Crank belt pulley loose, how to remove?

#1

My latest XKR problem is that the crank pulley that drives the accessory and supercharger belts, without warning, disengaged from the crankshaft. This happened the same day I got the car back on the road after resolving other problems. I removed the belts after jiggering a tool to release the SC tensioner and the pulley is just flopping about unattached.

I searched the forum and found other instances of this and learned that the pulley is locked in place by a tapered "split collet". This part was difficult to find but I have it in hand according to the dealer I ordered it from. It appears that this part completely disintegrated and fell out of my car. I am hopeful that the crank is OK since it doesn't appear to have a pin.

The question is how do I remove the center bolt that locks down the pulley? I put a socket on it and the engine dutifully turns over. There has to be a way to stop the crank from turning but other than jamming a bar into the flywheel, I have no idea. My plan is to take the car to a mechanic (due to lack of facility) but I never let anyone near this thing until I can thoroughly explain what needs to be done.

I searched the forum and found other instances of this and learned that the pulley is locked in place by a tapered "split collet". This part was difficult to find but I have it in hand according to the dealer I ordered it from. It appears that this part completely disintegrated and fell out of my car. I am hopeful that the crank is OK since it doesn't appear to have a pin.

The question is how do I remove the center bolt that locks down the pulley? I put a socket on it and the engine dutifully turns over. There has to be a way to stop the crank from turning but other than jamming a bar into the flywheel, I have no idea. My plan is to take the car to a mechanic (due to lack of facility) but I never let anyone near this thing until I can thoroughly explain what needs to be done.

#2

This is the JTIS procedure for Crankshaft Pulley removal:

JTIS XK8 Crankshaft Pulley Removal.pdf

Even with the special tool, the recommendation is to lock the torque convertor with a lever if the pulley nut is particularly stubborn.

Graham

JTIS XK8 Crankshaft Pulley Removal.pdf

Even with the special tool, the recommendation is to lock the torque convertor with a lever if the pulley nut is particularly stubborn.

Graham

#3

Thanks a lot for taking the time to help me. I dug through the JTIS but never found this bit. The categories are a little difficult to sort out.

My situation is different since the "pulley/damper" has broken loose so I'm not sure the standard procedure is going to work. It appears from the illustrations and description that the two screws in the tool rely on the "pulley/damper" being locked in place in order to secure the crank shaft.

I had assumed that the split ring was gone but now I'm thinking that the "pulley/damper" has sheared off around the split ring since the "damper securing bolt" is still very securely fastened. My "pulley/damper" is no longer attached to anything so fastening the tool to that doesn't get much. I guess we will be using the "torque converter" to lock it. This is what I was calling the flywheel.

I read in one of the forum threads that the "pulley/damper" was not available. I sure hope that isn't true.

My situation is different since the "pulley/damper" has broken loose so I'm not sure the standard procedure is going to work. It appears from the illustrations and description that the two screws in the tool rely on the "pulley/damper" being locked in place in order to secure the crank shaft.

I had assumed that the split ring was gone but now I'm thinking that the "pulley/damper" has sheared off around the split ring since the "damper securing bolt" is still very securely fastened. My "pulley/damper" is no longer attached to anything so fastening the tool to that doesn't get much. I guess we will be using the "torque converter" to lock it. This is what I was calling the flywheel.

I read in one of the forum threads that the "pulley/damper" was not available. I sure hope that isn't true.

#4

#5

I will be scrounging for a used damper/pulley. The price on that is $1,384.50. Just when I thought the world couldn't possibly get more absurd. This to replace something that should never break in a thousand years.

BTW, according to the list I saw the XK8 version is more expensive than the supercharger version. Makes me think they have it reversed. Looks like the car will be sitting awhile.

BTW, according to the list I saw the XK8 version is more expensive than the supercharger version. Makes me think they have it reversed. Looks like the car will be sitting awhile.

#6

Just to add: Do NOT use the Crank Locating Tool (That is used to align the Crankshaft for changing the Chains/Tensioners) to hold the Crankshaft from turning. This will only cause damage to the Flywheel.

One method is to get a High Torque Air Wrench on the Crankshaft Bolt. This requires a certain amount of space, of course.

