What job has taken you the longest so far?

#1

Hey guys,

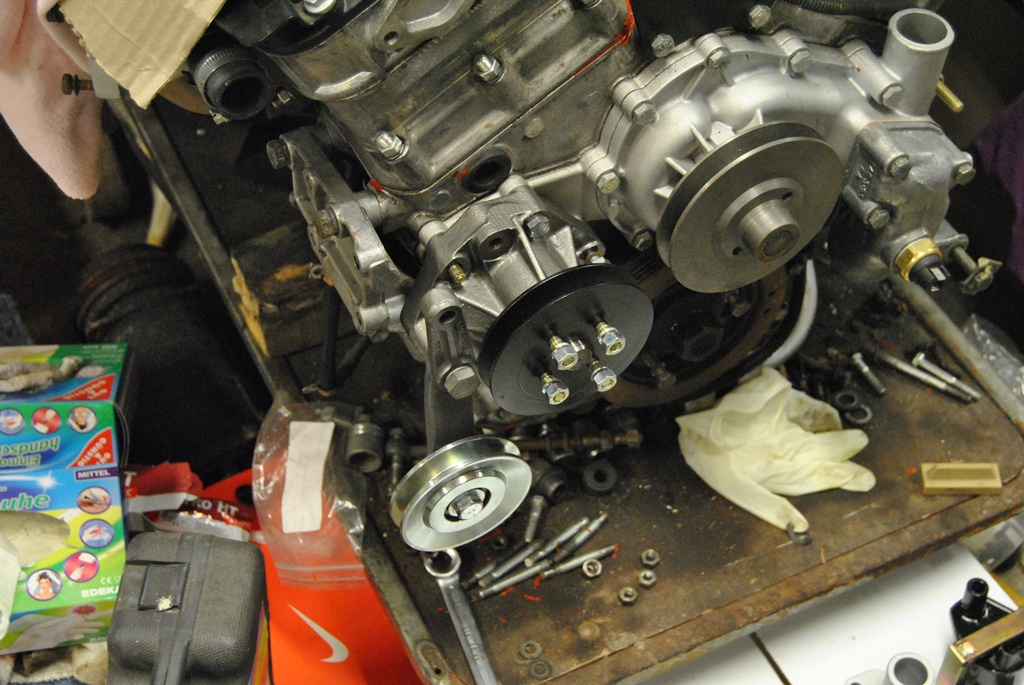

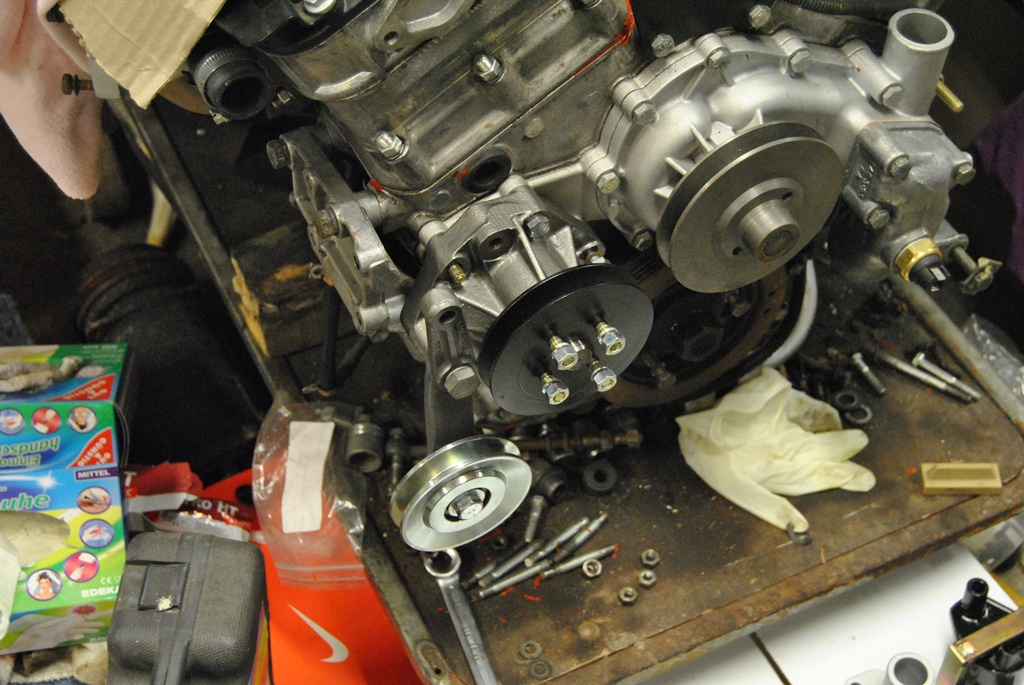

I have just finished the first part of my engine... Sounds stupid but it is how it is

After more than 16 hours of worktime, I have overhauled my fan bearing housing thingey... 16 hours for ONE piece?

Removal took about 10 minutes.

Taking it apart took about another 10 minutes.

Sourcing the parts I needed took about 2-3 hours (in total after spending hours phoning around for a bearing)

Cleaning the parts up and getting the grime off took a about 4 hours

Having them sandblasted (about 40 mins, 20 mins there, 20 mins back)

Spraying them about another 4 hours (waiting for paint to dry between coats)

Cleaning threads and preparing for assembly another 60 mins

Putting the bearing in was about 40 mins (as it wouldn't go it at first)

Adjusting the fan pulley on the bearing was another 20 mins

Inserting the studs about 5 mins

Testfitting the housing on the engine block about another 20 mins

Getting the arm all sorted another 30 mins

Finally getting everything sorted and on the engine another 40 mins

Removing it again to do other parts again 30 mins

Equals 965 mins so that is about 16 hours! And this picture doesn't even show it completed!

So, what took you long for ONE job. I'm not refering to say a headgasket change (which we all know takes for ever). I mean something which, in your mind, would be a job of a few minutes, maybe couple of hours, but turned into a looooong time job...!?

I have just finished the first part of my engine... Sounds stupid but it is how it is

After more than 16 hours of worktime, I have overhauled my fan bearing housing thingey... 16 hours for ONE piece?

Removal took about 10 minutes.

Taking it apart took about another 10 minutes.

Sourcing the parts I needed took about 2-3 hours (in total after spending hours phoning around for a bearing)

Cleaning the parts up and getting the grime off took a about 4 hours

