XK8 P0171, P0174, P0335 sat for a year

#1

I have owned a number of Jags over the years and only had my old 1990 XJS V12 convertible left until I picked a red 1999 XK8 that was not running.... don't ask.

The owner thought the alternator was bad and it wouldn't start. I trouble shot the no start and replaced the fuel pump. It now runs but it hesitated when you pumped the throttle and it only gets up to 3000 RPMs. I haven't driven it on the road yet because I haven't had time to get tags. I did retrieve P0171, P0174 and P0335 codes and the check engine light is on and the ABS light is on too. The Stability control and traction control messages are on as well.. The PO said the battery had run down just before it quit running.

I cleared the codes and started it up again and the codes didn't return but all the warning lights are still on. This car sat for a year so I expect some problems but this seems a little strange to have nearly every system show warnings.

I haven't worked on the V8 Jags but have done a lot on the V12 and the older 6's. Is this a case of picking these off one at a time or has anyone seen this happen on one of these after sitting for an extended period of time. BTW there is a good fully charged battery in it now and the volt meter is dead on 13 volts after starting.

The owner thought the alternator was bad and it wouldn't start. I trouble shot the no start and replaced the fuel pump. It now runs but it hesitated when you pumped the throttle and it only gets up to 3000 RPMs. I haven't driven it on the road yet because I haven't had time to get tags. I did retrieve P0171, P0174 and P0335 codes and the check engine light is on and the ABS light is on too. The Stability control and traction control messages are on as well.. The PO said the battery had run down just before it quit running.

I cleared the codes and started it up again and the codes didn't return but all the warning lights are still on. This car sat for a year so I expect some problems but this seems a little strange to have nearly every system show warnings.

I haven't worked on the V8 Jags but have done a lot on the V12 and the older 6's. Is this a case of picking these off one at a time or has anyone seen this happen on one of these after sitting for an extended period of time. BTW there is a good fully charged battery in it now and the volt meter is dead on 13 volts after starting.

#2

Welcome to the forum skymark,

You've already done the first essential by fitting a good battery. P0171 ('A' bank combustion too lean) and P0174 ('B' bank combustion too lean) are regulars. The possible causes are:

1. Engine misfire

2. Air intake leak between MAFS and throttle

3. Fuel filter, system blockage

4. Fuel injector blockage

5. Fuel pressure regulator failure (low fuel pressure)

6. Low fuel pump output

7. HO2S harness wiring condition fault

8. Exhaust leak (before catalyst)

9. ECM receiving incorrect signal from one or more of ECTS, MAFS, IATS, TPS

Of these, air leaks are the commonest cause.

P0335 is CKPS circuit malfunction. The possible causes are:

1. CKPS disconnected

2. CKPS gap incorrect / foreign matter on sensor face

3. CKPS sensing circuit open circuit, short circuit to ground, short circuit to high voltage

4. CKPS failure

When you get a minute, please follow this link New Member Area - Intro a MUST - Jaguar Forums - Jaguar Enthusiasts Forum to the New Member Area - Intro a MUST forum and post some information about yourself and your vehicle for all members to see. In return you'll get a proper welcome and some useful advice about posting to the forum.

Graham

You've already done the first essential by fitting a good battery. P0171 ('A' bank combustion too lean) and P0174 ('B' bank combustion too lean) are regulars. The possible causes are:

1. Engine misfire

2. Air intake leak between MAFS and throttle

3. Fuel filter, system blockage

4. Fuel injector blockage

5. Fuel pressure regulator failure (low fuel pressure)

6. Low fuel pump output

7. HO2S harness wiring condition fault

8. Exhaust leak (before catalyst)

9. ECM receiving incorrect signal from one or more of ECTS, MAFS, IATS, TPS

Of these, air leaks are the commonest cause.

P0335 is CKPS circuit malfunction. The possible causes are:

1. CKPS disconnected

2. CKPS gap incorrect / foreign matter on sensor face

3. CKPS sensing circuit open circuit, short circuit to ground, short circuit to high voltage

4. CKPS failure

When you get a minute, please follow this link New Member Area - Intro a MUST - Jaguar Forums - Jaguar Enthusiasts Forum to the New Member Area - Intro a MUST forum and post some information about yourself and your vehicle for all members to see. In return you'll get a proper welcome and some useful advice about posting to the forum.

