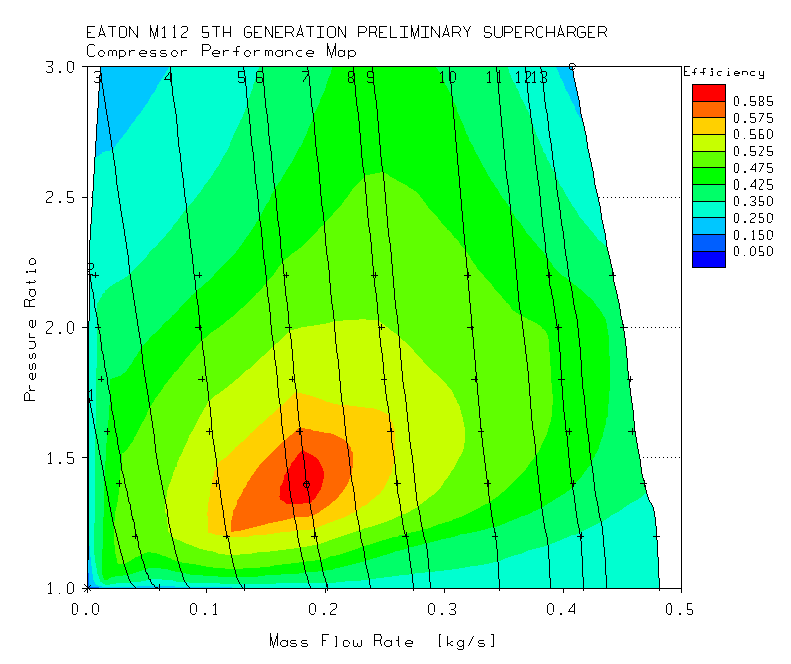

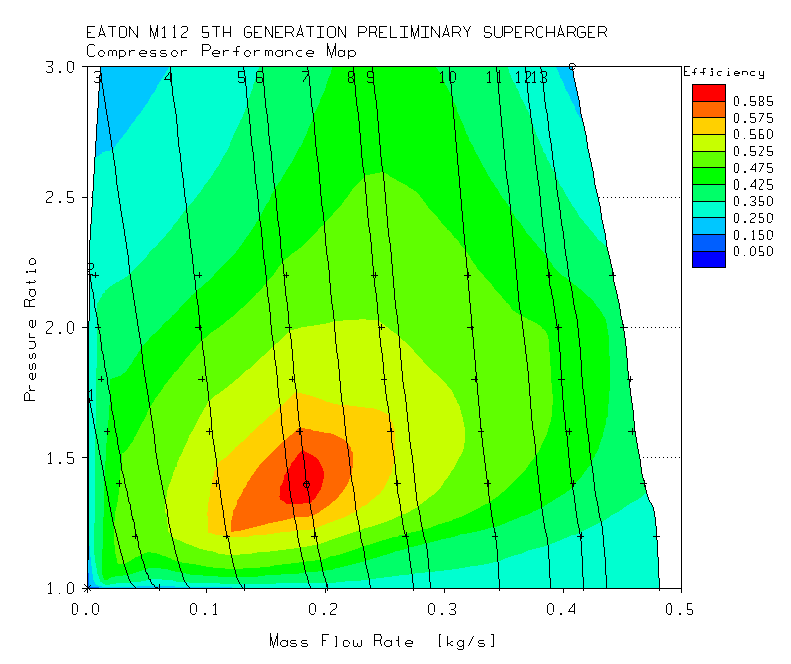

Here is an M112 SC map- mass flow vs Pressure ratio vs efficiency islands

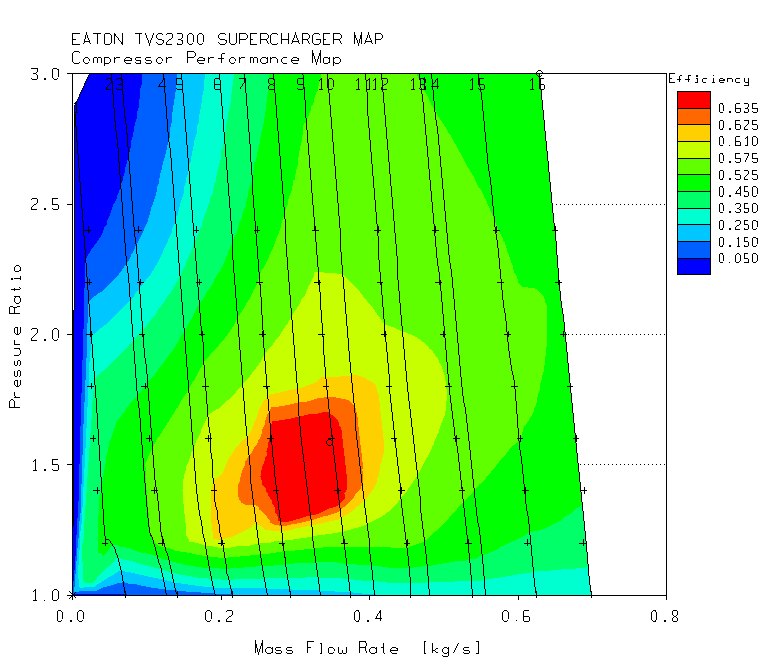

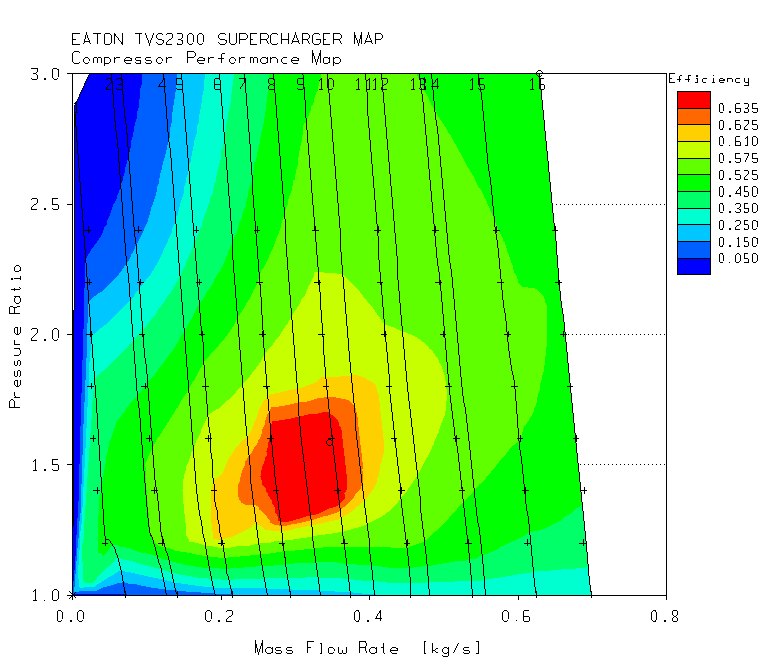

Heres a TVS2300 by comparison

An M112 gets pretty inefficient at pressure ratios greater than 2.2 and really shouldn't be revved above 14,000 rpm. The stock car has a pulley ratio of 2.08- so theres some leeway there.

By comparion, the TVS can be spun up to 18,000 rpm and is efficient at pressure ratios up to about 2.4. Best point adiabatic compressor efficiency of the TVS is about 65%, and an M112 is about 55% by comparison. The 4th Gen supercharger used on the old Aj27- not only had a difference in the more refined gears but didn't use an composite abrasive compound in the triple lobe blades to narrow the clearances. In my experience the 4th gen M112s have about 8 % less mass flow compared to the 5th gen M112s or thereabouts.

Avos- do you have SC maps for the OPCON Superchargers you use? I'm specifically interested in Adiabatic Compressor efficiency. I can get parasitic losses from that.

So, when matching superchargers- you're matching speed, pressure ratio and keeping an eye on charge temps.

You also want to look at peak cylinder pressure and knock. You really shouldn't go much above a peak cylinder pressure of 85 bar on the AJV8 for a prolonged time. By comparison the AJ133 was designed for 110 bar PCP. There are ways to beef up the AJV8 design- it is a closed deck block- which I prefer to the AJ133 open deck or the open deck arrangement of the Caddilac Northstar.

Avos- what PCP does your car run?

Finally- you don't want to run into high speed engine knock- but if you retard the ignition too much- your exhaust temps will get too high- as stock- 850 deg C is the limit in the Cats. This is why the SC cars run around 10:1 AFR at peak power.

When building your own motor- there are components you can replace, like exhaust valves and cats, that you cant in production, such as hastalite material etc

The other reason why people can get away with having high PCP than intended by design is:

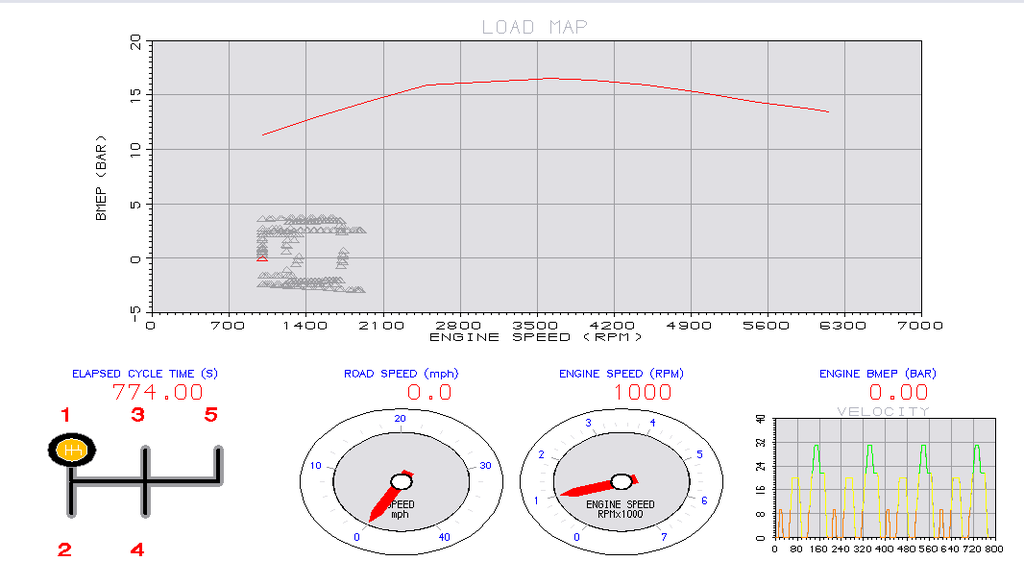

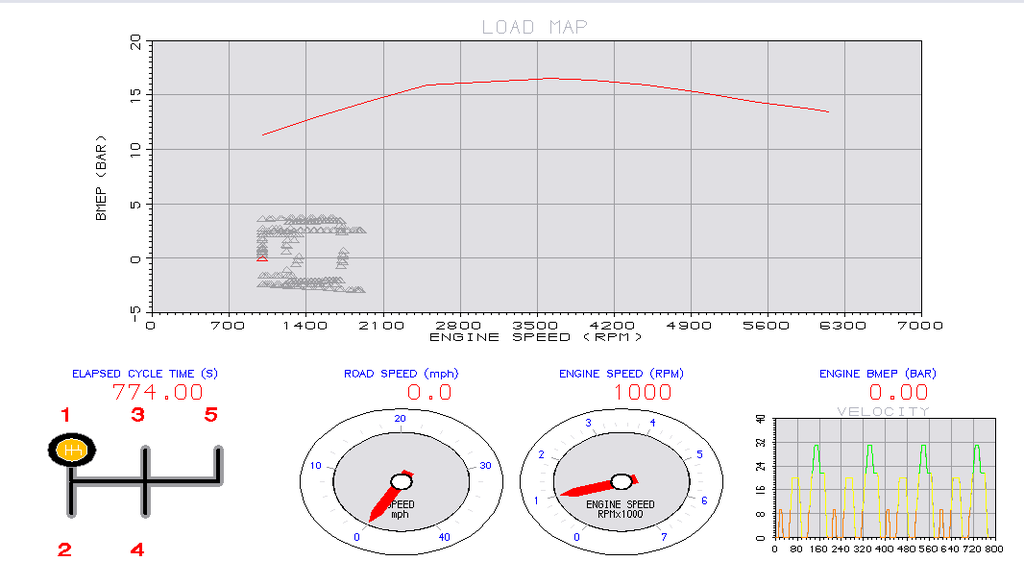

In typical driving even an hefty X308 wont reach much load. At 75 mph- steady state- the car is using less than 4 bar BMEP out of its 16-17 bar available. During the EURO cycle the car rarely sees above 3000 rpm and about 5 bar. In terms of cylinder pressures- you're much lower than peak here.

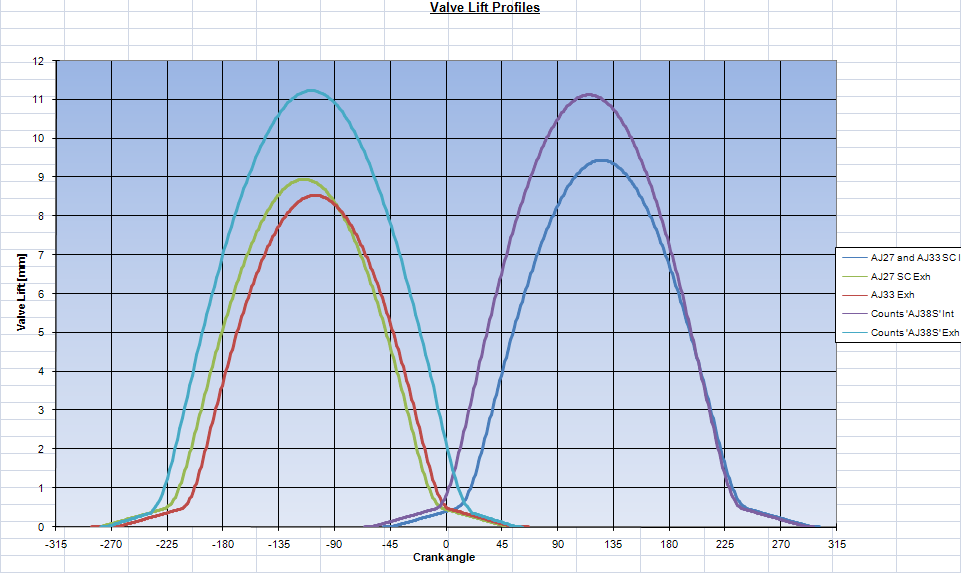

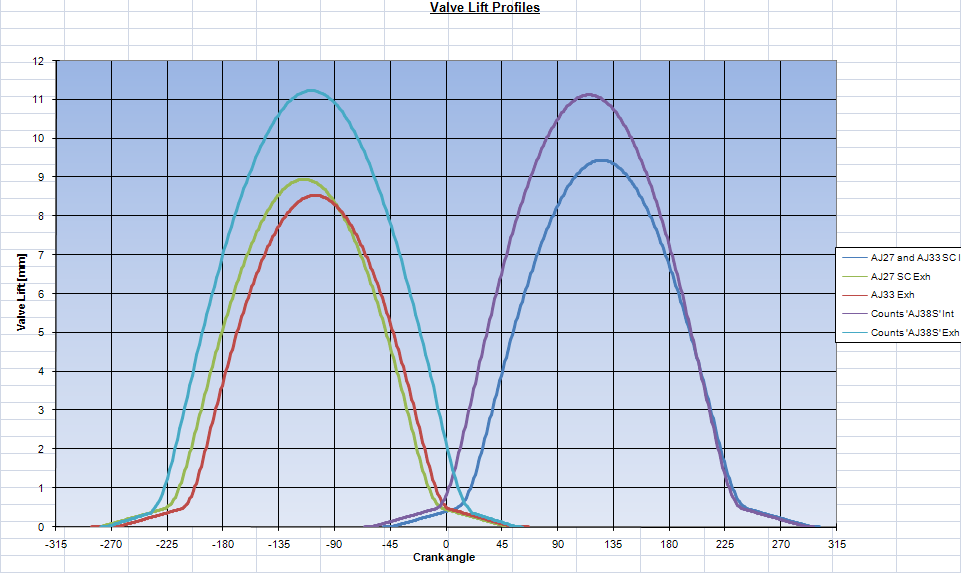

And last but not least, I've been designing some new cams for the AJV8- heres a snap shot:

You can see my new designs overlaid on top of the AJ27 SC and AJ33 SCs.

