HELP! Mystery rough idle problem has us baffled!

#1

Hello Fellow Jag Friends:

As many of you know, I've been "restoring" a 2001 VDP that wasn't very well cared for by the previous owner.

In addition to many routine maintenance things I've done (brakes, hoses, filters, bushings, thermostats, shocks, tie-rod ends, etc.), there has been a nagging ROUGH IDLE that is baffling me.

During a complimentary oil change at the Jag dealer, they did a brief inspection and also read codes. P1341 (Cam shaft position sensor fault) was thrown.

I proceeded to work on other areas of the car, such as replace the spark plugs... (made no difference)... replace the full and part-load breathers... replace the cam cover... etc etc., simply to address the known issues.

I then turned my attention back to the rough idle. A mobile mechanic with much Jag experience suggested that it's likely due to a bad ignition coil, but rather than swapping them all out, said I should get the codes read and see which cylinders are misfiring.

Another mobile mechanic--very thorough in his testing (keep reading)--did so... and got misfires on 7 & 8. We ran the gamut on testing for this issue and still came up short.

This is a total mystery and it's to the point now that if I can't resolve it, there's no sense in putting any more time or money fixing other parts of the car (which I'm happy to do, and enjoying the process of seeing the cat become healthy again), but since the rough idle is so annoying, it's not fun to drive.

I know there are many real experts in this forum... and many of you have helped me in the past... and I'm hoping you can steer me (and my mechanic) in the right direction. Short of paying $140/hour for my local Jag dealer to rerun all the diagnostics that my current mechanic already performed (no doubt they'd say it was necessary for them to do so), I'm hoping that you guys can shed some light on this VERY BAFFLING issue.

Here are all the tests performed. Thanks to Jim L. for providing me with the diagnostic flow-chart which my mechanic followed. I'm posting this in hopes that not only can someone help ME with this issue, but also other Jag owners who might be experiencing the same challenge... or will be ONE day.

I received this following report via email from my mechanic. I requested it so that I could post this to my knowledgeable Jag friends here in this forum:

When we started on your car the very first day, it came up with the following codes:

P0300 - Random/Multiple Cylinder Misfire Detected

P0307 - Cylinder 7 (Bank B, #3) Cylinder Misfire Detected

P0308 - Cylinder 8 (Bank B, #4 Cylinder Misfire Detected

P1316 - Misfire rate exceeds emissions

P0560 - System Voltage Low

I can attest the P0560 to the battery drain that you have been having, so we will set that aside for the moment. So on to the simplest way to check if Cyl 7 and 8 have bad coils, we swap them. I come back the following week, check the codes and we have the following:

P0300 - Random/Multiple Cylinder Misfire Detected

P0307 - Cylinder 7 (Bank B, #3) Cylinder Misfire Detected

P0308 - Cylinder 8 (Bank B, #4) Cylinder Misfire Detected

Then we delve into the very thorough and fantastic Pin Point Test List provided by Jaguar below:

(Our Results in BOLD)

2001 XJ RANGE - Engine Ignition - 303-07

Pinpoint Tests

A : DTC P0300, P0351, P0352, P0353, P0354, P0355, P0356, P0357, P0358, P1367, P1368; RANDOM

MISFIRE DETECTED, COIL PRIMARY/SECONDARY CIRCUIT MALFUNCTION, IGNITION MONITOR

MALFUNCTION

NOTE:

Unless multiple cylinder misfires are apparent, only one circuit will normally need to be tested. The DTC set will

indicate which cylinder is misfiring.

A1 : CHECK COIL FUNCTION BY SUBSTITUTION

1. Swap the suspect coil for a known good unit.

2. CLEAR the DTC. TEST the system for normal operation.

„hDoes the same DTC reoccur? The DTC will indicate if the same cylinder is misfiring.

-> Yes

INSTALL a new coil. CLEAR the DTC. TEST the system for normal operation.

-> No

We swapped coil packs 5 to 7 and 6 to 8. The same DTC occured

Goto <<A2>>

A2 : CHECK THE IGNITION COIL SUPPLY VOLTAGE

1. Disconnect the relevant ignition coil electrical connector(s).

2. Turn the ignition switch to the ON position.

3. Make sure the ignition coil relay is energised.

4. Measure the voltage between:

„hƒnCyl 1 PI51, pin 4 (PW) and GROUND.

„hƒnCyl 2 PI55, pin 4 (PW) and GROUND.

„hƒnCyl 3 PI52, pin 4 (PW) and GROUND.

„hƒnCyl 4 PI56, pin 4 (PW) and GROUND.

„hƒnCyl 5 PI53, pin 4 (PW) and GROUND.

„hƒnCyl 6 PI57, pin 4 (PW) and GROUND.

„hƒnCyl 7 PI54, pin 4 (PW) and GROUND.

„hƒnCyl 8 PI58, pin 4 (PW) and GROUND.

„hIs the voltage less than 10.5 Volts?

-> Yes

REPAIR the relevant ignition coil supply voltage circuit. This circuit includes the ignition coil relay. For

additional information, refer to the wiring diagrams. CLEAR the DTCs. TEST the system for normal

operation.

-> No

All 8 cylinders tested out to 12.56v with the ignition on

Goto <<A3>>

A3 : CHECK THE IGNITION COIL GROUND CIRCUIT

1. Turn the ignition switch to the OFF position.

2. Disconnect the relevant ignition coil electrical connector(s).

3. Measure the resistance between:

„hƒnCyl 1 PI51, pin 1 (B) and GROUND.

„hƒnCyl 2 PI55, pin 1 (B) and GROUND.

„hƒnCyl 3 PI52, pin 1 (B) and GROUND.

„hƒnCyl 4 PI56, pin 1 (B) and GROUND.

„hƒnCyl 5 PI53, pin 1 (B) and GROUND.

„hƒnCyl 6 PI57, pin 1 (B) and GROUND.

„hƒnCyl 7 PI54, pin 1 (B) and GROUND.

„hƒnCyl 8 PI58, pin 1 (B) and GROUND.

„hIs the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTCs. TEST the system for normal operation.

-> No

Passed the test.