Graham

The following users liked this post:

elic9 (01-26-2019)

#3

Graham

Thank you for the reply, I may have triggered these codes when I was trouble shooting the initial no-start problem. I took the air inlet hose off the throttle body and used starting fluid to determine the presence of ignition.The engine did start briefly so this more than likely triggered the P0171 and P0174 codes. Once I replaced the fuel pump the engine started and idled OK but the throttle response when I drove it a short circuit around the ramp was sluggish and acted like a cold engine with no cold compensation. It did improve as the car warmed up but was still sluggish. I cleared the codes and started it back up and no codes showed up. I just ordered a better OBD II

code reader to get a better picture because the Scangauge II I used didn't seem to react well with the Jag. I should have the new one tomorrow and it does do Jags.

I will access the CKPS sensor and check external condition harness and gap.

I should know more by the end of the weekend. It might be a few days before I get to it because my wife wants her new family room floor installed and that is just another hat I wear.

Mark

Thank you for the reply, I may have triggered these codes when I was trouble shooting the initial no-start problem. I took the air inlet hose off the throttle body and used starting fluid to determine the presence of ignition.The engine did start briefly so this more than likely triggered the P0171 and P0174 codes. Once I replaced the fuel pump the engine started and idled OK but the throttle response when I drove it a short circuit around the ramp was sluggish and acted like a cold engine with no cold compensation. It did improve as the car warmed up but was still sluggish. I cleared the codes and started it back up and no codes showed up. I just ordered a better OBD II

code reader to get a better picture because the Scangauge II I used didn't seem to react well with the Jag. I should have the new one tomorrow and it does do Jags.

I will access the CKPS sensor and check external condition harness and gap.

I should know more by the end of the weekend. It might be a few days before I get to it because my wife wants her new family room floor installed and that is just another hat I wear.

Mark

#4

ECTS (coolant) IATS (air) are suspects but would normally set codes. A partially blocked fuel filter or a gummed up throttle body wouldn't. Let's see what you new reader shows.

Graham

The following users liked this post:

elic9 (01-26-2019)

#5

Well gentleman I finally got my new scanner and the P0171, P0174 and the P0335 are showing up on the new one as well. The interesting thing is when I check the ABS codes, that I couldn't do on my old one, I get the dreaded C1095 code. There were no codes on the wheel sensors. I am going to pull the ABS controller and hope in fact I have a few solder joints to do. I had planned on moving the brake lines as opposed to disconnecting them but it sure looks tight. How far does the unit have to move to get it clear of the housing?<br />If the P0335 code identifys the Crank sensor it usually involves a "no start" condition. I am assuming it is a simple remove and clean the sensor. If the wire was damaged or the unit shot it would not start.<br />I did a few other things as well. I found a loose clamp just down stream of the MAP sensor. I checked the fuel pressure at the shreader valve and it was 35 PSI. I sprayed Electric cleaner on the lines I could get to to identify leaks but no success. I aslso removed the MAP sensor and cleaner it off with the electric cleaner.<br />I am going to fashion a smoke machine to probe further for a leak in the intake and pull the plugs and put them on a plug tester.<br />One other question if I might. I can read the fuel trims and I noticed a wide spread between 1 & 2 bank. I would assume the injectors would be suspect as a result?<br /><br />

#6

The sluggishness is likely related to the lean-running condition these codes indicate. Get an OBD reader that shows fuel trims (a cheap eBay/Amazon ELM327 is a great start). Anything over +5% Long Term is less than great. These codes show you might be at +25% right now on both sides.

Check the big air intake tube, top AND bottom for cracks.

Replace all o-rings to all tubes to the heads and throttle body

Check all the corrugated tubes, too.

Anywhere you see oil leaking there is likely air going in, too

Replace the VVT seals

Replace the dip stick o-ring

Check the valve covers for leaks

To go further, you can check YouTube and build a smoke tester for better visuals.

