Smog Check Computer Reset

#1

We are trying to get a smog check and they smog check center is saying that we need to drive it on the highway for 40 miles to reset the Oxygen sensor. I'm not sure that is the correct description, but I did drive it for over 50 miles on the highway at a consistent 60 MPH and we took it back to the smog check and they said that it still didn't reset.

Any idea what I should do?

Any idea what I should do?

#2

Join Date: Oct 2009

Location: Perth Ontario Canada

Posts: 11,058

Received 2,255 Likes

on

1,840 Posts

#3

All the requirements are in the related DTC summary that Jaguar publishes.

OBD SYSTEM READINESS – ENGINE MANAGEMENT

If DTC P1000 is flagged after DTCs have been cleared, all engine management OBD diagnostic monitor drive cycles HAVE NOT BEEN COMPLETED.

If DTC P1111 is flagged after DTCs have been cleared, all engine management OBD diagnostic monitor drive cycles HAVE BEEN COMPLETED.

OBD SYSTEM READINESS – TRANSMISSION

Use WDS Datalogger “TOTAL NUMBER OF DTC SET” to determine if transmission OBD monitoring has been completed.

OBD “TRIPS”

The OBD system defines 1 TRIP as an ignition cycle (ignition key OFF; wait 30 seconds; ignition key ON) plus a minimum engine coolant temperature increase of 22 °C

(40 °F) after which, the engine coolant temperature has to reach a minimum of 71 °C (160 °F).

OBD DIAGNOSTIC MONITORS

The Engine Management and Transmission Control systems are continuously checked during vehicle operation by the Engine Control Module (ECM) and Transmission

Control Module (TCM) on-board diagnostic (OBD) facilities. Powertrain OBD incorporates seven diagnostic monitors. Each monitor has an associated group of DTCs.

The diagnostic monitors will complete the diagnostic test(s) if a specified service “drive cycle” is carried out.

The seven diagnostic monitors are as follows:

– Heated Oxygen Sensors Monitor

– Adaptive Fuel Monitor

– Misfire Monitor

– Catalyst Efficiency Monitor

– Evaporative System Monitor

– Exhaust Gas Recirculation Monitor

– Comprehensive Component Monitor (Engine Management / Transmission)

DIAGNOSTIC MONITORS DRIVE CYCLES

Technicians can ensure that an OBD Monitor drive cycle is completed and that all or specific components have been checked by completing a specifieddrive cycle.

Use the following service drive cycles to confirm that the components and subsystems covered by the Diagnostic Monitors are operating correctly.

HEATED OXYGEN SENSORS MONITOR DRIVE CYCLE

Upstream (Universal) oxygen sensors:

1 Engine OFF; cooling fans inoperative >20 seconds.

2 Start engine and bring to normal operating temperature >82 °C (180 °F).

3 Drive the vehicle between 3000 – 4000 rpm in 3rd gear at a steady speed. Lift foot completely off accelerator and coast to a stop within 30 seconds. Do not touch

accelerator pedal for 4 seconds after coming to a stop.

4 Repeat Step 3.

5 Idle engine for 11 minutes.

Downstream oxygen sensors:

1 Start engine and bring to normal operating temperature >82 °C (180 °F).

2 Drive the vehicle steadily between 48 – 97 km/h (30 – 60 mph) for 10 minutes.

3 Drive the vehicle above 3000 rpm in 3rd gear at a steady speed. Lift foot completely off accelerator and coast for 30 seconds.

Oxygen sensor heaters:

1 Start engine and bring to normal operating temperature >82 °C (180 °F).

2 Idle engine for 3 minutes.

ADAPTIVE FUEL MONITOR DRIVE CYCLE

1 Start engine and bring to normal operating temperature >82 °C (180 °F).

2 Idle for a minimum of 10 minutes.

MISFIRE MONITOR DRIVE CYCLE

1 Record flagged DTC (s) and accompanying WDS DTC Monitor freeze frame(s) data.

2 Fuel level >25%.

3 Start the engine at a coolant temperature lower than the recorded freeze frame value (from Step 1).

4 Drive the vehicle to the recorded freeze frame conditions for 4 minutes. If CHECK ENGINE MIL flashes, lower the engine speed until the flashing stops.