The biggest issue with the AJ27 S/C cams is excessive pumping work it needs more blow down- the AJ27 SCs suffer from that and an immediate improvement can be made-the positive flip side to this is that it leads to refinement in terms of exhaust noise.

The new cams- need some attention to the ramp design and optimizing the overlap region to none- if possible. I don't know what happens if you run overlap on a SC engine- we never did due to HC emissions at Jag and perhaps because it could 'blow through' BUT...the Porsche 911 Turbo runs overlap...so I don't know. Needs further investigation

I was able to do all this over this long winter, but Now I'll likely be returning to working on my Challenger/Detroit iron I'm afraid.

Now I'll leave this all to the 'experts' of the forum to disseminate.

Instead I dug up some old dyno files and data I had for the AJV8 supercharged along with some test data that me and some other Jag pals generated recently in the cold fall months.

First off lets talk Exhaust back pressure - I heard someone say that 600 mbar back pressure is fine because that's what Avos has and his car still delivers. Where as I'm sure that's true, lower back pressure can always make things better. The other aspect is- it was measured behind the cats, this isn't in line with the rest of the industry so hard to compare- however I found some data.

When you plot Exhaust back pressure against engine airflow- you basically get a second order curve. This is very useful- as you can predict what your back pressure will become as you make more power.

You've probably often heard it said that an engine is just an air pump. In many ways this is true.

What is the airflow rate of an AJ33 4.2 supercharged?

Or an AJ27 SC?

The AJ34 SC as an air pump flows about 1350 kg/hr (sorry for all your imperial merchants- you're going to have to convert that yourselves)

The AJ27 SC is at around 1100-1220 kg/hr.

Here you can see Pre cat and post cat. At 1350 kg/hr the Cat of the AJ33 SC account for about 200 mbars, while the ceramic monolith of the stock car would be about another 100 mbars on top of that. The rest of the system on the X100/AJ34 flows about the same as an X308, even though the silencers are different SC vs NA.

The earlier cats of the X308 , AJ26 and AJ27 are less dense and therefore less restrictive. I believe they were 600 cpsi if memory serves and the early cats didn't have the airgap. For the AJ27 SC flow rate of 1200 ish- 200 cpsi cats should reduce this- perhaps to 500 mbar EBP for a stock exhaust.

Oh, stock X308 SC is around 750 mbar EBP, X350 and X100 4.2 SC are at 750-800 mbar but they flow more air.

Convention is to measure in the cat cone, the whole industry does it this way. Its a good reference point for comparisons and benchmarking.

Some cars, have exceptionally low back pressures- like the E39 BMW M5- which is around the 250-300 mbar mark and is still refined and quiet. The M5 5 litre flows a lot less air than an XJR because the XJR must flow enough for the parasitics of the eaton blower itself.

Next lets move onto intake manifold depression or loss

You can see here- different tests that were carried out- again- engine airflow vs Intake restriction.

It follows a 2nd order or even power curve.

The intake is pretty restrictive. I would echo the fact that roughly a 3 inch or 76mm diameter is pretty stingy. 3.5 inches is better. When Mina Gallery talk of keeping it to 3 inches for 'throttle response' - they are talking more bollox than Plums talks, basically and I lost respect for them. Throttle response is effected by the volume from the back of the intake valves to the throttle blade itself along with reciprocating mass of the engine and rotational inertia.

On the In-man-dep plot- you can see two very good intake systems- to the left and above- an Aston Martin Vantage- which I helped design and a benchmark Audi Turbo RS6. There are the dots in grey. The Audi data is a bit poor but you get an indication. The intakes there are of much lower restriction than the X308 or X100 unfortunately.

Its the reason why the last of the AJ34 S/C in the X150s have a totally different design of intake system and a lot less loss. This also requires a dual MAF intake-which is a hassle to integrate but not impossible, even on our 16 bit systems.

I have a question for 2007-2009 XKR 4.2 owners- where is your brake master cylinder and power steering reservoir mounted on your cars? And for that matter, the oil level dip stick? I have some ideas which I wont go into now, but probably a long shot. An AJV8 4.8 litre fitted with a TVS2300 but keeping the restrictive intake made 50-70 bhp more peak power with a better intake system.

Unfortunately the kind of engine airflow to get serious power- a good target is 1700-1900 kg/hr, but an appreciatible amount of this is lost as parasitics to the blower. The M112 consumes about 70 bhp at peak power- you see this manifest itself as heat in the intercooler tanks.

The TVS blower runs cooler. The measured tank temps of the Aj33 4.2 S/C are about 150-160 deg C at peak power. Too high here and you'll end up retarding your ignition, losing power here due to too high charge temps.

Here is an M112 SC map- mass flow vs Pressure ratio vs efficiency islands

Heres a TVS2300 by comparison

An M112 gets pretty inefficient at pressure ratios greater than 2.2 and really shouldn't be revved above 14,000 rpm. The stock car has a pulley ratio of 2.08- so theres some leeway there.