Having them sandblasted (about 40 mins, 20 mins there, 20 mins back)

Spraying them about another 4 hours (waiting for paint to dry between coats)

Cleaning threads and preparing for assembly another 60 mins

Putting the bearing in was about 40 mins (as it wouldn't go it at first)

Adjusting the fan pulley on the bearing was another 20 mins

Inserting the studs about 5 mins

Testfitting the housing on the engine block about another 20 mins

Getting the arm all sorted another 30 mins

Finally getting everything sorted and on the engine another 40 mins

Removing it again to do other parts again 30 mins

Equals 965 mins so that is about 16 hours! And this picture doesn't even show it completed!

So, what took you long for ONE job. I'm not refering to say a headgasket change (which we all know takes for ever). I mean something which, in your mind, would be a job of a few minutes, maybe couple of hours, but turned into a looooong time job...!?

The following users liked this post:

Flint Ironstag (09-21-2019)

#2

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,231 Likes

on

939 Posts

body and paint work,most time involved, around 8/10 months!

engine and transmission modify & rebuild, around 3 months.

remember NOTHING in my car is standard factory anymore.

i just dont like ordinary cars, never have ,and seems never will,sorry!

modifying into a custom build is far more satisfying for me!

and most will never get the money that is put into a car that is standard factory.(probably a custom also).

for me, it will never be about the money anyway!

engine and transmission modify & rebuild, around 3 months.

remember NOTHING in my car is standard factory anymore.

i just dont like ordinary cars, never have ,and seems never will,sorry!

modifying into a custom build is far more satisfying for me!

and most will never get the money that is put into a car that is standard factory.(probably a custom also).

for me, it will never be about the money anyway!

Last edited by ronbros; 09-09-2017 at 12:17 PM.