Note regarding misfire monitor DTCs:

If, on the first trip, the misfire is severe enough to cause excess exhaust emission, the individual cylinder DTC plus DTC P1316 will be logged. The

CHECK ENGINE MIL will not be activated. If the fault recurs on the second trip, the individual cylinder DTC plus DTC P1316 will be flagged, and the

CHECK ENGINE MIL will be activated.

If, on the first trip, the misfire is severe enough to cause catalyst damage (more severe than excess exhaust emission), the CHECK ENGINE MIL will flash while the

fault is present and the individual cylinder DTC plus DTC P1313 (bank 1), DTC P1314 (bank 2) will be logged. When the fault is no longer present the MIL will be

deactivated. If the fault recurs on the second trip, the CHECK ENGINE MIL will flash while the fault is present and the individual cylinder DTC plus DTC P1313 (bank 1),

DTC P1314 (bank 2) will be flagged. When the fault is no longer present the CHECK ENGINE MIL will be activated.

CATALYST EFFICIENCY MONITOR DRIVE CYCLE

1 Start engine and bring to normal operating temperature >75 °C (167 °F).

2 With the gear selector in Park or Neutral, hold the engine speed at 2500 rpm for 5 minutes.

3 Drive vehicle ensuring that vehicle speed exceeds 15 km/h (10 mph) and the engine speed exceeds 1500 rpm.

4 Stop the vehicle and check for any temporary DTCs using WDS.

EVAPORATIVE SYSTEM MONITOR DRIVE CYCLE (OBD II ONLY)

1 Ensure that fuel filler cap is fully closed (minimum three clicks, clockwise).

2 Fuel level >30% and <85%.

3 Using WDS, perform ECM DTC Clear (even if no DTCs are flagged).

4 Drive vehicle for a minimum of 2 minutes, and until engine is at normal operating temperature.

5 Using WDS, ensure that the EVAP Canister Purge Valve is operating by observing “PURGE VAPOR MANAGEMENT VALVE – DUTY CYCLE”. If the valve is not

active, ECM adaptions have not been learned. Conduct a “green ECM” Drive Cycle as described in Technical Service Bulletin.

6 Drive vehicle to the road where the EVAP System Drive Cycle will be conducted. Stop vehicle and switch OFF the ignition. Leave ignition OFF for 30 seconds, then

restart the engine.

7 Accelerate briskly to 80 km/h (50 mph) ensuring that the engine speed reaches a minimum of 3500 rpm for a minimum of 5 seconds.

8 (0.040 inch EVAP Test) View WDS “PURGE VAPOR MANAGEMENT VALVE – DUTY CYCLE”, “CANISTER CLOSE VALVE – VAPOR RECOVERY SYSTEM”, and

FUEL TANK PRESSURE – VAPOR RECOVERY SYSTEM”. Avoiding high engine loads, drive the vehicle steadily between 65 km/h (40 mph) and 100 km/h

(60 mph). Avoid driving conditions that will produce excessive fuel movement. WDS should give an indication that the test is active (it may take up to 30 minutes

before the test will initialize). When the test has initialized (EVAP Canister Close Valve CLOSED), it will take approximately 90 seconds for the test to complete.

9 (0.020 inch EVAP Test) Continue driving vehicle as explained in Step 8 for an additional 10 minutes.

10 Gently coast the vehicle to a stop. Allow the engine to idle for 2 minutes and view WDS “PURGE VAPOR MANAGEMENT VALVE – DUTY CYCLE”, “CANISTER

CLOSE VALVE – VAPOR RECOVERY SYSTEM”, and FUEL TANK PRESSURE – VAPOR RECOVERY SYSTEM”. WDS should give an indication that the test is

active. When the test has initialized (EVAP Canister Close Valve CLOSED), it will take approximately 90 seconds for the test to complete.

