Problem with Powerflex polybush on front upper arm

#1

I few weeks ago I reported a creak coming from the front right, on inspection I could see that one of the castor shims used on the upper arm fulcrum bolts had split and was working its way off the bolt.

Here is the pic again.

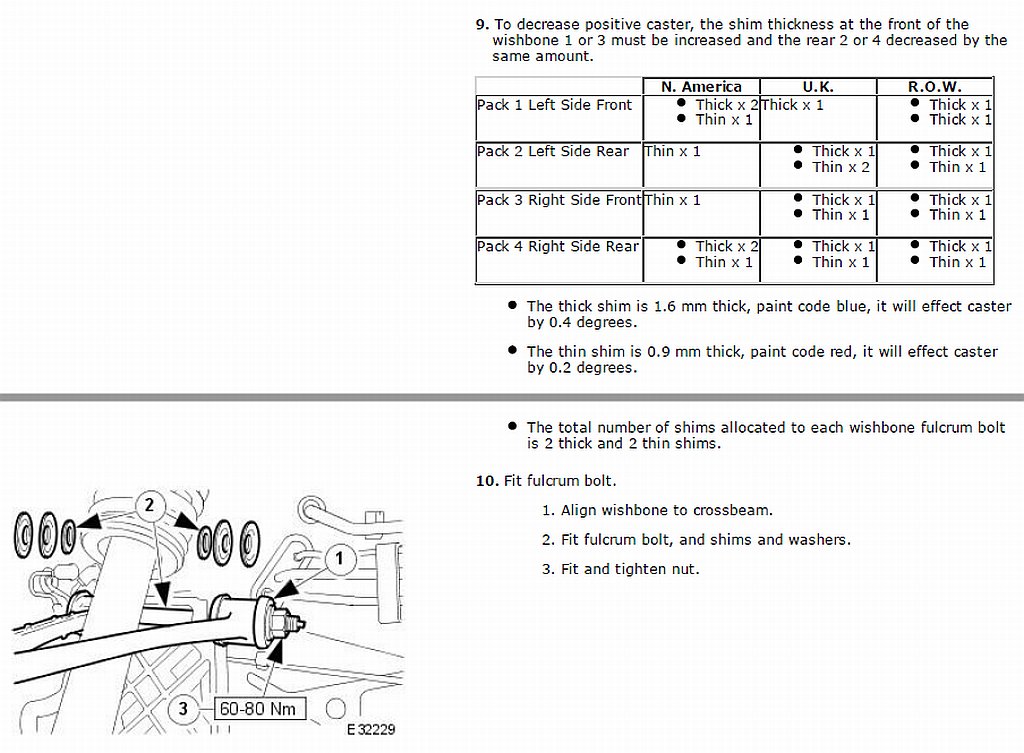

Today I rebuilt the upper arm with new shims (and lots of grease) and torqued the bolt up to 120Nm. I then pushed the arm up and down and saw that the fulcrum bolt was rotating with the arm.

Now I am pretty sure that the bolt, all washers and the poly bush inner sleeve should be fixed and should not move. I think that it is this movement that caused the initial problem with the castor shim.

Here is a video showing what I mean.

What are your thoughts, do you agree with my assumptions or have an alternative view?

Here is the pic again.

Today I rebuilt the upper arm with new shims (and lots of grease) and torqued the bolt up to 120Nm. I then pushed the arm up and down and saw that the fulcrum bolt was rotating with the arm.

Now I am pretty sure that the bolt, all washers and the poly bush inner sleeve should be fixed and should not move. I think that it is this movement that caused the initial problem with the castor shim.

Here is a video showing what I mean.

What are your thoughts, do you agree with my assumptions or have an alternative view?

#2

Join Date: Apr 2014

Location: Jersey, Channel Islands

Posts: 4,077

Received 2,291 Likes

on

1,503 Posts

Hi RD,

I agree that the fulcrum bolt and the inner spacers on the bushings shouldn't rotate. Certainly, when I did mine (although I used OEM bushings) that was the case.

THe bigger danger here is that the pivot bolt holes in the aluminium subframe could wear oval. Why Jaguar didn't sleeve these somehow I have no idea.