There is also a worse case where your trial run with starting fluid cracked the plastic intake, but let's keep those thoughts for later.

As you plug those leaks, you should see the trims going down (short term go negative almost instantly, and long term get lower, refreshed every 2 minutes). You can use that technique to your advantage: spray hydrocarbons around the heads, one area at a time. If some of it gets sucked in the engine, the short term trims should go negative almost instantly and inform you of the leak.

You might want to start pricing a replacement air flow meter. The later ones are super cheap, not sure about the earlier ones. You can always try and clean the one you have with a dedicated spray, but don't expect too much. Everything sort of starts with a good reliable measurement for air flow.

Best of luck, keep us posted.

Check the big air intake tube, top AND bottom for cracks.

Replace all o-rings to all tubes to the heads and throttle body

Check all the corrugated tubes, too.

Anywhere you see oil leaking there is likely air going in, too

Replace the VVT seals

Replace the dip stick o-ring

Check the valve covers for leaks

To go further, you can check YouTube and build a smoke tester for better visuals.

There is also a worse case where your trial run with starting fluid cracked the plastic intake, but let's keep those thoughts for later.

As you plug those leaks, you should see the trims going down (short term go negative almost instantly, and long term get lower, refreshed every 2 minutes). You can use that technique to your advantage: spray hydrocarbons around the heads, one area at a time. If some of it gets sucked in the engine, the short term trims should go negative almost instantly and inform you of the leak.

You might want to start pricing a replacement air flow meter. The later ones are super cheap, not sure about the earlier ones. You can always try and clean the one you have with a dedicated spray, but don't expect too much. Everything sort of starts with a good reliable measurement for air flow.

Best of luck, keep us posted.

#7

I priced a MAP sensor today and didn't get it and I am going to get one tomorrow. I agree that to insure I have a solid start point it just a good idea. I got a fuel filter as well. I didn't change it when I put the new fuel pump in and that was an oversight on my part. I had removed the intake tube to spray the starting fluid so no damage there. I am going to pull the crank sensor and clean and trace the harness up through the engine bay to insure there is no short in the harness. I will check and or replace the air cleaner as well. Is that accessed through the right wheel well?

Trending Topics

#8

#9

I priced a MAP sensor today and didn't get it and I am going to get one tomorrow...I got a fuel filter as well. I didn't change it when I put the new fuel pump in and that was an oversight on my part. I had removed the intake tube to spray the starting fluid so no damage there.

Changing the fuel filter is always good practice. It is in front of the driver side rear wheel, low and a bit deep. You can reach it with the wheel off. It is not near the fuel pump, so you would not have saved time with the earlier job, really.

I was talking about the intake runners on top of the engine. Those are all one plastic part and can crack if any of this starter fluid blew back.

FWIW, harbor freight has great o-ring kits for these repairs. Tons of variety for cheap. Always good to have around anyway.

Good luck.

#10

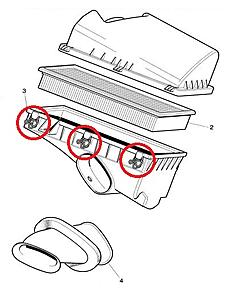

I did get to do a few things today. First I replaced the fuel filter and the air filter. The air filter that was in the box was a K&N and it didn't look like it would filter very well. When held up to the light it passed a lot of light... not good.I then cleaned the MAF sensor with dedicated cleaner. I the pulled the intake tube to the throttle body and checked for cracks and defects. I didn't spray starter fluid in it but worth the effort. The tube takes attention to detail to get the seal insert to mate correctly with the throttle body and the other end at the air filter needed some TLC as far as alignment was concerned.

I then hooked up my reader and cleared the engine codes and started it up NO check engine light and no codes. You guess which change did the trick.

I moved on to my next task the ABS system. I was doing a visual inspection to map out my approach to remove the controller and found the motor plug unplugged. It didn't remove the warning light and messages so on to the solder repair tomorrow. BTW I did check the three fuses in the left engine bay fuse box for the ABS.

I then hooked up my reader and cleared the engine codes and started it up NO check engine light and no codes. You guess which change did the trick.