Goto <<A4>>

A4 : CHECK THE IGNITION COIL SWITCHING CIRCUITS FOR HIGH RESISTANCE

1. Disconnect the battery negative terminal.

2. Disconnect the ECM electrical connector, EM84.

3. Disconnect the relevant ignition coil electrical connector(s).

4. Measure the resistance between:

„hƒnCyl 1 PI51, pin 1 (GU) and EM84, pin 12 (GU).

„hƒnCyl 2 PI55, pin 3 (GB) and EM84, pin 20 (GB).

„hƒnCyl 3 PI52, pin 3 (GR) and EM84, pin 11 (GR).

„hƒnCyl 4 PI56, pin 3 (GS) and EM84, pin 19 (GS).

„hƒnCyl 5 PI53, pin 3 (GO) and EM84, pin 10 (GO).

„hƒnCyl 6 PI57, pin 3 (GK) and EM84, pin 18 (GK).

„hƒnCyl 7 PI54, pin 3 (GW) and EM84, pin 09 (GW).

„hƒnCyl 8 PI58, pin 3 (GP) and EM84, pin 17 (GP).

„hIs the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTCs. TEST the system for normal operation.

-> No

Passed the test.

Goto <<A5>>

A5 : CHECK THE IGNITION COIL (CYLS 1, 4, 6, AND 7) MONITOR CIRCUITS FOR HIGH

RESISTANCE

1. Reconnect the ECM electrical connector, EM84.

2. Disconnect the ECM electrical connector, EM83.

3. Disconnect the relevant ignition coil electrical connector(s).

4. Measure the resistance between:

„hƒnCyl 1 PI51, pin 2 (YG) and EM83, pin 10 (YG).

„hƒnCyl 4 PI56, pin 2 (YG) and EM83, pin 10 (YG).

„hƒnCyl 6 PI57, pin 2 (YG) and EM83, pin 10 (YG).

„hƒnCyl 7 PI54, pin 2 (YG) and EM83, pin 10 (YG).

„hIs the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. This circuit includes the harness splice, PIS11. For additional

information, refer to the wiring diagrams. CLEAR the DTCs. TEST the system for normal operation.

-> No

Passed the test.

Goto <<A6>>

A6 : CHECK THE IGNITION COIL (CYLS 1, 4, 6, AND 7) MONITOR CIRCUITS FOR SHORT TO B+

VOLTAGE

1. Reconnect the battery negative terminal.

2. Disconnect the relevant ignition coil electrical connector(s).

3. Measure the voltage between:

„hƒnCyl 1 PI51, pin 2 (YG) and GROUND.

„hƒnCyl 4 PI56, pin 2 (YG) and GROUND.

„hƒnCyl 6 PI57, pin 2 (YG) and GROUND.

„hƒnCyl 7 PI54, pin 2 (YG) and GROUND.

„hIs the voltage greater than 1 volt?

-> Yes

REPAIR the short to B+ voltage. For additional information, refer to the wiring diagrams. CLEAR the DTCs.

TEST the system for normal operation.

-> No

No voltage was found in the above circuits.

Goto <<A7>>

A7 : CHECK THE IGNITION COIL (CYLS 1, 4, 6, AND 7) MONITOR CIRCUITS FOR SHORT TO

GROUND

1. Disconnect the relevant ignition coil electrical connector(s).

3 2012-05-02

2001 XJ RANGE - Engine Ignition - 303-07

2. Measure the resistance between:

„hƒnCyl 1 PI51, pin 2 (YG) and GROUND.

„hƒnCyl 4 PI56, pin 2 (YG) and GROUND.

„hƒnCyl 6 PI57, pin 2 (YG) and GROUND.

„hƒnCyl 7 PI54, pin 2 (YG) and GROUND.

„hIs the resistance less than 10,000 ohms?

-> Yes

REPAIR the short to GROUND. For additional information, refer to the wiring diagrams. CLEAR the DTCs.

TEST the system for normal operation.

-> No

The resistance was around 5,300 ohms, this could be part of the problem, even though the the same test for Cyls 2,3,5, and 8 had the same results, making me wonder if it is an ECM issue and not a wiring issue.

Goto <<A8>>

A8 : CHECK THE IGNITION COIL (CYLS 2, 3, 5, AND 8) MONITOR CIRCUITS FOR HIGH

RESISTANCE

1. Disconnect the relevant ignition coil electrical connector(s).

2. Measure the resistance between:

„hƒnCyl 2 PI55, pin 2 (YG) and EM83, pin 11 (YG).

„hƒnCyl 3 PI52, pin 2 (YG) and EM83, pin 11 (YG).

„hƒnCyl 5 PI53, pin 2 (YG) and EM83, pin 11 (YG).

„hƒnCyl 8 PI58, pin 2 (YG) and EM83, pin 11 (YG).

„hIs the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. This circuit includes the harness splice, PIS11. For additional

information, refer to the wiring diagrams. CLEAR the DTCs. TEST the system for normal operation.

-> No

Passed the test.

Goto <<A9>>

A9 : CHECK THE IGNITION COIL (CYLS 2, 3, 5, AND 8) MONITOR CIRCUITS FOR SHORT TO B+

VOLTAGE

1. Reconnect the battery negative terminal.

2. Disconnect the relevant ignition coil electrical connector(s).

3. Measure the voltage between:

„hƒnCyl 2 PI55, pin 2 (YG) and GROUND.

„hƒnCyl 3 PI52, pin 2 (YG) and GROUND.

„hƒnCyl 5 PI53, pin 2 (YG) and GROUND.

„hƒnCyl 8 PI58, pin 2 (YG) and GROUND.

„hIs the voltage greater than 1 volt?

-> Yes

REPAIR the short to B+ voltage. For additional information, refer to the wiring diagrams. CLEAR the DTCs.

TEST the system for normal operation.

-> No

No voltage was found in the above circuits.

Goto <<A10>>

A10 : CHECK THE IGNITION COIL (CYLS 2, 3, 5, AND 8) MONITOR CIRCUITS FOR SHORT TO

GROUND

1. Disconnect the relevant ignition coil electrical connector(s).

2. Measure the resistance between;

„hƒnCyl 2 PI55, pin 2 (YG) and GROUND.

„hƒnCyl 3 PI52, pin 2 (YG) and GROUND.

„hƒnCyl 5 PI53, pin 2 (YG) and GROUND.