By comparion, the TVS can be spun up to 18,000 rpm and is efficient at pressure ratios up to about 2.4. Best point adiabatic compressor efficiency of the TVS is about 65%, and an M112 is about 55% by comparison. The 4th Gen supercharger used on the old Aj27- not only had a difference in the more refined gears but didn't use an composite abrasive compound in the triple lobe blades to narrow the clearances. In my experience the 4th gen M112s have about 8 % less mass flow compared to the 5th gen M112s or thereabouts.

Avos- do you have SC maps for the OPCON Superchargers you use? I'm specifically interested in Adiabatic Compressor efficiency. I can get parasitic losses from that.

So, when matching superchargers- you're matching speed, pressure ratio and keeping an eye on charge temps.

You also want to look at peak cylinder pressure and knock. You really shouldn't go much above a peak cylinder pressure of 85 bar on the AJV8 for a prolonged time. By comparison the AJ133 was designed for 110 bar PCP. There are ways to beef up the AJV8 design- it is a closed deck block- which I prefer to the AJ133 open deck or the open deck arrangement of the Caddilac Northstar.

Avos- what PCP does your car run?

Finally- you don't want to run into high speed engine knock- but if you retard the ignition too much- your exhaust temps will get too high- as stock- 850 deg C is the limit in the Cats. This is why the SC cars run around 10:1 AFR at peak power.

When building your own motor- there are components you can replace, like exhaust valves and cats, that you cant in production, such as hastalite material etc

The other reason why people can get away with having high PCP than intended by design is:

In typical driving even an hefty X308 wont reach much load. At 75 mph- steady state- the car is using less than 4 bar BMEP out of its 16-17 bar available. During the EURO cycle the car rarely sees above 3000 rpm and about 5 bar. In terms of cylinder pressures- you're much lower than peak here.

And last but not least, I've been designing some new cams for the AJV8- heres a snap shot:

You can see my new designs overlaid on top of the AJ27 SC and AJ33 SCs.

The biggest issue with the AJ27 S/C cams is excessive pumping work it needs more blow down- the AJ27 SCs suffer from that and an immediate improvement can be made-the positive flip side to this is that it leads to refinement in terms of exhaust noise.

The new cams- need some attention to the ramp design and optimizing the overlap region to none- if possible. I don't know what happens if you run overlap on a SC engine- we never did due to HC emissions at Jag and perhaps because it could 'blow through' BUT...the Porsche 911 Turbo runs overlap...so I don't know. Needs further investigation

I was able to do all this over this long winter, but Now I'll likely be returning to working on my Challenger/Detroit iron I'm afraid.

Now I'll leave this all to the 'experts' of the forum to disseminate.

Last edited by Count Iblis; 12-19-2016 at 11:30 PM.

#108

A shame it wasnít cold enough 10 years ago when I started  , but great to share as much info now!

, but great to share as much info now!

Unfortunately not, best I ever found (many years ago) is attached, but I have been informed that these tests where possibly not reliable. KB does not share these, so only way to gat some idea is to check is browse thru their data. I just took it for granted, and leave the rpm around 12500' ish.

When I started I did try to look at BMEP figures, but not knowing what the design limits where, I left it, and went out and just took the risk and tried it out. But in hindsight, good that I didnít know it, as I would probably havenít gone as far as I have done.

What gave me confidence that there was some good room (indeed NOT for prolonged use, just street driving), was that back then many where spinning the Eaton excessively fast and got already rwhp figures approaching 400 without blowing the stuff up. You can imagine the massive power consumption there from the Eaton, so taking that into the equation I knew there would be some good room with the very efficient twin-screw units to reach, and there was indeed obviously.

When I started I did try to look at BMEP figures, but not knowing what the design limits where, I left it, and went out and just took the risk and tried it out. But in hindsight, good that I didnít know it, as I would probably havenít gone as far as I have done.

What gave me confidence that there was some good room (indeed NOT for prolonged use, just street driving), was that back then many where spinning the Eaton excessively fast and got already rwhp figures approaching 400 without blowing the stuff up. You can imagine the massive power consumption there from the Eaton, so taking that into the equation I knew there would be some good room with the very efficient twin-screw units to reach, and there was indeed obviously.

#109

Count, when I am looking the graph for valve lifts I can see values for many different engine types. AJ27 ( I guess means N/A ), AJ27SC, AJ33 ( I guess means N/A) , AJ33SC.

Can you confirm the values below?

AJ27SC: 240/230 9.0mm/8.4mm Timing 125/115 = LSA 120

AJ33SC 240/220 9.0mm/8.1mm Timing 120/110 = LSA 115

My current cams have as low as ICL 106.5 and LSA 110 . Generally LSA 113-116 is recommended for positive displacment SCs, but why not 110 when we still have zero overlap and target is to make max power at 6000rpm - not at 6500-7000. There is overlap just under 0.8mm, so idle is very smooth.

Can you confirm the values below?

AJ27SC: 240/230 9.0mm/8.4mm Timing 125/115 = LSA 120

AJ33SC 240/220 9.0mm/8.1mm Timing 120/110 = LSA 115

My current cams have as low as ICL 106.5 and LSA 110 . Generally LSA 113-116 is recommended for positive displacment SCs, but why not 110 when we still have zero overlap and target is to make max power at 6000rpm - not at 6500-7000. There is overlap just under 0.8mm, so idle is very smooth.

