"XJR 550" project

#41

Count i'm very curious as to your plans with the AM V8.

New pistons to drop the compression and put the Jaguar supercharger gear on top?

What about the firing order? It's different to the Jaguar engines if i'm not mistaken...

I've often wondered what a hybrid Jag & AM supercharged AJV8 would be like, hope to find out one day...

New pistons to drop the compression and put the Jaguar supercharger gear on top?

What about the firing order? It's different to the Jaguar engines if i'm not mistaken...

I've often wondered what a hybrid Jag & AM supercharged AJV8 would be like, hope to find out one day...

Hi Cambo- initial plans will be to strip the engine and see whats wrong with it. I was told that the engine was running low oil pressure.

The firing order for the Aston and the Jag should be the same, when I tested the AJ37 on the dyno years ago we kept regularly interchanged Jag bits and Aston bits- may be the convention in which the cylinders are named are different. The Aston Uses Spanish Oak ford EMS system while our Jags use Denso.

The Jag V8 has got the same firing order as my big block Chrysler motor or the Lexus. Even if it is different, its just a case of changing the cams really.

I will take the cylinder heads off and get a 3 D rubber moulding of the ports at work.

We just did this for an S54 M3 engine and a Ferrari F430. Once I have that I will scan them into a CAD file. I've learned a lot since I did the ports on the AM5/AJ37 engine and want to incorporate some of the learnings into new heads. I'll most likely not waste the Aston heads for the port work, but use AJ33 or Aj41 castings to begin new work with. The target is to get outstanding flow with good tumble also. This is the holy grail.

The BMW heads and the Ferrari heads get a good compromise of tumble, flow and velocity. With the Astons I was on the right path at the time, but in engineering terms that was 12 years ago!

This can all be measured at work. If you get the tumble in correct proportion in league with squish such that it breaks down into small eddies near TDC you can effectively get better knock limit with the engine.

I don't know whether the block can be interchanged with the Jag block or not- there may be brackets missing. With a good level of boost and say a peak cyinder pressure of 100-110 bar, I would probably put 91mm bore as an upper limit- but Im researching as to whether I could push this safely to 92 mms (only gives 6mms bridge distance) with a custom gasket design for a one off. A lot of things are possible for ones offs- you can throw money at than are for higher volume production.

The head castings could accommodate larger diameter tappets (like we used in a racing version of the AJV8- that made 622 Bhp N/A from a 4.5 litre!) that allowed a more aggressive cam profile.

The next trick will be to use a special type of positive displacement supercharger which working in league with the better flowing engine should allow much lower intercooler tank temps which will further improve knock limit.

Unfortunately- it may be a while, like some years, as Im currently focusing on my Dodge 470 build and designing a cam shaft for that- that allows it to rev to 7500 rpm. Have already done a lot of CNC port work with that motor with outstanding flow/velocity results.

The following users liked this post:

Panthro (09-21-2015)

#42

Thanks Count.

There was a rather long build thread on another forum of rebuilding the an AM V8 after it seized due to oil starvation. Might be an interesting read for you Vantage V8 4.7 engine rebuild - 6SpeedOnline - Porsche Forum and Luxury Car Resource

You are absolutely right.

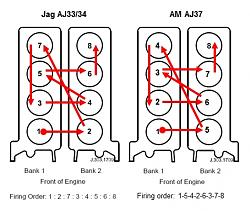

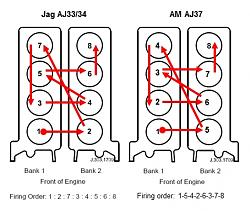

The Aston is 1-5-4-2-6-3-7-8, the Jag is 1-2-7-3-4-5-6-8, if you swap the cylinder numbers to run up the banks, it's the same. I made a picture (should have done it ages ago)...

Yep they are the same.

Funny how the Aston tuners put together 4-1 tuned length exhaust manifolds for the Vantage, and claimed them to be the greatest thing ever.

Does the AJ37 have the same volumetric efficiency problem between 6 & 8 (actually, 7 & 8) like the Jag versions?

So there has been a fair bit of wrong information getting around about the these engines, there's a lot more interchangeability in parts than people thought...

Aston heads & valvetrain bolting straight onto a Jag bottom end, sounds kind of appealing to me.

May be 12 year old design but for those of us looking to slap together a "better" AJV8 without re-designing every single component, you would say the AJ37 top end is a big enough improvement over the AJ33/34's?

Would love to know more about that engine! Impressive!

I'm in no particular rush

The Aston is 1-5-4-2-6-3-7-8, the Jag is 1-2-7-3-4-5-6-8, if you swap the cylinder numbers to run up the banks, it's the same. I made a picture (should have done it ages ago)...

Yep they are the same.

Funny how the Aston tuners put together 4-1 tuned length exhaust manifolds for the Vantage, and claimed them to be the greatest thing ever.

Does the AJ37 have the same volumetric efficiency problem between 6 & 8 (actually, 7 & 8) like the Jag versions?

So there has been a fair bit of wrong information getting around about the these engines, there's a lot more interchangeability in parts than people thought...

Aston heads & valvetrain bolting straight onto a Jag bottom end, sounds kind of appealing to me.

I'm in no particular rush

The following 2 users liked this post by Cambo:

Count Iblis (09-20-2015),

Panthro (09-21-2015)

#43

Sorry, forgot one!

You mean the 1UZ-FE V8?

Do they have similar problems of the adjacent firing cylinders causing problems on the exhaust side then?

I'm thinking in relation to the exhaust manifold design...

Do they have similar problems of the adjacent firing cylinders causing problems on the exhaust side then?

I'm thinking in relation to the exhaust manifold design...

#44

Thanks Count.

There was a rather long build thread on another forum of rebuilding the an AM V8 after it seized due to oil starvation. Might be an interesting read for you Vantage V8 4.7 engine rebuild - 6SpeedOnline - Porsche Forum and Luxury Car Resource

There was a rather long build thread on another forum of rebuilding the an AM V8 after it seized due to oil starvation. Might be an interesting read for you Vantage V8 4.7 engine rebuild - 6SpeedOnline - Porsche Forum and Luxury Car Resource

Thank you- that's very useful. Pavel seems to be good and digs deep, he's made an slight error on the woodruff key assumption but a minor one and its understandable.

Yes it will, or similar- the difference is that the supercharged engine has minimal overlap and still suffers from the charge robbing problem- mainly due to unfavourably grouped up intercoolers/plenums and the exhausting. On the AJ37- we tried a 264 duration cam which gave great results but were forced to restrict down to 256 due to this mal distrisbution problem. If I ever bought an Aston I would probably grind that same 264 profile again (I still have it!).

Aston heads & valvetrain bolting straight onto a Jag bottom end, sounds kind of appealing to me.

May be 12 year old design but for those of us looking to slap together a "better" AJV8 without re-designing every single component, you would say the AJ37 top end is a big enough improvement over the AJ33/34's?

May be 12 year old design but for those of us looking to slap together a "better" AJV8 without re-designing every single component, you would say the AJ37 top end is a big enough improvement over the AJ33/34's?

Massive- you've probably heard me whine about the AJ33 ports before and that unmentionable Austrian consultancy....

#45

#46

I have a set of AJ33 heads sitting in the garage that I was thinking to clean up and perhaps regrind the cams but if the Aston heads are a tremendous improvement and a direct bolt on to an AJ33SC, that might be a better/smarter path for us novices that don't have the skills to do all the CFD nor the 5 axis CNC to to make it real.

#47

Out of curiosity, do the 4.3 and 4.7 heads have the same ports and cam profiles or were there further changes along the way?

I have a set of AJ33 heads sitting in the garage that I was thinking to clean up and perhaps regrind the cams but if the Aston heads are a tremendous improvement and a direct bolt on to an AJ33SC, that might be a better/smarter path for us novices that don't have the skills to do all the CFD nor the 5 axis CNC to to make it real.

I have a set of AJ33 heads sitting in the garage that I was thinking to clean up and perhaps regrind the cams but if the Aston heads are a tremendous improvement and a direct bolt on to an AJ33SC, that might be a better/smarter path for us novices that don't have the skills to do all the CFD nor the 5 axis CNC to to make it real.

I have 3 different versions of the heads that I have looked at.

4.0 heads.

03/04 4.2L SC heads

06/09 XFR heads & 06/09 Rover 4.4L heads.

• XFR and Rover head castings appear to be the same, Rover heads have different tappet diameters and longer valve stems.)

• Rover and XFR inlet and outlet ports visually appear to be the same.

• The inlet port separators are the same between Rover and the XFR heads.

It appears that all of the 4.2 heads have a continuous flat machined surface across the inlet ports

The 4.0 heads have separate machined flats around the inlet ports.

The 03/04 4.2 inlet port separators are different than the 06/09 Rover and XFR heads.

(I presume that this is the generation of heads that Count Iblis has commented about.)

I found 3 images of an Aston Martin head that were posted by Pavel during his AM rebuild.

This picture shows an inlet port mounting configuration similar to the older 4.0L heads.

His 4.7 rebuild was a 09 engine, so it appears that AM continued to use a different casting than Jaguar.

The dome shape/design of the AM heads is different than all of the Jaguar heads.

I see differences in the dome designs between the 4.0 heads and 4.2 heads. I don’t know if the newer 4.2L N/A engines use the same heads. (But the Rover 4.4L heads have the same chamber domes as the 4.2 XFR heads)

I see differences in the inlet manifolds. Some have separators, others don’t.

Since my motivation is supercharged engines, I am not sure how important the inlet port flow path is compared to N/A engines. I am interested in the effect the ports have on the fuel being injected into the cylinder. Good flow, swirling, with high tumble, in order to maintain efficient combustion, emissions characteristics, and volumetric efficiency. = faster more even chamber burn = more power.

I am not sure what head chamber design is the best to start off and work with? Aston Martin or Jaguar 4.2L. (Count Ibis)?

In today’s modern 4-valve/cylinder engines, I am not sure if porting will contribute much to increased power in a Supercharged engine.

#48

The following 2 users liked this post by XJR-99:

Panthro (05-29-2016),

User 070620 (11-05-2015)

#49

Interesting to note the a-symmetry grind of your inlet ports. Were the shapes flow mapped to get that shape? Was some of this port shaping done to make cylinders 7 and 8 work better and not charge rob each other?

What was done to match the injector intake manifold? Was it ported to match?

What I find are 4 different dome configurations used on AJ-V8 engines. (See picture)

1. Older early 4.0 engines, typically N/A engines.

2. Your GT3 heads – (I’ve seen this configuration in other 4V overhead cam heads.)

3. Aston Martin 4.7L heads.

4. AJ33, AJ34, Rover 4.4L heads, supercharged 4.2 engines.

These shapes will affect compression ratio due to different dome volumes. Therefore the selected pistons will have to have a top shaped/dished to get a calculated compression.

Based on these dome shapes, I see mating piston top dish shapes and configurations.

The question is: What is the best shape for the combustion chamber? Most power? Least emissions? Least knock?

#50

#51

I am hoping that someone will chime in and state that the different chamber shapes are to optimize squish/quench. That one of the shapes was found to be best in the AJ engines.

I see a lot of the #2 GT3 style chamber shapes on other 4V heads. #4 shape, used in Jaguars appears to be about as common. In SC engines with lower compression ratios, has one shape over the other been proven to perform better?

I see a lot of the #2 GT3 style chamber shapes on other 4V heads. #4 shape, used in Jaguars appears to be about as common. In SC engines with lower compression ratios, has one shape over the other been proven to perform better?

#52

I saw the other pictures you posted in the XKR GT3 thread.

Interesting to note the a-symmetry grind of your inlet ports. Were the shapes flow mapped to get that shape? Was some of this port shaping done to make cylinders 7 and 8 work better and not charge rob each other?

What was done to match the injector intake manifold? Was it ported to match?

What I find are 4 different dome configurations used on AJ-V8 engines. (See picture)

1. Older early 4.0 engines, typically N/A engines.

2. Your GT3 heads – (I’ve seen this configuration in other 4V overhead cam heads.)

3. Aston Martin 4.7L heads.

4. AJ33, AJ34, Rover 4.4L heads, supercharged 4.2 engines.

These shapes will affect compression ratio due to different dome volumes. Therefore the selected pistons will have to have a top shaped/dished to get a calculated compression.

Based on these dome shapes, I see mating piston top dish shapes and configurations.

The question is: What is the best shape for the combustion chamber? Most power? Least emissions? Least knock?

Interesting to note the a-symmetry grind of your inlet ports. Were the shapes flow mapped to get that shape? Was some of this port shaping done to make cylinders 7 and 8 work better and not charge rob each other?

What was done to match the injector intake manifold? Was it ported to match?

What I find are 4 different dome configurations used on AJ-V8 engines. (See picture)

1. Older early 4.0 engines, typically N/A engines.

2. Your GT3 heads – (I’ve seen this configuration in other 4V overhead cam heads.)

3. Aston Martin 4.7L heads.

4. AJ33, AJ34, Rover 4.4L heads, supercharged 4.2 engines.

These shapes will affect compression ratio due to different dome volumes. Therefore the selected pistons will have to have a top shaped/dished to get a calculated compression.

Based on these dome shapes, I see mating piston top dish shapes and configurations.

The question is: What is the best shape for the combustion chamber? Most power? Least emissions? Least knock?

4 was outlined by the Austrian consultancy and although it built up the squish area it also lead to port flow chamber shrouding which we hastily tried to mitigate as much as we could at the end.

3 looks like it was done hastily to try to reduce compression ratio due to the 4.7 litre capacity increase.

I don't see a reason to reduce squish only on the exhaust side.

My understanding is that the 4.7 litre Aston has different ports to the 4.3 and larger valves also.

Number 1 combustion chamber configuration is classic quiescent chamber.

It's ok, but doesn't have much squish and could lead to quite a knock limited engine and a slow burn.

The biggest issue with the Gt3 heads I see is that I can still see the nasty asymmetry forced upon the ports by the AJ33 design in the consultancies misguided attempt at trying to boost swirl levels. It is far better on a pent roof engine to try to boost tumble. Tumble can increase turbulent kinetic energy at TDC in conjunction with appropriate squish, and can be used to mitigate knock limit AND dilution tolerance. Swirl can be used to boost dilution tolerance and mixing. Mixing is more important on GDi engine and on diesels. On Port injected engines mixing is typically less of an issue as atomisation is dictated by the fuel injector, targeting, mounting location and nozzle design.

It's not suprising that the misguided Austrian consultancy were very well versed in diesel engine design so were trying to pedal what they knew.

#53

The following users liked this post:

Count Iblis (09-28-2015)

#54

Count, is there any benifit to knife edging the crank shalf. I had (Falicon?) do that to my Ninja crank. Before it gloriously exploded, it was laughably, hilariously fast. 4th gear was pulling like 2nd.

I don't know if the crank was the cause (still have it for the big bore, cams and head prepared by....Dale Walker! Ha, I remembered to put in my Eliminator one day...

to put in my Eliminator one day...

Would taking that much weight off completely screw up everything? The way it revved after the knife edge was like a gun going off. Off or On. Just insane but I don't know if that would work on a V8, let alone a supercharged V8.

(Avos, your car **** stuff is almost as good as the Counts I can understand about 60% of the high brow tech you talk about so easily. I want to understand it all but .... I don't think I'm ever going to gain that much intelligence so I just pretend to sound cool.

I can understand about 60% of the high brow tech you talk about so easily. I want to understand it all but .... I don't think I'm ever going to gain that much intelligence so I just pretend to sound cool.

I don't know if the crank was the cause (still have it for the big bore, cams and head prepared by....Dale Walker! Ha, I remembered

to put in my Eliminator one day...

to put in my Eliminator one day...Would taking that much weight off completely screw up everything? The way it revved after the knife edge was like a gun going off. Off or On. Just insane but I don't know if that would work on a V8, let alone a supercharged V8.

(Avos, your car **** stuff is almost as good as the Counts

I can understand about 60% of the high brow tech you talk about so easily. I want to understand it all but .... I don't think I'm ever going to gain that much intelligence so I just pretend to sound cool.

I can understand about 60% of the high brow tech you talk about so easily. I want to understand it all but .... I don't think I'm ever going to gain that much intelligence so I just pretend to sound cool.

#55

Hi there!

I was just browsing through these posts and realised that I had missed your question about the flywheel. Actually the flywheel was custom made - something that Norman D had done for the job. I asked him to make it lighter (to make the car more "lively" and he confirmed that it is quite light already - but I don't have any day unfortunately.

/Mark

#56

Count. Over the past couple of days I've been researching shapes 2 and 4. Seems like most of the latest dohc heads are using shape 4. Shape 4 also seems to be more prevalent on 8.5:1 compression blown engines. I still see many race engine heads in shape 2. Perhaps an emissions trade off? Ford's tumble heads used shape 4, but had inlet port issues.

Do you know of any place that explains the main difference between the shapes? ZR1 LT5 heads used shape 4. (Late 90s technology.)

Do you know of any place that explains the main difference between the shapes? ZR1 LT5 heads used shape 4. (Late 90s technology.)

Last edited by Tijoe; 09-27-2015 at 10:02 PM. Reason: correct spelling

#57

Count, is there any benifit to knife edging the crank shalf. I had (Falicon?) do that to my Ninja crank. Before it gloriously exploded, it was laughably, hilariously fast. 4th gear was pulling like 2nd.

I don't know if the crank was the cause (still have it for the big bore, cams and head prepared by....Dale Walker! Ha, I remembered to put in my Eliminator one day...

to put in my Eliminator one day...

Would taking that much weight off completely screw up everything? The way it revved after the knife edge was like a gun going off. Off or On. Just insane but I don't know if that would work on a V8, let alone a supercharged V8.

(Avos, your car **** stuff is almost as good as the Counts I can understand about 60% of the high brow tech you talk about so easily. I want to understand it all but .... I don't think I'm ever going to gain that much intelligence so I just pretend to sound cool.

I can understand about 60% of the high brow tech you talk about so easily. I want to understand it all but .... I don't think I'm ever going to gain that much intelligence so I just pretend to sound cool.

I don't know if the crank was the cause (still have it for the big bore, cams and head prepared by....Dale Walker! Ha, I remembered

to put in my Eliminator one day...

to put in my Eliminator one day...Would taking that much weight off completely screw up everything? The way it revved after the knife edge was like a gun going off. Off or On. Just insane but I don't know if that would work on a V8, let alone a supercharged V8.

(Avos, your car **** stuff is almost as good as the Counts

I can understand about 60% of the high brow tech you talk about so easily. I want to understand it all but .... I don't think I'm ever going to gain that much intelligence so I just pretend to sound cool.

I can understand about 60% of the high brow tech you talk about so easily. I want to understand it all but .... I don't think I'm ever going to gain that much intelligence so I just pretend to sound cool.

On a V8 engine inparticular you have to make sure you have dynamic balance when you do this or else you can ruin your engine.

I would also be careful on an inline 4 too.

#58

Count. Over the past couple of days I've been researching shapes 2 and 4. Seems like most of the latest dohc heads are using shape 4. Shape 4 also seems to be more prevalent on 8.5:1 compression blown engines. I still see many race engine heads in shape 2. Perhaps an emissions trade off? Ford's tumble heads used shape 4, but had inlet port issues.

Do you know of any place that explains the main difference between the shapes? ZR1 LT5 heads used shape 4. (Late 90s technology.)

Do you know of any place that explains the main difference between the shapes? ZR1 LT5 heads used shape 4. (Late 90s technology.)

TiJoe, thanks for the examples.

unfortunately there is no texts or literature on this topic. COmpanys like AVL, or FEV may have their own internal info on it, but they usually contradict one another. Even IC engine books that cover combustion chamber design and talk of end gas trap and low surface to volume ratios don't usually cover the positioning of squish. Manufacturers will use transient CFD simulation and single cylinder test work to determine which direction to go.

The Ford eco Boost, at least the early one used on the F 150 is a GDi engine so shouldn't be directly compared , as in cylinder mixing becomes important, and the 'super knock phenomenon raises its ugly head' potentially.

Nevertheless- I was very disappointed by Ford with the initial launch of the Cyclone V6 engine

http://www.full-race.com/img/article...de/heads-3.jpg

My sources tell me the engine suffered serious combustion issues during late development. This is why on the F150 the boost is limited at low engine speeds and the engine feels quite peaky - totally inappropriate for that application and waste of an exceptional boosting system. Retarding the ignition wasn't enough to mitigate their super knock and other related combustion issues.

im sure Ford will get it right in their next iteration- they usually do.

The Lt5 Chamber and indeed engine was designed by Lotus.

http://www.onedirt.com/files/2011/06/LT5-head1.jpg

Lotus barely had the facilities to analyse such a design at that time. Two things strike me about that design- it has side squish- between the bore- which can cause undesirable and unstable Omega tumble and the chamber is very closed and the squish action on the charge looked like the turbulent kinetic energy will fight and cancel out a lot. Most likely these designs had a target squish area and just put it where ever they could without an understanding of flow shrouding. Racing outfits are notorious for doing things quickly without a solid understanding of combustion (although not all).

When we talk about emissions- we talk about speeding up the burn for a more stable combustion and mitigating knock like I outlined before. There is nothing else. We're after stable combustion to be able to retard the ignition more without running into misfire and to be able to withstand residuals and dilution within the combustion chamber. There is nothing else.

My original comments about balancing squish area with NOT shrouding the port airflow still apply (which effects performance).

#60

I marked up a couple images. One the posted GT3 chamber image and the other a stock late model 4.2L head cylinder.

It is interersting to note that the frowns on the stock chamber do not shroud the valves and are pulled back so they don't impede flow. I assume that they are there to create more squish, perhaps to cool the valves? Or redirect the flow in the chamber? (The pistons have matching frowns on them)

Did they have to reduce the size of the chamber to get the compression ratio they wanted?

Does anyone have a picture of the chamber for the new Ford GT350 5.2L engine? I couldn't find anything pictures on the internet. Could be a good comparision of latest chamber design, (despite direct injection)

It is interersting to note that the frowns on the stock chamber do not shroud the valves and are pulled back so they don't impede flow. I assume that they are there to create more squish, perhaps to cool the valves? Or redirect the flow in the chamber? (The pistons have matching frowns on them)

Did they have to reduce the size of the chamber to get the compression ratio they wanted?

Does anyone have a picture of the chamber for the new Ford GT350 5.2L engine? I couldn't find anything pictures on the internet. Could be a good comparision of latest chamber design, (despite direct injection)

Last edited by Tijoe; 09-30-2015 at 08:56 AM. Reason: spelling: Add question