„hƒnCyl 8 PI58, pin 2 (YG) and GROUND.

„hIs the resistance less than 10,000 ohms?

-> Yes

REPAIR the short to GROUND. For additional information, refer to the wiring diagrams. CLEAR the DTCs.

TEST the system for normal operation.

-> No

The resistance was around 5,300 ohms, this could be part of the problem, even though the the same test for Cyls 1,4,6, and 7 had the same results, making me wonder if it is an ECM issue and not a wiring issue.

INSTALL a new ECM. <<303-04>> Before replacing a ECM, contact Dealer technical support.

B : CHECK SPARK PLUG RESISTANCE

B1 : CHECK SPARK PLUG RESISTANCE

1. Remove the suspect spark plug(s).

2. Measure the resistance between the spark plug center electrode tip and the spark plug HT contact.

„hIs the resistance between 8,000 and 12,000 ohms? (nominal 10,000 ohms)

-> Yes

Check ignition coil and circuits. See possible sources list for misfire.

-> No

INSTALL a new spark plug. CLEAR the DTC. TEST the system for nomal operation.

The Spark Plugs all read ~4200 ohms, they are NGK Iridium, this too could also be an issue.

Next, we went on to test both cam position sensors and their circuits because the dealer told you your car had a code for it when it was in for service a few months ago. We used the following pinpoint test list.

(Our Results in BOLD)

1999 XJ RANGE - Electronic Engine Controls - 303-14

BF : DTC P0340; CAMSHAFT POSITION (CMP) SENSOR CIRCUIT MALFUNCTION

BF1 : CHECK THE CMP SENSOR FOR CORRECT INSTALLATION

1. Turn the ignition switch to the OFF position.

2. Check the CMP sensor for correct installation.

„hIs the CMP sensor correctly installed?

-> Yes

Goto <<BF2>>

-> No

INSTALL the CMP sensor correctly. CLEAR the DTCs. TEST the system for normal operation.

No brainer on this one, on to step 2.

BF2 : CHECK THE CMP SENSOR FOR FOREIGN DEBRIS

1. Remove the CMP sensor and inspect for foreign debris.

„hIs the CMP sensor free of foreign debris?

-> Yes

Goto <<BE3>>

-> No

CLEAN the sensor and wheel. INSTALL the sensor. CLEAR the DTCs. TEST the system for normal

operation

Sensor was clean of all debris, wiped off and put back in.

BF3 : CHECK THE CMP SENSOR SENSE CIRCUIT FOR HIGH RESISTANCE

1. Disconnect the battery negative terminal.

2. Disconnect the ECM electrical connector, EM13.

3. Measure the resistance between EM13, pin 20 (B) and PI15, pin 01 (B).

„hIs the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

-> No

Passed this test.

Goto <<BF3>>

BF4 : CHECK THE CMP SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

1. Reconnect the battery negative terminal.

2. Turn the ignition switch to the ON position.

3. Measure the voltage between EM13, pin 20 (B) and GROUND.

„hIs the voltage greater than 3 volts?

-> Yes

REPAIR the short circuit. For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST

the system for normal operation.

-> No

The circuits ended up having 9.44v and 9.45v respectively to each of the cam sensors, driver and passenger side.

Goto <<BF5>>

BF5 : CHECK THE CMP SENSOR SENSE CIRCUIT FOR SHORT TO GROUND

1. Turn the ignition switch to the OFF position.

2. Measure the resistance between PI15, pin 01 (B) and GROUND.

„hIs the resistance less than 10,000 ohms?

-> Yes

REPAIR the short circuit. For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST

the system for normal operation.

-> No

The circuits had 5,300 ohms on both sides.

INSTALL a new CMP sensor. CLEAR the DTC. TEST the system for normal operation.

My mechanic concluded by saying:

After all of this testing, this brings me to 3 different conclusions:

1) There has been some serious hacking or damage done to the wiring harness

2) There is something wrong with the ECM and it needs to be replaced

3) On a totally different subject, I would replace those spark plugs with ones that ohm out correctly to play it safe.

Thanks to all who can lend some assistance to this very frustrated VDP owner.

Sincerely,

SirJag

As many of you know, I've been "restoring" a 2001 VDP that wasn't very well cared for by the previous owner.

In addition to many routine maintenance things I've done (brakes, hoses, filters, bushings, thermostats, shocks, tie-rod ends, etc.), there has been a nagging ROUGH IDLE that is baffling me.

During a complimentary oil change at the Jag dealer, they did a brief inspection and also read codes. P1341 (Cam shaft position sensor fault) was thrown.

I proceeded to work on other areas of the car, such as replace the spark plugs... (made no difference)... replace the full and part-load breathers... replace the cam cover... etc etc., simply to address the known issues.

I then turned my attention back to the rough idle. A mobile mechanic with much Jag experience suggested that it's likely due to a bad ignition coil, but rather than swapping them all out, said I should get the codes read and see which cylinders are misfiring.

Another mobile mechanic--very thorough in his testing (keep reading)--did so... and got misfires on 7 & 8. We ran the gamut on testing for this issue and still came up short.

This is a total mystery and it's to the point now that if I can't resolve it, there's no sense in putting any more time or money fixing other parts of the car (which I'm happy to do, and enjoying the process of seeing the cat become healthy again), but since the rough idle is so annoying, it's not fun to drive.

I know there are many real experts in this forum... and many of you have helped me in the past... and I'm hoping you can steer me (and my mechanic) in the right direction. Short of paying $140/hour for my local Jag dealer to rerun all the diagnostics that my current mechanic already performed (no doubt they'd say it was necessary for them to do so), I'm hoping that you guys can shed some light on this VERY BAFFLING issue.

Here are all the tests performed. Thanks to Jim L. for providing me with the diagnostic flow-chart which my mechanic followed. I'm posting this in hopes that not only can someone help ME with this issue, but also other Jag owners who might be experiencing the same challenge... or will be ONE day.