I moved on to my next task the ABS system. I was doing a visual inspection to map out my approach to remove the controller and found the motor plug unplugged. It didn't remove the warning light and messages so on to the solder repair tomorrow. BTW I did check the three fuses in the left engine bay fuse box for the ABS.

#11

The tube takes attention to detail to get the seal insert to mate correctly with the throttle body and the other end at the air filter needed some TLC as far as alignment was concerned.

I then hooked up my reader and cleared the engine codes and started it up NO check engine light and no codes. You guess which change did the trick.

I then hooked up my reader and cleared the engine codes and started it up NO check engine light and no codes. You guess which change did the trick.

Some of the codes are 2-trips and might come back. I would encourage you to check the fuel trims to see where you stand. The code trips at 25% correction for fuel, but anything in the teens can be noticed. Recommendation is to get it down to around 5 if possible/cost effective.

#12

I did get the ABS controller out without disconnecting the brake lines. I was disappointed at first because the solder joints in question didn't look defective. I then got a magnifying eye piece and it looked strange and I realized there was a coating over the solder joint. I got a skill knife and stripped it away and in fact the left one was separated from the board. The right one was sketchy looking but I re-soldered them both and it is in a vice here in my garage setting up after re-sealing. I'll take it up to the hanger tomorrow and put it all back together and report back. A couple of things that might help the next person to take this job on might like to know. First when you are removing the controller take the complete mount off before you attempt to separate the box from the assembly. The windshield washer neck can be removed by turning it clockwise and it will separate from the neck and give you more room to work. You will have to remove the forward wheel well panel to get you hand in to hold the neck when you re-install it. When you begin to separate the controller box lid from the unit there are lock clips on the bushings that the attach bolts go through. You really need to pop those off before you attempt any method you use to separate the lid from the box. I wish I had seen them it would have made the job easier.

The following users liked this post:

cjd777 (03-17-2018)

#13

Well the saga continues. I reinstalled the ABS controller and the Stability, Traction Fail messages were gone as was the ABS light but... the Electrical Fault and Suspension Fail messages appeared. I pulled the plugs back off the controller to confirm that wasn't the source of the warning but they remained. I pulled a few fuses based on a post that dealt with this problem to no avail. I did a soft reset still no success. I fulled a 5 amp fuse that I miss identified put it back and the next start up the messages were gone. Test drove for about 25 miles and no messages but the check engine light returned with the P0171 & P0174 codes. The fuel trims were showing about 8.25 on each side fairly steady.

When I fist started driving the car when I punched it the RPM went to 4000 fairly quick but the car didn't respond in kind. It was as if the tranny was slipping. The further I drove it that disappeared and actually drove pretty normal but with a slight stumble at each shift point.

I did reset the codes when I got back and they stayed out while the car sat and idled but I am under no illusion they will return I am sure.

I am leaning toward the MAF sensor. I drove the car about ten miles before it came back on after continual being on for a week.

When I fist started driving the car when I punched it the RPM went to 4000 fairly quick but the car didn't respond in kind. It was as if the tranny was slipping. The further I drove it that disappeared and actually drove pretty normal but with a slight stumble at each shift point.

I did reset the codes when I got back and they stayed out while the car sat and idled but I am under no illusion they will return I am sure.

I am leaning toward the MAF sensor. I drove the car about ten miles before it came back on after continual being on for a week.

#14

Well the saga continues. I reinstalled the ABS controller and the Stability, Traction Fail messages were gone as was the ABS light but... the Electrical Fault and Suspension Fail messages appeared. I pulled the plugs back off the controller to confirm that wasn't the source of the warning but they remained. I pulled a few fuses based on a post that dealt with this problem to no avail. I did a soft reset still no success. I fulled a 5 amp fuse that I miss identified put it back and the next start up the messages were gone. Test drove for about 25 miles and no messages but the check engine light returned with the P0171 & P0174 codes. The fuel trims were showing about 8.25 on each side fairly steady.