#3

I'm not doing this for cash, Ron. The car will be worth a 'tad' more than what I invested i to it when done, but I am mainly doing it for my pleasure and for a long life.

Modified cars are great, if it isn't rare. My XJ8 is getting all the stuff done to it, what makes it mine and my taste. Heck, I want a 1971-1973 Chevy Camaro like spoiler on the rear... Who cares what others think! But back to this topic...

Bodywork takes time. Engine alone too... But I was refering to a job you thought(!!!) would be say a 10 min job which turnes into a nearly impossible task!

Modified cars are great, if it isn't rare. My XJ8 is getting all the stuff done to it, what makes it mine and my taste. Heck, I want a 1971-1973 Chevy Camaro like spoiler on the rear... Who cares what others think! But back to this topic...

Bodywork takes time. Engine alone too... But I was refering to a job you thought(!!!) would be say a 10 min job which turnes into a nearly impossible task!

The following users liked this post:

ronbros (09-09-2017)

#4

Join Date: Jul 2010

Location: Austin tx and Daytona FL.

Posts: 7,362

Received 1,231 Likes

on

939 Posts

Daim, at 83 yrs old , any job i do takes me 3 times as long, than it did 20yrs ago!

then again, most say i,m to old, but that dont stop me!

wife says if that gets you up and going, go for it!!

(except these damn computers), i,m still tying to figure out the upside down pictures, i have tried rotating ,but still comes on forum upside down?

Ron

then again, most say i,m to old, but that dont stop me!

wife says if that gets you up and going, go for it!!

(except these damn computers), i,m still tying to figure out the upside down pictures, i have tried rotating ,but still comes on forum upside down?

Ron

Last edited by ronbros; 09-09-2017 at 12:36 PM.

#5

Do you use a windows computer or an apple one? Windows: rotate, exit the programme and then open again. Should stay rotated then. Rotating online is a waste of time...

Regarding age: my grandad was I think 79 when he passed away. He would still work under his car. He even moved to a house with a garage pit! Just to be able to work under his car. He would do the valve setting, oil changes, etc.

Regarding age: my grandad was I think 79 when he passed away. He would still work under his car. He even moved to a house with a garage pit! Just to be able to work under his car. He would do the valve setting, oil changes, etc.

The following users liked this post:

ronbros (09-09-2017)

#6

Starter removal. Took me 3 days to get out the top bolt, as the exhaust needs to come out and then I can't see the bolt, so it's kind of like fishing to find it. There was a heat shield in the way, so I couldn't get the socket/universal joint on the bolt squarely so that added complication.

The following users liked this post:

rocketlift (10-07-2019)

#7

Hi Daim

You're not even on the 'Nursery Slopes' with that Job.

It took me Three Days! to remove the Nut that was on Top of just One Shock Absorber! in order to change the Shock Absorber Bushes.

This is a job that usually takes 5 Minutes!

The Story of that 'Nightmare' Starts right here: https://www.jaguarforums.com/forum/x...122634/page63/

You're not even on the 'Nursery Slopes' with that Job.

It took me Three Days! to remove the Nut that was on Top of just One Shock Absorber! in order to change the Shock Absorber Bushes.

This is a job that usually takes 5 Minutes!

The Story of that 'Nightmare' Starts right here: https://www.jaguarforums.com/forum/x...122634/page63/

Last edited by orangeblossom; 09-09-2017 at 04:55 PM.

Trending Topics

#8

Replacing the rear shocks.

Took me 2 years as I ended up with the WHILE YOU'RE AT IT syndrome.

Ended up with a full bare metal respray top and bottom and every suspension component cleaned/replaced and painted. LOL

Now I live in a dairy farming area every time I take her out (in Winter) it comes home full of mud and cow poo.

Took me 2 years as I ended up with the WHILE YOU'RE AT IT syndrome.

Ended up with a full bare metal respray top and bottom and every suspension component cleaned/replaced and painted. LOL

Now I live in a dairy farming area every time I take her out (in Winter) it comes home full of mud and cow poo.

The following 2 users liked this post by warrjon:

orangeblossom (09-09-2017),

ronbros (09-09-2017)

#10

I can think of many over the years, and as arthritis crept in, it just snowballed.