I received this following report via email from my mechanic. I requested it so that I could post this to my knowledgeable Jag friends here in this forum:

SEQUENCE OF TESTING AND RESULTS

When we started on your car the very first day, it came up with the following codes:

P0300 - Random/Multiple Cylinder Misfire Detected

P0307 - Cylinder 7 (Bank B, #3) Cylinder Misfire Detected

P0308 - Cylinder 8 (Bank B, #4 Cylinder Misfire Detected

P1316 - Misfire rate exceeds emissions

P0560 - System Voltage Low

I can attest the P0560 to the battery drain that you have been having, so we will set that aside for the moment. So on to the simplest way to check if Cyl 7 and 8 have bad coils, we swap them. I come back the following week, check the codes and we have the following:

P0300 - Random/Multiple Cylinder Misfire Detected

P0307 - Cylinder 7 (Bank B, #3) Cylinder Misfire Detected

P0308 - Cylinder 8 (Bank B, #4) Cylinder Misfire Detected

Then we delve into the very thorough and fantastic Pin Point Test List provided by Jaguar below:

(Our Results in BOLD)

2001 XJ RANGE - Engine Ignition - 303-07

Pinpoint Tests

A : DTC P0300, P0351, P0352, P0353, P0354, P0355, P0356, P0357, P0358, P1367, P1368; RANDOM

MISFIRE DETECTED, COIL PRIMARY/SECONDARY CIRCUIT MALFUNCTION, IGNITION MONITOR

MALFUNCTION

NOTE:

Unless multiple cylinder misfires are apparent, only one circuit will normally need to be tested. The DTC set will

indicate which cylinder is misfiring.

A1 : CHECK COIL FUNCTION BY SUBSTITUTION

1. Swap the suspect coil for a known good unit.

2. CLEAR the DTC. TEST the system for normal operation.

„hDoes the same DTC reoccur? The DTC will indicate if the same cylinder is misfiring.

-> Yes

INSTALL a new coil. CLEAR the DTC. TEST the system for normal operation.

-> No

We swapped coil packs 5 to 7 and 6 to 8. The same DTC occured

Goto <<A2>>

A2 : CHECK THE IGNITION COIL SUPPLY VOLTAGE

1. Disconnect the relevant ignition coil electrical connector(s).

2. Turn the ignition switch to the ON position.

3. Make sure the ignition coil relay is energised.

4. Measure the voltage between:

„hƒnCyl 1 PI51, pin 4 (PW) and GROUND.

„hƒnCyl 2 PI55, pin 4 (PW) and GROUND.

„hƒnCyl 3 PI52, pin 4 (PW) and GROUND.

„hƒnCyl 4 PI56, pin 4 (PW) and GROUND.

„hƒnCyl 5 PI53, pin 4 (PW) and GROUND.

„hƒnCyl 6 PI57, pin 4 (PW) and GROUND.

„hƒnCyl 7 PI54, pin 4 (PW) and GROUND.

„hƒnCyl 8 PI58, pin 4 (PW) and GROUND.

„hIs the voltage less than 10.5 Volts?

-> Yes

REPAIR the relevant ignition coil supply voltage circuit. This circuit includes the ignition coil relay. For

additional information, refer to the wiring diagrams. CLEAR the DTCs. TEST the system for normal

operation.

-> No

All 8 cylinders tested out to 12.56v with the ignition on

Goto <<A3>>

A3 : CHECK THE IGNITION COIL GROUND CIRCUIT

1. Turn the ignition switch to the OFF position.

2. Disconnect the relevant ignition coil electrical connector(s).

3. Measure the resistance between:

„hƒnCyl 1 PI51, pin 1 (B) and GROUND.

„hƒnCyl 2 PI55, pin 1 (B) and GROUND.

„hƒnCyl 3 PI52, pin 1 (B) and GROUND.

„hƒnCyl 4 PI56, pin 1 (B) and GROUND.

„hƒnCyl 5 PI53, pin 1 (B) and GROUND.

„hƒnCyl 6 PI57, pin 1 (B) and GROUND.

„hƒnCyl 7 PI54, pin 1 (B) and GROUND.

„hƒnCyl 8 PI58, pin 1 (B) and GROUND.

„hIs the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTCs. TEST the system for normal operation.

-> No

Passed the test.

Goto <<A4>>

A4 : CHECK THE IGNITION COIL SWITCHING CIRCUITS FOR HIGH RESISTANCE

1. Disconnect the battery negative terminal.

2. Disconnect the ECM electrical connector, EM84.

3. Disconnect the relevant ignition coil electrical connector(s).

4. Measure the resistance between:

„hƒnCyl 1 PI51, pin 1 (GU) and EM84, pin 12 (GU).

„hƒnCyl 2 PI55, pin 3 (GB) and EM84, pin 20 (GB).

„hƒnCyl 3 PI52, pin 3 (GR) and EM84, pin 11 (GR).

„hƒnCyl 4 PI56, pin 3 (GS) and EM84, pin 19 (GS).

„hƒnCyl 5 PI53, pin 3 (GO) and EM84, pin 10 (GO).

„hƒnCyl 6 PI57, pin 3 (GK) and EM84, pin 18 (GK).

„hƒnCyl 7 PI54, pin 3 (GW) and EM84, pin 09 (GW).

„hƒnCyl 8 PI58, pin 3 (GP) and EM84, pin 17 (GP).

„hIs the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTCs. TEST the system for normal operation.

-> No

Passed the test.

Goto <<A5>>

A5 : CHECK THE IGNITION COIL (CYLS 1, 4, 6, AND 7) MONITOR CIRCUITS FOR HIGH

RESISTANCE

1. Reconnect the ECM electrical connector, EM84.

2. Disconnect the ECM electrical connector, EM83.

3. Disconnect the relevant ignition coil electrical connector(s).

4. Measure the resistance between:

„hƒnCyl 1 PI51, pin 2 (YG) and EM83, pin 10 (YG).

„hƒnCyl 4 PI56, pin 2 (YG) and EM83, pin 10 (YG).

„hƒnCyl 6 PI57, pin 2 (YG) and EM83, pin 10 (YG).

„hƒnCyl 7 PI54, pin 2 (YG) and EM83, pin 10 (YG).

„hIs the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. This circuit includes the harness splice, PIS11. For additional

information, refer to the wiring diagrams. CLEAR the DTCs. TEST the system for normal operation.

-> No

Passed the test.

Goto <<A6>>

A6 : CHECK THE IGNITION COIL (CYLS 1, 4, 6, AND 7) MONITOR CIRCUITS FOR SHORT TO B+

VOLTAGE

1. Reconnect the battery negative terminal.

2. Disconnect the relevant ignition coil electrical connector(s).

3. Measure the voltage between:

„hƒnCyl 1 PI51, pin 2 (YG) and GROUND.

„hƒnCyl 4 PI56, pin 2 (YG) and GROUND.

„hƒnCyl 6 PI57, pin 2 (YG) and GROUND.

„hƒnCyl 7 PI54, pin 2 (YG) and GROUND.

„hIs the voltage greater than 1 volt?

-> Yes

REPAIR the short to B+ voltage. For additional information, refer to the wiring diagrams. CLEAR the DTCs.

TEST the system for normal operation.

-> No

No voltage was found in the above circuits.

Goto <<A7>>

A7 : CHECK THE IGNITION COIL (CYLS 1, 4, 6, AND 7) MONITOR CIRCUITS FOR SHORT TO

GROUND

1. Disconnect the relevant ignition coil electrical connector(s).

3 2012-05-02

2001 XJ RANGE - Engine Ignition - 303-07

2. Measure the resistance between:

„hƒnCyl 1 PI51, pin 2 (YG) and GROUND.

„hƒnCyl 4 PI56, pin 2 (YG) and GROUND.

„hƒnCyl 6 PI57, pin 2 (YG) and GROUND.

„hƒnCyl 7 PI54, pin 2 (YG) and GROUND.

„hIs the resistance less than 10,000 ohms?

-> Yes

REPAIR the short to GROUND. For additional information, refer to the wiring diagrams. CLEAR the DTCs.

TEST the system for normal operation.

-> No

The resistance was around 5,300 ohms, this could be part of the problem, even though the the same test for Cyls 2,3,5, and 8 had the same results, making me wonder if it is an ECM issue and not a wiring issue.

Goto <<A8>>

A8 : CHECK THE IGNITION COIL (CYLS 2, 3, 5, AND 8) MONITOR CIRCUITS FOR HIGH

RESISTANCE

1. Disconnect the relevant ignition coil electrical connector(s).

2. Measure the resistance between:

„hƒnCyl 2 PI55, pin 2 (YG) and EM83, pin 11 (YG).

„hƒnCyl 3 PI52, pin 2 (YG) and EM83, pin 11 (YG).

„hƒnCyl 5 PI53, pin 2 (YG) and EM83, pin 11 (YG).

„hƒnCyl 8 PI58, pin 2 (YG) and EM83, pin 11 (YG).

„hIs the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. This circuit includes the harness splice, PIS11. For additional

information, refer to the wiring diagrams. CLEAR the DTCs. TEST the system for normal operation.

-> No

Passed the test.

Goto <<A9>>

A9 : CHECK THE IGNITION COIL (CYLS 2, 3, 5, AND 8) MONITOR CIRCUITS FOR SHORT TO B+

VOLTAGE

1. Reconnect the battery negative terminal.

2. Disconnect the relevant ignition coil electrical connector(s).

3. Measure the voltage between:

„hƒnCyl 2 PI55, pin 2 (YG) and GROUND.

„hƒnCyl 3 PI52, pin 2 (YG) and GROUND.

„hƒnCyl 5 PI53, pin 2 (YG) and GROUND.

„hƒnCyl 8 PI58, pin 2 (YG) and GROUND.

„hIs the voltage greater than 1 volt?

-> Yes

REPAIR the short to B+ voltage. For additional information, refer to the wiring diagrams. CLEAR the DTCs.

TEST the system for normal operation.

-> No

No voltage was found in the above circuits.

Goto <<A10>>

A10 : CHECK THE IGNITION COIL (CYLS 2, 3, 5, AND 8) MONITOR CIRCUITS FOR SHORT TO

GROUND

1. Disconnect the relevant ignition coil electrical connector(s).

2. Measure the resistance between;

„hƒnCyl 2 PI55, pin 2 (YG) and GROUND.

„hƒnCyl 3 PI52, pin 2 (YG) and GROUND.

„hƒnCyl 5 PI53, pin 2 (YG) and GROUND.

„hƒnCyl 8 PI58, pin 2 (YG) and GROUND.

„hIs the resistance less than 10,000 ohms?

-> Yes

REPAIR the short to GROUND. For additional information, refer to the wiring diagrams. CLEAR the DTCs.

TEST the system for normal operation.

-> No

The resistance was around 5,300 ohms, this could be part of the problem, even though the the same test for Cyls 1,4,6, and 7 had the same results, making me wonder if it is an ECM issue and not a wiring issue.

INSTALL a new ECM. <<303-04>> Before replacing a ECM, contact Dealer technical support.

B : CHECK SPARK PLUG RESISTANCE

B1 : CHECK SPARK PLUG RESISTANCE

1. Remove the suspect spark plug(s).

2. Measure the resistance between the spark plug center electrode tip and the spark plug HT contact.

„hIs the resistance between 8,000 and 12,000 ohms? (nominal 10,000 ohms)

-> Yes

Check ignition coil and circuits. See possible sources list for misfire.

-> No

INSTALL a new spark plug. CLEAR the DTC. TEST the system for nomal operation.

The Spark Plugs all read ~4200 ohms, they are NGK Iridium, this too could also be an issue.

Next, we went on to test both cam position sensors and their circuits because the dealer told you your car had a code for it when it was in for service a few months ago. We used the following pinpoint test list.

(Our Results in BOLD)

1999 XJ RANGE - Electronic Engine Controls - 303-14

BF : DTC P0340; CAMSHAFT POSITION (CMP) SENSOR CIRCUIT MALFUNCTION

BF1 : CHECK THE CMP SENSOR FOR CORRECT INSTALLATION

1. Turn the ignition switch to the OFF position.

2. Check the CMP sensor for correct installation.

„hIs the CMP sensor correctly installed?

-> Yes

Goto <<BF2>>

-> No

INSTALL the CMP sensor correctly. CLEAR the DTCs. TEST the system for normal operation.

No brainer on this one, on to step 2.

BF2 : CHECK THE CMP SENSOR FOR FOREIGN DEBRIS

1. Remove the CMP sensor and inspect for foreign debris.

„hIs the CMP sensor free of foreign debris?

-> Yes

Goto <<BE3>>

-> No

CLEAN the sensor and wheel. INSTALL the sensor. CLEAR the DTCs. TEST the system for normal

operation

Sensor was clean of all debris, wiped off and put back in.

BF3 : CHECK THE CMP SENSOR SENSE CIRCUIT FOR HIGH RESISTANCE

1. Disconnect the battery negative terminal.

2. Disconnect the ECM electrical connector, EM13.

3. Measure the resistance between EM13, pin 20 (B) and PI15, pin 01 (B).

„hIs the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

-> No

Passed this test.

Goto <<BF3>>

BF4 : CHECK THE CMP SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

1. Reconnect the battery negative terminal.

2. Turn the ignition switch to the ON position.

3. Measure the voltage between EM13, pin 20 (B) and GROUND.

„hIs the voltage greater than 3 volts?

-> Yes

REPAIR the short circuit. For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST

the system for normal operation.

-> No

The circuits ended up having 9.44v and 9.45v respectively to each of the cam sensors, driver and passenger side.

Goto <<BF5>>

BF5 : CHECK THE CMP SENSOR SENSE CIRCUIT FOR SHORT TO GROUND

1. Turn the ignition switch to the OFF position.

2. Measure the resistance between PI15, pin 01 (B) and GROUND.

„hIs the resistance less than 10,000 ohms?

-> Yes

REPAIR the short circuit. For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST

the system for normal operation.

-> No

The circuits had 5,300 ohms on both sides.

INSTALL a new CMP sensor. CLEAR the DTC. TEST the system for normal operation.

My mechanic concluded by saying:

After all of this testing, this brings me to 3 different conclusions:

1) There has been some serious hacking or damage done to the wiring harness

2) There is something wrong with the ECM and it needs to be replaced

3) On a totally different subject, I would replace those spark plugs with ones that ohm out correctly to play it safe.

Thanks to all who can lend some assistance to this very frustrated VDP owner.

Sincerely,

SirJag

Last edited by SirJag; 05-10-2012 at 02:25 AM.

#2

There's a signal generator or reluctor on the rear of each inlet cam that the CMPS takes the signal from, if this is misaligned then misfires occur.

What do a full set of s/h coils cost in your neck of the woods? Are the boots in good order? do they 'pop' when you pull them off the plugs?

Are there any obvious hacks to the ignition harness? I ask as the engineer feels (point 1) serious hacking - if so replace.

Something wrong with the ecu? unlikely as it's reporting the faults - it sounds like the fault lies between it and the plugs. Along with the cam sensors, the crank sensor can benefit from a check, clean, replace as this can cause misfires also.

What do a full set of s/h coils cost in your neck of the woods? Are the boots in good order? do they 'pop' when you pull them off the plugs?

Are there any obvious hacks to the ignition harness? I ask as the engineer feels (point 1) serious hacking - if so replace.

Something wrong with the ecu? unlikely as it's reporting the faults - it sounds like the fault lies between it and the plugs. Along with the cam sensors, the crank sensor can benefit from a check, clean, replace as this can cause misfires also.

The following users liked this post:

SirJag (05-10-2012)

#3

Jaguar used two ways to count cylinder numbers. By your reference to 7 and 8 I assume that you are referring to the rear two on the left side. Since they are both on the same side have you considered that the exhaust cam chain has jumped a sprocket tooth? Correctly aligned on that side the cam flats should be almost in align. The right side has the flats turned down slightly to the center.

The following users liked this post:

SirJag (05-10-2012)

#4

There's a signal generator or reluctor on the rear of each inlet cam that the CMPS takes the signal from, if this is misaligned then misfires occur.

What do a full set of s/h coils cost in your neck of the woods? Are the boots in good order? do they 'pop' when you pull them off the plugs?

Are there any obvious hacks to the ignition harness? I ask as the engineer feels (point 1) serious hacking - if so replace.

Something wrong with the ecu? unlikely as it's reporting the faults - it sounds like the fault lies between it and the plugs. Along with the cam sensors, the crank sensor can benefit from a check, clean, replace as this can cause misfires also.

What do a full set of s/h coils cost in your neck of the woods? Are the boots in good order? do they 'pop' when you pull them off the plugs?

Are there any obvious hacks to the ignition harness? I ask as the engineer feels (point 1) serious hacking - if so replace.

Something wrong with the ecu? unlikely as it's reporting the faults - it sounds like the fault lies between it and the plugs. Along with the cam sensors, the crank sensor can benefit from a check, clean, replace as this can cause misfires also.

Thanks for your reply.

In response, my mechanic said:

"Next time we work on the car, I will pull the valve covers and check the positions of the reluctor wheels in relation to the crank.

Regarding the coils, they are fairly easy to take on and off the plugs, not much pop to the boots, but they aren't beaten up, melted, or in poor condition appearance wise, but the loose boots could be an issue.

When I work on the car next, I will take a photo of those butt connectors under the ECM and post it to the board to see if they are factory originals or hacked in.

From my ECM experiences, and the input of Tad, we have both had experiences with automotive computers that would have internal shorts and/or damage and still throw codes.

As for the crank sensor, we will clean and inspect it, as well as do the wiring tests to it as well. We have not had a crank sensor code, but it is a good idea."

I'll let you know the results.

Thanks again for your help!

SirJag

#5

Jaguar used two ways to count cylinder numbers. By your reference to 7 and 8 I assume that you are referring to the rear two on the left side. Since they are both on the same side have you considered that the exhaust cam chain has jumped a sprocket tooth? Correctly aligned on that side the cam flats should be almost in align. The right side has the flats turned down slightly to the center.

Thanks so much for your response.

My mechanic replied:

"By talking about cylinders numbered 7 and 8, I am referring to the rear 2 cylinders on the driver's(left) side of the car.

We will check the timing of all 4 camshafts in relation to the crank at the same rime we check the reluctors for the cam sensors.

What does intrigue me is that no one finds the lack of resistance of the spark plugs as something to be alarmed of.

Also, I forgot to mention in our initial report that #7 spark plug was about a turn and a half loose."

Just to note, tightening the plug mentioned above made no difference.

I'll keep you (and everyone else interested in this topic) informed as to results.

