Air suspension problem - front end won't raise

#1

Hello, I've read all sorts of posts on the air suspension problems which seem so common. Even so, I'm kinda stuck. The car is a 2006 xj8. I've redone the piston ring with Bagpipe Andy's kit. I had stripped plastic threads where the fitting fits in. I got it tight enough that it's not leaking. When I hooked it back up, the rear raised up in nothing flat and stays up. The front raised just a tiny bit...1/4" maybe. It then lowers right back down to exactly where it was. As soon as I hear the compressor kick off, I turn off the car and listen for leaks. I hear absolutely no hissing. I've done the soap bubble thing many times. No bubbles at all, anywhere. I loosened the fittings near the ecats until they hissed and tightened them up. No leaks there. None apparent on the air shocks either. No bubbles and quieter than a dead mouse. I checks the level sensor on the suspension while the wheel was off. It seems to be tightly attached and the wires looked ok. All the grounds seem tight. Air compressor kicks on, but just won't raise the front...maybe a super tiny bit, if at all. Any suggestions. My head is hurtin big time.

Thank you, Ben

Thank you, Ben

#3

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,392

Received 12,739 Likes

on

6,380 Posts

Hi Ben,

Welcome to the Jaguar Forums! It's great to have you with us.

I have moved your post from the forum for the X308 to the forum for the X350, which is the Jaguar factory project code for your 2006 XJ8. Here you will find knowledgeable owners of similar cars.

Please visit the New Member Area - Intro a MUST and post a required introduction so we can learn something about you and your Jaguar and give you a proper welcome.

Cheers,

Don

Welcome to the Jaguar Forums! It's great to have you with us.

I have moved your post from the forum for the X308 to the forum for the X350, which is the Jaguar factory project code for your 2006 XJ8. Here you will find knowledgeable owners of similar cars.

Please visit the New Member Area - Intro a MUST and post a required introduction so we can learn something about you and your Jaguar and give you a proper welcome.

Cheers,

Don

Last edited by Don B; 06-14-2018 at 09:45 AM.

The following users liked this post:

AD2014 (06-22-2018)

#4

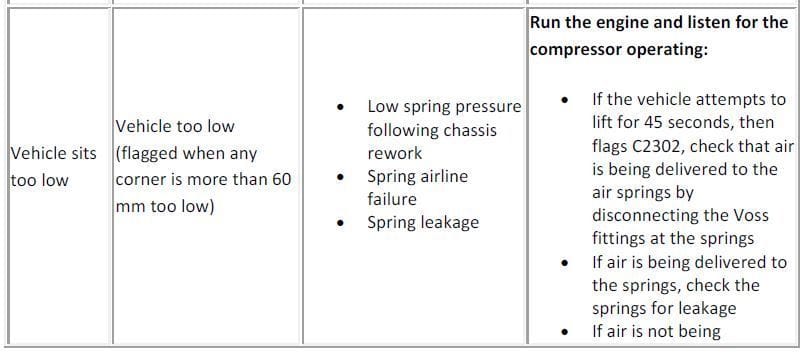

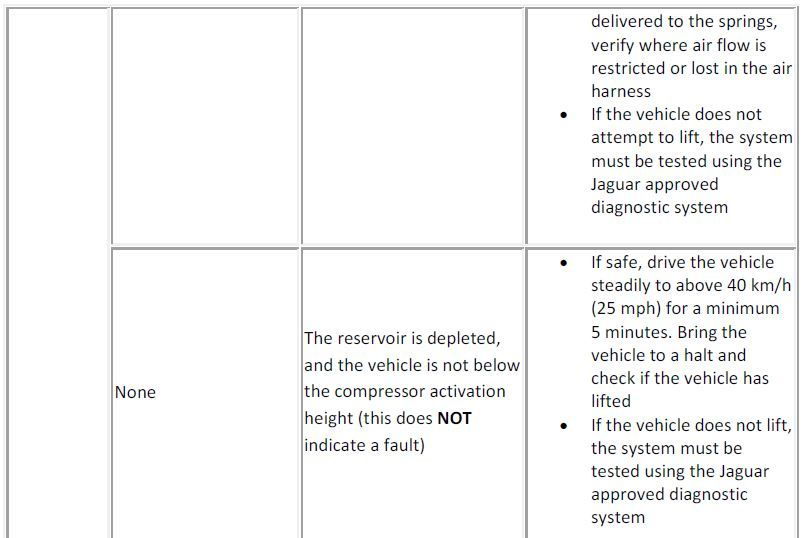

Yes. I drove it about 5 miles with speeds up to about 60mph. I'm glad the road was smooth! It never lifted. Tires actually scrape when turning sharply.

Thank you Don for putting me where I belong. Lol.

This whole suspension thing could drive a guy insane. Any and all advice would be and is very much appreciated.

Thank you Don for putting me where I belong. Lol.

This whole suspension thing could drive a guy insane. Any and all advice would be and is very much appreciated.

