Throttle Return Spring from lever on front carb to anchor bracket 64 3.8 MOD

#1

Hello all,

Quick Question.

I know about the throttle return spring that attaches to the bracket at the oil filter and the throttle linkage arm (#75 in the photo).

I also know that spring #74 in the photo at one end attaches to the bottom of the "Y" bracket below the front carb, but where does the other end attach to the front carb?

It would be great if someone could post a photo for me.

Thanks so much.

Lin

Quick Question.

I know about the throttle return spring that attaches to the bracket at the oil filter and the throttle linkage arm (#75 in the photo).

I also know that spring #74 in the photo at one end attaches to the bottom of the "Y" bracket below the front carb, but where does the other end attach to the front carb?

It would be great if someone could post a photo for me.

Thanks so much.

Lin

#2

#3

Jon,

Perfect! Thank you.

After looking at your photos and at mine, I see my problem and no wonder I couldn't figure out where the spring attached!

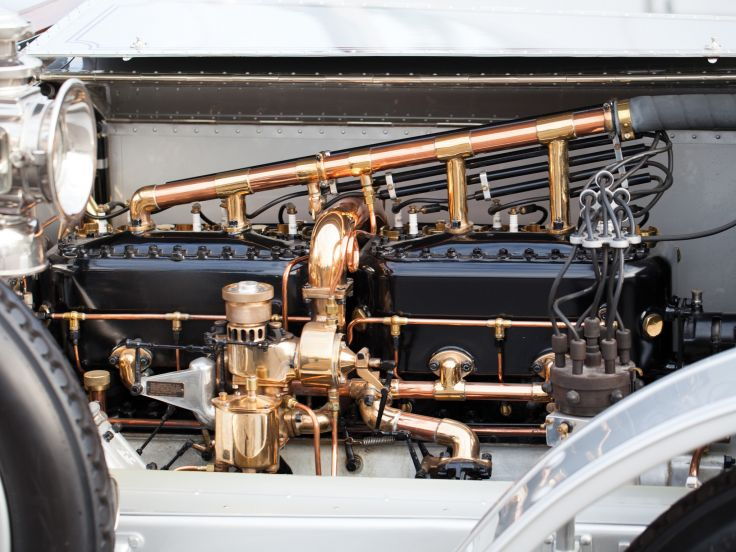

See the attached photos, one before restoration and one after.

I didn't do the carb rebuild myself and it appears that the fellow that did it failed to re-install the lever upon rebuild. So now I will go dig through old parts - in the attic, of course - to see if I can find it or one like it to use.

Thanks, again!

Lin

Perfect! Thank you.

After looking at your photos and at mine, I see my problem and no wonder I couldn't figure out where the spring attached!

See the attached photos, one before restoration and one after.

I didn't do the carb rebuild myself and it appears that the fellow that did it failed to re-install the lever upon rebuild. So now I will go dig through old parts - in the attic, of course - to see if I can find it or one like it to use.

Thanks, again!

Lin

#4

On initial set up the linkage between the two carbs is loosened so that both valves can be moved independently.

The spring is put in place on the front carb to shut the valve tight.

You then physically close the valve tight on the rear carb and tighten up the linkage.

This is all done while the main accelerator spring is disconnected.

This procedure ensures that both carbs are shut, so you can balance them with the big idle screw to the left of each carb.

In the photo the nut in the red circle is loosened so the pedal linkage is allowed to rotate freely on the shaft.

This is so the first procedure can be carried out above.

At this point the big accelerator pedal return spring is attached.

The screw circled in green is now adjusted and locked off.

It's adjusted so the linkage doesn't "go over centre", it's not that critical so, long as it allows the full accelerator travel to full both butterfly valves.

The screw circled in green also takes the load of the strong return spring for the accelerator pedal.

Finally the accelerator linkage on the front carb is tightened up. (the nut circled in red)

Last edited by JeffR1; 04-29-2017 at 10:37 AM.

The following 2 users liked this post by JeffR1:

littlelic69 (04-29-2017),

TilleyJon (04-29-2017)

#5

Lin, That's the problem when you let someone else do something !!!

If you are struggling, I may have a spare you can have, happy hunting in the loft !!

Jeff --- I know the set up procedure, what I was trying to say (badly) that in theory, if the main spring shut the rear carb and the front carb was manually shut, the same principle would apply and the main spring would close both carbs, but if the link were to become loose the front carb could be left open when the foot came off the gas and leave the engine revving !

It was my thought that the front spring was as a prevention of this happening when it was designed, I don't think they thought of the setup procedure and put in the front spring, if everything was perfect, in principle you would only require one spring. Just my thoughts of course.

If you are struggling, I may have a spare you can have, happy hunting in the loft !!

Jeff --- I know the set up procedure, what I was trying to say (badly) that in theory, if the main spring shut the rear carb and the front carb was manually shut, the same principle would apply and the main spring would close both carbs, but if the link were to become loose the front carb could be left open when the foot came off the gas and leave the engine revving !

It was my thought that the front spring was as a prevention of this happening when it was designed, I don't think they thought of the setup procedure and put in the front spring, if everything was perfect, in principle you would only require one spring. Just my thoughts of course.

Last edited by TilleyJon; 04-29-2017 at 11:26 AM.

#6

Yeah I kind of wondered... Surly he must know the set-up procedure.

If you had only one spring, that spring would have to be strong enough so you wouldn't have to hold you foot off the accelerator pedal _ the front of your shin would get quite sore.

A single strong spring like that would put too much pressure on the butterfly valves and wear the soft aluminum that they rest up against.

That's what that screw is doing circled in green, it keeps that larger spring from putting pressure on the butterfly valves, it's sole purpose is to give adequate pedal resistance, although, as you pointed out, if the linkage between the carbs did come lose, the arrangement would prevent the engine form revving.

Having two springs solves this problem, not only that, the first spring that holds the valves shut also adds to the pedal resistance.

The whole thing is poorly designed IMO. This arrangement tugs on the butterfly shaft in a sideways fashion, wearing the bushing out closest to the spring.

If you look at a pair of Zenith Stromberg carbs, its return spring is coiled around the shaft. This prevents sideways wear on the bushings and allows use of a stronger spring.

However even with this arrangement a stronger spring will wear out the soft aluminum where the butterfly valve comes in contact with the carb body.

But if I recall, the Stromberg carbs didn't have a separate needle screw to adjust the idle/balance.

It was done solely by the main butterfly valve, so the valve edge never came in hard contact with the carb body.

I would have to check and make sure.

My TR7 had Stromberg's, but it's been so long, I can't remember.

If you had only one spring, that spring would have to be strong enough so you wouldn't have to hold you foot off the accelerator pedal _ the front of your shin would get quite sore.

A single strong spring like that would put too much pressure on the butterfly valves and wear the soft aluminum that they rest up against.

That's what that screw is doing circled in green, it keeps that larger spring from putting pressure on the butterfly valves, it's sole purpose is to give adequate pedal resistance, although, as you pointed out, if the linkage between the carbs did come lose, the arrangement would prevent the engine form revving.

Having two springs solves this problem, not only that, the first spring that holds the valves shut also adds to the pedal resistance.

The whole thing is poorly designed IMO. This arrangement tugs on the butterfly shaft in a sideways fashion, wearing the bushing out closest to the spring.

If you look at a pair of Zenith Stromberg carbs, its return spring is coiled around the shaft. This prevents sideways wear on the bushings and allows use of a stronger spring.

However even with this arrangement a stronger spring will wear out the soft aluminum where the butterfly valve comes in contact with the carb body.

But if I recall, the Stromberg carbs didn't have a separate needle screw to adjust the idle/balance.

It was done solely by the main butterfly valve, so the valve edge never came in hard contact with the carb body.

I would have to check and make sure.

My TR7 had Stromberg's, but it's been so long, I can't remember.

Last edited by JeffR1; 04-29-2017 at 12:15 PM.

#7

Hi Jeff, I see where your coming from, both ways are dependent on perfect adjustment. if someone were to slacken off the intermediate throttle stop screw or it wears after the setup is complete, the full force of both springs would come to bear on the butterflies, with a single spring one has to adjust the stop to just take the pressure off the butterflies. Also if the throttle was setup over center then there would be a force greater than both springs applied every time you pushed the throttle down from idle position as the linkage went to and past center !!!

As you say not a great design. SU actually make throttle return springs that go around the shaft, and I thought that stops were used to take the spring load off the butterflies in that instance but I may be wrong.

Don't you just love the good old carb, takes me back to my Grandfather with his ear to some twin Webers and a screwdriver in his hand, he was better than Crypton tuning and with only his ears a screwdriver and experience.

As you say not a great design. SU actually make throttle return springs that go around the shaft, and I thought that stops were used to take the spring load off the butterflies in that instance but I may be wrong.

Don't you just love the good old carb, takes me back to my Grandfather with his ear to some twin Webers and a screwdriver in his hand, he was better than Crypton tuning and with only his ears a screwdriver and experience.

Last edited by TilleyJon; 04-29-2017 at 02:52 PM.

Trending Topics

#8

Jeff and Jon,

Thank you both. I did not have the lever in the attic. I found one that might work that was on my original carbs for my Healey (HD6 s just like the MK2). However it looks a little longer than the one in Jon's photo. It looks like SNG Barratt has it in stock so I will order one from them.

Lin

Thank you both. I did not have the lever in the attic. I found one that might work that was on my original carbs for my Healey (HD6 s just like the MK2). However it looks a little longer than the one in Jon's photo. It looks like SNG Barratt has it in stock so I will order one from them.

Lin

#9

#10

#11

I am good listening to the exhaust _ too rich _ or too lean...

On my 51 Bentley, it's really simple, but in some ways quite tricky, there are no idle/balancing screws, it's all done with the butterfly valves.

But what always works every time is to shut both valves hard, put the adjustment in the "middle" that connects the two carbs and lock it up.

I then give the idle screw 3 turns for initial start up.

When I do it this way, they always work out to be balanced.

That car is very finicky, the slightest turn of the mixture nut on the bottom of the carb is all it takes.

Turning it by a "flat" like the manual says is way too much.

The car idles at around 500/600 rpm, so any slight adjustment shows in the exhaust. (some say the Bentley should idle at 400, but I think that's just to slow for any engine)

Here's what I use, it's not the most accurate from what I've read though.

One of these days I'll get something better.

Sort of getting off subject here, but I think MK2 may find this interesting.

The following users liked this post:

csbush (05-02-2017)

#12

when I bought my S type in 2004 one of the things I found was that the long spring was just hanging at the bottom, and I couldn't figure out where it went either. The car did come with its factory service manual but even the manual was unclear. The local Jaguar mechanic was the one who showed me, and the bracket was still there but incorrectly oriented.

#13

#15