Sincerely,

SirJag

#6

QUESTION:

We tested all the ignition coils.

According to Jag's trouble-shooting flow-chart (see below), it says that if the resistance is less than 10,000 ohms, we need to repair the short-to-ground. HOWEVER, **ALL** coils tested at 5,300 ohms so what the heck would that mean?

Thanks all,

SirJag

A7 : CHECK THE IGNITION COIL (CYLS 1, 4, 6, AND 7) MONITOR CIRCUITS FOR SHORT TO

GROUND

1. Disconnect the relevant ignition coil electrical connector(s).

3 2012-05-02

2001 XJ RANGE - Engine Ignition - 303-07

2. Measure the resistance between:

„hƒnCyl 1 PI51, pin 2 (YG) and GROUND.

„hƒnCyl 4 PI56, pin 2 (YG) and GROUND.

„hƒnCyl 6 PI57, pin 2 (YG) and GROUND.

„hƒnCyl 7 PI54, pin 2 (YG) and GROUND.

„hIs the resistance less than 10,000 ohms?

-> Yes

REPAIR the short to GROUND. For additional information, refer to the wiring diagrams. CLEAR the DTCs.

We tested all the ignition coils.

According to Jag's trouble-shooting flow-chart (see below), it says that if the resistance is less than 10,000 ohms, we need to repair the short-to-ground. HOWEVER, **ALL** coils tested at 5,300 ohms so what the heck would that mean?

Thanks all,

SirJag

A7 : CHECK THE IGNITION COIL (CYLS 1, 4, 6, AND 7) MONITOR CIRCUITS FOR SHORT TO

GROUND

1. Disconnect the relevant ignition coil electrical connector(s).

3 2012-05-02

2001 XJ RANGE - Engine Ignition - 303-07

2. Measure the resistance between:

„hƒnCyl 1 PI51, pin 2 (YG) and GROUND.

„hƒnCyl 4 PI56, pin 2 (YG) and GROUND.

„hƒnCyl 6 PI57, pin 2 (YG) and GROUND.

„hƒnCyl 7 PI54, pin 2 (YG) and GROUND.

„hIs the resistance less than 10,000 ohms?

-> Yes

REPAIR the short to GROUND. For additional information, refer to the wiring diagrams. CLEAR the DTCs.

#7

It sounds like they are saying you have a short between the wire going to the coil and ground. I don't see how that could happen unless maybe there was oil in the spark plug holes ? If not, and all the coils measure the same, then either none of them are bad, or all of them are. Are they OEM coils ? I have heard of guys replacing their coils with aftermarket ones and having them not work correctly in the Jag even though they were listed as the correct part. Have your secondary cam chain tensioners been replaced ?

The following users liked this post:

SirJag (05-14-2012)

Trending Topics

#8

Hi SirJag

You should consider buying a new or used Original Equipment ignition coil that is known to be good.

Motorcars LTD has your 4 pin (LNE1510AB) used ($37.84) and new ($81.14) plus shipping. I would call them with questions about their parts (have they been tested, etc).

Gaudin Jaguar Parts has list price of $143 less 25% ($107.25) plus shipping($14.95).

Not sure if Nalley Jaguar price on this is more or less after you consider the 15% discount with free shipping (List pricing varies).

Maybe this is where you can start the process of elimination.

Jim Lombardi

You should consider buying a new or used Original Equipment ignition coil that is known to be good.

Motorcars LTD has your 4 pin (LNE1510AB) used ($37.84) and new ($81.14) plus shipping. I would call them with questions about their parts (have they been tested, etc).

Gaudin Jaguar Parts has list price of $143 less 25% ($107.25) plus shipping($14.95).

Not sure if Nalley Jaguar price on this is more or less after you consider the 15% discount with free shipping (List pricing varies).

Maybe this is where you can start the process of elimination.

Jim Lombardi

The following users liked this post:

SirJag (05-14-2012)

#9

It sounds like they are saying you have a short between the wire going to the coil and ground. I don't see how that could happen unless maybe there was oil in the spark plug holes ? If not, and all the coils measure the same, then either none of them are bad, or all of them are. Are they OEM coils ? I have heard of guys replacing their coils with aftermarket ones and having them not work correctly in the Jag even though they were listed as the correct part. Have your secondary cam chain tensioners been replaced ?

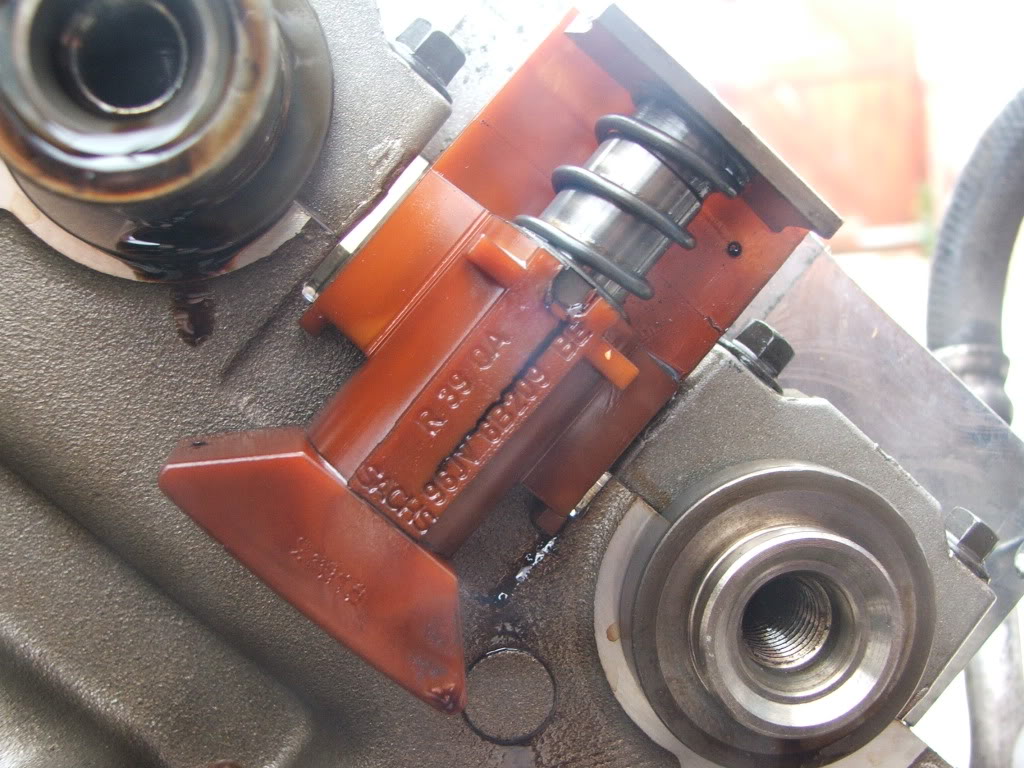

Not sure if they're OEM... I'll eyeball them next time we're in there. Are far as the tensioners, I need to check that too. Last mechanic said he believed that the parts looked new. Do you--or does anyone--know if the ORIGINAL tensioners were RED/ORANGE color?