11 If the 0.020 inch EVAP Test is not activated, the purge system vapor concentration may be too great. To reduce the vapor concentration proceed as follows:

12 Drive the vehicle for an additional 30 minutes avoiding driving conditions that will produce excessive fuel movement. Repeat Step 10. If the 0.020 inch EVAP Test

is still not activated, repeat the Drive Cycle from Step 6.

13 Using WDS, check for and clear flagged DTCs.

EXHAUST GAS RECIRCULATION MONITOR DRIVE CYCLE

1 Start engine and bring to normal operating temperature >82 °C (180 °F).

2 Drive the vehicle in 3rd gear at 2500 rpm. Maintain a steady speed for 1 minute, then lift foot completely off accelerator and coast for a minimum of 10 seconds.

COMPREHENSIVE COMPONENT MONITOR ENGINE MANAGEMENT DRIVE CYCLE

To avoid unnecessary complexity, a single comprehensive engine management drive cycle has not been developed for the XJ. Refer to the individual DTC for specific

drive cycle / monitoring conditions.

COMPREHENSIVE COMPONENT MONITOR TRANSMISSION DRIVE CYCLE

To avoid unnecessary complexity, a single comprehensive transmission drive cycle has not been developed for the XJ. Refer to the individual DTC for specific drive

cycle / monitoring conditions.

OBD SYSTEM READINESS – ENGINE MANAGEMENT

If DTC P1000 is flagged after DTCs have been cleared, all engine management OBD diagnostic monitor drive cycles HAVE NOT BEEN COMPLETED.

If DTC P1111 is flagged after DTCs have been cleared, all engine management OBD diagnostic monitor drive cycles HAVE BEEN COMPLETED.

OBD SYSTEM READINESS – TRANSMISSION

Use WDS Datalogger “TOTAL NUMBER OF DTC SET” to determine if transmission OBD monitoring has been completed.

OBD “TRIPS”

The OBD system defines 1 TRIP as an ignition cycle (ignition key OFF; wait 30 seconds; ignition key ON) plus a minimum engine coolant temperature increase of 22 °C

(40 °F) after which, the engine coolant temperature has to reach a minimum of 71 °C (160 °F).

OBD DIAGNOSTIC MONITORS

The Engine Management and Transmission Control systems are continuously checked during vehicle operation by the Engine Control Module (ECM) and Transmission

Control Module (TCM) on-board diagnostic (OBD) facilities. Powertrain OBD incorporates seven diagnostic monitors. Each monitor has an associated group of DTCs.

The diagnostic monitors will complete the diagnostic test(s) if a specified service “drive cycle” is carried out.

The seven diagnostic monitors are as follows:

– Heated Oxygen Sensors Monitor

– Adaptive Fuel Monitor

– Misfire Monitor

– Catalyst Efficiency Monitor

– Evaporative System Monitor

– Exhaust Gas Recirculation Monitor

– Comprehensive Component Monitor (Engine Management / Transmission)

DIAGNOSTIC MONITORS DRIVE CYCLES

Technicians can ensure that an OBD Monitor drive cycle is completed and that all or specific components have been checked by completing a specifieddrive cycle.

Use the following service drive cycles to confirm that the components and subsystems covered by the Diagnostic Monitors are operating correctly.

HEATED OXYGEN SENSORS MONITOR DRIVE CYCLE

Upstream (Universal) oxygen sensors:

1 Engine OFF; cooling fans inoperative >20 seconds.

2 Start engine and bring to normal operating temperature >82 °C (180 °F).

3 Drive the vehicle between 3000 – 4000 rpm in 3rd gear at a steady speed. Lift foot completely off accelerator and coast to a stop within 30 seconds. Do not touch

accelerator pedal for 4 seconds after coming to a stop.

4 Repeat Step 3.

5 Idle engine for 11 minutes.

Downstream oxygen sensors:

1 Start engine and bring to normal operating temperature >82 °C (180 °F).

2 Drive the vehicle steadily between 48 – 97 km/h (30 – 60 mph) for 10 minutes.

3 Drive the vehicle above 3000 rpm in 3rd gear at a steady speed. Lift foot completely off accelerator and coast for 30 seconds.