RHD starter motor probably tops the list after my 1 coffee so far.

Really stupid thought there Mr Jaguar.

Whilst "playing" and getting nowhere, I saw the oil stains (leaks playing games), and the next knuckle buster had the vocabulary soar, so OUT with teh engine. That took 6 hours, and I spent 3 days p*&^ing with that starter.

Next would be the heater tap on the S Type V6, worse than a starter motor on a V12, followed by the sway bar mount rubbers, coz the heater tap MUST be removed for access to the RH bracket top bolt, REALLY, in the 21st century, surely that tap could go somewhere else, there IS plenty of room.

RHD starter motor probably tops the list after my 1 coffee so far.

Really stupid thought there Mr Jaguar.

Whilst "playing" and getting nowhere, I saw the oil stains (leaks playing games), and the next knuckle buster had the vocabulary soar, so OUT with teh engine. That took 6 hours, and I spent 3 days p*&^ing with that starter.

Next would be the heater tap on the S Type V6, worse than a starter motor on a V12, followed by the sway bar mount rubbers, coz the heater tap MUST be removed for access to the RH bracket top bolt, REALLY, in the 21st century, surely that tap could go somewhere else, there IS plenty of room.

#11

#12

My worst job and the longest by far was cleaning 30 years of gunk and grease and grit out of the V inside and outside, and the front and back of the engine, and all the underneath and sides. A toothbrush, loads of white spirit, and two weeks of horrible grimy work, as I could only bear doing the job for about 40 mins max at a time.

One before and a couple of after photos attached. Clean, but does not hold a candle to Daim's great work!

One before and a couple of after photos attached. Clean, but does not hold a candle to Daim's great work!

The following 3 users liked this post by Greg in France:

#13

Join Date: Mar 2008

Location: Pacific Northwest USA

Posts: 24,743

Received 10,757 Likes

on

7,101 Posts

Jeeez, I could probably a dozen good examples from my memory banks !

Most recently, though, from my V12 conversion project

1) Non-destructive breaking down of the donor car was vastly more time consuming that I anticipated

2) Cleaning the V12 engine, even when out of the car, was sucking SO many hours I had to stop and call it "good enough" . It was seriously filthy and the oil/grease/dirt was very much "baked" into place. It's a good thing that the project goal was "driver quality" rather than "show quality"

Cheers

DD

Most recently, though, from my V12 conversion project

1) Non-destructive breaking down of the donor car was vastly more time consuming that I anticipated

2) Cleaning the V12 engine, even when out of the car, was sucking SO many hours I had to stop and call it "good enough" . It was seriously filthy and the oil/grease/dirt was very much "baked" into place. It's a good thing that the project goal was "driver quality" rather than "show quality"

Cheers

DD

The following 2 users liked this post by Doug:

Grant Francis (09-10-2017),

orangeblossom (09-10-2017)

#14

Join Date: Jul 2012

Location: Walnut Creek, California

Posts: 6,796

Received 2,399 Likes

on

1,880 Posts

Geez! Like Doug, so many!!! Like stars in the sky over the decades of messing with IC powered cars.

Like Ron, it has gotten slower. I hope to see 88 this month.

My two venerable old cars are for the most part OK, for now.

Present challenges are, for the most part.

1. Severely deferred yard work

2. Old Troy Bilt Chipper Shredders. One loaned to my neighbor and doing it's job quite well. I lumped it a couple of years ago!

3. Anothe neighbor gave me a bigger one, a "super Tomahawk" !!! With issues, to be expected.

Solutions in progress. Son opines, too slow!!!

Carl

Like Ron, it has gotten slower. I hope to see 88 this month.

My two venerable old cars are for the most part OK, for now.

Present challenges are, for the most part.

1. Severely deferred yard work

2. Old Troy Bilt Chipper Shredders. One loaned to my neighbor and doing it's job quite well. I lumped it a couple of years ago!

3. Anothe neighbor gave me a bigger one, a "super Tomahawk" !!! With issues, to be expected.

Solutions in progress. Son opines, too slow!!!