Thanks so much

SirJag

#10

Hi SirJag

You should consider buying a new or used Original Equipment ignition coil that is known to be good.

Motorcars LTD has your 4 pin (LNE1510AB) used ($37.84) and new ($81.14) plus shipping. I would call them with questions about their parts (have they been tested, etc).

Gaudin Jaguar Parts has list price of $143 less 25% ($107.25) plus shipping($14.95).

Not sure if Nalley Jaguar price on this is more or less after you consider the 15% discount with free shipping (List pricing varies).

Maybe this is where you can start the process of elimination.

Jim Lombardi

You should consider buying a new or used Original Equipment ignition coil that is known to be good.

Motorcars LTD has your 4 pin (LNE1510AB) used ($37.84) and new ($81.14) plus shipping. I would call them with questions about their parts (have they been tested, etc).

Gaudin Jaguar Parts has list price of $143 less 25% ($107.25) plus shipping($14.95).

Not sure if Nalley Jaguar price on this is more or less after you consider the 15% discount with free shipping (List pricing varies).

Maybe this is where you can start the process of elimination.

Jim Lombardi

Thanks for your post.

I'm finding it hard to believe that they're all bad. We swapped the 2 that the codes suggested were problems with cyl. 7 & 8... no difference.

But I'll keep your info at hand in case we do go that route.

Many thanks...

SirJag

#11

See the picture for imminent failure. You can see the crack along the upper tensioner body, the next thing is loss of tension in the chain and skipping, along with valve damage.

If skipping one tooth, you'll get misfires on that bank, if two teeth are skipped it's goodnight Vienna.

The following users liked this post:

SirJag (05-17-2012)

#12

The following users liked this post:

SirJag (05-17-2012)

#13

Join Date: Sep 2008

Location: Damon /Houston, Texas

Posts: 7,254

Received 2,183 Likes

on

1,355 Posts

???? flow charts????? really. ok you have a misfires on 7/8, you swapped coils and it stays there. several things cause misses, by far coils, next injectors, swap the injectors before you waste a bunch of time on electrical flow charts. Its easier and less obtrusive in to the elctrical system. the flow chart is *** U ME ING you have a electrical fault. And while you may still, youve eliminated the most likely, now go to number 2 the injectors..................

The following users liked this post:

SirJag (05-16-2012)

#14

Hi

Here are photo of the old and new tensioners I found on the Jaguar World Monthly Forum:

Also here is some of the text there:

the original tensioners looked fine in place, but when they came out i could see that all the work was worth the effort ,

the right bank one had a 1mm split starting on it, but worse then this the bottom ( spring ) slipper was severely worn and gouged out, showing ' bubbles ' in the original plastic moulding wearing through...... the new aluminium tensioner can be seen in the background

Jim Lombardi

Here are photo of the old and new tensioners I found on the Jaguar World Monthly Forum:

Also here is some of the text there:

the original tensioners looked fine in place, but when they came out i could see that all the work was worth the effort ,

the right bank one had a 1mm split starting on it, but worse then this the bottom ( spring ) slipper was severely worn and gouged out, showing ' bubbles ' in the original plastic moulding wearing through...... the new aluminium tensioner can be seen in the background

Jim Lombardi

Last edited by jimlombardi; 05-14-2012 at 07:10 AM.

The following users liked this post:

SirJag (05-16-2012)

#17

Gentlemen:

I learned today that the spark plugs NGK 5464 do not fit the 2001 VDP despite what some website say. So, that's the first issue. I need to replace the plugs.

Question: The installed plugs being wrong, does it seem logical that the code reader would show misfires only on 7 & 8? Or, do you guys think it's perhaps a multi-faceted problem, with more than just the wrong plugs creating the problem?

Mechanic coming tomorrow and we'll check the injectors, as suggested. Or should we wait until the new (correct) plugs are installed?

Thank you,

SirJag

I learned today that the spark plugs NGK 5464 do not fit the 2001 VDP despite what some website say. So, that's the first issue. I need to replace the plugs.

Question: The installed plugs being wrong, does it seem logical that the code reader would show misfires only on 7 & 8? Or, do you guys think it's perhaps a multi-faceted problem, with more than just the wrong plugs creating the problem?

Mechanic coming tomorrow and we'll check the injectors, as suggested. Or should we wait until the new (correct) plugs are installed?

Thank you,

SirJag

#18

Gentlemen

Please see my response to the spark plug issue SirJag brings up here (see post# 7):

https://www.jaguarforums.com/forum/x...2-sites-73241/

Jim Lombardi

Please see my response to the spark plug issue SirJag brings up here (see post# 7):

https://www.jaguarforums.com/forum/x...2-sites-73241/

Jim Lombardi

The following users liked this post:

SirJag (05-17-2012)

#19

SirJag

Have you removed any of the spark plugs too see if they fouled with oil?

When you had the ignition coils out, did you noticed any oil around the spark plugs (the Valve Cover Spark Plug Seals may have failed).

Just another possible issue that may cause the misfire DTC codes.

Jim Lombardi

Have you removed any of the spark plugs too see if they fouled with oil?

When you had the ignition coils out, did you noticed any oil around the spark plugs (the Valve Cover Spark Plug Seals may have failed).

Just another possible issue that may cause the misfire DTC codes.

Jim Lombardi

The following users liked this post:

SirJag (05-17-2012)