#110

Count, when I am looking the graph for valve lifts I can see values for many different engine types. AJ27 ( I guess means N/A ), AJ27SC, AJ33 ( I guess means N/A) , AJ33SC.

Can you confirm the values below?

AJ27SC: 240/230 9.0mm/8.4mm Timing 125/115 = LSA 120

AJ33SC 240/220 9.0mm/8.1mm Timing 120/110 = LSA 115

My current cams have as low as ICL 106.5 and LSA 110 . Generally LSA 113-116 is recommended for positive displacment SCs, but why not 110 when we still have zero overlap and target is to make max power at 6000rpm - not at 6500-7000. There is overlap just under 0.8mm, so idle is very smooth.

Can you confirm the values below?

AJ27SC: 240/230 9.0mm/8.4mm Timing 125/115 = LSA 120

AJ33SC 240/220 9.0mm/8.1mm Timing 120/110 = LSA 115

My current cams have as low as ICL 106.5 and LSA 110 . Generally LSA 113-116 is recommended for positive displacment SCs, but why not 110 when we still have zero overlap and target is to make max power at 6000rpm - not at 6500-7000. There is overlap just under 0.8mm, so idle is very smooth.

The 240 period profile for both the AJ27 and early AJ33 intake are identicle in timing and duration. For the exhaust its a 220 period for the AJ33 and a 230 period for the earlier AJ27. The peak valve lifts you quoted are correct but they DO NOT include the ramp heights. In this case the ramp heights are 0.45mm. The profiles that we evolved went down to 0.36mm and involved shimless buckets and the longer valves themselves (first pioneered on Land Rovers)- this gives a benefit in terms of power vs idle speed smoothness requirements.

Like that sheet I circulated, we describe the profiles using MOP= Maximum opening points. There's Inlet maximum opening points and Exhaust maximum opening points. Everyone in the industry does it that way, even Ford and BMW. I don't do LSAs, just like I don't quote figures at 50 thou lift or go on about CFM when describing ports. The aftermarket don't know what they're on about. They MUST concede to the OEMS or STFU. These rules of thumb you read on vizard or smokey yunicks books, often don't apply to engines with 4 valves, with such big valves as the Jaguar or engines with VVT.

The most important events are overlap, IVC and EVO, and possibly EVC.

Lets walk through the AJ33 S/C example- its 240 IP (intake period) timed at 120 IMOP (Intake maximum opening point) and 220 EP @ 110 EMOP.

I'll walk through it once for you with a reference to LSA, and then allow you to calculate it yourself as I don't align to the bollox references of the aftermarket. This gives

Intake open BTC=0

Intake close ABC=60

Exhaust open BBC=40

Exhaust close ATC=0

Intake duration=240

Exhaust duration=220

Intake center=120

Exhaust center=110

Lobe separation=115

Advance=-5Degrees

overlap=0

As the valve events are quoted at top of ramps, the overlap is only over the ramps. The ramp periods on these older engines are 27 degrees. The later ramps are 20 degrees long. I may look into even shorter ramps.

My current profile is showing a much more advanced optimum IMOP to either the AJ33 or AJ27 above. This is using a combination of dyno data and very sophisticated thermos fluids/1 D cycle simulation code.

You can see that when optimising these timings , for the intake at least, the intake closing point or IVC is coming out as the same no matter what the duration.

The problem with your 106.5 MOP is that you will boost low speed torque and starve top end. I'm assuming you're running a 240 period. Again, on intake, IVC is the dominant factor. If you have some overlap but your engine runs smoothly, then that's good and I'll take your word for it.

Between the dyno and simulation I have tried 220 intake periods all the way up to 272 profiles using the latest short ramps. I did the same for exhaust and I'm getting the need for longer exhaust periods. When I do this- the Volumetric Efficiency stays the same but the power goes up at top end. This is what tells me that the pumping losses are too high and that the engine needs high blow down. If you look at the AJ133 profiles, this is the directions we took also.

I hope this helps

Last edited by Count Iblis; 12-20-2016 at 11:16 AM.

#112

#113

Found the cam spec card. It says: Duration@0.1mm valve lift: 264/264 , maxlift @110 ATDC / 110 BTDC.

#114

That's shorter than stock.

The Jag 240 profile at 0.1mm of lift has a duration of about 318 degs.

I wonder where they got the profile from.

So the profile is shorter than stock and it sounds like with 106.5 MOP its advanced. This will boost your low speed but could cause it to starve top end power and breathing.

The extra blow down needed by the S/C Jag V8- requires an earlier EVO point and/or longer period overall.

I haven't found anyone that sells Jaguar cam blanks. I have found a place that will regrind original cams. They're not cheap though...

The Jag 240 profile at 0.1mm of lift has a duration of about 318 degs.

I wonder where they got the profile from.

So the profile is shorter than stock and it sounds like with 106.5 MOP its advanced. This will boost your low speed but could cause it to starve top end power and breathing.

The extra blow down needed by the S/C Jag V8- requires an earlier EVO point and/or longer period overall.

I haven't found anyone that sells Jaguar cam blanks. I have found a place that will regrind original cams. They're not cheap though...

#115

That's shorter than stock.

The Jag 240 profile at 0.1mm of lift has a duration of about 318 degs.

I wonder where they got the profile from.

So the profile is shorter than stock and it sounds like with 106.5 MOP its advanced. This will boost your low speed but could cause it to starve top end power and breathing.

