anyone know FINAL torque value cylinder head bolts

#1

Just picked up a cream puff off of Craigslist (2002 xj8 vdp) cheap. Bought it from a guy who bought it with a hg problem and tried to fix it but was unsuccessful. Car runs and drives, but does blow white smoke. I was able to drive it to my house, but checked the oil and it's a milkshake for sure. He said he replaced the hg's (showed me the old ones and the boxes and receipt for the new ones as well as a receipt from a machine shop for skimming the heads (so i know he did the work), I asked him his torue values for the hg and he was not sure. He had a receipt from an oil change 2 days ago with the vin on there btw, so this is the new oil being milkshaked.

So, I want to grab my torque wrench and slowly up the torque numbers until it doesn't click and starts turning the bolt; but want to know what the final value is. He explained the pattern he used and it was the right pattern; I am hoping he may have forgot the last 45 degree turn! Ive searched and searched with no luck on this number. If I had to guess, I would say 80lbs?

So, I want to grab my torque wrench and slowly up the torque numbers until it doesn't click and starts turning the bolt; but want to know what the final value is. He explained the pattern he used and it was the right pattern; I am hoping he may have forgot the last 45 degree turn! Ive searched and searched with no luck on this number. If I had to guess, I would say 80lbs?

#2

The following users liked this post:

xjrwithproblems (12-14-2011)

#3

Hi Mark

Update:

The images in your last post seem to be changing everytime I look at the posting. When you insert an image in the post, you need to upload it to another website (such photobucket.com) then use the Insert Image and enter the website link for that image you uploaded to that website. You can also use the Go Advance editing and use Attachments to upload files from your PC as attachments that will be viewed a snapshot in the posting. It appear that you copied and pasted information from your Alldata webpage subscription into the posting. I right clicked your images in the posting and they show the Alldata weblinks.

End of Update.

Looks like all the torque values are correct, but the diagrams do not look like the correct ones for the 98-03 Jaguar XJ8.