Oxygen sensor heaters:

1 Start engine and bring to normal operating temperature >82 °C (180 °F).

2 Idle engine for 3 minutes.

ADAPTIVE FUEL MONITOR DRIVE CYCLE

1 Start engine and bring to normal operating temperature >82 °C (180 °F).

2 Idle for a minimum of 10 minutes.

MISFIRE MONITOR DRIVE CYCLE

1 Record flagged DTC (s) and accompanying WDS DTC Monitor freeze frame(s) data.

2 Fuel level >25%.

3 Start the engine at a coolant temperature lower than the recorded freeze frame value (from Step 1).

4 Drive the vehicle to the recorded freeze frame conditions for 4 minutes. If CHECK ENGINE MIL flashes, lower the engine speed until the flashing stops.

Note regarding misfire monitor DTCs:

If, on the first trip, the misfire is severe enough to cause excess exhaust emission, the individual cylinder DTC plus DTC P1316 will be logged. The

CHECK ENGINE MIL will not be activated. If the fault recurs on the second trip, the individual cylinder DTC plus DTC P1316 will be flagged, and the

CHECK ENGINE MIL will be activated.

If, on the first trip, the misfire is severe enough to cause catalyst damage (more severe than excess exhaust emission), the CHECK ENGINE MIL will flash while the

fault is present and the individual cylinder DTC plus DTC P1313 (bank 1), DTC P1314 (bank 2) will be logged. When the fault is no longer present the MIL will be

deactivated. If the fault recurs on the second trip, the CHECK ENGINE MIL will flash while the fault is present and the individual cylinder DTC plus DTC P1313 (bank 1),

DTC P1314 (bank 2) will be flagged. When the fault is no longer present the CHECK ENGINE MIL will be activated.

CATALYST EFFICIENCY MONITOR DRIVE CYCLE

1 Start engine and bring to normal operating temperature >75 °C (167 °F).

2 With the gear selector in Park or Neutral, hold the engine speed at 2500 rpm for 5 minutes.

3 Drive vehicle ensuring that vehicle speed exceeds 15 km/h (10 mph) and the engine speed exceeds 1500 rpm.

4 Stop the vehicle and check for any temporary DTCs using WDS.

EVAPORATIVE SYSTEM MONITOR DRIVE CYCLE (OBD II ONLY)

1 Ensure that fuel filler cap is fully closed (minimum three clicks, clockwise).

2 Fuel level >30% and <85%.

3 Using WDS, perform ECM DTC Clear (even if no DTCs are flagged).

4 Drive vehicle for a minimum of 2 minutes, and until engine is at normal operating temperature.

5 Using WDS, ensure that the EVAP Canister Purge Valve is operating by observing “PURGE VAPOR MANAGEMENT VALVE – DUTY CYCLE”. If the valve is not

active, ECM adaptions have not been learned. Conduct a “green ECM” Drive Cycle as described in Technical Service Bulletin.

6 Drive vehicle to the road where the EVAP System Drive Cycle will be conducted. Stop vehicle and switch OFF the ignition. Leave ignition OFF for 30 seconds, then

restart the engine.

7 Accelerate briskly to 80 km/h (50 mph) ensuring that the engine speed reaches a minimum of 3500 rpm for a minimum of 5 seconds.

8 (0.040 inch EVAP Test) View WDS “PURGE VAPOR MANAGEMENT VALVE – DUTY CYCLE”, “CANISTER CLOSE VALVE – VAPOR RECOVERY SYSTEM”, and

FUEL TANK PRESSURE – VAPOR RECOVERY SYSTEM”. Avoiding high engine loads, drive the vehicle steadily between 65 km/h (40 mph) and 100 km/h

(60 mph). Avoid driving conditions that will produce excessive fuel movement. WDS should give an indication that the test is active (it may take up to 30 minutes

before the test will initialize). When the test has initialized (EVAP Canister Close Valve CLOSED), it will take approximately 90 seconds for the test to complete.