The extra blow down needed by the S/C Jag V8- requires an earlier EVO point and/or longer period overall.

I haven't found anyone that sells Jaguar cam blanks. I have found a place that will regrind original cams. They're not cheap though...

The Jag 240 profile at 0.1mm of lift has a duration of about 318 degs.

I wonder where they got the profile from.

So the profile is shorter than stock and it sounds like with 106.5 MOP its advanced. This will boost your low speed but could cause it to starve top end power and breathing.

The extra blow down needed by the S/C Jag V8- requires an earlier EVO point and/or longer period overall.

I haven't found anyone that sells Jaguar cam blanks. I have found a place that will regrind original cams. They're not cheap though...

#116

NO, NO, NO.......I do not open all the specs, but they are great cams worked well for a few guys here and have much more duration and lift than stock ones. If you look at your own 1mm duration you have about 227/232 , these have 220/220. You don't like aftermarket guys talkings....but what I know, there is not so much matter what's the advertised durations. Real flow start later so 1mm or 0.050" tells much more about the cam specs. I have compared very much to 03-04 4V Cobra cams - stock and aftermarket ones. Stock ones are 186/194 @0.050 and 114LSA. They have found that best timing is 108/114 - LSA 111. There are several aftermarket ones and well known Crower Stage 3 are 222/222 @ 0.050 with 12mm lift.

The 'not much happens at below valve lift or 50 thou valve lift' is a common after market comment. One of the guys that worked for me would say this too. Low lift shock wave tuning can happen here, along with a lot of residual gas implications and refinement and durability (on closing velocities) implications also. The fact that Jaguar Land Rover went from 0.45 mm ramps to 0.36mm ramps and this showed a appreciable performance benefit as well as refinement contradicts that. I'm not trying to be an ****, I'm just showing that this is not true. The original of 50 thou lift duration came from the aftermarket copying GM in the 50s, GM later changed. The Mopar and direct connection performance catalogues stated NOT to use this method either.

I ended up firing this guy eventually because he didn't listen and kept following after market practices. It was too bad.

How did you pick up what my duration was at 1mm? Did you use a data scanner? I checked, and you were pretty much spot on.

#117

A shame it wasnít cold enough 10 years ago when I started  , but great to share as much info now!

, but great to share as much info now!

Unfortunately not, best I ever found (many years ago) is attached, but I have been informed that these tests where possibly not reliable. KB does not share these, so only way to gat some idea is to check is browse thru their data. I just took it for granted, and leave the rpm around 12500' ish.

When I started I did try to look at BMEP figures, but not knowing what the design limits where, I left it, and went out and just took the risk and tried it out. But in hindsight, good that I didnít know it, as I would probably havenít gone as far as I have done.

What gave me confidence that there was some good room (indeed NOT for prolonged use, just street driving), was that back then many where spinning the Eaton excessively fast and got already rwhp figures approaching 400 without blowing the stuff up. You can imagine the massive power consumption there from the Eaton, so taking that into the equation I knew there would be some good room with the very efficient twin-screw units to reach, and there was indeed obviously.

Unfortunately not, best I ever found (many years ago) is attached, but I have been informed that these tests where possibly not reliable. KB does not share these, so only way to gat some idea is to check is browse thru their data. I just took it for granted, and leave the rpm around 12500' ish.

When I started I did try to look at BMEP figures, but not knowing what the design limits where, I left it, and went out and just took the risk and tried it out. But in hindsight, good that I didnít know it, as I would probably havenít gone as far as I have done.

What gave me confidence that there was some good room (indeed NOT for prolonged use, just street driving), was that back then many where spinning the Eaton excessively fast and got already rwhp figures approaching 400 without blowing the stuff up. You can imagine the massive power consumption there from the Eaton, so taking that into the equation I knew there would be some good room with the very efficient twin-screw units to reach, and there was indeed obviously.

Thanks for sharing that. The lobes look very much like a Lysholm compressor with a male and female rotor. We tried that on the dyno, and indeed it was more efficient and gave cooler tank temps also and was quieter. Ours was an IHI deal, (Mitsubishi heavy industries). Looking on the internet- it looks like a Lysholm has efficiencies that are in the 60s like a TVS blower.

#118

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,231 Likes

on

939 Posts

so much knowledge about cams, alot over my head!

couple things i do remember ,was when Buick grand national turbo cams came around factory was no over lap , and that up set a lot of guys who immediatly put in wide overlap cams, and lost a ton of low end torque!

finally cam companies caught on and started a new world of aftermarket cams and parts!

another one a remember was mid 1960s was Chet Herbert(a very smart cam guy),

Roots blowers were getting known, and he came out with what he called a 400 degree cam for superchraged engines , OK again a never really understood what he meant, but i run one in a SBC stroker S/C, it went 200mph in 7.25et 1/4mile, front engined dragster, on 30% nitromethane and 70% methanol.

got a divorce and moved to Florida.

hey Count great you mention Smokey Yunick, i knew him personally, gotta give him credit , i was at a dyno session,1975, when he made a twin turbo SBC go almost 1000HP , ran it at Indy and hard to make(YIKES 2/ 4 barrel carbs keep up in corners).

FI was just coming around and in its infancy!