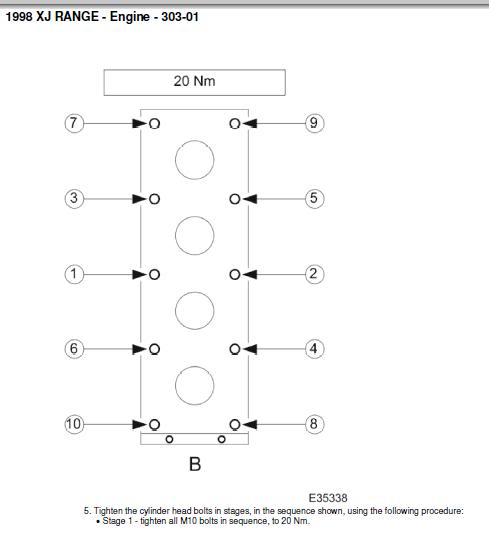

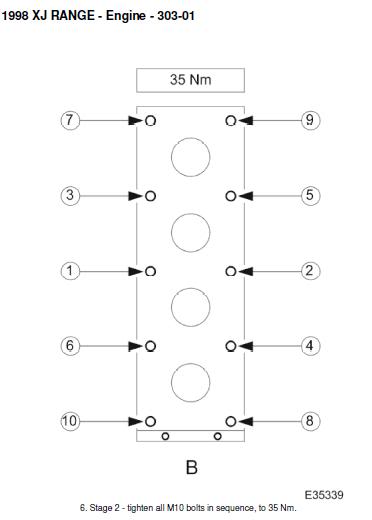

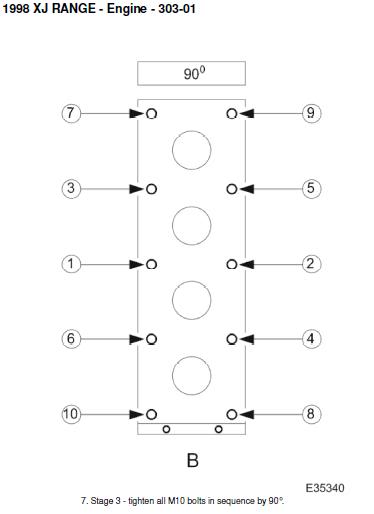

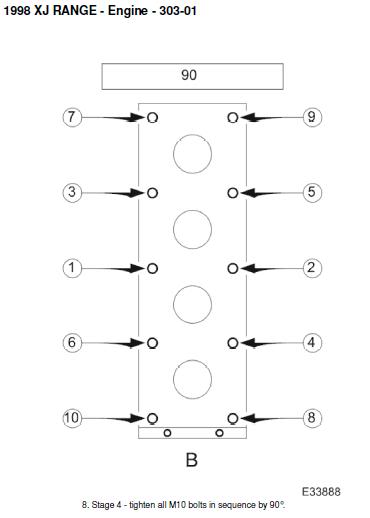

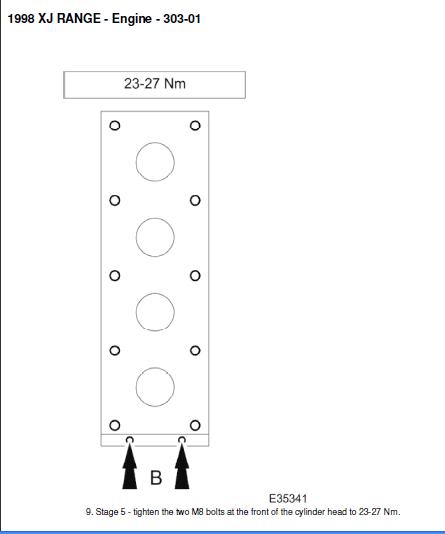

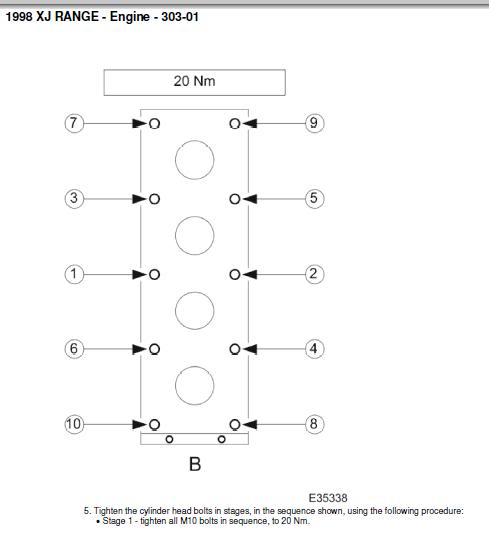

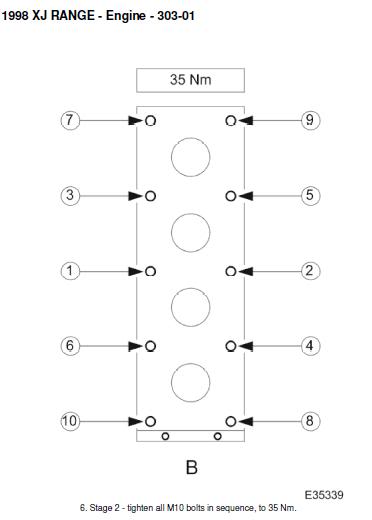

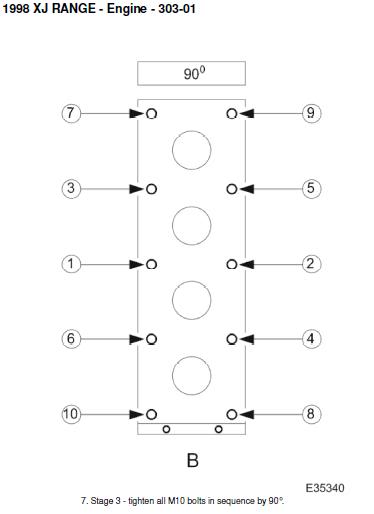

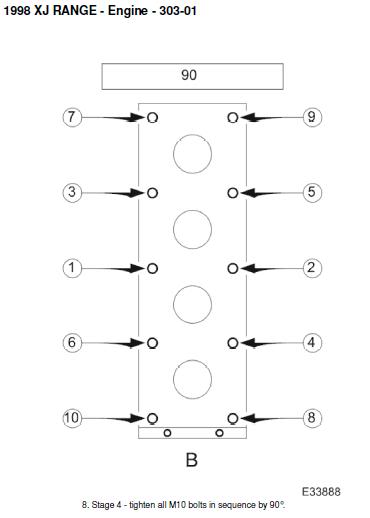

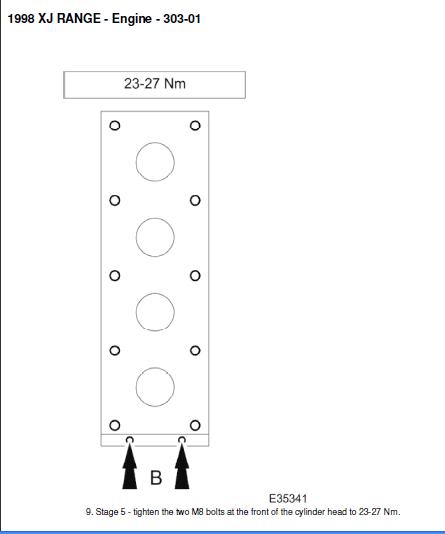

Here are page extracts from the JTIS shop repair manual (also I checked my 2001 XJ8 AlldataDIY subscription and found the exact same diagrams):

Jim Lombardi

Update:

The images in your last post seem to be changing everytime I look at the posting. When you insert an image in the post, you need to upload it to another website (such photobucket.com) then use the Insert Image and enter the website link for that image you uploaded to that website. You can also use the Go Advance editing and use Attachments to upload files from your PC as attachments that will be viewed a snapshot in the posting. It appear that you copied and pasted information from your Alldata webpage subscription into the posting. I right clicked your images in the posting and they show the Alldata weblinks.

End of Update.

Looks like all the torque values are correct, but the diagrams do not look like the correct ones for the 98-03 Jaguar XJ8.

Here are page extracts from the JTIS shop repair manual (also I checked my 2001 XJ8 AlldataDIY subscription and found the exact same diagrams):

Jim Lombardi

Last edited by jimlombardi; 12-13-2011 at 04:02 PM.

The following users liked this post:

xjrwithproblems (12-14-2011)

#4

#5

I don't think you'll find an actual torque value because the bolts are torque-to-yield. The procedure basically uses the torque values to crush the gasket like a preload. The final torque angle is used to stretch the bolts. The engineers have determined that a very specific amount of bolt stretch will provide a specific amount of clamping force. Simply torquing a bolt does not get a specific clamping effect as other factors could affect how the bolt does the clamping, the easiest example would be debris in the threads. This debris could give a torque value where a clean hole may not. To remove this doubt, engineers use the torque angle sequence to provide the proper clamping. Upon removal, those bolts are very tight and actually snap free when using a breaker bar.

As far as the white smoke, could be many things that include moisture in the cats, moisture in the exhaust, another HG failure, etc...

As far as the white smoke, could be many things that include moisture in the cats, moisture in the exhaust, another HG failure, etc...

The following users liked this post:

xjrwithproblems (12-14-2011)

#7

Trending Topics

#8

When I posted that stuff this morning, I did a copy and paste from a word doc. Guess that doesn't work to well; but, it was funny ...

I deleted everything from that post so that you won't have to scroll through it all. I could put back if you want to keep the entertainment value.

So, with all of the discussion above, what do you think about studs versus bolts on these engines?

I deleted everything from that post so that you won't have to scroll through it all. I could put back if you want to keep the entertainment value.

So, with all of the discussion above, what do you think about studs versus bolts on these engines?

#9

I know it would be better to start from scratch, I probably will anyway because I would need to take the chains off to do the heads, but i was just trying to save on buying new gaskets and bolts, as they are clearly new. I'm going to keep this car, so I would probably go with ARP head studs, maybe even put in the 4.2 metal gaskets if they work but i need to do a little more research.

#10

Jimlombardi and Hispeed, thanks for those diagrams. And Blackx300, thanks for the in depth view of stretch bolts.

What I actually think I'm going to do is push air in each cylinder and see which hole creates bubbles in the reservoir tank. that will give me a better idea if all, or just some, or even one bolt is properly torqued.

What I actually think I'm going to do is push air in each cylinder and see which hole creates bubbles in the reservoir tank. that will give me a better idea if all, or just some, or even one bolt is properly torqued.

#11

I predict a small disater with the proposed method of testind. I doubt the leak is caused by ther gasket is not tight. Although my experience is limited to several engines and situations for head gaskets, in general, gasket leak is caused by a mechanical failure. In my XJR case, the metal crush ring had somehow migrated inward towards the cylinder and had developed a crack at a singel point. No amount of tightening could have slowed the leak, and I doubt there is much extra bolt stretch before the bolt breaks.

In a production environment, the relationship between angle and torque is measured and a stretch bolt is tightened until it's torque begins reducing after a maximum level and the angle is set after that.

In a production environment, the relationship between angle and torque is measured and a stretch bolt is tightened until it's torque begins reducing after a maximum level and the angle is set after that.

Last edited by sparkenzap; 12-14-2011 at 04:04 AM.

#12

Cometic has MLS gaskets, and you can get them in different thicknesses. The 4.2 jaguar gaskets are about 0.030” thick, whereas your 4.0 composite gaskets are about 0.050”.

The thinner 0.030”one would work, but slightly increase compression (would guess to about 9.3 or so).

Here are the correct partnos for the Cometic ones if you want to go the same thickness:

1xC4376 0.050 "87mm AND 1xC43770.050" 87mm

Disadvantage of the arp studs, is that you need to lift the engine as you can’t take of/install the heads with the engine in place. I have been using the stock torque to yield bolts without any issues, even with the power output I have, so they go a long way. Just make sure that when you install new bolts that the threads in the block are 100% clean.

The thinner 0.030”one would work, but slightly increase compression (would guess to about 9.3 or so).

Here are the correct partnos for the Cometic ones if you want to go the same thickness:

1xC4376 0.050 "87mm AND 1xC43770.050" 87mm

Disadvantage of the arp studs, is that you need to lift the engine as you can’t take of/install the heads with the engine in place. I have been using the stock torque to yield bolts without any issues, even with the power output I have, so they go a long way. Just make sure that when you install new bolts that the threads in the block are 100% clean.

#13

Thread

Thread Starter

Forum

Replies

Last Post

aholbro1

XJ XJ6 / XJR6 ( X300 )

17

08-05-2021 05:02 AM

al_roethlisberger

XJ XJ6 / XJR6 ( X300 )

7

09-11-2015 10:04 PM

joesoap

XJ XJ6 / XJ8 / XJR ( X350 & X358 )

13

09-10-2015 01:09 AM

1964Daimler

MKI / MKII S type 240 340 & Daimler

2

09-09-2015 11:20 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)