9 (0.020 inch EVAP Test) Continue driving vehicle as explained in Step 8 for an additional 10 minutes.

10 Gently coast the vehicle to a stop. Allow the engine to idle for 2 minutes and view WDS “PURGE VAPOR MANAGEMENT VALVE – DUTY CYCLE”, “CANISTER

CLOSE VALVE – VAPOR RECOVERY SYSTEM”, and FUEL TANK PRESSURE – VAPOR RECOVERY SYSTEM”. WDS should give an indication that the test is

active. When the test has initialized (EVAP Canister Close Valve CLOSED), it will take approximately 90 seconds for the test to complete.

11 If the 0.020 inch EVAP Test is not activated, the purge system vapor concentration may be too great. To reduce the vapor concentration proceed as follows:

12 Drive the vehicle for an additional 30 minutes avoiding driving conditions that will produce excessive fuel movement. Repeat Step 10. If the 0.020 inch EVAP Test

is still not activated, repeat the Drive Cycle from Step 6.

13 Using WDS, check for and clear flagged DTCs.

EXHAUST GAS RECIRCULATION MONITOR DRIVE CYCLE

1 Start engine and bring to normal operating temperature >82 °C (180 °F).

2 Drive the vehicle in 3rd gear at 2500 rpm. Maintain a steady speed for 1 minute, then lift foot completely off accelerator and coast for a minimum of 10 seconds.

COMPREHENSIVE COMPONENT MONITOR ENGINE MANAGEMENT DRIVE CYCLE

To avoid unnecessary complexity, a single comprehensive engine management drive cycle has not been developed for the XJ. Refer to the individual DTC for specific

drive cycle / monitoring conditions.

COMPREHENSIVE COMPONENT MONITOR TRANSMISSION DRIVE CYCLE

To avoid unnecessary complexity, a single comprehensive transmission drive cycle has not been developed for the XJ. Refer to the individual DTC for specific drive

cycle / monitoring conditions.

#5

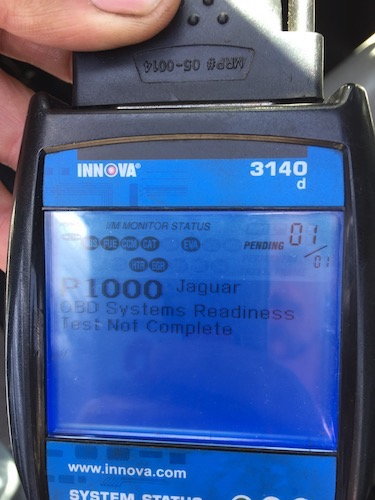

Probably best to get your own OBD tool - one that also reads live data.

That way you can check for codes, pending codes, sensor etc values, OBD monitor status etc.

---

The current situation shows you have at least one fault so more data (like the above) will give you a chance to find what's wrong.

That way you can check for codes, pending codes, sensor etc values, OBD monitor status etc.

---

The current situation shows you have at least one fault so more data (like the above) will give you a chance to find what's wrong.

#6

#7

Trending Topics

#8

#9

Join Date: Oct 2009

Location: Perth Ontario Canada

Posts: 11,058

Received 2,255 Likes

on

1,840 Posts

No idea what an 'O2S light' is.

The only code showing is P1000 which means that one or more system monitors is not yet set. You must drive the car until all the monitors have completed the self tests at which time P1000 will be replaced by P1111.

The only code showing is P1000 which means that one or more system monitors is not yet set. You must drive the car until all the monitors have completed the self tests at which time P1000 will be replaced by P1111.

#10

#12

Thanks for all your help. I did the recommended procedure for the upstream and downstream ixygen sensors.

That worked!

Got the smog check and all is well!

Also I bought a KOBRA Wireless OBD2 on Amazon and it works great as well.

Thanks again for all your help!

3 Drive the vehicle above 3000 rpm in 3rd gear at a steady speed. Lift foot completely off accelerator and coast for 30 seconds.

Got the smog check and all is well!

Also I bought a KOBRA Wireless OBD2 on Amazon and it works great as well.

Thanks again for all your help!

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)