Smokey was sometimes nice and sometimes not so.

boy oh, he had sometime tales of the back of the old days in pits, and some of the girls that hung around there after hours,in trailers etc.

anyway keep up the good work, i have to admit i understand aftermarket cam numbers much better than UK /metric.

couple things i do remember ,was when Buick grand national turbo cams came around factory was no over lap , and that up set a lot of guys who immediatly put in wide overlap cams, and lost a ton of low end torque!

finally cam companies caught on and started a new world of aftermarket cams and parts!

another one a remember was mid 1960s was Chet Herbert(a very smart cam guy),

Roots blowers were getting known, and he came out with what he called a 400 degree cam for superchraged engines , OK again a never really understood what he meant, but i run one in a SBC stroker S/C, it went 200mph in 7.25et 1/4mile, front engined dragster, on 30% nitromethane and 70% methanol.

got a divorce and moved to Florida.

hey Count great you mention Smokey Yunick, i knew him personally, gotta give him credit , i was at a dyno session,1975, when he made a twin turbo SBC go almost 1000HP , ran it at Indy and hard to make(YIKES 2/ 4 barrel carbs keep up in corners).

FI was just coming around and in its infancy!

Smokey was sometimes nice and sometimes not so.

boy oh, he had sometime tales of the back of the old days in pits, and some of the girls that hung around there after hours,in trailers etc.

anyway keep up the good work, i have to admit i understand aftermarket cam numbers much better than UK /metric.

The following users liked this post:

Count Iblis (12-20-2016)

#119

so much knowledge about cams, alot over my head!

couple things i do remember ,was when Buick grand national turbo cams came around factory was no over lap , and that up set a lot of guys who immediatly put in wide overlap cams, and lost a ton of low end torque!

finally cam companies caught on and started a new world of aftermarket cams and parts!

another one a remember was mid 1960s was Chet Herbert(a very smart cam guy),

Roots blowers were getting known, and he came out with what he called a 400 degree cam for superchraged engines , OK again a never really understood what he meant, but i run one in a SBC stroker S/C, it went 200mph in 7.25et 1/4mile, front engined dragster, on 30% nitromethane and 70% methanol.

got a divorce and moved to Florida.

hey Count great you mention Smokey Yunick, i knew him personally, gotta give him credit , i was at a dyno session,1975, when he made a twin turbo SBC go almost 1000HP , ran it at Indy and hard to make(YIKES 2/ 4 barrel carbs keep up in corners).

FI was just coming around and in its infancy!

Smokey was sometimes nice and sometimes not so.

boy oh, he had sometime tales of the back of the old days in pits, and some of the girls that hung around there after hours,in trailers etc.

anyway keep up the good work, i have to admit i understand aftermarket cam numbers much better than UK /metric.

couple things i do remember ,was when Buick grand national turbo cams came around factory was no over lap , and that up set a lot of guys who immediatly put in wide overlap cams, and lost a ton of low end torque!

finally cam companies caught on and started a new world of aftermarket cams and parts!

another one a remember was mid 1960s was Chet Herbert(a very smart cam guy),

Roots blowers were getting known, and he came out with what he called a 400 degree cam for superchraged engines , OK again a never really understood what he meant, but i run one in a SBC stroker S/C, it went 200mph in 7.25et 1/4mile, front engined dragster, on 30% nitromethane and 70% methanol.

got a divorce and moved to Florida.

hey Count great you mention Smokey Yunick, i knew him personally, gotta give him credit , i was at a dyno session,1975, when he made a twin turbo SBC go almost 1000HP , ran it at Indy and hard to make(YIKES 2/ 4 barrel carbs keep up in corners).

FI was just coming around and in its infancy!

Smokey was sometimes nice and sometimes not so.

boy oh, he had sometime tales of the back of the old days in pits, and some of the girls that hung around there after hours,in trailers etc.

anyway keep up the good work, i have to admit i understand aftermarket cam numbers much better than UK /metric.

I LIKE those rules of thumb, they get you started. Try it in Germany and everyone wants to start from first priciples with the best data never available. However its all about balance and everything in moderation. The quoting cam duration at 50 thou I wont back down on for the reasons given and I'm tired of having these discussions. I give the succinct reasons and no one can counter but theyre steadfast.

Looks like you did it the right way- got divorced and moved somewhere warmer. I went to sub arctic conditions!

#120

One thing though, I am not running the Opcon models (although I started with a 1.7L unit as a proof of concept), but the KB 2.6 High Compression versions, (a higher internal compression), making them from about 15 psi and up more efficient again for max power.

Attached is the best lysholm graph I have seen, but unfortunately I have nothing (except standard info from KB) about the comprehensive performance charts. This one at least can be nicely used to compare against the TVS 2.3.

Below some more (sales) info from KB between the Lysholm and Opcon:

http://www.not2fast.com/turbo/maps/A...RvsLYSHOLM.pdf

Here differences for the newer generation KB vs the older Opcons they used:

BIG BORE Supercharger

And here is a comparison from KB between the different compression ratios used:

H Series Supercharger

Attached is the best lysholm graph I have seen, but unfortunately I have nothing (except standard info from KB) about the comprehensive performance charts. This one at least can be nicely used to compare against the TVS 2.3.

Below some more (sales) info from KB between the Lysholm and Opcon:

http://www.not2fast.com/turbo/maps/A...RvsLYSHOLM.pdf

Here differences for the newer generation KB vs the older Opcons they used:

BIG BORE Supercharger

And here is a comparison from KB between the different compression ratios used:

H Series Supercharger

The following 2 users liked this post by avos:

Count Iblis (12-21-2016),

Panthro (06-06-2017)