Carl

The following users liked this post:

Dukejag (09-18-2019)

#15

My worst job and the longest by far was cleaning 30 years of gunk and grease and grit out of the V inside and outside, and the front and back of the engine, and all the underneath and sides. A toothbrush, loads of white spirit, and two weeks of horrible grimy work, as I could only bear doing the job for about 40 mins max at a time.

One before and a couple of after photos attached. Clean, but does not hold a candle to Daim's great work!

One before and a couple of after photos attached. Clean, but does not hold a candle to Daim's great work!

Btw. I hate the mix and match of imperial and metric threads all over my engine... That takes ages to sort out.

The following users liked this post:

orangeblossom (09-10-2017)

#17

#18

Like ronbro and Grant, seems I always think, well that's an easy job only to have it turn into a major task, but the with old injuries from the military days, the body says "Are you freakin kidding me?"

A couple of times, when doing all the engine cleaning and checking the wiring, I laid on the creeper a bit too long, 5 to 10 mins. can be long for me with bulging disc and arthritis in lower back, thought I was going to get stuck like that for the rest of the night. All I could think of was me looking like an overturned turtle tryin to upright itself LMFAO

A couple of times, when doing all the engine cleaning and checking the wiring, I laid on the creeper a bit too long, 5 to 10 mins. can be long for me with bulging disc and arthritis in lower back, thought I was going to get stuck like that for the rest of the night. All I could think of was me looking like an overturned turtle tryin to upright itself LMFAO

Last edited by daverb; 09-11-2017 at 01:12 AM.

The following 2 users liked this post by daverb:

Grant Francis (09-11-2017),

ronbros (09-11-2017)

#19

Another example: the ABS unit on the actuator attached to the pedal is all metric. The screws that connected it to the body are imperial.

If you wanted to change it all to metric, well, you'll be redrilling, cutting etc. a good year...

#20

Join Date: Nov 2013

Location: Inverell, NSW, Australia

Posts: 3,014

Received 1,410 Likes

on

876 Posts

Great (and not so great) memories . . .

I smiled a rueful smile at the early references to starter motors by Grant & others because it was the very first Jaguar lesson I learned in the journey of turning my avatar Mk1 into a fire-breather. My mentors then were spanned across several successful Jaguar racing teams . . . each having a list of mods that enabled a full Jag saloon XK engine R&R in under an hour . . . and in those days the back of pits area at most tracks was little more than hardstand with perhaps a tent top for shade.

R&R starter motor turned out to be a walk in the park - a template for the (RHD) drivers floor with dimensions of access hole to be cut and filed clean; then dimensions of a cover plate that, with a few pk screws, turned an apparently standard floor into a "no holes barred" 5 minute R&R of the starter motor. Snapping flush the very last head stud in an XK block, comes close if you count a wasted day or more completing a 2 minute task.

No . . . I like the theme of changing perspective as Father Time pushes at us. Now, my largest under estimation is how much time it seems to take just getting started . . . the impact of "other stuff" over what I would prefer to be doing!!!

Cheers,

Ken

I smiled a rueful smile at the early references to starter motors by Grant & others because it was the very first Jaguar lesson I learned in the journey of turning my avatar Mk1 into a fire-breather. My mentors then were spanned across several successful Jaguar racing teams . . . each having a list of mods that enabled a full Jag saloon XK engine R&R in under an hour . . . and in those days the back of pits area at most tracks was little more than hardstand with perhaps a tent top for shade.

R&R starter motor turned out to be a walk in the park - a template for the (RHD) drivers floor with dimensions of access hole to be cut and filed clean; then dimensions of a cover plate that, with a few pk screws, turned an apparently standard floor into a "no holes barred" 5 minute R&R of the starter motor. Snapping flush the very last head stud in an XK block, comes close if you count a wasted day or more completing a 2 minute task.

No . . . I like the theme of changing perspective as Father Time pushes at us. Now, my largest under estimation is how much time it seems to take just getting started . . . the impact of "other stuff" over what I would prefer to be doing!!!

Cheers,

Ken

The following 3 users liked this post by cat_as_trophy: