Oh Crap - The X-Type "Rumble" - Help! RESOLVED

#1

*** RESOLVED: See bottom of this Opening Post for resolution ***

Hi all, took delivery of my 2003 X-Type 2.5 today. 21k miles. Pristine condition. It's a real eye catcher... except...

On my 2.5 hour drive home from the seller's house, I noticed a distinct rumble and vibration starting at around 50mph, and continuing on upwards until it gets lost in the road noise/feel around 80-90mph. I have searched and found tons of threads on this topic, but I have yet to find someone who has resolved the issue successfully.

Is there a solution to this problem? Am I just not seeing it? Please help the "new guy" out.

The car does have its original, 2003 Continental 16" tires on it. Yes they are 10 years old. But they do only have 21k miles on them.

The car runs beautifully smooth and quiet, right up to about 50mph, when it starts to feel like I'm riding on a very mild rumble-strip. Then, as I speed up, it adds a low bass frequency to the mix. How do I make my car ride quiet? And am I hurting it by driving it like this?

Thanks!

*** THE FIX - MARCH 2013***

It was the driveshaft. Jaguar issued a TSB for 2002-2004 X-Types regarding driveline vibrations:

http://www.jagrepair.com/images/TSB/...0Vibration.pdf

I replaced it with a refurbished driveshaft from these guys:

2003 Jaguar X Type Drive Shaft - Jaguar X Type Driveline - Free Shipping

It's a pretty simple DIY job, as long as you have the jacks, stands, and an extra set of hands.

The vibration improved by about 90%. There is still a very distant rumble starting around 65mph. It's so faint that, if I hadn't already known about the vibration issue, I probably wouldn't be listening for it and wouldn't notice it. I don't think passengers would notice it. It's no longer felt in the steering wheel, seats or body. Just slightly audible. Could just be that, at 65mph, it's road noise.

I'm going to switch out the original TC and rear differential fluid with fresh synthetics. Hopefully that will clean up the last 10%. If not, I have a 1-year warranty on this refurbished driveshaft. They will send me a replacement if I request it. For now, it's so close to perfect that I'd be afraid to chance another install.

Another benefit is that this refurbished driveshaft came with the needle-greaseable carrier bearing. My original bearing did not have the slots to insert the needle.

Side note: The refurbished driveshaft came with two new coupling gaskets. I didn't not know this, so I ordered two from the dealer ($23.00 each) thinking I would need them. After seeing the gaskets that came with the shaft, I'm glad I had the dealer's gaskets as well. The dealer's gaskets are thicker and made of better material. I used them instead of the ones included. I'm keeping those for spares.

My ride is a lot more enjoyable now. Thanks for everyone's support and advice.

*** FIXING IT FURTHER - APRIL, 2014 ***

After a year of driving around with my "improved rumble," I decided that "good enough" wasn't good enough. I took my car to the local Jag dealer in Clarksville, MD. They charge $165 to diagnose a problem. My plan was to let them diagnose and then make any repairs myself. They took my car and gave me a complimentary loaner while they worked on it.

The next day, the dealer called me back and informed me that, while they could reproduce the problem, they couldn't pinpoint the source. The tech speculated that indexing the drive-shaft would resolve the issue, but they wanted to charge me $580 to test that theory, without guaranteeing a fix. I declined the service and picked up my car to attempt the indexing myself. They had washed it for me. Nice touch.

That weekend, I put the car up on 4 jack-stands and began the process of testing the different bolt positions on both the front and the rear of the shaft. Starting with the rear, I pulled the bolts, rotated one hole (clockwise), bolted it back on, and spun it up to 70mph on the jack-stands. I felt for any change in vibration, for better or worse. I settled on 180 degrees from original hole as being the most improved. I repeated the process on the front of the shaft. Again, 180 degrees was the best.

Once all bolts were snug, I jacked it down and took it for a road test.

NOTICEABLE IMPROVEMENT!

Not only does the vibration start later and end earlier, it's much more subtle. It's quieter, almost unnoticeable, unless you knew what to listen for. Now, I only tested 12 of the possible 36 bolt combinations (6 bolts in front, 6 in back) and could probably spend hours fine-tuning it further. I'll leave that for next spring. For now, good enough IS good enough.

- Ryan

Hi all, took delivery of my 2003 X-Type 2.5 today. 21k miles. Pristine condition. It's a real eye catcher... except...

On my 2.5 hour drive home from the seller's house, I noticed a distinct rumble and vibration starting at around 50mph, and continuing on upwards until it gets lost in the road noise/feel around 80-90mph. I have searched and found tons of threads on this topic, but I have yet to find someone who has resolved the issue successfully.

Is there a solution to this problem? Am I just not seeing it? Please help the "new guy" out.

The car does have its original, 2003 Continental 16" tires on it. Yes they are 10 years old. But they do only have 21k miles on them.

The car runs beautifully smooth and quiet, right up to about 50mph, when it starts to feel like I'm riding on a very mild rumble-strip. Then, as I speed up, it adds a low bass frequency to the mix. How do I make my car ride quiet? And am I hurting it by driving it like this?

Thanks!

*** THE FIX - MARCH 2013***

It was the driveshaft. Jaguar issued a TSB for 2002-2004 X-Types regarding driveline vibrations:

http://www.jagrepair.com/images/TSB/...0Vibration.pdf

I replaced it with a refurbished driveshaft from these guys:

2003 Jaguar X Type Drive Shaft - Jaguar X Type Driveline - Free Shipping

It's a pretty simple DIY job, as long as you have the jacks, stands, and an extra set of hands.

The vibration improved by about 90%. There is still a very distant rumble starting around 65mph. It's so faint that, if I hadn't already known about the vibration issue, I probably wouldn't be listening for it and wouldn't notice it. I don't think passengers would notice it. It's no longer felt in the steering wheel, seats or body. Just slightly audible. Could just be that, at 65mph, it's road noise.

I'm going to switch out the original TC and rear differential fluid with fresh synthetics. Hopefully that will clean up the last 10%. If not, I have a 1-year warranty on this refurbished driveshaft. They will send me a replacement if I request it. For now, it's so close to perfect that I'd be afraid to chance another install.

Another benefit is that this refurbished driveshaft came with the needle-greaseable carrier bearing. My original bearing did not have the slots to insert the needle.

Side note: The refurbished driveshaft came with two new coupling gaskets. I didn't not know this, so I ordered two from the dealer ($23.00 each) thinking I would need them. After seeing the gaskets that came with the shaft, I'm glad I had the dealer's gaskets as well. The dealer's gaskets are thicker and made of better material. I used them instead of the ones included. I'm keeping those for spares.

My ride is a lot more enjoyable now. Thanks for everyone's support and advice.

*** FIXING IT FURTHER - APRIL, 2014 ***

After a year of driving around with my "improved rumble," I decided that "good enough" wasn't good enough. I took my car to the local Jag dealer in Clarksville, MD. They charge $165 to diagnose a problem. My plan was to let them diagnose and then make any repairs myself. They took my car and gave me a complimentary loaner while they worked on it.

The next day, the dealer called me back and informed me that, while they could reproduce the problem, they couldn't pinpoint the source. The tech speculated that indexing the drive-shaft would resolve the issue, but they wanted to charge me $580 to test that theory, without guaranteeing a fix. I declined the service and picked up my car to attempt the indexing myself. They had washed it for me. Nice touch.

That weekend, I put the car up on 4 jack-stands and began the process of testing the different bolt positions on both the front and the rear of the shaft. Starting with the rear, I pulled the bolts, rotated one hole (clockwise), bolted it back on, and spun it up to 70mph on the jack-stands. I felt for any change in vibration, for better or worse. I settled on 180 degrees from original hole as being the most improved. I repeated the process on the front of the shaft. Again, 180 degrees was the best.

Once all bolts were snug, I jacked it down and took it for a road test.

NOTICEABLE IMPROVEMENT!

Not only does the vibration start later and end earlier, it's much more subtle. It's quieter, almost unnoticeable, unless you knew what to listen for. Now, I only tested 12 of the possible 36 bolt combinations (6 bolts in front, 6 in back) and could probably spend hours fine-tuning it further. I'll leave that for next spring. For now, good enough IS good enough.

- Ryan

Last edited by rclangelan; 04-08-2014 at 03:39 PM. Reason: Resolved Issue on 3/17/13 - Again on 4/4/14

#2

Join Date: May 2008

Location: Great Mills, MD

Posts: 14,223

Likes: 0

Received 3,826 Likes

on

3,145 Posts

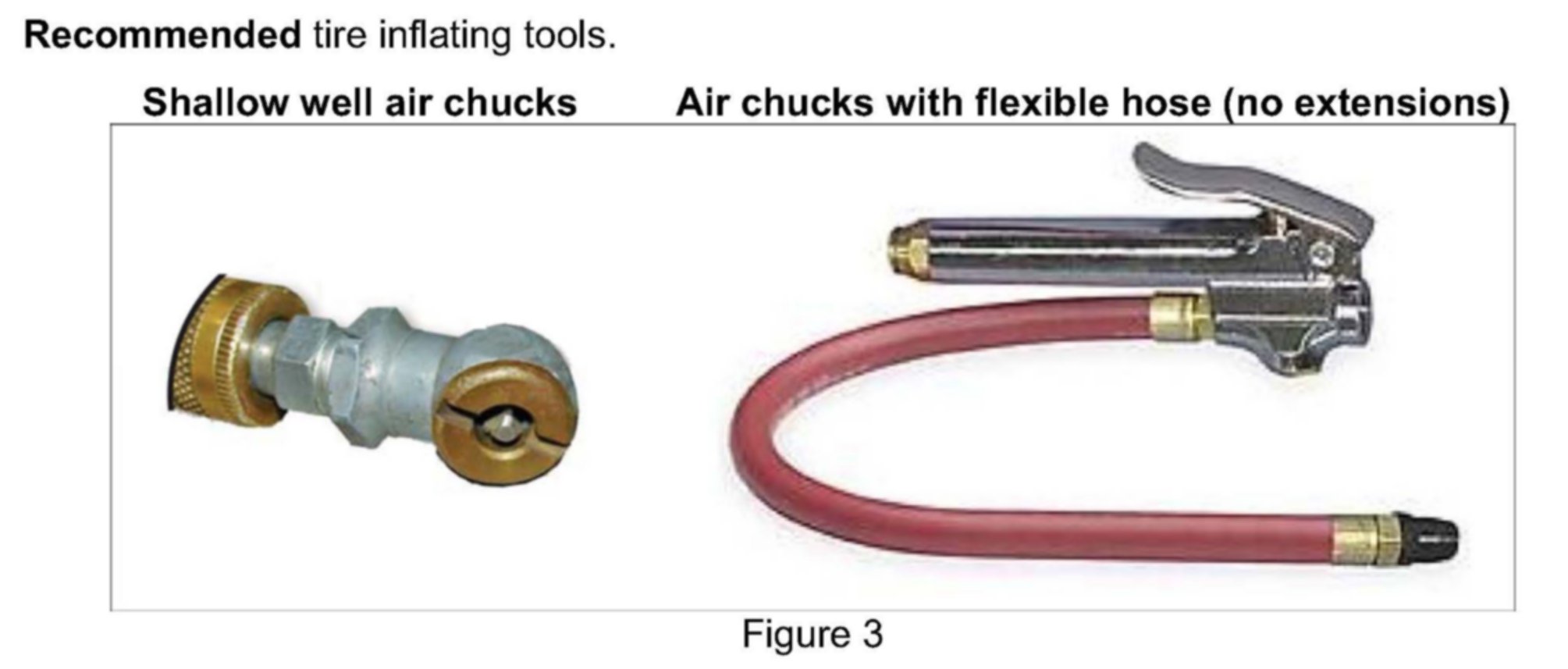

RC, I would first start with getting a needle attachment to a grease gun and applying some grease to the carrier bearing for the rear driveshaft. If that makes the noise change, then you most likely have a carrier bearing that is going out. If that doesn't help, then I would start looking at a new set of tires and while they are putting on the tires, have the shop do a suspension check to see if there is anything wrong.

Do you feel the vibration in the steering wheel? If so, it could be simply that the alignment is out just slightly as this is a common problem with the X-Types. Granted, may also be that a wheel is out of balance and it will only show itself once the vehicle is up to speed. But, again, that would be corrected with the new tires. Then finally, it may be that the car has had a wheel brush up against something and been bent. That will cause a good wobble/noise in the car. But, again, a shop that does the tire replacement should pick that up for you.

Do you feel the vibration in the steering wheel? If so, it could be simply that the alignment is out just slightly as this is a common problem with the X-Types. Granted, may also be that a wheel is out of balance and it will only show itself once the vehicle is up to speed. But, again, that would be corrected with the new tires. Then finally, it may be that the car has had a wheel brush up against something and been bent. That will cause a good wobble/noise in the car. But, again, a shop that does the tire replacement should pick that up for you.

#3

Thermo,

I will have to grease the carrier bearing and see if that helps. I do have a needle attachment. Yes, the rumble can be felt in the steering wheel. Would that be alignment, or tire balance?

Gonna have tires balanced this week.

Thanks for your help!

I will have to grease the carrier bearing and see if that helps. I do have a needle attachment. Yes, the rumble can be felt in the steering wheel. Would that be alignment, or tire balance?

Gonna have tires balanced this week.

Thanks for your help!

Last edited by rclangelan; 01-08-2013 at 10:45 AM.

#4

Join Date: May 2008

Location: Great Mills, MD

Posts: 14,223

Likes: 0

Received 3,826 Likes

on

3,145 Posts

RC, the steering wheel shaking can be either alignment or balance. Since you are having the tires balanced, also have them do a "trueness check" of the tires. Some members have had issues with the tires taking a slight hit to the side and bending the rims, causing them not to roll right (leading to a wobble like you are seeing).

Take it step by step and lets see what you have. Since you are feeling it in the steering wheel, it probably isn't the centering bearing on the rear drive shaft. Granted, doesn't hurt to give it a squirt of grease though.

Take it step by step and lets see what you have. Since you are feeling it in the steering wheel, it probably isn't the centering bearing on the rear drive shaft. Granted, doesn't hurt to give it a squirt of grease though.

#5

Thanks. Will check on all of that. The rims on this car are flawless, and have definitely never touched a curb, rock, or anything. Those types of impacts tend to leave scratches and nicks in the metal. These rims are all pristine. What else would cause a wheel to be untrue?

The rear passenger tire does have a plug in the groove between the tread. Would that affect anything?

The rear passenger tire does have a plug in the groove between the tread. Would that affect anything?

Last edited by rclangelan; 01-06-2013 at 09:23 PM.

#6

Join Date: May 2008

Location: Great Mills, MD

Posts: 14,223

Likes: 0

Received 3,826 Likes

on

3,145 Posts

rc, it may be that the alignment is out. If the rims are not suffering from any sort of road rash, then you may be good. The only other possibility is if they hit a pot hole and that some how twisted the rim up without leaving a mark on the rim. A quality tire shop should be able to spot a bent rim with no problems. If no bent rims, then odds are it is simply an alignment issue and you need to get that taken care of.

#7

Or maybe it could just be the car was suiting for an extended period of time and the tires are somewhat flat spotted, but that usually goes away fairly quickly. Or it could be the tires need to be replaced, not from wear, but from age. Chances are they are original with that low mileage. Am guessing something tire related.

Trending Topics

#8

I'm putting money on the tires.

But, my x-type had a minor rumble from new. Not a big thing, but it was always there. I ignore it now.

I've had transfer case failure and that's not the source of the minor rumble. Lubing the carrier bearing helps mine some.

But in my case it always nearly goes away after prolonged driving.

But, my x-type had a minor rumble from new. Not a big thing, but it was always there. I ignore it now.

I've had transfer case failure and that's not the source of the minor rumble. Lubing the carrier bearing helps mine some.

But in my case it always nearly goes away after prolonged driving.

#9

With only 21k miles in 10 years, the car definitely did a lot of sitting. I'm taking in to have it MD inspected at a shop that also does tires and alignments this Wednesday morning. I'm going to have them check the alignment and balance or replace the tires. Hope to have it resolved Wednesday.

Thanks for all the advice so far.

Thanks for all the advice so far.

#10

Ok, had the car MD inspected today. Passed.

At the same time, I had them check the balance of the tires. They did find them unbalanced and re-balanced for me.

Rumbling has improved greatly, but not completely disappeared. The steering wheel now has less of an aggressive wobble and more of a vibration. The noise has improved too. I'm wondering if the tires themselves (Conti TouringContact AS) are just old and need replacing. That model of tire gets poor reviews on TireRack anyway.

I did over-inflate my tires to 42 psi, just for diagnostic purposes. They were wearing on the outside edges, suggesting under inflation. They are still over-inflated after the balancing. Perhaps relaxing them back down to 33-35psi will resolve the remaining noise/vibration. Will try that out after work.

At the same time, I had them check the balance of the tires. They did find them unbalanced and re-balanced for me.

Rumbling has improved greatly, but not completely disappeared. The steering wheel now has less of an aggressive wobble and more of a vibration. The noise has improved too. I'm wondering if the tires themselves (Conti TouringContact AS) are just old and need replacing. That model of tire gets poor reviews on TireRack anyway.

I did over-inflate my tires to 42 psi, just for diagnostic purposes. They were wearing on the outside edges, suggesting under inflation. They are still over-inflated after the balancing. Perhaps relaxing them back down to 33-35psi will resolve the remaining noise/vibration. Will try that out after work.

#12

#13

UPDATE:

I pulled the trigger on a new set of Michelin Primacy MXV4s today. Great, smooth, quiet ride. But the rumble remains. Between 50 and 70 mph, there is a noticeable rumble (low bass frequency) through the entire cabin and a slight steering wheel vibrations. It's not as noticeable as it was with the old (original) tires. The rumble is quieter and the vibrations less intense, but it's noticeable enough.

The shop tested the alignment. It passed the test. Alignment is good. Tires are brand new.

The car needed tires anyway, so I'm not upset about spending the money on the Michelins. They improved the ride quality in other ways:

- Less road noise

- Less impact and noise over bumps

- Less tires vibration (not to be confused with the rumble)

So, what's the next component that I should be inspecting to solve this rumble? Thanks for the advice.

I pulled the trigger on a new set of Michelin Primacy MXV4s today. Great, smooth, quiet ride. But the rumble remains. Between 50 and 70 mph, there is a noticeable rumble (low bass frequency) through the entire cabin and a slight steering wheel vibrations. It's not as noticeable as it was with the old (original) tires. The rumble is quieter and the vibrations less intense, but it's noticeable enough.

The shop tested the alignment. It passed the test. Alignment is good. Tires are brand new.

The car needed tires anyway, so I'm not upset about spending the money on the Michelins. They improved the ride quality in other ways:

- Less road noise

- Less impact and noise over bumps

- Less tires vibration (not to be confused with the rumble)

So, what's the next component that I should be inspecting to solve this rumble? Thanks for the advice.

#14

Did you grease the carrier bearing?

Also, change the transfer case lube. Prior to repairing my transfer case, when I changed the TC gear oil, the car was always quieter.

Another thought, and a fairly easy one too. If possible, re-index the driveshaft. Simply remove the CJ-Joint from the flange on the TC, then install it again 180 degrees out. When you do it, exercise the CV-Joint a bit too, to spread the grease around inside it.

I'm now at 130K miles and I have only very moderate rumble that settles down after a bit of highway driving. It's certainly not anything annoying.

Also, change the transfer case lube. Prior to repairing my transfer case, when I changed the TC gear oil, the car was always quieter.

Another thought, and a fairly easy one too. If possible, re-index the driveshaft. Simply remove the CJ-Joint from the flange on the TC, then install it again 180 degrees out. When you do it, exercise the CV-Joint a bit too, to spread the grease around inside it.

I'm now at 130K miles and I have only very moderate rumble that settles down after a bit of highway driving. It's certainly not anything annoying.

#18

My apologies for the long post.

This TSB talks about the alignment marks and the 180 degree rotation of the prop shaft.

XT100-08

DATE

05/04 Amended

03/05 X-TYPE

MODEL

2002 MY-ON

X-TYPE VIN

C00001-ON Driveshaft Vibration - Diagnostic Method - Repair

Remove and destroy Bulletin XT100-08, dated 05/04.

Replace with this Bulletin.

Revisions are marked with a bar and asterisks. Issue:

A new procedure has been developed for use after the WDS Vehicle Vibration Analyzer (VVA) has confirmed a vehicle vibration.

Action:

After a driveshaft vibration has been confirmed using WDS VVA, follow the workshop procedure outlined below.

WORKSHOP PROCEDURE

Note :

There is no Labor Time Allowance to carry out road test diagnosis. Jaguar recommends a claim of 0.50 hrs. as straight time for VVA. Warning : Driveshaft bolts are one-time use only. Use new bolts for the final repair. Existing bolts may be reused throughout the diagnostic procedures. 1. Raise vehicle on twin-post lift. 2. Check for alignment of the green line on the rear differential flange with white paint spot on the rear of the driveshaft. If not aligned continue from step 3; if aligned continue from step 16. 3. Remove the rear driveshaft joint to rear differential flange bolts and links where accessible. 4. Rotate the driveshaft and remove the remaining rear driveshaft joint to rear differential flange securing bolts and links. 5. Displace driveshaft from the rear differential flange. 6. Remove and discard the gasket from the rear differential flange (where installed). 7. Clean the mating faces. 8. Install a new gasket to the rear differential flange, if previously installed. *9. Rotate the driveshaft 180°from the original position.* 10. Position the driveshaft to the rear differential flange. 11. Install, but do not final-tighten the accessible bolts and links that secure the rear driveshaft joint to the rear differential flange. 12. Rotate driveshaft and install, but do not final-tighten, the remaining bolts and links that secure the rear driveshaft joint to the rear differential flange. 13. With the driveshaft joint fully seated in the rear differential flange, final tighten the accessible securing bolts to 44 Nm (32 lb. ft.). 14. Rotate driveshaft and final tighten the bolts securing the driveshaft to the rear differential flange to 44 Nm (32 lb. ft.). 15. Lower vehicle. If the VVA still confirms a driveshaft vibration, or the paint marks were already aligned:

16. Loosen the 6 bolts at the rear differential flange/driveshaft mating surface. Reseat the driveshaft and retorque to 44 Nm (32 lb. ft.). 17. If the VVA still confirms a driveshaft vibration, install a new driveshaft (see Workshop Manual, section: 205-01, SR047.15.01).

Note :Ensure colored marks are aligned at the rear differential. If the VVA still confirms a driveshaft vibration, check the flange inside diameter and run-out as described below.

CHECKING DIFFERENTIAL FLANGE INSIDE DIAMETER AND RUN-OUT

1. Raise vehicle on twin-post ramp. 2. Remove driveshaft (see Workshop Manual, section: 205-01, SRO 47.15.01). 3. Clean mating faces.

4. Using a suitable measuring device, measure and record the rear differential driveshaft locating flange inside diameter (Illustration 1). 5. Mount a suitable magnetic base dial indicator and mount on the rear differential.

6. Measure and record the rear differential driveshaft locating flange inside diameter run-out (Illustration 2). 7. If the inside diameter is greater than 94.076 mm or less than 94.030 mm and/or the run-out is greater than 0.12 mm, install a new drive pinion flange and seal (see Workshop Manual, section: 205-02, SRO 51.25.13).

Note :Ensure colored marks are aligned at the rear differential. If the inside diameter is between 94.076 mm and 94.030 mm and/or the run-out is less than 0.12 mm, continue with the procedure below.

If the VVA still confirms a driveshaft vibration check the transfer case flange inside diameter and runout as described below:

CHECKING TRANSFER CASE FLANGE INSIDE DIAMETER AND RUN-OUT

1. Raise vehicle on twin-post ramp. 2. Remove driveshaft (see Global Technical Reference GTR Workshop Manual, section: 205-01). 3. Clean the face of transfer case output flange.

4. Use a suitable measuring device, to measure the inside diameter of the transfer case output flange (Illustration 3). 5. Assemble a suitable magnetic base Dial Test Indicator (DTI) and mount to transfer case.

6. Measure the run-out of the inside diameter of the transfer case output flange (Illustration 4). If the inside diameter is greater than 94.076 mm or less than 94.030 mm and/or the run-out is greater than 0.12 mm, continue from step 7. If readings are in specification continue from step 8.

7. Install a new drive pinion seal and flange (see Global Technical Reference GTR Workshop Manual, section: 308-07, SRO 46.10.04). If the VVA still confirms a driveshaft vibration:

8. Install a new driveshaft (see Global Technical Reference GTR Workshop Manual, section 205-01, SRO 51.25.13).

This one addresses the 70 mph whine.

XT205-01

X-TYPE

DATE 08/01

MODEL

2002 MY-ON

X-TYPE VIN

C00001-ON Whine on Deceleration at 112 Km/h/(70 MPH) - Rear Differential - Add Weight to Differential Bracket

Issue:

Some 2002 MY X-TYPE vehicles may experience a whining noise from the differential on deceleration at speeds of around 112 Km/h/70 mph. This bulletin provides a procedure to "retune" the differential mounting bracket by adding mass (weight) to it.

Action:

In case of a customer complaint of the above condition on a 2002 MY X-TYPE remove and retune the differential mounting bracket as outlined in the following procedure.

MODIFICATION PROCEDURE

1. Raise vehicle. 2. Remove rear wheels and tires. 3. Remove the rear differential. Refer to JTIS, section: 205-02 SRO 51.25.13. 4. Remove the rear sub frame from the vehicle. Refer to JTIS, section: 502-00 SRO 64.25.01.90. 5. Remove the differential mounting bracket to rear sub frame securing bolts. 6. Remove the differential mounting bracket from the rear sub frame assembly 7. Clean outer ends of the differential mounting bracket with cleaning fluid.

8. Cut the two 120 g strips of wheel weights into four 60 g strips, remove backing tape and apply wheel weights to the differential mounting bracket (Illustration 1). Note: Firmly push along the full length of the wheel weight strips to ensure good adhesion to the differential mounting bracket. 9. Reinstall the differential mounting bracket to the rear sub frame. 10. Install the securing bolts for the differential mounting bracket. Torque figure 106 Nm. 11. Reinstall the rear sub frame to vehicle. Refer to JTIS, section: 502-00. 12. Reinstall the rear differential. Refer to JTIS, section: 205-02 SRO 51.25.13. 13. Perform the under body misalignment check in JTIS, section 502-00 SRO 64.25.01.90. 14. Reinstall rear wheel and tire assemblies. 15. Lower vehicle.

And finally, there is the following, not often talked about, TSB.

XT100-03

X-TYPE

DATE:

06/02 MODEL:

2002 MY X-TYPE VIN:

C00001-C83408 "Boom" at 2900 RPM - Rear Differential - Install Weight Under Differential

Issue:

Some 2002 MY X-TYPE vehicles may experience an unacceptable "boom" at 2900 RPM. A 2 Kg damper weight is available that can be installed under the rear final drive unit to address this concern.

Action:

In case of a customer complaint of the above condition on a 2002 X-TYPE vehicle within the above VIN range, install a new 2 kg damper beneath the rear final drive as follows:

Jag tech should have access to these oldies but goodies. If they gave you a refurbished prop shaft from an '02 there is likely nowhere that grease is going to get into the center bearing.

This TSB talks about the alignment marks and the 180 degree rotation of the prop shaft.

XT100-08

DATE

05/04 Amended

03/05 X-TYPE

MODEL

2002 MY-ON

X-TYPE VIN

C00001-ON Driveshaft Vibration - Diagnostic Method - Repair

Remove and destroy Bulletin XT100-08, dated 05/04.

Replace with this Bulletin.

Revisions are marked with a bar and asterisks. Issue:

A new procedure has been developed for use after the WDS Vehicle Vibration Analyzer (VVA) has confirmed a vehicle vibration.

Action:

After a driveshaft vibration has been confirmed using WDS VVA, follow the workshop procedure outlined below.

WORKSHOP PROCEDURE

Note :

There is no Labor Time Allowance to carry out road test diagnosis. Jaguar recommends a claim of 0.50 hrs. as straight time for VVA. Warning : Driveshaft bolts are one-time use only. Use new bolts for the final repair. Existing bolts may be reused throughout the diagnostic procedures. 1. Raise vehicle on twin-post lift. 2. Check for alignment of the green line on the rear differential flange with white paint spot on the rear of the driveshaft. If not aligned continue from step 3; if aligned continue from step 16. 3. Remove the rear driveshaft joint to rear differential flange bolts and links where accessible. 4. Rotate the driveshaft and remove the remaining rear driveshaft joint to rear differential flange securing bolts and links. 5. Displace driveshaft from the rear differential flange. 6. Remove and discard the gasket from the rear differential flange (where installed). 7. Clean the mating faces. 8. Install a new gasket to the rear differential flange, if previously installed. *9. Rotate the driveshaft 180°from the original position.* 10. Position the driveshaft to the rear differential flange. 11. Install, but do not final-tighten the accessible bolts and links that secure the rear driveshaft joint to the rear differential flange. 12. Rotate driveshaft and install, but do not final-tighten, the remaining bolts and links that secure the rear driveshaft joint to the rear differential flange. 13. With the driveshaft joint fully seated in the rear differential flange, final tighten the accessible securing bolts to 44 Nm (32 lb. ft.). 14. Rotate driveshaft and final tighten the bolts securing the driveshaft to the rear differential flange to 44 Nm (32 lb. ft.). 15. Lower vehicle. If the VVA still confirms a driveshaft vibration, or the paint marks were already aligned:

16. Loosen the 6 bolts at the rear differential flange/driveshaft mating surface. Reseat the driveshaft and retorque to 44 Nm (32 lb. ft.). 17. If the VVA still confirms a driveshaft vibration, install a new driveshaft (see Workshop Manual, section: 205-01, SR047.15.01).

Note :Ensure colored marks are aligned at the rear differential. If the VVA still confirms a driveshaft vibration, check the flange inside diameter and run-out as described below.

CHECKING DIFFERENTIAL FLANGE INSIDE DIAMETER AND RUN-OUT

1. Raise vehicle on twin-post ramp. 2. Remove driveshaft (see Workshop Manual, section: 205-01, SRO 47.15.01). 3. Clean mating faces.

4. Using a suitable measuring device, measure and record the rear differential driveshaft locating flange inside diameter (Illustration 1). 5. Mount a suitable magnetic base dial indicator and mount on the rear differential.

6. Measure and record the rear differential driveshaft locating flange inside diameter run-out (Illustration 2). 7. If the inside diameter is greater than 94.076 mm or less than 94.030 mm and/or the run-out is greater than 0.12 mm, install a new drive pinion flange and seal (see Workshop Manual, section: 205-02, SRO 51.25.13).

Note :Ensure colored marks are aligned at the rear differential. If the inside diameter is between 94.076 mm and 94.030 mm and/or the run-out is less than 0.12 mm, continue with the procedure below.

If the VVA still confirms a driveshaft vibration check the transfer case flange inside diameter and runout as described below:

CHECKING TRANSFER CASE FLANGE INSIDE DIAMETER AND RUN-OUT

1. Raise vehicle on twin-post ramp. 2. Remove driveshaft (see Global Technical Reference GTR Workshop Manual, section: 205-01). 3. Clean the face of transfer case output flange.

4. Use a suitable measuring device, to measure the inside diameter of the transfer case output flange (Illustration 3). 5. Assemble a suitable magnetic base Dial Test Indicator (DTI) and mount to transfer case.

6. Measure the run-out of the inside diameter of the transfer case output flange (Illustration 4). If the inside diameter is greater than 94.076 mm or less than 94.030 mm and/or the run-out is greater than 0.12 mm, continue from step 7. If readings are in specification continue from step 8.

7. Install a new drive pinion seal and flange (see Global Technical Reference GTR Workshop Manual, section: 308-07, SRO 46.10.04). If the VVA still confirms a driveshaft vibration:

8. Install a new driveshaft (see Global Technical Reference GTR Workshop Manual, section 205-01, SRO 51.25.13).

This one addresses the 70 mph whine.

XT205-01

X-TYPE

DATE 08/01

MODEL

2002 MY-ON

X-TYPE VIN

C00001-ON Whine on Deceleration at 112 Km/h/(70 MPH) - Rear Differential - Add Weight to Differential Bracket

Issue:

Some 2002 MY X-TYPE vehicles may experience a whining noise from the differential on deceleration at speeds of around 112 Km/h/70 mph. This bulletin provides a procedure to "retune" the differential mounting bracket by adding mass (weight) to it.

Action:

In case of a customer complaint of the above condition on a 2002 MY X-TYPE remove and retune the differential mounting bracket as outlined in the following procedure.

MODIFICATION PROCEDURE

1. Raise vehicle. 2. Remove rear wheels and tires. 3. Remove the rear differential. Refer to JTIS, section: 205-02 SRO 51.25.13. 4. Remove the rear sub frame from the vehicle. Refer to JTIS, section: 502-00 SRO 64.25.01.90. 5. Remove the differential mounting bracket to rear sub frame securing bolts. 6. Remove the differential mounting bracket from the rear sub frame assembly 7. Clean outer ends of the differential mounting bracket with cleaning fluid.

8. Cut the two 120 g strips of wheel weights into four 60 g strips, remove backing tape and apply wheel weights to the differential mounting bracket (Illustration 1). Note: Firmly push along the full length of the wheel weight strips to ensure good adhesion to the differential mounting bracket. 9. Reinstall the differential mounting bracket to the rear sub frame. 10. Install the securing bolts for the differential mounting bracket. Torque figure 106 Nm. 11. Reinstall the rear sub frame to vehicle. Refer to JTIS, section: 502-00. 12. Reinstall the rear differential. Refer to JTIS, section: 205-02 SRO 51.25.13. 13. Perform the under body misalignment check in JTIS, section 502-00 SRO 64.25.01.90. 14. Reinstall rear wheel and tire assemblies. 15. Lower vehicle.

And finally, there is the following, not often talked about, TSB.

XT100-03

X-TYPE

DATE:

06/02 MODEL:

2002 MY X-TYPE VIN:

C00001-C83408 "Boom" at 2900 RPM - Rear Differential - Install Weight Under Differential

Issue:

Some 2002 MY X-TYPE vehicles may experience an unacceptable "boom" at 2900 RPM. A 2 Kg damper weight is available that can be installed under the rear final drive unit to address this concern.

Action:

In case of a customer complaint of the above condition on a 2002 X-TYPE vehicle within the above VIN range, install a new 2 kg damper beneath the rear final drive as follows:

Jag tech should have access to these oldies but goodies. If they gave you a refurbished prop shaft from an '02 there is likely nowhere that grease is going to get into the center bearing.

#19

Thanks to all for the information. I wonder if this is related to my 2003 XJR whining after i back off the accelerator. Not a transmission issue because i slipped it into neutral and it still has the same noise. Sounds terrible and seems to come from the right rear. You guys are the best.

Thread

Thread Starter

Forum

Replies

Last Post

FS[NorthWest]: 2004 X-type 3.0 24,500miles! $8500

millertic

PRIVATE For Sale / Trade or Buy Classifieds

0

09-30-2015 08:11 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)