Jaguar Formula E Suspensions Explained

Gorgeously rendered video goes over the finer points of suspension on Formula E cars.

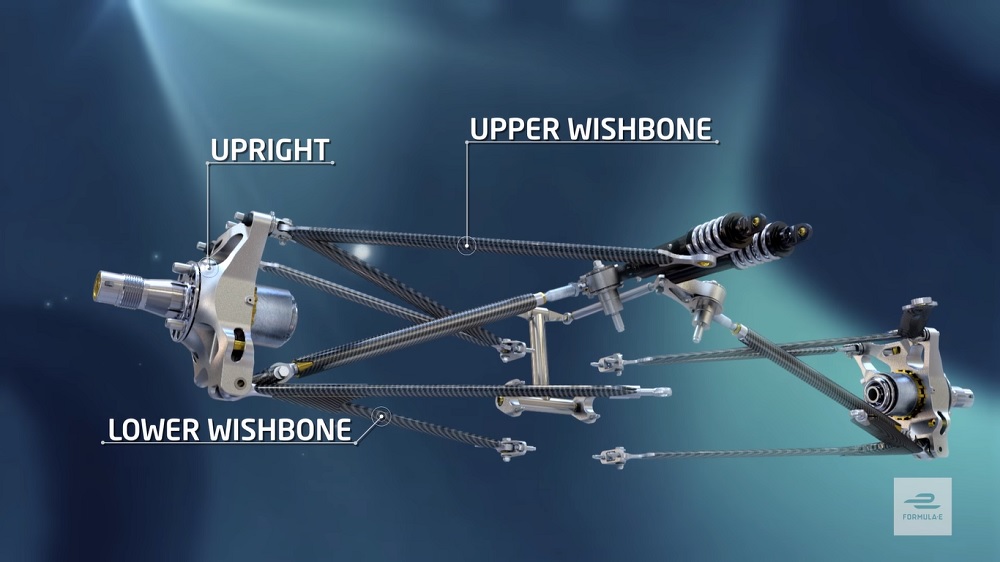

Since the series inception, Formula E cars have all used chassis built by France’s Spark. The company has also provided many of the car’s other components, like the suspension. And Formula E put together these two great looks at how the suspension works on cars like the Jaguar Racing I-Type.

The designs are, as you might expect, very modern. The rear suspension features push-rod designs with carbon-fiber wishbones that attach the spindles to the chassis. Needle-bearing-filled rockers connect to the horizontally mounted coilover setup, which dampens bumps. All of that can be tuned through cleverly tapered anti-rollbars that connect both sides of the suspension.

Bodywork hides all of this work, as is the case with the front suspension. The front suspension includes a similar push-rod setup to the rear, albeit with torsion bars instead of coil springs. That’s actually an old suspension concept, but these are more finely tunable than the ones you’ll find on a ‘68 Dodge Charger.

Since Formula E races on closed public streets, suspension tuning becomes paramount. All sessions from Free Practice 1 to the race are held in one day. That also means engineers like those at Jaguar Racing need to sort it quickly.

Jaguar Racing hopes that 2014-2015 Formula E champion Nelson Piquet Jr. breathes new life into the team. The program struggled in the 2016-2017 season. Piquet replaces Adam Carroll, who scored points in only two races. He’ll pair with young New Zealander Mitch Evans, who showed promise with four Top 10 finishes, including a fourth place in Mexico.

The other major change for the 2017-2018 season comes from the motor output. Maximum output bumps from 170 kilowatts (about 227 HP) to 180 kW (241 HP). The 2018-2019 season will see more power and no more mid-race car switching.