removing lower shock bushing

#1

I just removed by driver front strut assembly, compressed the spring, and got the top mount off. It is entirely crumbled, and I ordered new ones from welsh enterprises. I also ordered the bottom shock bushings. They too are totally destroyed, but I am having a really hard time removing them. Do they need to be pressed out? Or is there a diy way of doing it?

I was also careful to take all the shimms from the fulcrum bolt, and had them in the perfect order for reassembly. However, when I went inside for a glass of ice tea, my grandson grabbed the bolt, and took all the shims off. Now I have no idea how to reassemble them, Luckily I did not take off the passenger side, and will be much more careful this time,

My question is "Are both sides shimmed the same way? Is there a way of determining how to place the shims in the proper order?

I was also careful to take all the shimms from the fulcrum bolt, and had them in the perfect order for reassembly. However, when I went inside for a glass of ice tea, my grandson grabbed the bolt, and took all the shims off. Now I have no idea how to reassemble them, Luckily I did not take off the passenger side, and will be much more careful this time,

My question is "Are both sides shimmed the same way? Is there a way of determining how to place the shims in the proper order?

#3

+1 Rothwell

FWIW here are a few thoughts to consider:

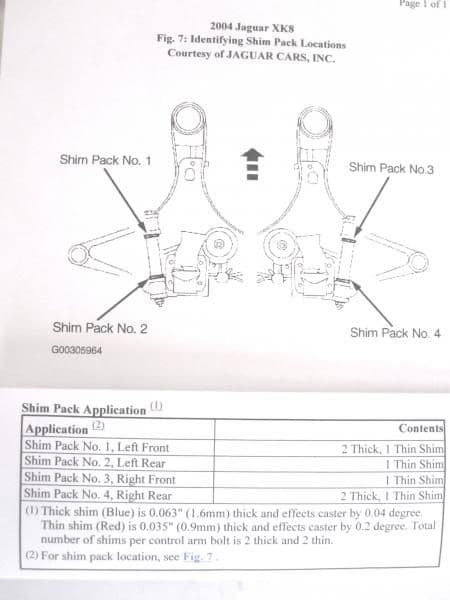

The shim packs are not symmetrical but rather crisscross for right side vs left side as Rothwell's diagram shows. A drop of superglue between shims and retaining washers helps on reassembly.(Some I have read, use a copper pipe)

Take care that the spacer does not press on the "inner race so to speak" or pinch and damage the new rubber seals of the new bushing. (I actually ground a step in the old outer race to make a spacer so that I could force the new rubber into that step with a screwdriver, then I could press the new bushing in with it. )

Lastly, make sure that the new bushing is not cocked going in.

FWIW here are a few thoughts to consider:

The shim packs are not symmetrical but rather crisscross for right side vs left side as Rothwell's diagram shows. A drop of superglue between shims and retaining washers helps on reassembly.(Some I have read, use a copper pipe)

Take care that the spacer does not press on the "inner race so to speak" or pinch and damage the new rubber seals of the new bushing. (I actually ground a step in the old outer race to make a spacer so that I could force the new rubber into that step with a screwdriver, then I could press the new bushing in with it. )

Lastly, make sure that the new bushing is not cocked going in.

#4

#6

When replacing my lower shock bushes, I found they had rusted solid in position. I couldn't even shift them using a 10 ton hydraulic press.

In the end I pushed out the centre metal tube complete with the rubber insert then cut a slot in the remaining bush outer sleeve with a hacksaw. After a lot of bashing with a cold chisel, I managed to fold the sleeve in on it's self and remove it.

Just try not to cut into the shock absorber eye although a slight nick shouldn't cause a problem.

I found it quite time consuming so good luck.

In the end I pushed out the centre metal tube complete with the rubber insert then cut a slot in the remaining bush outer sleeve with a hacksaw. After a lot of bashing with a cold chisel, I managed to fold the sleeve in on it's self and remove it.

Just try not to cut into the shock absorber eye although a slight nick shouldn't cause a problem.

I found it quite time consuming so good luck.

Last edited by DandyAndy; 02-08-2017 at 04:03 AM.

#7

The general "consensus" is that if you have an aging standard suspension, it is best to just buy a new shock with the bushing built in. The removal of the bushing seem to be only worth it if you have the more expensive adaptive suspension, as each shock is way more expensive. Obviously, your wallet, your time, your call.

Best of luck, keep us posted.