Mike

I agree that the fulcrum bolt and the inner spacers on the bushings shouldn't rotate. Certainly, when I did mine (although I used OEM bushings) that was the case.

THe bigger danger here is that the pivot bolt holes in the aluminium subframe could wear oval. Why Jaguar didn't sleeve these somehow I have no idea.

Mike

#3

Join Date: Oct 2009

Location: Perth Ontario Canada

Posts: 11,058

Received 2,255 Likes

on

1,840 Posts

If the stock OEM piece is a 'captured' type rubber bushing, I think I understand what you're seeing and why.

Stock bushings allow suspension movement strictly through the twisting/torsion of the rubber element itself. Neither the inner or outer surface of the bushing rotates against the mating piece.

Poly bushings are the opposite. The material is rigid, so it is allowed to rotate against other surfaces. In your case, the bushing seems to be seized against both the shaft and the a-arm, so the only thing left that can move is the shaft with respect to the frame- which it should not do as suggested above.

Stock bushings allow suspension movement strictly through the twisting/torsion of the rubber element itself. Neither the inner or outer surface of the bushing rotates against the mating piece.

Poly bushings are the opposite. The material is rigid, so it is allowed to rotate against other surfaces. In your case, the bushing seems to be seized against both the shaft and the a-arm, so the only thing left that can move is the shaft with respect to the frame- which it should not do as suggested above.

The following users liked this post:

michaelh (08-18-2016)

The following users liked this post:

Johnken (08-18-2016)

#5

Just my 2 cents but I don't see where it could not rotate as an assembly, the bolt is torqued tight against the bushings on each side, the bolt itself is free turning inside the control arm support so what would prevent the complete assembly, bolt, shims, bushings, control arm, from rotating with the control are?

#6

+1 on the previous two messages. The first thing I thought of is: You always need to use two wrenches (opposing force) to loosen this nut. You can not just unscrew the nut on the left, the bolt will turn. That tells me it is going to rotate just as you see RaceDiagnostics. Heck, I had to use opposing force to get a reading on the torque wrench too. I think you are OK mate.

Does my logic make sense?

John

Does my logic make sense?

John

#7

I have never had mine apart nor had cause to have a very close look at it but l imagined that tightening the fulcrum bolt would have a tightening effect on the inner sleeves and washers/ shims thereby clamping down on the main support in a squeezing action and preventing any movement of the bolt, either lateral or rotational.

Or am l imagining wrongly?

Or am l imagining wrongly?

Last edited by baxtor; 08-19-2016 at 12:20 AM.

Trending Topics

#8

I did a comparison to the lower arm, on these the bolts do not move and the poly part of the bush rotates round its inner steel sleeve. I am now pretty convinced that this is how the uppers should also work.

Any rotation of the top bolt would cause wear where the small washers rub against the sub frame and in the hole for the fulcrum bolt in the subframe.

I have now written to Powerflex about the issue.

Any rotation of the top bolt would cause wear where the small washers rub against the sub frame and in the hole for the fulcrum bolt in the subframe.

I have now written to Powerflex about the issue.

The following users liked this post:

cjd777 (08-19-2016)

#11

Here is the response from Powerflex.

I think the main issue is with the mild steel washers they have used, they have corroded and are pinching down on the poly part of the bush.

I will see if I can make up a set of stainless steel ones.

Hi Jim

You are correct that the arm and bush should turn around the bolt, sleeve and washers.

Its difficult to say why this is happening but the assembly looks very dry.

Once you torque the bolt up it should lock the washers, sleeves etc to the chassis.

Are the bushes over hanging the sleeves, the torque of the bolt only clamping up on the polyurethane rather than the sleeve?

Or a spacing issue from the inner washer to chassis?

I will get a new set sent out to you to replace the split bush if you let us have your address.

Iím off next week but please let James know if you need any further information on sales@powerflex.co.uk

Best regards

Paul Solbe

Design & Development Manager

You are correct that the arm and bush should turn around the bolt, sleeve and washers.

Its difficult to say why this is happening but the assembly looks very dry.

Once you torque the bolt up it should lock the washers, sleeves etc to the chassis.

Are the bushes over hanging the sleeves, the torque of the bolt only clamping up on the polyurethane rather than the sleeve?

Or a spacing issue from the inner washer to chassis?

I will get a new set sent out to you to replace the split bush if you let us have your address.

Iím off next week but please let James know if you need any further information on sales@powerflex.co.uk

Best regards

Paul Solbe

Design & Development Manager

I will see if I can make up a set of stainless steel ones.

#12

There appears to be a gap between the shim set and the sub frame, did you insert the stepped washer from the original bush assembly at at all? As I'm sure that when I did mine there was no gap and the stepped washers were thrown away. Also did you lubricate the center sleeve and washers with the power bush set as when the whole assemble is tightened up, that is where the movement should take place, no lube and its just going to move in the next easiest place.

#13

There appears to be a gap between the shim set and the sub frame, did you insert the stepped washer from the original bush assembly at at all? As I'm sure that when I did mine there was no gap and the stepped washers were thrown away. Also did you lubricate the center sleeve and washers with the power bush set as when the whole assemble is tightened up, that is where the movement should take place, no lube and its just going to move in the next easiest place.

The gap is where the castor shims are placed, and you can see there is plenty lubrication from the video.

#14

Thats the point, I cant see any lube around the bush/washers, it looks as dry as the proverbial nuns bits. As for the shim , the washer is flat, the sub frame is flat, the shims are bigger than the washers, why would there appear to be a gap? It just looks like the shim is the stepped washer from the original bush?

#15

Thats the point, I cant see any lube around the bush/washers, it looks as dry as the proverbial nuns bits. As for the shim , the washer is flat, the sub frame is flat, the shims are bigger than the washers, why would there appear to be a gap? It just looks like the shim is the stepped washer from the original bush?

#16

#17

I have no idea what that washer/shim is that you have fitted (arrow) ,there were no washers that big on mine even the stepped ones. All i can say is that have you made sure that the nut hasn't bottomed on the thread so the assembly isn't tight enough? Mine was marginal so I put 2 of the stepped washers back, one under the head and one under the nut so the whole lot could be locked up. just a thought

#18

You seem to be confusing the bush washer with the caster shims.

There should be a 2.5mm gap between the subframe and the bush washer on the right side of the vehicle made up with one thick and one thin shim.

Did you refit these?

#19

#20

Join Date: Apr 2014

Location: Jersey, Channel Islands

Posts: 4,077

Received 2,291 Likes

on

1,503 Posts

I believe Powerflex has the answer:

Once you torque the bolt up it should lock the washers, sleeves etc to the chassis.

Are the bushes over hanging the sleeves, the torque of the bolt only clamping up on the polyurethane rather than the sleeve?

which is what Paul alluded to in an earlier post.

If the sleeve is too short then torquing up the fulcrum bolt will just squash and deform the polybush so it's too tight to rotate on the inner sleeve. That could also explain why the shim you've arrowed was squeezed out because it would be rubbing against the subframe when the whole assembly rotates. Normally, it and any adjacent washers would be pinched.

FWIW, the OEM bushings work in exactly the same way. The inside of the bush has a sleeve within a sleeve separated by a yellow plastic bearing material. This allows the bush to rotate freely with the arm once the bolt is tightened and the innermost sleeve pinched. Almost makes them worth the cost...

Just my 2c.

Mike

By the way, it looks like Powerflex customer service is good.

Once you torque the bolt up it should lock the washers, sleeves etc to the chassis.

Are the bushes over hanging the sleeves, the torque of the bolt only clamping up on the polyurethane rather than the sleeve?

which is what Paul alluded to in an earlier post.

If the sleeve is too short then torquing up the fulcrum bolt will just squash and deform the polybush so it's too tight to rotate on the inner sleeve. That could also explain why the shim you've arrowed was squeezed out because it would be rubbing against the subframe when the whole assembly rotates. Normally, it and any adjacent washers would be pinched.

FWIW, the OEM bushings work in exactly the same way. The inside of the bush has a sleeve within a sleeve separated by a yellow plastic bearing material. This allows the bush to rotate freely with the arm once the bolt is tightened and the innermost sleeve pinched. Almost makes them worth the cost...

Just my 2c.

Mike

By the way, it looks like Powerflex customer service is good.

Last edited by michaelh; 08-20-2016 at 09:12 AM.