#5

If you have no fault indicated then the ASM thinks the car is at the correct height, except that it actually isn't ! It seems to me that the height calibration for the front may have been lost or the front height detector is not working correctly. A re-calibration of the ride height should put matters right.

The following users liked this post:

Don B (06-14-2018)

#7

Frasier,

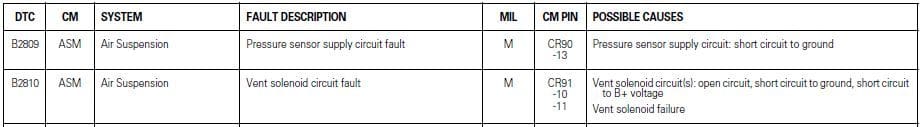

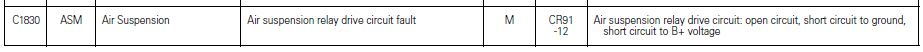

Ran a diagnostic and got these three codes.

B2810...air suspension vent solenoid circuit failure.

C1830...air suspension compressor relay circuit failure.

C2302...leveling plausibility error.

it's been about 30 hours since I messed with the car. The rear end settled about half an inch lower than yesterday. The yellow light on dash is now off. No longer says air suspension fault. The red light remains on saying vehicle too low. Started car and compressor runs maybe 10 seconds and then stops. Kicks on a minute or so later and runs 10 seconds again. Switched out relay #1 using same type of relay. Compressor kicked on maybe 30 seconds and then off. Then back to 10 seconds on minute off pattern. Car didn't rise at all this time. Not even the back. Compressor after running seemed to vent air. Kind of a pfffftttt. Crazy dang system wants to send me to the liquor store.

How do you gather info on the leveling sensors?

Ran a diagnostic and got these three codes.

B2810...air suspension vent solenoid circuit failure.

C1830...air suspension compressor relay circuit failure.

C2302...leveling plausibility error.

it's been about 30 hours since I messed with the car. The rear end settled about half an inch lower than yesterday. The yellow light on dash is now off. No longer says air suspension fault. The red light remains on saying vehicle too low. Started car and compressor runs maybe 10 seconds and then stops. Kicks on a minute or so later and runs 10 seconds again. Switched out relay #1 using same type of relay. Compressor kicked on maybe 30 seconds and then off. Then back to 10 seconds on minute off pattern. Car didn't rise at all this time. Not even the back. Compressor after running seemed to vent air. Kind of a pfffftttt. Crazy dang system wants to send me to the liquor store.

How do you gather info on the leveling sensors?

Trending Topics

#9

Join Date: Nov 2009

Location: The beautiful Mornington Peninsula in OZ

Posts: 2,974

Received 740 Likes

on

623 Posts

I suggest that you examine the vent solenoid particulary the wiring first and then the

solenoid itself for deposits preventing operation.

info here:https://www.jaguarforums.com/forum/x...-133030/page2/

solenoid itself for deposits preventing operation.

info here:https://www.jaguarforums.com/forum/x...-133030/page2/

The following users liked this post:

Don B (06-15-2018)

#10

meirion 1,

Thank you for your advice. I actually took the compressor apart and saw exactly what you were posting about. I cleaned everything thoroughly and made sure all orifices were open and clean. I really went slowly making sure I had everything clean and went slowly putting it all back together. I really thought it was gonna work. And it did, initially anyway. The rear aired up quickly. I was jazzed...until I noticed the front very barely moved. Gonna look into the height sensors and recalibration suggestion after work tomorrow, actually today. Lol. It's 3:41 here. Funny how the mind won't stop sometimes. Maybe not so funny.

Thank you.

Thank you for your advice. I actually took the compressor apart and saw exactly what you were posting about. I cleaned everything thoroughly and made sure all orifices were open and clean. I really went slowly making sure I had everything clean and went slowly putting it all back together. I really thought it was gonna work. And it did, initially anyway. The rear aired up quickly. I was jazzed...until I noticed the front very barely moved. Gonna look into the height sensors and recalibration suggestion after work tomorrow, actually today. Lol. It's 3:41 here. Funny how the mind won't stop sometimes. Maybe not so funny.

Thank you.

#11

Join Date: Nov 2009

Location: The beautiful Mornington Peninsula in OZ

Posts: 2,974

Received 740 Likes

on

623 Posts

You need to be sure that the vent valve is working electrically.

I will look for pinout test to do that.

You could try the following:

Depressurise system completely by breaking joint in pipework near ballast tank.

Remove battery connections and touch together for say 10 secs.

Remake pipe joint and reconnect battery.

Start engine and if needed drive for up to 20 mins.

I will look for pinout test to do that.

You could try the following:

Depressurise system completely by breaking joint in pipework near ballast tank.

Remove battery connections and touch together for say 10 secs.

Remake pipe joint and reconnect battery.

Start engine and if needed drive for up to 20 mins.