Trending Topics

#8

I used the same procedure as Andy and was able to replace them with a 6" bench vise. The bushings were $31 with shipping from the British Parts International site on ebay, so worth the effort to me. The bushings weren't rusted in, but very tight.

I now have a 20 ton HF press and that might work without cutting the sleeve but I haven't had the opportunity to try yet.

I now have a 20 ton HF press and that might work without cutting the sleeve but I haven't had the opportunity to try yet.

The following users liked this post:

Ungn (02-08-2017)

#9

#11

I got the press from autozone, but could not budge the bushing at all. I think the tool was missing the correct bushing insert. I am going to wait until I get the bushings on Monday, and take them to a machine shop to remove and insert them. I really have no need for a twenty ton press, and afraid I may botch it up.

I do have the adaptive shocks and they seem to be ok...the car has 58,000 miles, so I think I will reuse the shocks. I would switch to the bilstein shocks but I wonder if they would work with the adaptive system.

I gave up trying to remove my calipers, and could not get the bolts to budge. The rotors are in good shape, and although I wanted to have them resurfaced, I will give up and use them as is.

I started the engine and it roared to life, but then the lights came on....dsc not avail, suspension fault, cruise not avail etc....but then I remembered the shocks were disconnected, the brake sensors were disconnected, etc....hopefully those codes will disappear once I reinstall the shocks.

Thank you for all who posted. I deeply appreaciate all the wealth of knowledge that all of you offer.

I do have the adaptive shocks and they seem to be ok...the car has 58,000 miles, so I think I will reuse the shocks. I would switch to the bilstein shocks but I wonder if they would work with the adaptive system.

I gave up trying to remove my calipers, and could not get the bolts to budge. The rotors are in good shape, and although I wanted to have them resurfaced, I will give up and use them as is.

I started the engine and it roared to life, but then the lights came on....dsc not avail, suspension fault, cruise not avail etc....but then I remembered the shocks were disconnected, the brake sensors were disconnected, etc....hopefully those codes will disappear once I reinstall the shocks.

Thank you for all who posted. I deeply appreaciate all the wealth of knowledge that all of you offer.

#12

Be aware that it is almost impossible to push in the new bush without damaging the rubber boot, the solution is to remove the boot first and replace afterwards.

I pushed the new bush in using the old sleeve in a vice, I had to also use another spacer on the other side to get the bush all the way in.

Its easier to use a hook like this to get to boot securing clips back into place.

I pushed the new bush in using the old sleeve in a vice, I had to also use another spacer on the other side to get the bush all the way in.

Its easier to use a hook like this to get to boot securing clips back into place.

#13

Here is a pic of the old sleeve that I ground a step in to accomodate the rubber.

#14

Thanks to all your great posts, I managed to get the old shock bushings out and pressed in the new ones. All was great until I reinstalled the spring. The top shaft of the shock absorber broke as i was tightening it...too much corrosion where it rested. So Now i have hugher (huge x 3) problem...My shock part number is MJB2140EC, and looks like I will be searching the web trying to find one cheap. My question is that I know I should replace both, but wonder if I can reuse the other one without problems. It is not leaking and only has 56,000 on it. Does any one know where i can get these shocks fairly cheaply??

#15

#16

#17

#19

Finally got the shocks and installed them with little problems. I did find that the arm for the HID headlights was disconnected, but managed to get it back on.

While I changed the bushings and mounts, I decided to change the brakes, and replaced them so easily that I could not believe that Jaguar made it so easy....two pins, remove spring, pop in new brake shoes.

My car is still on jackstands, and ready to put the tires on.,BUT

My abs light came on, and cannot figure out why. All I did is clean the sensors, the entire wheel area, and cleaned the contacts. Could the light go on because the car is off the ground???? With the engine running, I pump the break pedal and all seems fine, but is seems to move slowly to the floor...I checked for leaks and there are none, and fluid is still full....Did I forget to do something, or did I ruin some part<<<

While I changed the bushings and mounts, I decided to change the brakes, and replaced them so easily that I could not believe that Jaguar made it so easy....two pins, remove spring, pop in new brake shoes.

My car is still on jackstands, and ready to put the tires on.,BUT

My abs light came on, and cannot figure out why. All I did is clean the sensors, the entire wheel area, and cleaned the contacts. Could the light go on because the car is off the ground???? With the engine running, I pump the break pedal and all seems fine, but is seems to move slowly to the floor...I checked for leaks and there are none, and fluid is still full....Did I forget to do something, or did I ruin some part<<<