When I fist started driving the car when I punched it the RPM went to 4000 fairly quick but the car didn't respond in kind. It was as if the tranny was slipping. The further I drove it that disappeared and actually drove pretty normal but with a slight stumble at each shift point.

I did reset the codes when I got back and they stayed out while the car sat and idled but I am under no illusion they will return I am sure.

I am leaning toward the MAF sensor. I drove the car about ten miles before it came back on after continual being on for a week.

I almost forgot the Restricted Performance message came on and off intermittently.

When I fist started driving the car when I punched it the RPM went to 4000 fairly quick but the car didn't respond in kind. It was as if the tranny was slipping. The further I drove it that disappeared and actually drove pretty normal but with a slight stumble at each shift point.

I did reset the codes when I got back and they stayed out while the car sat and idled but I am under no illusion they will return I am sure.

I am leaning toward the MAF sensor. I drove the car about ten miles before it came back on after continual being on for a week.

I almost forgot the Restricted Performance message came on and off intermittently.

#15

Hmm, at least one of the long term fuel trims should be at +25 for the code to appear. Fuel trims are an "elevation" map, based on RPM and Load. Air leaks are best identified at idle (or deceleration) with high vacuum. High fuel trims at higher load/rpm may point to fuel issues or air flow meter. For now, disregard the short term trims.

#16

Well gentlemen I finally nailed it. I was focusing on the MAF sensor and in the back of my mind I remembered a post from a while back about cleaning the MAF sensor. I was going to drive it down to Advance Auto and plunk down the $134 plus core. It seems I forgot about the embedded portion that can only be seen looking straight down the cavity next to the ruby drop. When I cleaned it the other day it was in need of cleaning and it did make a difference but obviously was not THE fix. I went back and cleaned the cavity area that has the two transistor looking elements and bam! Tha Car now runs like a bat outta hell. I just got back from a fifty mile jaunt, no codes, and no messages. Ran and shifted solid. I guess the moral of this story is “ ya gotta be smarter than a MAF sensor.”

Thank you all for your insights this has been a royal PITA.

Thank you all for your insights this has been a royal PITA.

The following users liked this post:

RJ237 (03-19-2018)

#17

I guess It ain't over till it's over. I was out for a drive today and got the messages and the P0172 and The P0174 code again but the car still ran good. Needless to say I was more than a little bummed. I won't go into the long explanation but I returned to the driver's side fuse box and found a problem with the ignition relay at the top of the fuse block. It seems the cut out for the fuse block was touching the relay and it was kinda cocked a little. I moved it and got a few lights on the dash flicker and the codes and messages returned. I took a dremel and cut the surround back a little so it didn't interfere with the relay and all is well in Jag town.

#18

The ONLY 2 DTCs I would be concerned with right now are P1798 and P1260

P1798 (TCM)

CAN INST token message missing

Possible Causes

Other CAN control module CAN related fault(s)

CAN open circuit fault – INST to TCM

CAN short circuit fault

INST failure

TCM failure

P1260 (ECM)

Security input malfunction

Possible Causes

KTM to ECM circuit: short circuit, high resistance or open circuit

Loss of ignition switched power supply to the ECM PIN EM82-09 for greater than 16 milliseconds

KTM failure

Security system incorrectly configured

(KTM / ECM)

None of the other DTCs are related to a NON START.

Maybe the key transponder system lost it's configuration?? Wrong Key??

Can bus fault with the TCM or INSTPK??

bob

P1798 (TCM)

CAN INST token message missing

Possible Causes

Other CAN control module CAN related fault(s)

CAN open circuit fault – INST to TCM

CAN short circuit fault

INST failure

TCM failure

P1260 (ECM)

Security input malfunction

Possible Causes

KTM to ECM circuit: short circuit, high resistance or open circuit

Loss of ignition switched power supply to the ECM PIN EM82-09 for greater than 16 milliseconds

KTM failure

Security system incorrectly configured

(KTM / ECM)

None of the other DTCs are related to a NON START.

Maybe the key transponder system lost it's configuration?? Wrong Key??

Can bus fault with the TCM or INSTPK??

bob

#19

Thread

Thread Starter

Forum

Replies

Last Post

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)