#14

Join Date: Nov 2009

Location: The beautiful Mornington Peninsula in OZ

Posts: 2,974

Received 740 Likes

on

623 Posts

You really need the test procedure because the valve only fires briefly at certain times.

I think you could put 12 volts across the valve itself briefly to see if it clicks.

If it does not click check for continuity.

Ensure that the valve is completely disconnected electrically from the vehicle

when doing that.

You can download the Electrical Guide from the stickies on this forum.

Page 5.3 shows the compressor and vent valve.

I think you could put 12 volts across the valve itself briefly to see if it clicks.

If it does not click check for continuity.

Ensure that the valve is completely disconnected electrically from the vehicle

when doing that.

You can download the Electrical Guide from the stickies on this forum.

Page 5.3 shows the compressor and vent valve.

Last edited by meirion1; 06-16-2018 at 06:16 PM.

#15

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,392

Received 12,739 Likes

on

6,380 Posts

Sorry I've been scarce - hectic times in my life right now and it's not letting up.

The pinpoint tests G256924p8 for the exhaust valve or vent solenoid begin on pdf page 278 of the Chassis section of the Workshop Manual, which can be downloaded here:

Jaguar X350 Workshop Manual Section 2. Chassis

Given that Flashvictim has carefully cleaned the exhaust valve and other internals of the compressor, and it seems to be opening noticeably, I'm thinking about possible causes of B2810 and C1830:

Both codes can be caused by an open circuit, and since this is frequently caused by corrosion on the grounds, it would be worth cleaning them. For the air suspension relay, the ground is one of the two behind the right headlamp. The vent solenoid is grounded through the ASM, which is grounded below the right rear seat or in front of the Rear Electronic Module (REM). The air compressor is grounded behind the left headlamp. All of these grounds develop a thin whitish layer of aluminum oxide, which is an electrical insulator. At the link below is some info about cleaning them and the very low torque specification for the ground nuts to prevent snapping the studs off the body:

Earths/Grounds Near Headlamps

C2302 is one of the codes that can be flagged when the compressor piston ring becomes so worn that it cannot pressurize the system in the time allotted by the ASM (the even more common code is C2303, Reservoir Plausibility Error). The possible causes of both codes are the same, "Mechanical/pneumatic fault such as: --pipe disconnected, --air leak."

The Jaguar documentation does not offer an explanation of what is different about how C2302 and C2303 are triggered, but the Workshop Manual suggests C2302 can be triggered by insufficient air pressure/delivery or a leak in one or more air springs:

Since Flashvictim has already replaced the compressor piston ring with Andy's kit, one question would be whether the ring might have been installed upsided down with the lap joint the wrong way round, but we would think that if the compressor were not supplying sufficient pressure the rear end would not rise properly either.

One possible cause of the front end not lifting might be a problem in the valve block in the trunk under the spare wheel. It might be worth cleaning the electrical connectors at the valve block and also testing for leaks at all the connections at the valve block and reservoir.

Since Flashvictim's '06 has only one front height sensor, a leak in either front air spring could prevent the front end from rising....

Cheers,

Don

Last edited by Don B; 06-17-2018 at 09:03 PM.

#17

Join Date: Nov 2009

Location: The beautiful Mornington Peninsula in OZ

Posts: 2,974

Received 740 Likes

on

623 Posts

Hi Don

Many thanks for the information that you have posted.

I think there may be a pinpoint section for the compressor vent valve missing from the

chassis section of the workshop manual since I am unable to locate the reference which

you posted ie G256924p8. Perhaps you could confirm this when you have time?

Many thanks for the information that you have posted.

I think there may be a pinpoint section for the compressor vent valve missing from the

chassis section of the workshop manual since I am unable to locate the reference which

you posted ie G256924p8. Perhaps you could confirm this when you have time?

#18

Join Date: Feb 2014

Location: Crossroads of America

Posts: 19,392

Received 12,739 Likes

on

6,380 Posts

I have repaired the link in my previous post to go directly to the Chassis section download (which is available in the X350 HOW TO quick links thread). Unless I'm going crazy (which is perfectly possible), the pinpoint tests for the vent solenoid are on pdf pages 278-280.

Please let me know if you still don't find it and I'll try again!

Cheers,

Don

The following users liked this post:

AD2014 (06-22-2018)

#20

Thank you all so much for the advice. I've been preoccupied with my wife the last week or so as she's been very ill. I've not purposefully not responded. I'm going to try all that was suggested. I read that someone wondered if I put the compressor ring on upside down. I actually thought of that also. I double checked that. It was ok.

I did not realize that a recalibration was something that required very expensive equipment and/or a jaguar repair facility. Again, thank you guys. You've made me feel very welcome with all your advice and the speed in which you deliver it. I'll let you know what's going on.

Ben (flashvictim)

I did not realize that a recalibration was something that required very expensive equipment and/or a jaguar repair facility. Again, thank you guys. You've made me feel very welcome with all your advice and the speed in which you deliver it. I'll let you know what's going on.

Ben (flashvictim)