One method is to get a High Torque Air Wrench on the Crankshaft Bolt. This requires a certain amount of space, of course.

#7

Trending Topics

#8

Walt...Powerhouse Automotive on ebay sells their pulley upgrade kit optionally with the base crank pulley for about $653.

Get this kit for 1/2 the cost AND get a nice power 45bhp boost! Turn lemons into lemonade!

Jaguar XJR XKR s Type supercharger Lower Pulley Upgrade 45 50 BHP FTLB No Exch | eBay

Get this kit for 1/2 the cost AND get a nice power 45bhp boost! Turn lemons into lemonade!

Jaguar XJR XKR s Type supercharger Lower Pulley Upgrade 45 50 BHP FTLB No Exch | eBay

#9

Alot of work, but removing the cams on one bank, then feeding the end of a rope into a sparkplug hole in a cyl. that's at the bottom will prevent the engine from turning when it comes up and compresses the rope. Hopefully an impact wrench or even a couple good hits with a heavy hammer on the end of a breaker bar will do it first. Good luck.

#10

Yes lemonade is looking very appealing right now!

First I have to get that sucker off to see what the situation is. As you know there isn't a lot of visibility down there. I felt around with my fingers but difficult to determine what is up from that. The fact that the pulley is completely loose says that either the split ring is completely gone or the pulley broke loose from the hub. I have some hope for the former based on some other threads on this subject. It will take a right angle air wrench to get in there. I had no problem with a normal ratchet.

I am in the absolute worst couple of weeks of winter right now so will have to wait a bit to get on this. There is a garage not far from where the car is parked so I can drive it down there to get access to a lift. I learned by default that you can drive one of these cars a short distance without any belts. The dash lit up like a Christmas tree and the steering was non-existent but I don't think any harm was done. There was no sign of severe over heating (on a cold day) although I'm sure it got hotter than normal. When it broke I was in a bad spot on a narrow windy mountain road (what else!) but was able to run it down hill to a safe spot. This was my joy ride after getting the last set of problems fixed and I end up with a ride home on a truck. Gotta love the Jag! Solid black on the Consumer Reports frequency of repair chart and holding that spot solidly.

I did have this same problem on a Toyota many years ago (early 80's). In that case the pulley/damper was secured by a key that twisted off because the crank end was not properly heat treated. The dealer replaced the crank shaft and the damn thing did the same thing a couple of years later. Toyota knew about the problem but never fixed the crank. Of course they denied any responsibility (never saw this before) even though a Toyota mechanic told me there was a service bulletin on this problem. Deep down the auto companies all drink the same stuff. Deny, deny, and then deny some more.

First I have to get that sucker off to see what the situation is. As you know there isn't a lot of visibility down there. I felt around with my fingers but difficult to determine what is up from that. The fact that the pulley is completely loose says that either the split ring is completely gone or the pulley broke loose from the hub. I have some hope for the former based on some other threads on this subject. It will take a right angle air wrench to get in there. I had no problem with a normal ratchet.

I am in the absolute worst couple of weeks of winter right now so will have to wait a bit to get on this. There is a garage not far from where the car is parked so I can drive it down there to get access to a lift. I learned by default that you can drive one of these cars a short distance without any belts. The dash lit up like a Christmas tree and the steering was non-existent but I don't think any harm was done. There was no sign of severe over heating (on a cold day) although I'm sure it got hotter than normal. When it broke I was in a bad spot on a narrow windy mountain road (what else!) but was able to run it down hill to a safe spot. This was my joy ride after getting the last set of problems fixed and I end up with a ride home on a truck. Gotta love the Jag! Solid black on the Consumer Reports frequency of repair chart and holding that spot solidly.

I did have this same problem on a Toyota many years ago (early 80's). In that case the pulley/damper was secured by a key that twisted off because the crank end was not properly heat treated. The dealer replaced the crank shaft and the damn thing did the same thing a couple of years later. Toyota knew about the problem but never fixed the crank. Of course they denied any responsibility (never saw this before) even though a Toyota mechanic told me there was a service bulletin on this problem. Deep down the auto companies all drink the same stuff. Deny, deny, and then deny some more.

#12

Walt, I would suggest using an impact tool and start with low torque value the hammering affect might (should) turn it loose. I would also use a little PB Blaster to help. The crank will rotate a little but not fast enough to not enable the impact tool to do its job. I have had a lot of luck using a tighten then loosen process to free up the bolts on many projects. If need be we can get it to my house and I will get it on my lift and work on it for you.

#13

I assume you also have removed the fans and all of the coolant hoses behind the radiator for as much space as possible? I had to get a sheared bolt out of the alternator bracket once, and with the fans and shroud out, it was so much better. Of course, I'm not sure if the S/C adds more parts to contend with in front there.

What about taking off the bumper cover, radiator, and fans to get 'direct' access? I know its labor, but it could make all the difference in the world when 'torque' is needed.

What about taking off the bumper cover, radiator, and fans to get 'direct' access? I know its labor, but it could make all the difference in the world when 'torque' is needed.

#14

Back in the day we used to remove every crank bolt that way - I haven't(thankfully) had to do it on the Jag. but the principle is presumably the same. May be obvious but I'll state it anyway you must be sure to secure the breaker bar against the chassis/subframe properly or else all sorts of possibilities exist for carnage.

#15

I'm a geezer, and in my day we always used the breaker bar/starter method to break loose the crank bolt. But we always first confirmed motor rotation direction. Found the most reliable place for the other end of the breaker bar was the garage floor. Modern cars often have frame members in the way, so I would tie the breaker bar handle to a frame member instead. Whatever, make sure the breaker bar handle is at 90 degrees from the crank bolt.

#16

#17

THERE MUST BE ABSOLUTELY NO CHANCE THAT THE ENGINE FIRES.

Disable the ignition or the fuel injection by removing the fuse. Removing the fuel pump relay is insufficient due to residual pressure in the fuel rail.

Mentally picture that the crank and bar will rotate clockwise when facing the engine. Therefore, a bar positioned between 12 and 6 will sweep downwards. Find a position for the bar in the range of 2 to 4 such that it can rest against the ground or frame rail while remaining aligned with the front face of the pulley. Shim the handle at the contact point with the ground/frame rail to get a snug fit on the socket to prevent slippage. Rotate engine in clockwise direction if necessary.

Triple check all positioning. Mentally prepare your fingers to snap the key on and off rather than twist and hold. Bump starter with key.

Another way to do this is to raise the left front corner on a jack, position bar on the ground as above, position yourself so that you are shielded from a flying bar or socket, lower jack slowly. With a two foot bar, you can achieve a torque approaching 2000 foot/pounds through the magic of leverage and gravity. That is what the butler would call "sufficient".

Soaking the joint the days before with penetrating oil can be helpful. Occasionally tap the bolt head to encourage the penetrant to seep into the joint.

SAFETY FIRST AND DO NOT DO THIS UNLESS YOU UNDERSTAND IT COMPLETELY.

Do not expect that the bolt will be completely loose. The above only breaks the initial bond sufficiently to be able to continue manual loosening.

Last edited by plums; 02-05-2013 at 02:16 PM.

#18

Thanks to all for some very creative ideas!

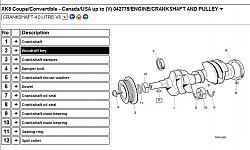

Graham, that crank parts diagram is very helpful. I am hoping that key is intact or the $1400 damper will be the least of my worries. I am still confused about how that all goes together. I was assuming that split ring was wedged into the damper hub by the center bolt but that wouldn't work with a key. We will see when this thing is apart.

Due to lack of facilities I plan to turn this over to whatever mechanic I can talk into doing the work. I'll report back once I know what happened.

Graham, that crank parts diagram is very helpful. I am hoping that key is intact or the $1400 damper will be the least of my worries. I am still confused about how that all goes together. I was assuming that split ring was wedged into the damper hub by the center bolt but that wouldn't work with a key. We will see when this thing is apart.

Due to lack of facilities I plan to turn this over to whatever mechanic I can talk into doing the work. I'll report back once I know what happened.

#19

The woodruf key is only for the cam chain sprockets, and the pulley is press fit via the main bolt pressing on the split collet. What is very weird is that you don’t have the latter anymore, it’s very strong material, and pending on how far the bolt is out it just can’t disappear. That sounds more as if the pulley was fitted without the collet…

#20